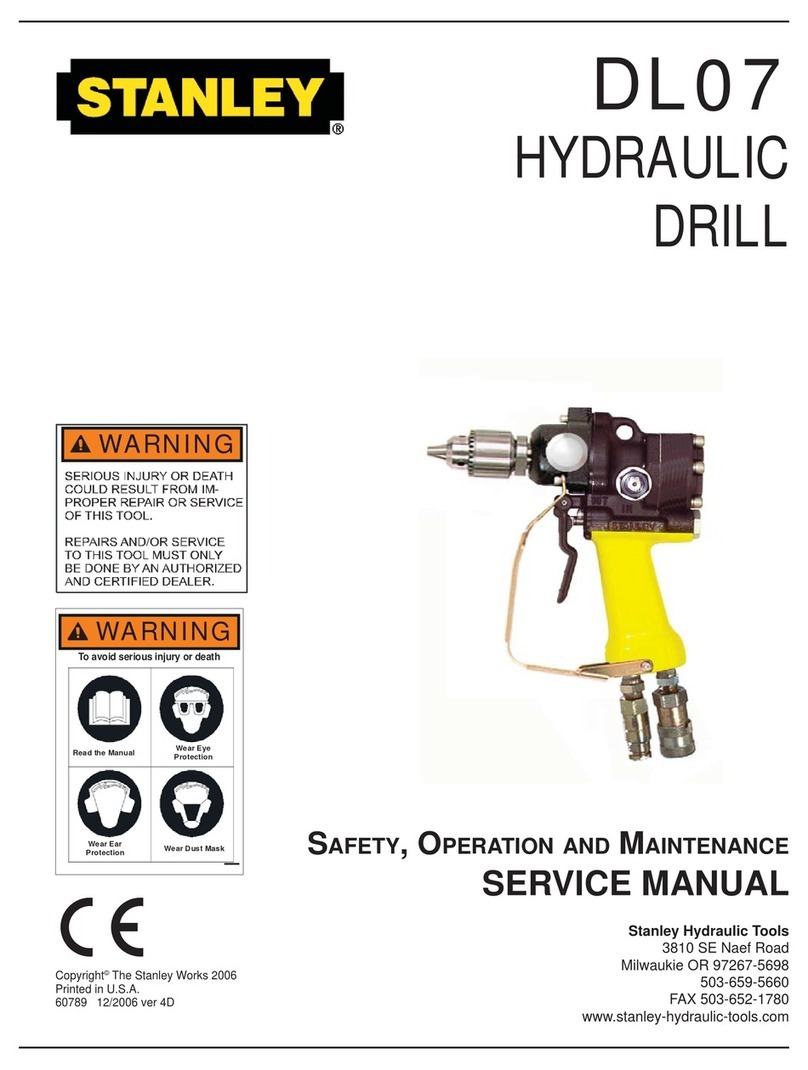

TheSAFETYTAG,P/N15875,shownatright,smaller

thanactualsize,isattachedtothetoolwhenshipped

fromthefactory.Readandunderstandthesafety

instructionslistedonthistagbeforeremoval.We

suggestyouretainthistagandattachittothetool

whennotinuse.

ANameTagStickerisattachedtothetool.Neverexceedtheflowandpressurelevelsspecifiedon

thissticker.Theinformationlistedonthenametagstickermustbelegibleatalltimes.Replacethis

stickerifitbecomeswornordamaged.AreplacementisavailablefromyourlocalStanley

distributor.

ToolDecals&Tags

6

DANGER DANGER

1.FAILURETOUSEHYDRAULICHOSE WHENUSING

HYDRAULICTOOLSONORNEARELECTRICALLINES

MAYRESULTINDEATHORSERIOUSINJURY.

BEFOREUSINGHOSE

ONORNEARELECTRICLINES.

BESURETHEHOSEIS.THE

HOSESHOULDBEREGULARLYTESTEDFORELECTRICCURRENT

LEAKAGEINACCORDANCEWITHYOURSAFETYDEPARTMENT

INSTRUCTIONS.

