CONTENT

1. SAFETY DEFINITIONS ................................................................................................................................................... 2

1.1 GENERAL SAFETY RULES .......................................................................................................................................................................... 2

1.2 PROJECTILE HAZARDS .............................................................................................................................................................................. 2

1.3 OPERATING HAZARDS............................................................................................................................................................................... 3

1.4 REPETITIVE MOTIONS HAZARDS............................................................................................................................................................ 3

1.5 ACCESSORY HAZARDS .............................................................................................................................................................................. 3

1.6 WORKPLACE HAZARDS............................................................................................................................................................................. 3

1.7 NOISE HAZARDS.......................................................................................................................................................................................... 3

1.8 ADDITIONAL SAFETY INSTRUCTIONS FOR PNEUMATIC AND HYDRAULIC TOOL ................................................................ 4

2. SPECIFICATIONS............................................................................................................................................................ 5

2.1 TOOL SPECIFICATION................................................................................................................................................................................. 5

3. INTENT OF USE.............................................................................................................................................................. 6

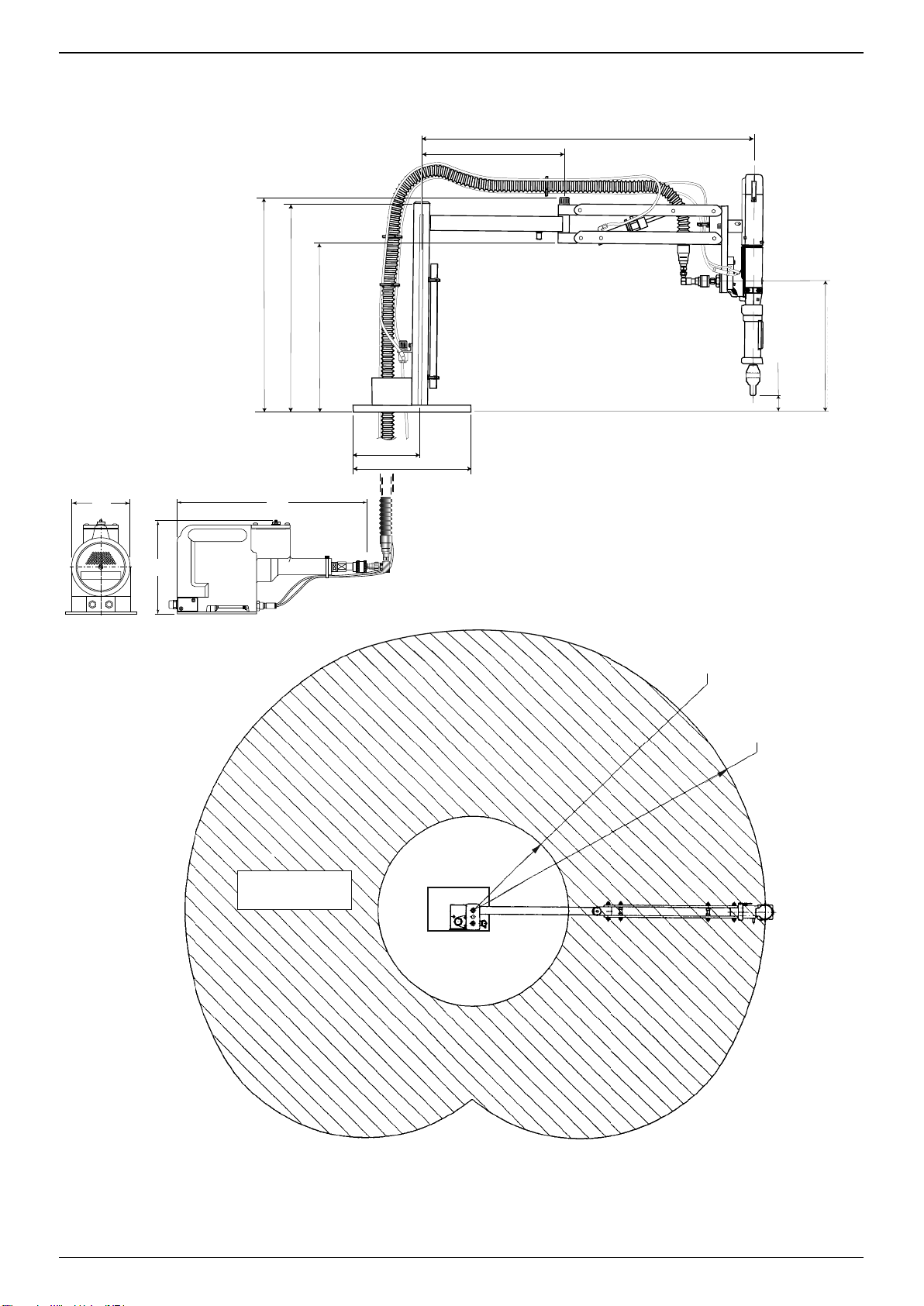

3.1 TOOL DIMENSIONS - 07535 MKII MODEL........................................................................................................................................... 7

4. PUTTING INTO SERVICE................................................................................................................................................ 8

