STALEX BS-712R User manual

METAL CUTTING BAND SAW

Model: BS-712R

Specifications

Cutting Capacity: 7’’ Round (180mm)

7’’X12’’ Rectangle (180x300mm)

Blade Speed: 86-132-178-260 FPM 60Hz

72-110-148-217 FPM 50Hz

Blade Size: 3/4’’x0.032’’x93’’ (19X0.9X2360mm)

Operation Manual

SAFETY

1. Know your band saw. Read the operator’s Manual carefully. Learn the

operations, applications and limitations as well as the specific potential

hazards peculiar to this band saw.

2. This unit is equipped with a three prong (grounded) plug for your

protection against shock hazards and should be plugged directly into a

property grounded three prong receptacle. Where a two prong wall

receptacle is encountered. It must be replaced with a properly

grounded three prong receptacle in accordance with the National

Electrical Code and Local Codes and Ordinances.

3. Use only 3-wire extension cords that have 3-prong grounding type

plugs.

4. Replace or repair damaged or worn cord immediately.

5. Keep guards in place and in working order.

6. Be especially careful when using band saw in vertical position to keep

fingers and hands out of path of blade.

7. Wear ear protection if exposed to long periods of very noisy shop

operations.

8. Use safety goggles, hardhat and safety shoes. Also use face or dust

mask if cutting operation is dusty.

9. Wear proper apparel. No loose clothing or jewelry to get caught in

moving parts. Do not wear a tie or gloves.

10. Don’t overreach. Keep your proper footing and balance at all times.

11. Secure work. Always use the vise to hold work. Clamp securely. Never

handhold the work with saw in horizontal position.

12. Keep work area clean. Cluttered areas and benches invite accidents.

13. Avoid dangerous environment. Don not use the band saw in damp or

wet location. Keep work area well illuminated.

14. Don’t force tool. It will do the job better and safer at the rate for which it

was designed.

15. Disconnect power cord before adjusting and servicing and before

changing blade.

16. Safety is a combination of operator’s common sense and alertness at

all times when the saw is being used.

17. Never stand on tool. Serious injury could occur if the tool is tipped or if

the cutting tool is accidentally contacted.

18. Check damaged parts. Before further use of the tools, a guard or other

parts that it will operate to assure that it will operate properly

19. And perform its intend function-check for alignment of moving parts;

binding of moving parts, breakage of parts, mounting and any other

conditions that may affect its operation. A guard or other part that is

damaged should be properly repaired or replaced.

20. When moving the saw, ALWAYS have the head lowered to the

horizontal position.

缺电路部分

IMPORTANT:

Coolant pump motor voltage must always be the same as machine motor

voltage.

ASSEMBLY

A 3/4 or 1 HP motor split phase or capacitor start is recommended for best

economical performance. Counter clockwise is required. Note that

rotation can be reversed by following directions given on terminal or

nameplate.

1. Assemble the motor Mounting plate to the head using the long bolt.

Note that the flat side of the plate faces up.

2. Assemble the guard plate to the head using the screw and lock washer

and the carriage bolt. Washer and wing nut are used to secure the

motor mounting plate to the guard plate through the slotted hole in the

guard plate. These components also serve to position and lock the

motor in place or proper speed/belt adjustment.

3. Place the spacer over the long bolt and secure it with the nut.

4. Secure the motor to the motor mounting plate with the four volts and

nuts. Note that the motor shaft is placed through the large opening in

the guard plate and must be parallel with the drive shaft.

5. Assemble the motor pulley, the smaller of the two provided to the

motor shaft. Note the larger diameter must be closest to the motor. Do

not tighten the set screw.

6. Assemble the driven pulley, the larger off the two provided to the

protruding drive shaft. Note the smaller diameter must be closest to the

bearing. Do not tighten the set screw.

7. Place the belt into one of the pulley groove and the other end into the

respective grooves of the second pulley.

8. Line up the belt and both pulleys such that the belt is running parallel in

the pulley grooves.

9. Tighten the set screws of both pulleys in this position.

10. Place the belt into proper pulley combination for proper blade speed.

See material cutting chart.

11. Adjust the position of the motor to obtain approximately 1/2’’

depression in the belt when applying pressure with your thumb.

12. Tighten the head screw holding the motor mounting plate to the guard

plate.

13. Connect the electrical harness to the motor terminal box. The motor

should be protected with a time delay fuse or circuit breaker with a

rated amperage slightly greater than the full-load amperage of the

motor.

