Standex RGM23 Manual

GLASS DOOR

REFRIGERATED MERCHANDISER

Installation, Operation and Maintenance Instructions

Models RGM23, RGM48 and RGM72

2 11/18 161744

TABLE OF CONTENTS

INTRODUCTION ...............................................................................................................................................................3

STORE CONDITIONS.......................................................................................................................................................3

WARNING LABELS AND SAFETY INSTRUCTIONS .....................................................................................................4

PRE-INSTALLATION INSTRUCTIONS ...........................................................................................................................5

Inspection for Shipping Damage.................................................................................................................................5

INSTALLATION INSTRUCTIONS....................................................................................................................................5

Uncrating ....................................................................................................................................................................5

Shelving Installation....................................................................................................................................................5

Location .....................................................................................................................................................................5

Electrical Supply .........................................................................................................................................................5

Initial Cleaning ............................................................................................................................................................6

OPERATION .....................................................................................................................................................................6

Set-Up.........................................................................................................................................................................6

Lights .........................................................................................................................................................................6

Temperature Control ..................................................................................................................................................6

Defrost ........................................................................................................................................................................6

MAINTENANCE ................................................................................................................................................................6

Surface Cleaning ........................................................................................................................................................6

Door Gasket................................................................................................................................................................6

Doors/Hinges ..............................................................................................................................................................7

Condenser Cleaning ..................................................................................................................................................7

Notice to Store Owners/Managers..............................................................................................................................7

Electrical .....................................................................................................................................................................7

PARTS LIST......................................................................................................................................................................8

SALE AND DISPOSAL.....................................................................................................................................................9

WIRING DIAGRAM .........................................................................................................................................................10

3 11/18 161744

INTRODUCTION

This manual contains important instructions for installing, using, and servicing a Refrigerated Merchandiser case.

Read all these documents carefully before installing or servicing your equipment.

STORE CONDITIONS

The Refrigerated Merchandiser cases are designed to operate best in the controlled environment of an air-

conditioned store. The store temperature should be at or below +75°F and a relative humidity of 55% or less. At higher

temperature or humidity conditions, the performance of these cases may be affected and the capacity diminished.

The Refrigerated Merchandiser should not be positioned where it is directly exposed to rays of sun or near a direct

source of radiant heat or airflow. This will adversely affect the case and will result in poor performance.

If this case is to be located against a wall, there must be at least 2” space between the wall and the back of the case.

This space will allow for the circulation of air behind the case and extend the life of the unit.

NOTICE

Read this manual before installing your cabinet. Keep the manual and refer to it before

doing any service on the equipment. Failure to do so could result in personal injury or

damage to the cabinet.

DANGER

Improper or faulty hook-up of electrical components on the refrigeration units can result

in severe injury or death.

All electrical wiring hook-ups must be done in accordance with all applicable local, regional or

national standards.

NOTICE

Installation and service of the refrigeration and electrical components of the cabinet

must be performed by a refrigeration mechanic and/or a licensed electrician.

The portions of this manual covering refrigeration and electrical components contain technical instructions intended

only for persons qualified to perform refrigeration and electrical work.

This manual cannot cover every installation, use or service situation. If you need additional information, call the

Customer Service Department.

4 11/18 161744

WARNING LABELS AND SAFETY INSTRUCTIONS

This symbol is the safety-alert symbol. When you see this symbol on your cabinet or in this

manual, be alert to the potential for personal injury or damage to your equipment.

Be sure you understand all safety messages and always follow recommended precautions and safe operating

practices.

NOTICE TO EMPLOYERS

You must make sure that everyone who installs, uses or services your cabinet is

thoroughly familiar with all safety information and procedures.

Important safety information is presented in this section and throughout the manual. The following signal words are

used in the warnings and safety messages:

DANGER: Severe injury or death will occur if you ignore the message.

WARNING: Severe injury or death can occur if you ignore the message.

CAUTION: Minor injury or damage to your cabinet can occur if you ignore the message.

NOTICE: This is important installation, operation or service information. If you ignore the

message, you may damage your cabinet.

WARNING!

GROUND REQUIRED

FOR SAFE OPERATION

5 11/18 161744

PRE-INSTALLATION INSTRUCTIONS

INSPECTION FOR SHIPPING DAMAGE

Inspect all cartons and crates for damage as soon as they arrive. If damage is noted to shipping crates or cartons or

if a shortage is found, note this on the bill of lading (all copies) prior to signing. The receiving party is responsible for

filing all freight claims with the delivering truck line.

If damage is discovered when the cabinet is uncrated, immediately call the delivering truck line and follow up the call

with a written report indicating concealed damage to your shipment. Ask for an immediate inspection of your concealed

damage item. Crating material must be retained to show the inspector from the truck line.

INSTALLATION INSTRUCTIONS

This cabinet should be uncrated, set up and installed by competent service people.

Warning!– This cabinet uses a flammable refrigerant. Use caution with handling, moving and maintaining this

cabinet to avoid either damaging the refrigerant tubing or increasing the risk of a refrigerant leak.

Uncrating

Remove the protective covering (banding, shrink wrap, cardboard, plywood inner liners) and set aside. The cabinet is

nested on the shipping pallet with L shaped metal brackets on each side. Remove the metal brackets from the pallet and the

cabinet (screws). Using a team of assistants, slide the cabinet off the pallet.