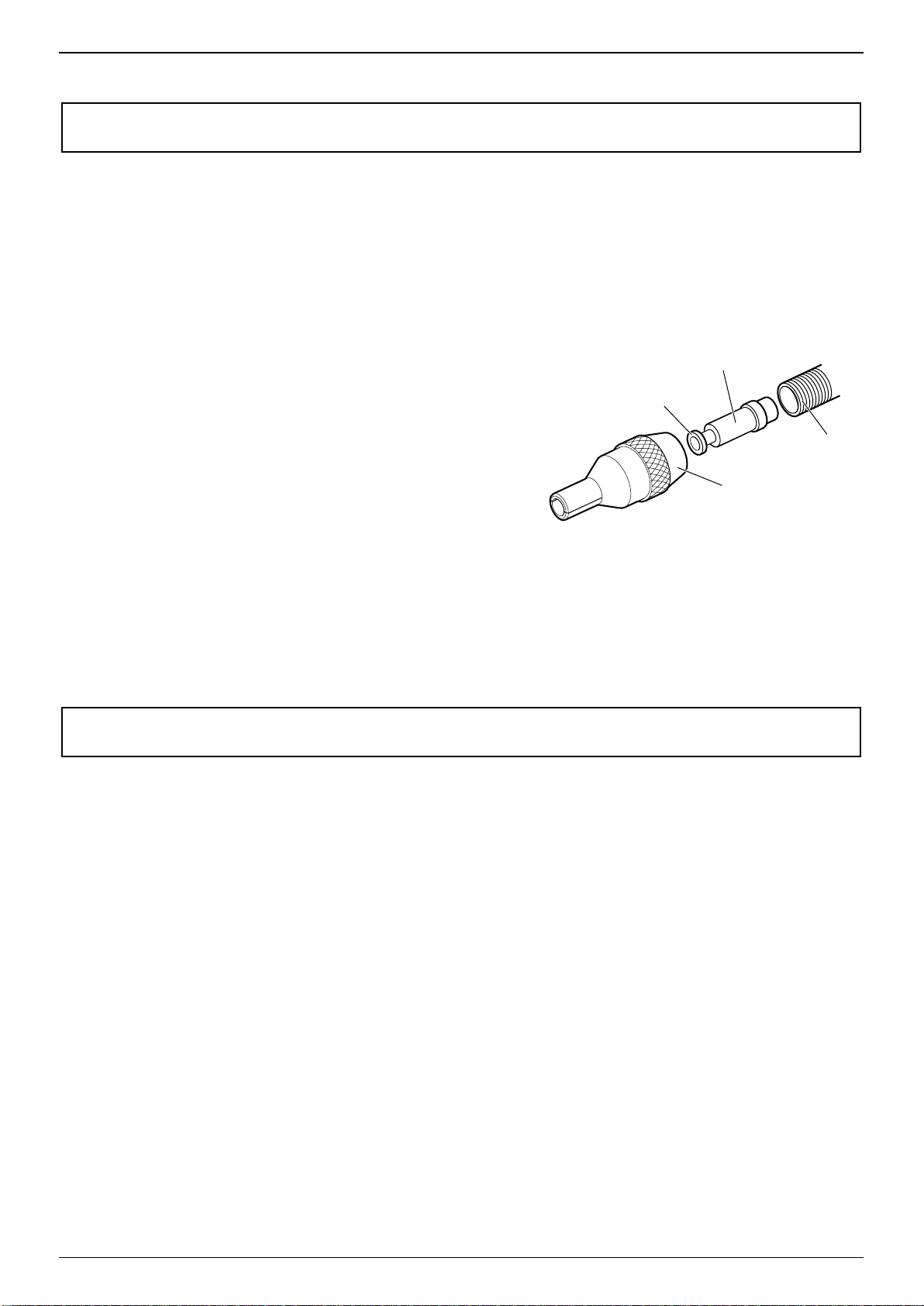

4.1 AIR SUPPLY .................................................................................................................................................................................................... 8

4.2 CURSOR .......................................................................................................................................................................................................... 9

4.3 LOADING AND RELOADING THE TOOL................................................................................................................................................ 9

4.4 OPERATING PROCEDURE........................................................................................................................................................................10

4.5 PLACING EQUIPMENT..............................................................................................................................................................................10

5. SERVICING THE TOOL..................................................................................................................................................11

5.1 DAILY/ WEEKLY...........................................................................................................................................................................................11

5.2 MOLY LITHIUM GREASE EP 3753 SAFETY DATA..............................................................................................................................11

5.3 SERVICE KIT..................................................................................................................................................................................................12

6. MAINTENANCE............................................................................................................................................................13

6.1 DISMANTLING 07535-02500 MK II......................................................................................................................................................13

6.2 GENERAL ASSEMBLY OF BASE TOOL 07535-02500 MKII.............................................................................................................15

6.3 PARTS LIST FOR BASE TOOL 07535-02500 MKII..............................................................................................................................16

6.4 GENERAL ASSEMBLY OF PANTOGRAPH ARM..................................................................................................................................17

6.5 PARTS LIST FOR PANTOGRAPH ARM ..................................................................................................................................................18

6.6 INTENSIFIER 07531-02200 - MAINTENANCE....................................................................................................................................19

6.7 INTENSIFIER 07531-02200......................................................................................................................................................................20