INSTALLATION

The saw may be mounted on your own bench or stand. The rear end of

the saw must be mounted flush with the rear of the stand or bench to

permit vertical operation for this band saw. A steel your dealer for this

band saw. This stand has punched holes to effect easy assembly to the

base using eight standard bolts.

OPERATION

WORK SET UP

1. Raise the saw head to vertical position.

2. Open vise to accept the piece to be cut by rotating the wheel at the end

of the base.

3. Place work piece on saw bed. If the piece is long support the end.

4. Clamp work piece securely in vise

WORK STOP ADJUSTMENT

1. Loose the thumb holding the work stop casting to the shaft.

2. Adjust the work stop casting to the desired length position.

3. Rotate the work stop as close to the bottom of the cut as possible.

4. Tighten thumb screw.

5. Do not allow the blade to rest on the work while the motor is shut off.

CONVERTING FOR VERTICAL USE

Nothing, slitting, contour work may be done with the saw in the vertical

position in the following manner:

1. Rotate the head to the vertical position.

2. Assemble a 10’’x10’’ table (an option that may be purchased from your

dealer to the guide bar using the screws provided and the guide bar

knob.)

BLADE SPEEDS

When using your band saw always change the blade speed to best suit

the material being cut. The material cutting shaft given suggested settings

for several materials.

4 SPEED MATERIAL CUTTING CHART

Material

Speed F.P.M. Belt Groove Used

60Hz 50Hz

Motor pulley Saw pulley

Tool, Stainless alloy

Steels, bearing bronze

86 72 Small Largest

Medium to high carbon

132 110 Medium Large

Low to medium carbon

Steels soft brass 178 148 Large Medium

Aluminum plastic 260 217 Largest Small

BLADE DIRECTION OF TRAVEL

Be sure the blade is assembled to the pulleys so that the vertical edge

engages the work piece first.

STARTING SAW

CAUTION: NEVER OPERATE SAW WITHOUT BLADE GUARDS IN

PLACE.

Be sure the blade is not in contact with the work when the motor is started.

Start the motor, allow the saw to come to full speed, and then begin the

cut by left the head down slowly onto the work. DO NOT DROP OR

FORCE. Let the weight of the saw head provide the cutting force. The

saw automatically shuts off at the end of the cut.

BLADE SELECTION

An 8-tooth per inch, general-use blade is furnished with this metal cutting

band saw. Additional blades in 4,6,8 and 10 tooth sizes are available. The

choice of the blade pitch is governed by the thickness of the work to be

cut; the thinner the work piece, the more teeth advised. A minimum of

three teeth should engage the work piece at all times for proper cutting. If

the teeth of the blade are so far apart that they straddle the work, severe

damage to the work piece and to the blade can result.

CHANGING BLADE

Raise saw head to vertical position and open the blade guards. Loosen

tension screw knob sufficiently to allow the saw blade to slip off the

wheels. Install the new blade with teeth slanting toward the motor as

follows:

1. Place the blade in between each of the guide bearings.

2. Slip the blade around the motor pulley (bottom) with the left hand and

hold in position.

3. Hold the blade taut against the motor pulley by pulling the blade

upward with the right hang which is placed at the top of the blade.

4. Remove left hand from bottom pulley and place it at the top aide of the

blade to continue the application on the upward pull on the blade.

5. Remove right hand from blade and adjust the position of the top pulley

to permit left hand to slip the blade around the pulley using the thumb

index and little finger as guides.

6. Adjust the blade tension knob clockwise until it is just right enough so

no blade slippage occurs. Do not tighten excessively.

7. Replace the blade guards.

8. Place 2-3 drops of oil on the blade.

USAGE OF THE QUICK VISE

Your machine is equipped with a quick than action vise jaw, which allows

you to instantly position the movable vise jaw (B). Simply turn hand wheel

(A) counter clockwise 1/2 turn and move the vise jaw (B) to the desired

position. Then tighten the vise jaw (B) against the work piece by turning

hand-wheel clockwise.

QUICK VISE ADJUSTMENT FOR ANGLE CUT

1. Loosen the A.B.C. Screw.

2. Adjust rear vise to the threaded hole position. (E)

3. Set the scale to the desired angle.

4. Adjust the front vise (D) to parallel the rear vise (E).

5. Tighten the A.B.C. Screw.

BLADE GUIDE BEARING ADJUSTMENT

ATTENTION: This is the most important adjustment on your saw. It is

impossible to get satisfactory work form your saw if the blade guides are

not properly adjusted. The blade guide bearing on your metal. Cutting

Band Saw is adjusted and power tested with several test cuts before

leaving the factory to insure proper setting. The need for adjustment

should rarely occur when the saw is used properly. If the guides do get out

of adjustment, it is extremely important to readjust immediately. If

improper adjustment is maintained, the blade will not cut straight, and if

the situation is not corrected it will cause serious blade damage.

