7

ENGLISH

• Do not overreach and do not cut above shoulder height.

This helps prevent unintended tip contact and enables better

control of the chain saw in unexpectedsituations.

• Only use replacement bars and chains specified by the

manufacturer. Incorrect replacement bars and chains may

cause chain breakage and/orkickback.

• Follow the manufacturer’s sharpening and maintenance

instructions for the saw chain. Decreasing the depth gauge

height can lead to increasedkickback.

The Following Precautions Should Be

Followed to Minimize Kickback:

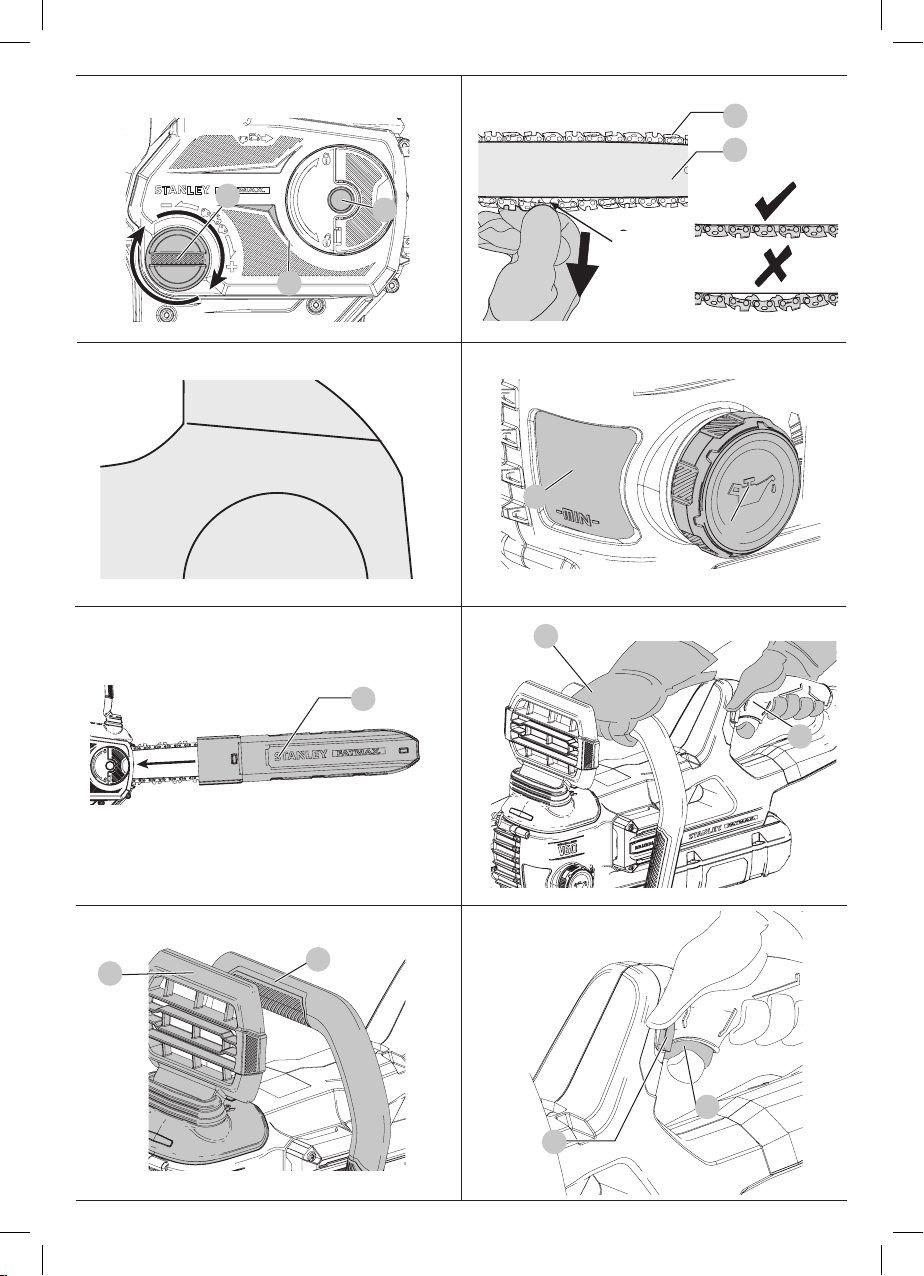

1. Grip saw firmly. Hold the chain saw firmly with both

hands when the motor is running. Use a firm grip with

thumbs and fingers encircling the chain saw handles.