WARNING - The cabinet has Casters installed on the base and will be unstable until all four casters are on the floor. Use

caution when sliding the unit off the pallet so the unit does not tip. Use a team of at least three to remove the cabinet from the

pallet.

Inside the cabinet you will find Shelves, Shelf Clips and a literature package.

Shelving Installation

The unit comes with Shelves and Shelf Supports. The Shelf Supports clip into the Pilaster Strips on the inside walls

of the unit and the Shelf then sits on the Shelf Supports. Four Shelf Supports are supplied for each Shelf. The Shelves

can be installed at any height to suit your needs and are adjustable in 1/2” height increments. The shelves come with

Product Identification Strips that can be attached to the front edge of the shelves. The Product Identification Strips will

accept pricing and product descriptor tags to suit your requirements.

Location

NOTICE! The refrigeration system located at the bottom of the unit requires free air access for proper operation. Allow

a minimum of 2” between the back of the unit and the wall.

Do not locate next to heat generating equipment or in direct sunlight.

Make sure that the cabinet is level to allow for proper drainage of condensate water.

Confirm that the floor is capable of supporting the weight of the cabinet and its contents.

This unit is intended for indoor use only.

Electrical Supply

WARNING! To prevent electrical shock and fire be sure the unit is properly grounded.

Confirm that the electrical supply has the correct voltage, frequency and current carrying capacity for the requirements

of the unit (see data plate on inside of unit). The unit should be isolated on a circuit. Do not use an extension cord to

get power to the unit. Improper installations will void the compressor warranty.

6 11/18 161744

Initial Cleaning

Keep the equipment clean and sanitary so it will meet your local sanitation codes. Clean the cabinet with a mild

detergent and water, then rinse to remove any residual manufacturing oils. Do not use any chlorine based cleaners

on the stainless steel.

OPERATION

Set-Up

When loading the unit with product take care not to block the flow of air that could result in poor performance. Do not

push product all the way to the back wall as cold air is intended to flow down the back wall to the floor of the unit and

return to the top.

Do not completely fill the unit with warm product as it will take an extended time to cool.

Rotate stock regularly to prevent the accumulation of old stock. Use a first-in / first-out system.

The shelves have a load capacity of 100 pounds per shelf. Do not overload the shelves.

Do not load product within 3” of the top of the unit for proper operation.

Lights

The interior cabinet and display sign lights are controlled via an on/off switch on the front of the unit under the top

facade.

Temperature Control

The Temperature Control is located behind the Lower Front Grill of the unit. It will display the current air temperature

inside the cabinet.To adjust the setting of the Temperature Control, first remove the Lower Front Grill (remove 2

screws and lift off), then turn the control knob clockwise for colder and counter-clockwise for warmer temperatures.

Allow the cabinet a couple of hours to reach the new temperatures. The cabinet will hold temperatures of approximately

42°F at a set point of #1, 38°F at setting #5 and 34°F at setting #9.

Defrost

The Refrigerated Merchandiser relies on Off Cycle defrost with an addition defrost programmed into the Temperature

Control that will shut the refrigeration system down every 6 hours for 20 minutes to facilitate a complete defrost.

MAINTENANCE

Warning! This cabinet uses a flammable refrigerant. All service should be done by factory authorized service

personnel using original equipment parts to minimize the risk of possible ignition due to incorrect replacement parts or

improper service.

Surface Cleaning

The interior and exterior can be cleaned using soap and warm water. Always rinse thoroughly after cleaning. Do not

use an abrasive cleaner as it will scratch the surface.

When cleaning stainless steel cleaning solutions need to be alkaline based or non-chlorinated. Any cleaner containing

chlorides will damage the protective layer of the stainless steel. Chlorides are commonly found in hard water, salts

and household and industrial cleaners. If cleaners with chlorides are used be sure to rinse repeatedly and dry

thoroughly.

Routine cleaning of stainless steel can be done with soap and water. Extreme stains or grease should be cleaned with

a non-abrasive cleaner and plastic scrub pad. Always rub with the grain of the steel.

Door Gasket

Gaskets require regular cleaning to prevent mold and mildew build up and also to keep the elasticity of the gasket.

Cleaning can be done with the use of warm soapy water. Avoid full strength cleaning products on gaskets as this can

cause them to become brittle and prevent proper seals. Never use sharp tools to scrape or clean the gasket which

could possibly tear the gasket and rip the bellows.

7 11/18 161744

Door Gaskets can easily be replaced without the use of tools. The gaskets are dart style so they can be pulled out of

the groove in the door and replaced by pressing the new gasket back into the groove.

Doors/Hinges

Should a door become out of alignment with the unit it can be straightened out by loosening the screws that hold the

hinges, straightening the door and retightening the hinge screws.

Condenser Cleaning

The Condenser Coil is located behind the Lower Front Grill. Always disconnect the unit from power prior to performing

any maintenance procedures including cleaning the Condenser Coil. The Condenser Coil requires regular cleaning.

Recommended cleaning is every 3 months. In some instances you may find that there is a large amount of debris and

dust or grease accumulated on the coil prior to the 3 month period. In these cases the coil should be cleaned every 1

month.