Because guide adjustment is a critical factor in the performance of your

saw, it is always best to try a new blade to see if this will correct poor

cutting before beginning to adjust. If a blade becomes dull on one side

sooner than the other, for example, it will begin cutting crooked. A blade

change will correct this problem, the guide adjustment will not. If a new

blade does not correct the problem, check the blade and guides for proper

spacing.

NOTE: There should be from 000 (just touching) 001 clearance between

the blade and guide bearings, to obtain this clearance adjust as follows.

1. The inner guide bearing is fixed and cannot be adjusted.

2. The outer guide bearing is mounted to an eccentric bushing and can

be adjusted.

3. Loose the nut while holding the bolt with an Allen wrench.

4. Position the eccentric by turning the bolt to the desired position of

clearance.

5. Tighten the nut.

6. Adjust the second blade guide bearing in the same manner.

BLADE TRACK ADJUSTMENT

1. Open the blade guard.

2. Remove the blade guide assemblies (top and bottom)

3. Loosen the hex head screw in the tilting mechanism to a point where it

is loose but snug.

4. With the machine running, adjust both the set screw and blade tension

knob simultaneously to keep constant tension on the blade. The set

screw and blade tension knob are always tuned in opposite directions,

when one is turned clockwise the other is turned counterclockwise.

The blade is tracking properly when the back side just touches the

shoulder of pulley or a slight gap appears near the center line of the

pulley. Care should be taken not to over tighten the saw blade since

this will give a false adjustment and limit life of the blade.

5. Tighten the hex head screw in tilting mechanism IMPORTANT:

Sometimes for trying to make this critical adjustment it is possible to

cause the basic setting to be misaligned. Should this occur, proceeds

as follows:

a. Loosen the set screw and back it out as far as it can go and still

remain in the threaded hold.

b. Turn the hex head screw clockwise until it stops (do not

tighten).

c. Turn the set screw clockwise until its bottoms, then continue for

half a turn and check the tracking by turning on the machine.

d. If further adjustment is required, go back to step 4.

6. Turn off power to the machine.

7. Replace the blade guide assemblies – it may be necessary to loosen

the blade tension lightly.

8. Adjust the vertical position of blade guide bearing assemblies so that

the back side of the blade just touches the ball bearings.

9. Make a final run to check tracking. If required, touch up adjustment

(See stop 4)

10. Replace the blade guards.

MAINTENANCE

CAUTION: MAKE CERTAIN THAT THE UNIT IS DISCONNECTED FROM THE

POWER SOURCE BEFORE ATTEMTING TO SERVICE OR REMOVE ANY

COMPONENT!

LUBRICATION

Lubricate the following components using SAE-30 oil as noted.

1. Ball bearing none.

2. Driven pulley bearing 6-8 drops a week.

3. Vise lead screw as needed.

4. The drive gears run in an oil bath and will not require a lubricant

change more often than once a year, unless the lubricant is

accidentally contaminated or a leak occurs because of improper

replacement of the gear box cover. During the first few days of

operation, the worm gear drive will run hot. Unless the temperature

exceeds 200F, there is no cause for alarm.

The following lubricants may be used for the gear box:

Atlantic Refinery Co., Mogul Cyl. Oil

Cities Service Optimums No.6

Gulf Refinery Co Medium Gear Oil

Pure Oil co. Park Clipper

SHIPPING CONTAINER CONTENTS

Saw 1

Wheel axis 2

Wheel 4

Split pin 4

Material stop bar 1

Material stop 1

Belt cover 1

Vertical cutting plate 1

Tools required for assembly

#2 cross point screwdriver

Pliers

Unpacking and clean-up

1. Finish uncrating the saw. Inspect it for shipping damage. If any

damage has occurred, contact your distributor.

2. Unbolt the saw from the skid and place it on a level surface.

3. Clean rust protected surfaces with kerosene, diesel oil, oil a mild

solvent. Do not use cellulose based solvents such as paint thinner or

lacquer thinner. These will damage painted surfaces.