6.8 INTEGRAL HANDLE AND TRIGGER ASSEMBLY ................................................................................................................................21

6.9 PILOT VALVE 07005-00590 - MAINTENANCE ...................................................................................................................................23

6.10 PROTECTING THE ENVIRONMENT.......................................................................................................................................................23

7. PILOT VALVE 07005-00590.........................................................................................................................................24

8. PRIMING ......................................................................................................................................................................25

8.1 OIL DETAILS.................................................................................................................................................................................................25

8.2 PRIMING PROCEDURE..............................................................................................................................................................................25

9. FAULT DIAGNOSIS.......................................................................................................................................................26

10. EC DECLARATION OF CONFORMITY..........................................................................................................................27

11. UK DECLARATION OF CONFORMITY .........................................................................................................................28

12. PROTECT YOUR INVESTMENT! ...................................................................................................................................29

©2021 Stanley Black & Decker inc.

All rights reserved.

The information provided may not be reproduced and/or made public in any way and through any means (electronically or

mechanically) without prior explicit and written permission from STANLEY Engineered Fastening. The information provided

is based on the data known at the moment of the introduction of this product. STANLEY Engineered Fastening pursues a

policy of continuous product improvement and therefore the products may be subject to change. The information provided

is applicable to the product as delivered by STANLEY Engineered Fastening. Therefore, STANLEY Engineered Fastening

cannot be held liable for any damage resulting from deviations from the original specications of the product.

The information available has been composed with the utmost care. However, STANLEY Engineered Fastening will not

accept any liability with respect to any faults in the information nor for the consequences thereof. STANLEY Engineered

Fastening will not accept any liability for damage resulting from activities carried out by third parties. The working names,

trade names, registered trademarks, etc. used by STANLEY Engineered Fastening should not be considered as being free,

pursuant to the legislation with respect to the protection of trademarks.

ORIGINAL INSTRUCTION ENGLISH

1