If the build-up on the coil consists of only light dust and debris, the coil can be cleaned with a simple brush. Heavier

dust build-up may require a vacuum or compressed air to clean the coil. If heavier grease is present there are

degreasing agents available specifically for cleaning condenser coils.

Failure to maintain a clean Condenser Coil can cause high temperatures and excessive run times. Continuous

operation with a dirty or clogged coil can result in Compressor failures. Neglecting the Condenser Coil cleaning

procedures will void any warranties associated with Compressor failure.

NOTICE TO STORE OWNERS / MANAGERS

CAUTION! Moisture or liquid around or under the cabinet is a potential slip/fall hazard for persons walking by

or working in the general area of the cabinet. Any cabinet malfunction or housekeeping problem that creates

a slip/fall hazard around or under the cabinet should be corrected immediately.

If moisture or liquid is observed around or under the cabinet, an immediate investigation should be made by qualified

personnel to determine the source of the moisture or liquid. The investigation should determine if the cabinet is

malfunctioning or if there is a drainpipe leaking.

ELECTRICAL

WARNING

Before servicing electrical components in the case or the doors or door frames make sure all

power to case is off. Always use a qualified technician.

Check voltage and amps drawn to determine proper line and fuse or circuit breaker size. Check power supply for low

voltage. If voltage reads 120 with no load, and it drops below 104 when the compressor tries to start, it is an indication

of too small supply wiring or too long of run.

It is recommended that a separate circuit be run for each cabinet to prevent another appliance blowing the fuse or

breaker, causing loss of product.

The cabinet must be grounded.

8 11/18 161744

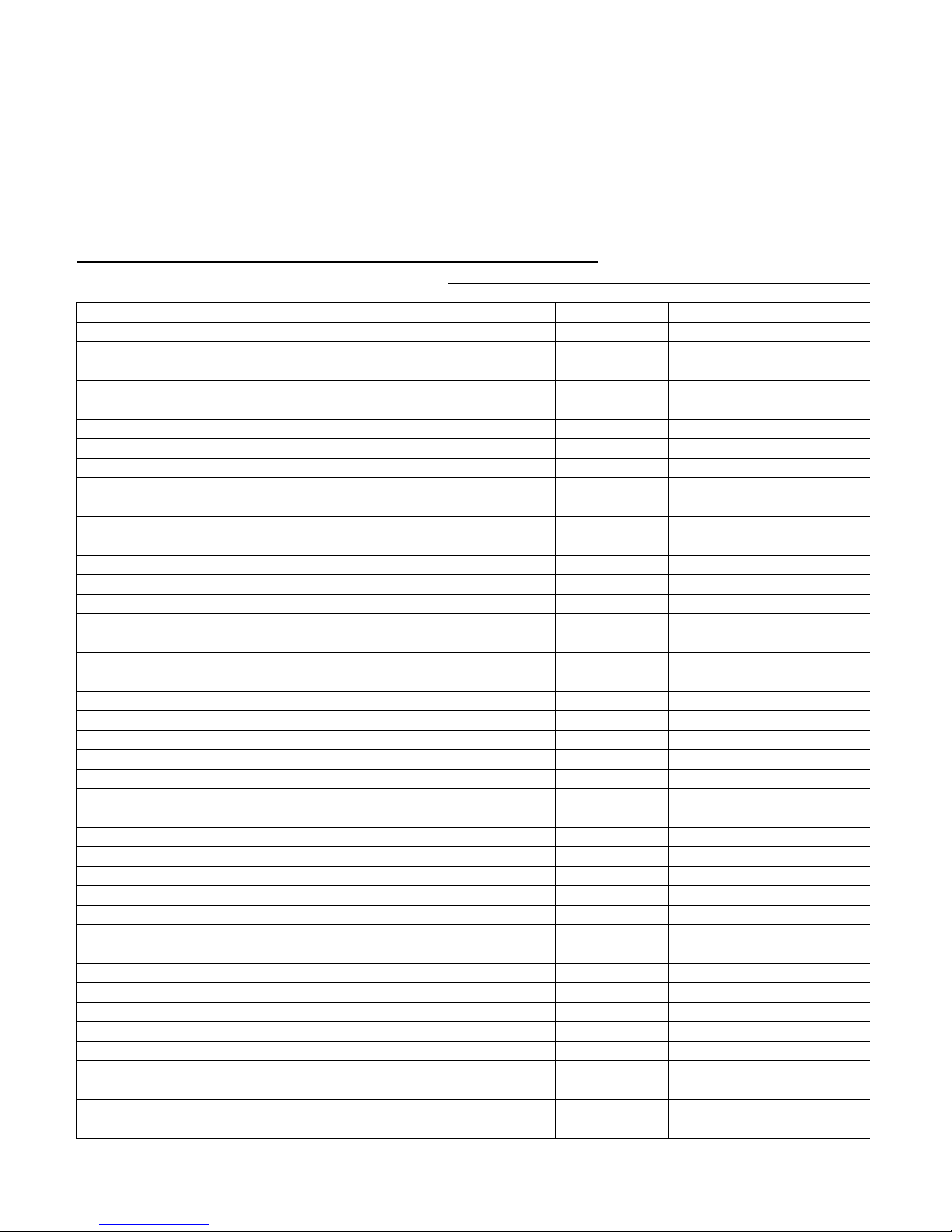

PARTS LIST

The table below gives replacement part numbers. Use this chart when ordering replacement parts for your cabinets.