Assembly

1. Place blocking under the ends of the saw base to allow wheel

installation. Caution: Make sure saw is steady while temporarily

supported.

2. Slide wheel axles through holes in base.

3. Slide wheel onto axles and fasten with pins. Bend pins to hold in place.

4. Slide material stop bar (A, Fig. 1) into base and secure by tightening

bolt (B). Slide material stop (C) onto bar and tighten blot (D).

5. Slide belt cover over pulley assemblies and fasten with screws and

washers (A, Fig. 2).

6. Close belt cover and secure with lock knob (B).

7. Remove transportation strap and keep for later use should the saw be

moved any distance.

Vertical cutting plate assembly

Note: these steps are only necessary if

using the band saw in the vertical mode.

! Warning

Disconnect band saw from the power source before

making any repairs or adjustments!

Failure to comply may cause serious injury!

1. Disconnect the band saw from the power source.

2. Raise the arm to the vertical position and lock in

place by turning the hydraulic cylinder valve to

the off position.

3. Remove two screws (A, Fig. 3) and the

deflector plate (B).

4. Guide blade through slot in table and fasten

with two screws. See Fig. 4.

Coolant tank preparation

Use of a water-soluble coolant will increase cutting

efficiency and prolong blade life. Do not use black

cutting oil as a substitute. Change cutting oil often

and follow manufacturers instructions as to its uses and precautions.

1. Disconnect machine from the power source.

2. Remove coolant return hose from tank cover.

3. Slide tank out of saw base and carefully remove lid containing coolant pump.

4. Fill tank to approximately 80% of capacity.

5. Place lid back onto tank and place tank assembly back into base.

6. Replace return hose back into hole in tank lid.

Electric Box (For UE-712A)

A. Part No. A-Emergency stop switch (EMS).

It stops all electric motors including coolant pump.

B. Part No. B-Start switch.

C. Part No. C-Stop switch.

There is a relay inside the electric box.

When machine is overloaded and the

current is to high. This relay will switch

off automatically as protections. It cuts

off all electrics and machine stops.

Open the electric box and find this switch

in white button. Please reset this white

button to function the electrics again.

If this machine gets overloaded too often,

try to adjust the really-make the setting of

current higher.

Adjusting blade square to table

1. Disconnect machine from the power source.

2. Place machinist’s square on table next to blade

as pictured in Fig. 13.

3. Check to see blade makes contact with square

along the entire width of the blade.

4. If adjustment is necessary, loosen bolts (A Fig. 13)

and rotate blade guide assemblies slightly in the

same direction until blade makes contact with the

square along it’s entire width.

5. Tighten bolts (A).

6. Connect machine to the power source.

Note: If adjustment to square blade to table is

necessary, be sure to check blade adjustments again.

Adjusting blade square to vise

1. Disconnect machine from the power source.

2. Place a machinist’s square as pictured in figure 14. Square should lie along entire

length of vise and blade without a gap.

3. If adjustment is necessary, loosen bolts holding vice and adjust vise so that square lines

up properly. Tighten bolts.

4. Connect machine to the power source.

Adjusting blade guides

1. Disconnect machine from the power source.

2. Loosen knob (A. Fig. 8) and bolt (B).

Slide blade guide assemblies as close as

possible to the material without interesting

with the cut.

3. Tighten knob (A) and bolt (B) and connect

4. machine to the power source.

Vise adjustment

! Warning

Do not make any adjustments or load/unload

material from vise while machine is running!

Failure to comply may cause serious injury!

To set the vise for 0 to 45 degree cutting:

1. Remove bolt assemblies (C. Fig. 9)

2. Position vise and re-install as

pictured in Fig. 10. Pay particular

attention to bolt hole location.

3. Set vise to desired angle, re-install

bolts, and lighten nut and bolt

assemblies.

4. Adjust movable vise parallel to fixed

vise by loosening blot (A, Fig. 10),

adjusting to parallel and tightening bolt.

To set vise for maximum width of stock cutting:

1. Remove nut and bolt assemblies.

2. Position vise and re-install bolt assemblies as pictured in Fig 9.

TROUBLE SHOOTING CHART

Symptom Possible Cause (s) Corrective Action

Excessive Blade

Breakage

1. Material loose in vise

2. Incorrect speed or feed

3. Blade teeth spacing too

large

4. Material too coarse

5. Incorrect blade tension

6. Teeth in contact with

material before saw is

started

7. Blade rubs on wheel

flange

8.