Chain saw will pull forward when cutting on the bottom edge

of the bar, and push backward when cutting along the top

edge of thebar.

2. Do not overreach.

3. Keep proper footing and balance at alltimes.

4. Don’t let the nose of the guide bar contact a log, branch,

ground or otherobstruction.

5. Don’t cut above shoulderheight.

6. Use devices such as low kickback chain and reduced

kickback guide bars that reduce the risks associated

withkickback.

7. Only use replacement bars and chains specified by the

manufacturer or theequivalent.

8. Never let the moving chain contact any object at the tip

of the guidebar.

9. Keep the working area free from obstructions such

as other trees, branches, rocks, fences, stumps, etc.

Eliminate or avoid any obstruction that your saw chain could

hit while you are cutting through a particular log orbranch.

10. Keep your saw chain sharp and properly tensioned. A

loose or dull chain can increase the chance of kickback.

Check tension at regular intervals with the motor stopped and

tool unplugged, never with the motorrunning.

11. Begin and continue cutting only with the chain moving

at full speed. If the chain is moving at a slower speed, there is

a greater chance for kickback tooccur.

12. Cut one log at atime.

13. Use extreme caution when re-entering a previous cut.

Engage ribbed bumpers into wood and allow chain to reach

full speed before proceeding withcut.

14. Do not attempt plunge cuts or borecuts.

15. Watch for shifting logs or other forces that could close a

cut and pinch or fall intochain.

Kickback Safety Features

WARNING: The following features are included on your

saw to help reduce the hazard of kickback; however such

features will not totally eliminate this dangerous reaction.

As a chain saw user do not rely only on safety devices.

You must follow all safety precautions, instructions, and

maintenance in this manual to help avoid kickback and

other forces which can result in seriousinjury.

• Reduced-Kickback Guide Bar, designed with a small radius

tip which reduces the size of the kickback danger zone on

bar tip. A reduced - kickback guide bar is one which has

been demonstrated to significantly reduce the number and

seriousness of kickbacks when tested in accordance with safety

requirements for electric chainsaws.

• Low-Kickback Chain, designed with a contoured depth gauge and

guard link which deflect kickback force and allow wood to gradually

ride into thecutter.

• Do not operate chain saw while in a tree, on a ladder, on a

scaffold, or from any unstablesurface.

• Hold tool by insulated gripping surfaces when performing an

operation where the cutting tool may contact hidden wiring.

Contact with a “live” wire will make exposed metal parts of the

tool “live” and shock theoperator.

• Do not attempt operations beyond your capacity or

experience. Read thoroughly and understand completely all

instructions in thismanual.

• Before you start chain saw, make sure saw chain is not

contacting anyobject.

• Do not operate a chain saw with one hand! Serious injury to the

operator, helpers, or bystanders may result from one handed

operation. A chain saw is intended for two-handed useonly.

• Keep the handles dry, clean, and free of oil orgrease.

• Do not allow dirt, debris, or sawdust to build up on the motor

or outside airvents.

• Stop the chain saw before setting itdown.

• Do not cut vines and/or small underbrush.

• Use extreme caution when cutting small size brush and

saplings because slender material may catch the saw chain

and be whipped toward you or pull you offbalance.

WARNING: Some dust created by power sanding, sawing,

grinding, drilling, and other construction activities

contains chemicals known to the State of California to

cause cancer, birth defects or other reproductive harm.

Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other

masonry products, and

• a

rsenic and chromium from chemically-treatedlumber.

Your risk from these exposures varies, depending on how often you

do this type of work. To reduce your exposure to these chemicals:

work in a well ventilated area, and work with approved safety

equipment, such as those dust masks that are specially designed

to filter out microscopicparticles.

• Avoid prolonged contact with dust from power sanding,

sawing, grinding, drilling, and other construction activities.

Wear protective clothing and wash exposed areas with soap

and water. Allowing dust to get into your mouth, eyes, or lay

on the skin may promote absorption of harmfulchemicals.

WARNING: Use of this tool can generate and/or disburse

dust, which may cause serious and permanent respiratory

or otherinjury.