Always Advise Cabinet Model and Serial Number When Ordering Parts

MODEL

Part Description

RGM23

RGM48

RGM72

Compressor (includes electricals)

161658

161659

161660

Compressor Electrical Kit (Overload,Relay, Capacitor,..)

161661

161662

161663

Condenser Fan Motor

161664

161664

161665

Condenser Fan Blade

161666

161666

161667

Condenser Fan Bracket

161668

161668

161669

Condenser Coil

161670

161670

161671

Drier

161672

161672

161672

Capillary Tube

161673

161674

161675

Heat Exchanger-cap tube/suction line (Cabinet/Mach. Comp.)

161676/161679

161677/161680

161678/161681

Evaporator Coil

161682

161683

161684

Evaporator Fan Motor

161685

161686

161687

Evaporator Fan Blade

161688

161689

161689

Evaporator Fan Motor Assy (motor, blade, bracket)

161690

161691

161692

Evaporator Panel W/Fan Guard

161693

161694

161694

Condensate Pan (w/o hot gas loop)

161695

161695

161695

Temperature Control Assy (with display and sensors)

161696

161696

161696

Temperature Control Sensor Kit (includes both sensors)

161697

161697

161697

Light Power Switch

161698

161698

161698

LED Light Driver

161699

161670

161670

LED Sign Light

161701

161702

161703

LED Door Light

161704

161704

161704

Shelf

161705

161706

161706 Ends/161707 Center

Shelf Product Identifier Strip

161708

161709

161709

Shelf Support Clip

161710

161710

161710

Pilaster

161711

161711

161711

Lower Front Grill

161712

161713

161714

Rear Grill

161715

161716

161717

Door Lock w/Key

161718

161718

161718

Terminal Block

161719

161719

161719

Door Switch Assy

161720

161720

161720

Advertising Panel Assy

161721

161722

161723

Door Assy RH

161724

161724

161724

Door Assy LH

161725

161725

161725

Door Hinge Top Right

161726

161726

161726

Door Hinge Top Left

161727

161727

161727

Door Hinge Bottom Right

161728

161728

161728

Door Hinge Bottom Left

161729

161729

161729

Door Gasket

161730

161730

161730

Evaporator Drain Pan

161731

161732

161732

Caster Kit (3.63 OAH) set of 2

161733

161733

161733

Power Cord

161734

161734

161734

9 11/18 161744

SALE AND DISPOSAL

OWNER RESPONSIBILITY

If you sell or give away your cabinet; you must make sure that all safety labels and the IOM Instructions are

included with it. If you need replacement labels or manuals, contact the Customer Service Department and we will

provide them at no charge.

The Customer Service Department should be contacted at the time of sale or disposal of your cabinet so records

may be kept of its new location.