Misaligned guide

bearings

9. Cracking at weld

1. Clamp work securely

2. Adjust speed or feed

3. Replace with a small teeth

spacing blade

4. Use a blade of slow speed

and small teeth spacing

5. Adjust where blade just

does not slip on wheel

6. Place blade in correct with

work after motor is started

7. Adjust wheel alignment

8. Adjust guide bearings

9. Weld again, note the weld

skill

Premature Blade

Dulling

1. Teeth too coarse

2. Too much speed

3. Inadequate feed pressure

4. Hard spots or scale on

material

5. Work hardening of

material

6. Blade twist

7. Insufficient blade

1. Use finer teeth

2. Decrease speed

3. Decrease spring tension

on side of saw

4. Reduce speed, increase

feed pressure

5. Increase feed pressure by

reducing spring tension

6. Replace with a new blade,

and adjust blade tension

7. Tighten blade tension

adjustable knob

Unusual Wear on

Side/Back of Blade

1. Blade guides worn

2. Blade guide bearings not

adjusted properly

3. Blade guide bearing

bracket is loose

1. Replace

2. Adjust as per operators

manual

3. Tighten

Symptom Possible Cause (s) Corrective Action

Teeth Ripping from

Blade

1. Tooth too coarse for work

2. Too heavy pressure, too

slow speed

3. Vibrating work piece

4. Gullets loading

1. Use finer tooth blade

2. Decrease pressure,

increase speed

3. Clamp work piece

securely

4. Use coarse tooth blade or

brush to remove chips

Motor running too hot

1. Blade tension too high

2. Drive belt tension too high

3. Gears need lubrication

4. Cut is binding blade

5. Gears aligned improperly

1. Reduce tension on blade

2. Reduce tension on drive

belt

3. Check oil bath

4. Decrease feed and speed

5. Adjust gears so that worm

is in center of gear

Bad Cuts

1. Feed pressure too great

2. Guide bearing not

adjusted properly

3. Inadequate blade tension

4. Dull blade

5. Speed incorrect

6. Blade guide spaced out

too much

7. Blade guide assembly

loose

8. Blade truck too far away

from wheel flanges

1. Reduce pressure by

increasing spring tension

on side of saw

2. Adjust guide bearing, the

clearance can not be

greater than 0.001mm

3. Increase blade tension by

adjust blade tension

4. Replace blade

5. Adjust speed

6. Adjust guides space

7. Tighten

8. Re-track blade according

to operating instructions

Bad Cuts

(Rough)