10 11/18 161744

This manual suits for next models

2

Table of contents

Other Standex Merchandiser manuals

Popular Merchandiser manuals by other brands

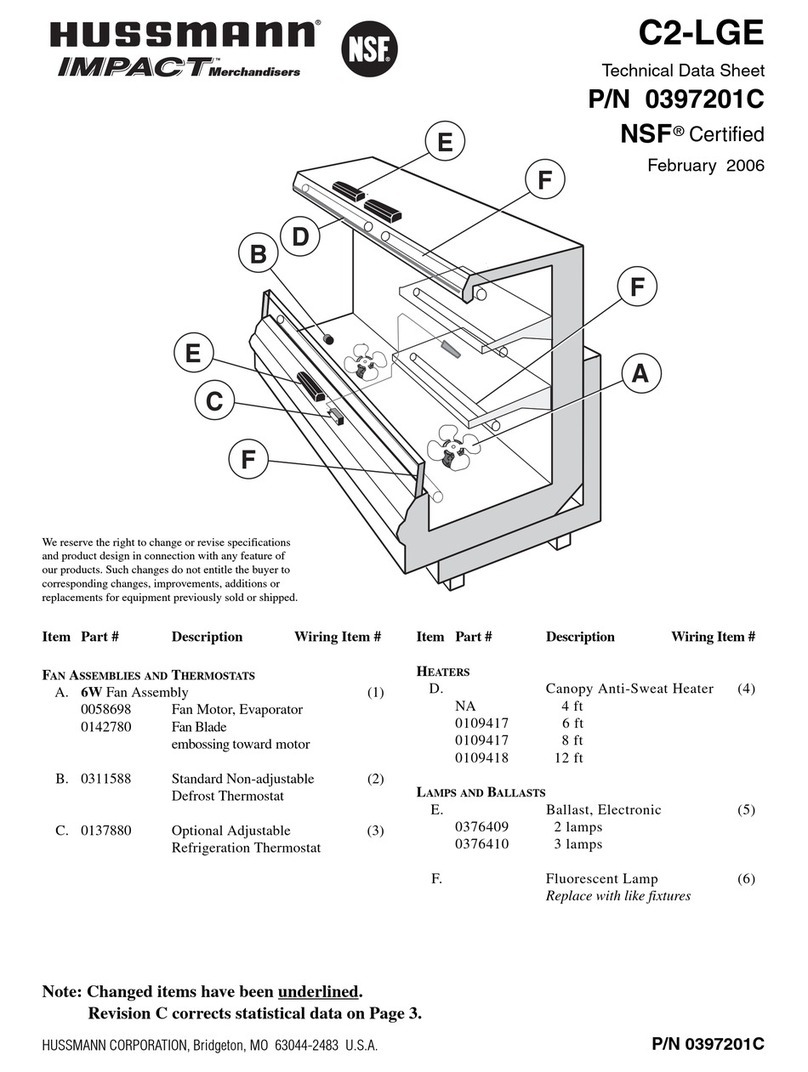

Hussmann

Hussmann Impact C2-LGE Technical data sheet

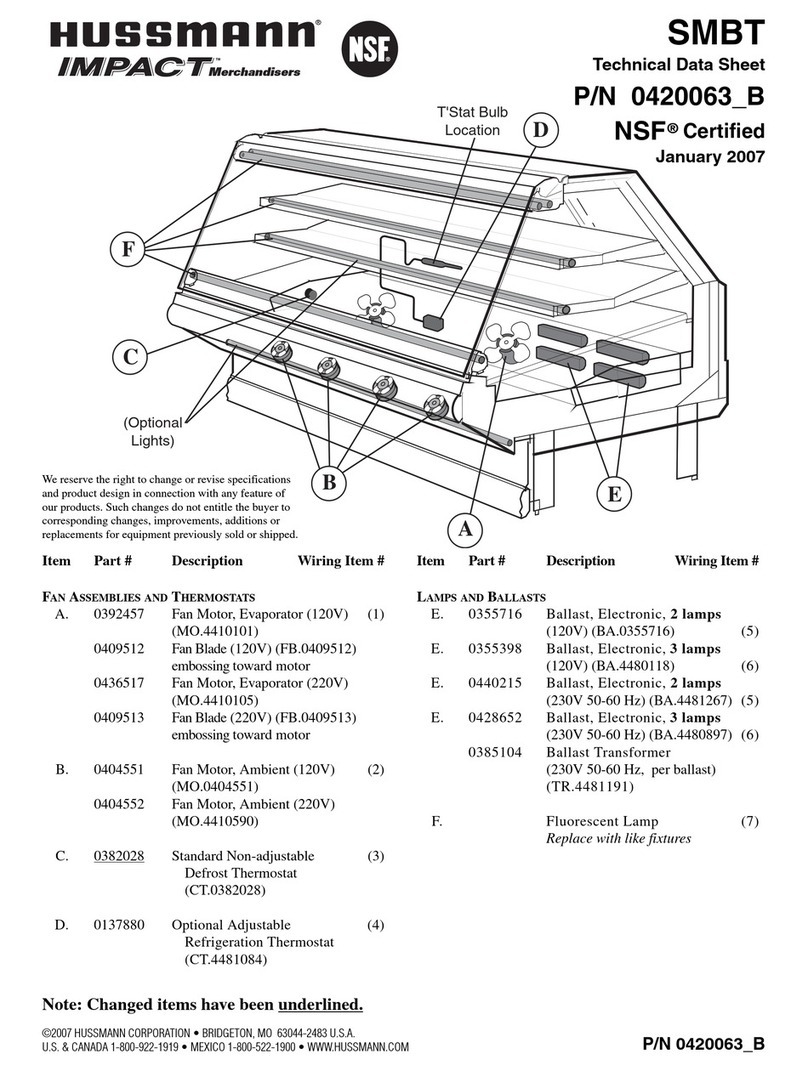

Hussmann

Hussmann SMBT Technical data sheet

Hatco

Hatco Glo-Ray GRDW-2 Installation & operating manual

Hussmann

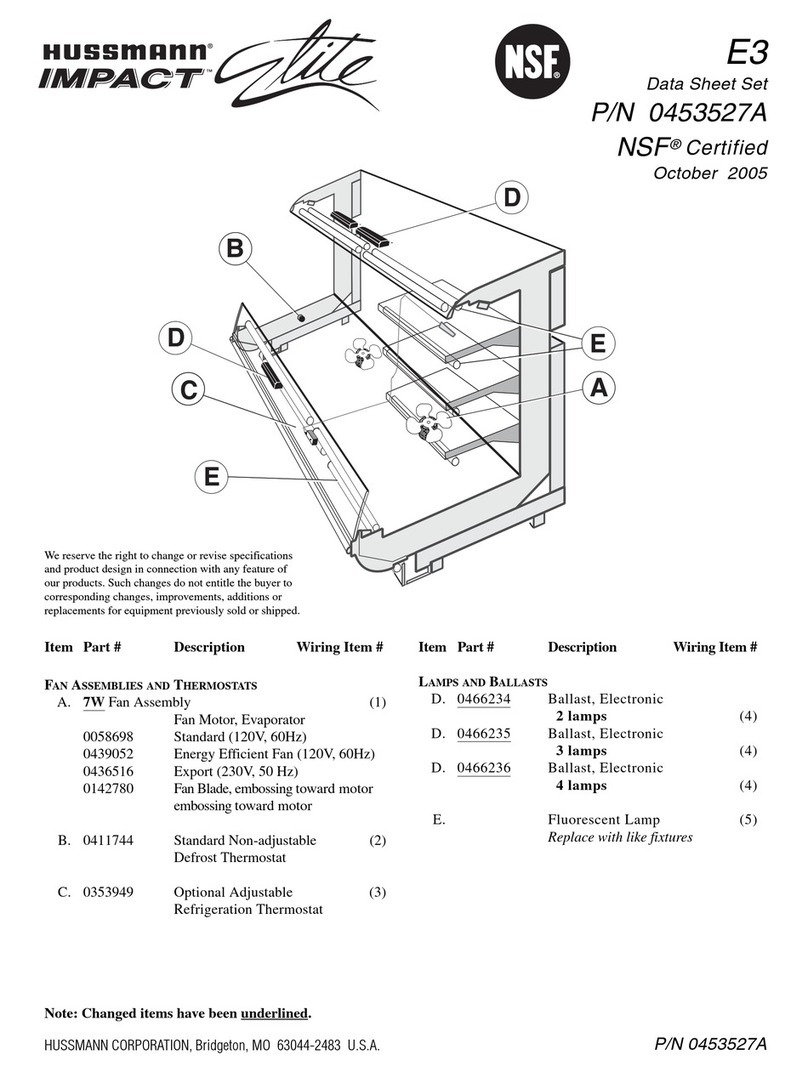

Hussmann IMPACT Elite E3 datasheet

Hussmann

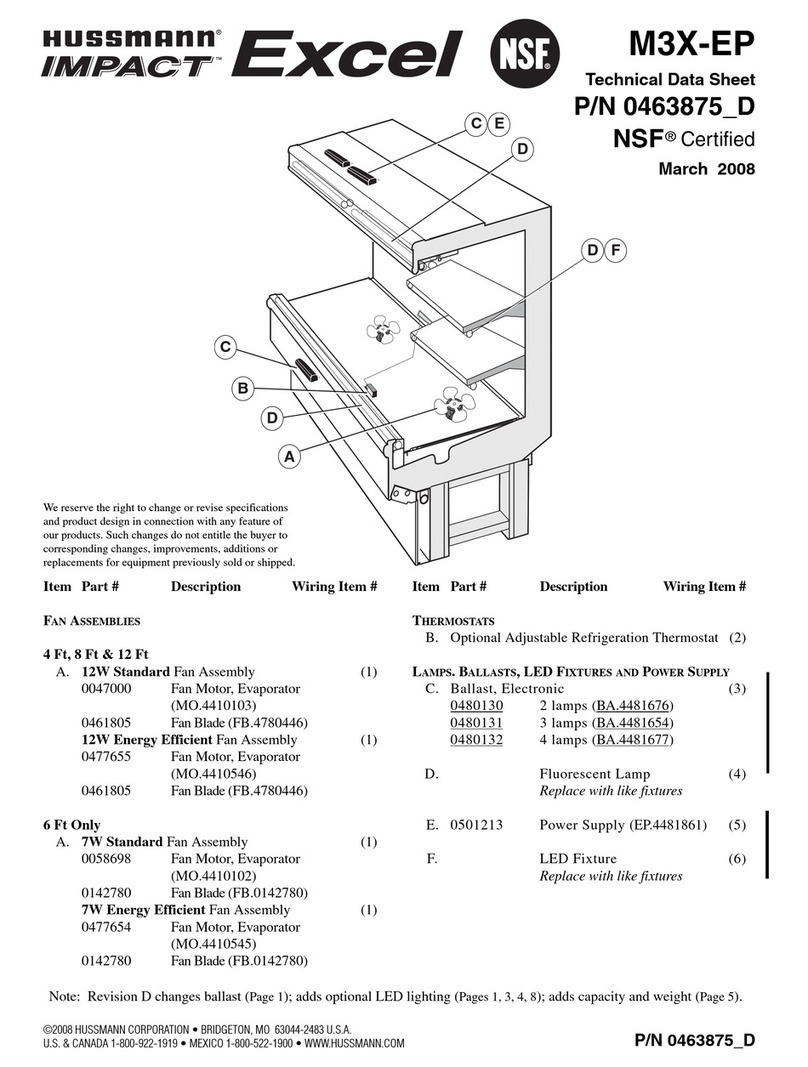

Hussmann Impact Excel M3X-EP Technical data sheet