1. Too much speed or feed

2. Blade is too coarse

3. Blade tension loose

1. Decrease speed or feed

2. Replace with finer blade

3. Adjust blade tension

Blade is twisting 1. Cut is binding blade

2. Too much blade tension

1. Decrease feed pressure

2. Decrease blade tension

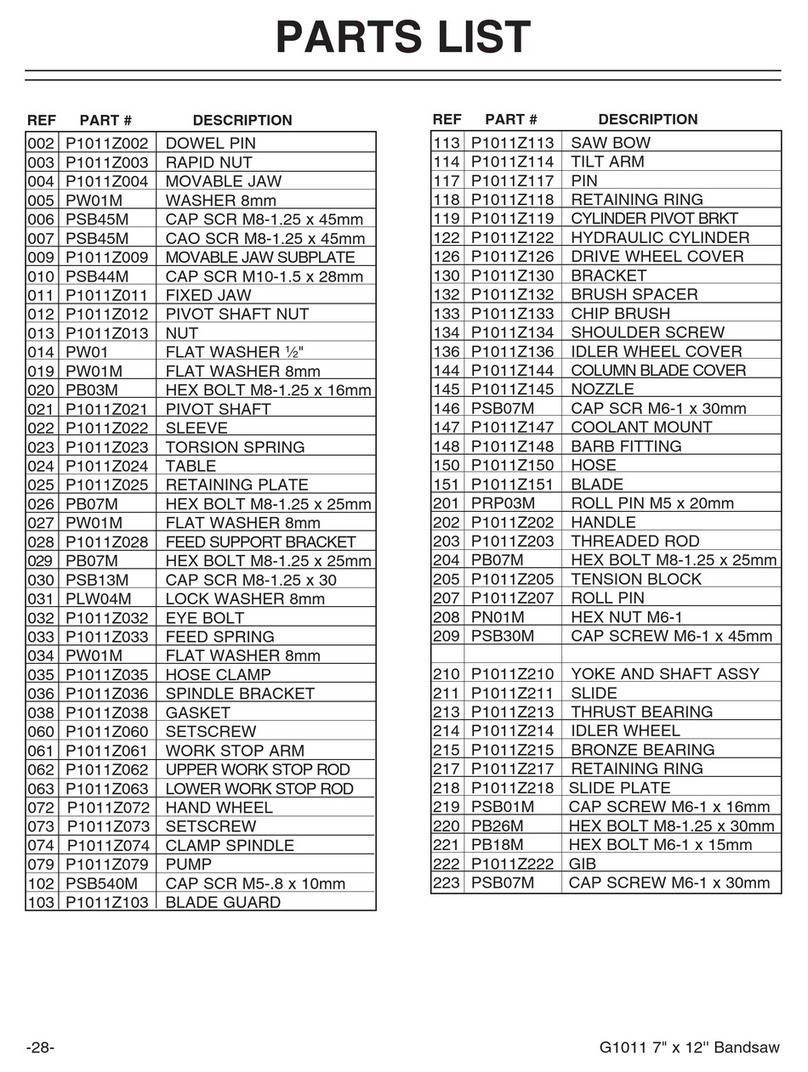

PARTS LIST

Part

No. Description Qty. Part

No. Description Qty.

77

142

143

144

145

146

147

148

149

150

151

118

119

119-1

119-2

120

121

122

123

123-1

124

125

126

127

128

129

130

130-1

131

132

133

134

135

136

136-1

137

137-1

138

139

140

141

188

189

190

191

192

193

194

195

196

197

198

199

200

201

Bearing bushing (front)

Vertical cutting plate

Adjustable blade seat

Hex. Hd. screw

Top support

Spring washer

Nut

Round hd. screw

Washer

Brush holder

Hex. Hd. screw

Ball bearing

Hex. Hd. screw

Spring washer

Washer

Oil seal

Bear box

Sping washer

Hex. Hd. screw

Adj. Screw

Blade wheel (rear)

Bearing bushing

Hex. Soc. Screw

Blade

Blade back cover

Wheel cover

Plum screw

Washer

Adjustable guide knob

Adjustable bracket (rear)

Ball bearing

Adjustable blade seat (rear)

Bearing pin

Eccentric shaft assembly

Center shaft assembly

Nut

Spring washer

Washer

Spring washer

Hex. Soc. Screw

Hd. screw

Washer

Pulley cover

Plum screw

Key

Motor

Hex. Hd. screw

Motor mount plate

Washer

Spring washer

Nut

C-ring

Ball bearing

Block plate

Oil seal

1

1

1

2

1

2

2

2

2

1

2

3

1

1

1

1

1

4

4

2

1

1

3

1

1

1

2

2

2

1

2

1

2

2

2

4

4

2

2

1

2

2

1

1

1

1

4

1

4

4

4

1

3

1

1

152

153

154

154-1

155

156

157

158

159

160

161

161-1

163

164

164-1

165

166

167

168

169

170

170-1

170-2

171

172

173

174

175

176

176-1

177

178

179

180

181

182

183

184

185

186

187

202

203

204

205

206

207

208

209

210

211

212

213

214

217

Nut

Brush

Hex. Hd. screw

Spring washer

Magnetic switch

Nozzle

Set screw

Nozzle support

Valve

Round hd. screw

Hex. Soc. Screw

Spring washer

Adjustable bracket (front)

Blade guard

Round hd. screw

Hex. Hd. screw

Sliding guide plate

Set screw

Hex. Hd. screw

Blade tension sliding block

Hex. Hd. screw

Spring washer

Washer

Sliding draw block

Bracket

Bearing bushing (rear)

Ball bearing

Blade wheel (front)

Washer

Spring washer

Hex. Hd. screw

Round hd. screw

Washer

Washer

Blade adjustable handle

Vertical cutting plate

Belt

Worm pulley

Motor pulley

Set screw

Hex. Hd. screw

Bearing bushing

Worm shaft

Hex. Hd. screw

Washer

Support plate

Limit switch rack

Hex. Hd. screw

Nut

Washer

Spring washer

Hex. Hd. screw

Nut

Hex. Hd. screw

C-ring

2

1

3

3

1

1

1

1

1

2

1

1

1

1

2

4

2

1

2

1

1

1

1

1

1

1

2

1

1

1

1

2

2

1

1

1

1

1

1

3

2

1

1

2

2

1

1

1

1

1

1

1

1

1

2

Table of contents

Other STALEX Saw manuals