Polar Refrigeration

Polar Refrigeration GC872-A instruction manual

Global Solutions

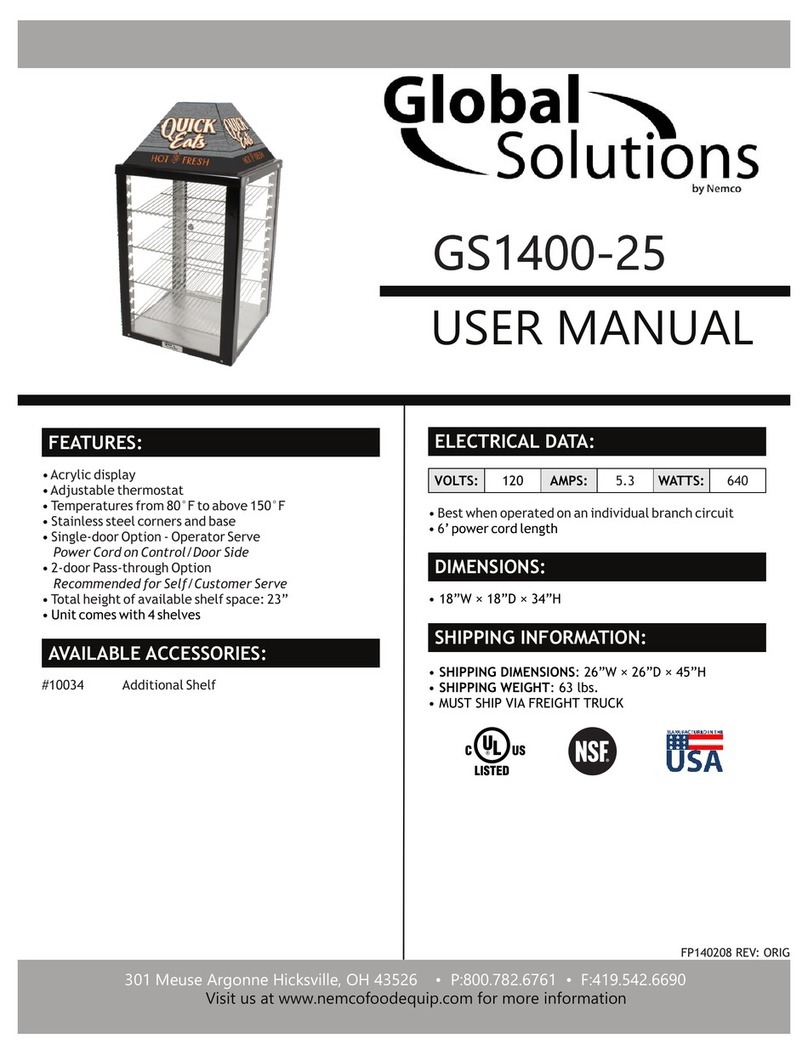

Global Solutions GS1400-25 user manual

Alto-Shaam

Alto-Shaam HSM-24/3S/T Operator's manual

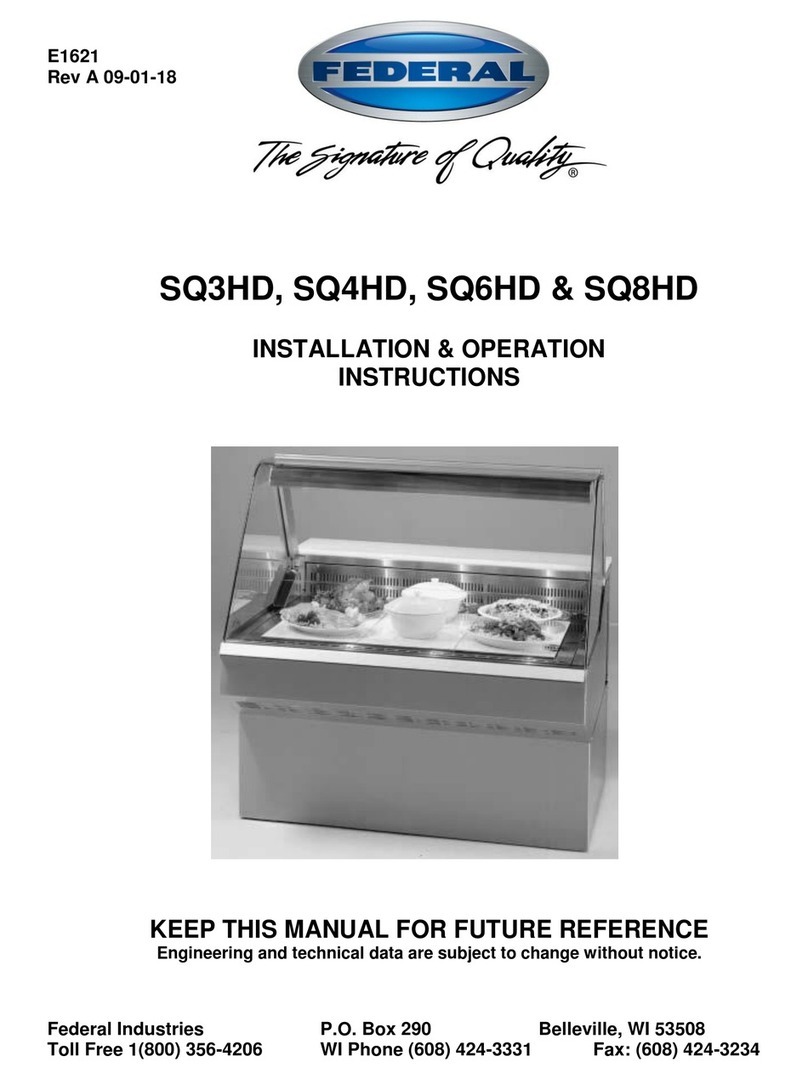

Federal

Federal SQ3HD Installation & operation instructions

Blizzard

Blizzard GD350 Original instructions

Hussmann

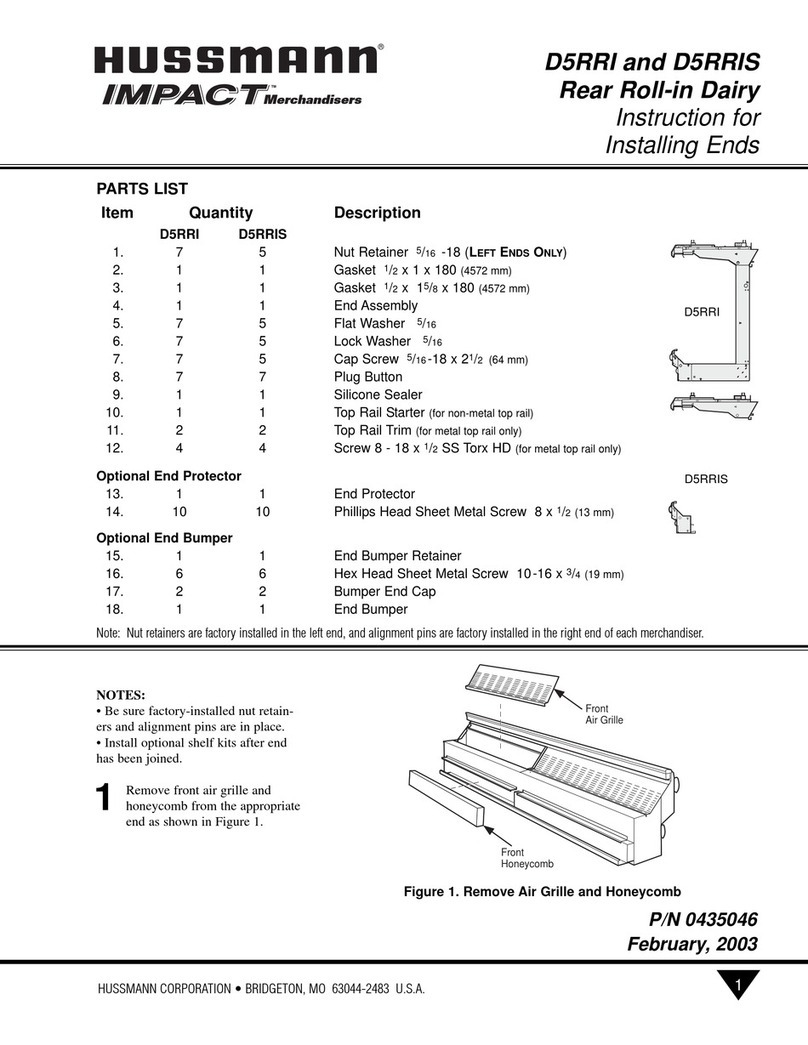

Hussmann IMPACT D5RRI Parts installation and removal guide

Hussmann

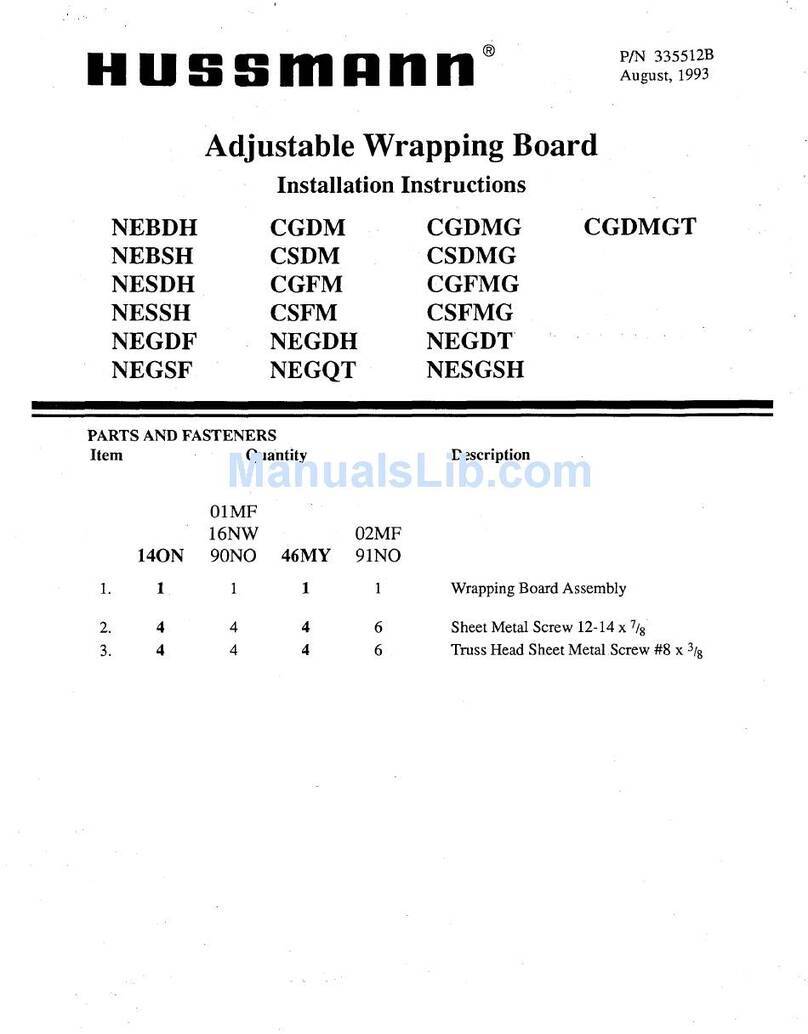

Hussmann CGDM install guide