2.AHYDRAULICLEAKORBURSTMAYCAUSEOIL

INJECTIONINTOTHEBODYORCAUSEOTHERSEVEREPERSONAL

INJURY.

A.DONOTEXCEEDSPECIFIEDFLOWAND

PRESSUREFORTHISTOOL.EXCESSFLOWOR

PRESSUREMAYCAUSEALEAKORBURST.

B.DONOTEXCEEDRATEDWORKINGPRESSURE

OFHYDRAULICHOSEUSEDWITHTHISTOOL.

EXCESSPRESSUREMAYCAUSEALEAKOR

BURST.

C.CHECKTOOL,HOSE,COUPLERS&

CONNECTORSDAILYFOR

LEAKS.DONOTFEELFORLEAKSWITH

YOURHANDS.CONTACTWITHALEAKMAY

RESULTINSEVEREPERSONALINJURY.

LABELEDAND

CERTI-FIEDASNON-CONDUCTIVE

LABELEDANDCERTIFIEDAS

NON-CONDUCTIVE

MAINTAINEDASNON-CONDUCTIVE

D.DONOTLIFTORCARRYTOOLBYTHEHOSES.DONOTABUSE

HOSE.DONOTUSEKINKED,TORNORDAMAGEDHOSES.

3.MAKESUREHYDRAULICHOSESAREPROPERLY

CONN-ECTEDTOTHETOOLBEFOREPRESSURIZING

SYSTEM.SYSTEMPRESSUREHOSEMUSTALWAYS

BECONNECTEDTOTOOL“IN”PORT.SYSTEM

RETURNHOSEMUSTALWAYSBECONNECTEDAT

TOOL“OUT”PORT.REVERSINGCONNECTIONSMAY

CAUSEREVERSETOOLOPERATIONWHICHCAN

CAUSESEVEREPERSONALINJURY.

4.DONOTCONNECTCLOSED-CENTERTOOLSTO

OPEN-CENTERHYDRAULICSYSTEMS.THISMAY

CAUSEEXTREMESYSTEMHEATAND/ORSEVERE

PERSONALINJURY.

DONOTCONNECTOPEN-CENTERTOOLSTOCLOSED-CENTER

HYDRAULICSYSTEMS.THISMAYRESULTINLOSSOFOTHER

HYDRAULICFUNCTIONSPOWEREDBYTHESAMESYSTEMAND/OR

SEVEREPERSONALINJURY.

5.BYSTANDERSMAYBEINJUREDINYOURWORK

AREA.KEEPBYSTANDERSCLEAROFYOURWORK

AREA.

6.WEARHEARING,EYE,FOOT,HANDANDHEADPROTECTION.

7.TOAVOIDPERSONALINJURYOREQUIPMENTDAMAGE,ALLTOOL

REPAIR,MAINTENANCEANDSERVICEMUSTBE

PERFORMEDBYAUTHORIZEDANDPROPERLY

TRAINEDPERSONNEL.

IMPORTANT IMPORTANT

READOPERATIONMANUALAND

SAFETYINSTRUCTIONSFORTHIS

TOOLBEFOREUSINGIT.

USEONLYPARTSANDREPAIR

PROCEDURESAPPROVEDBY

STANLEYANDDESCRIBEDINTHE

OPERATIONMANUAL.

TAGTOBEREMOVEDONLYBYTOOL

OPERATOR.

READOPERATIONMANUALAND

SAFETYINSTRUCTIONSFORTHIS

TOOLBEFOREUSINGIT.

USEONLYPARTSANDREPAIR

PROCEDURESAPPROVEDBY

STANLEYANDDESCRIBEDINTHE

OPERATIONMANUAL.

TAGTOBEREMOVEDONLYBYTOOL

OPERATOR.

(517) (517)15875 15875

SEEOTHERSIDE SEEOTHERSIDE

11207

CircuitType“D”Decal 30Lpmat138bar

BHTMACATEGORY

28323

“CE”Decal

29149

RotationDirectionSticker

60807

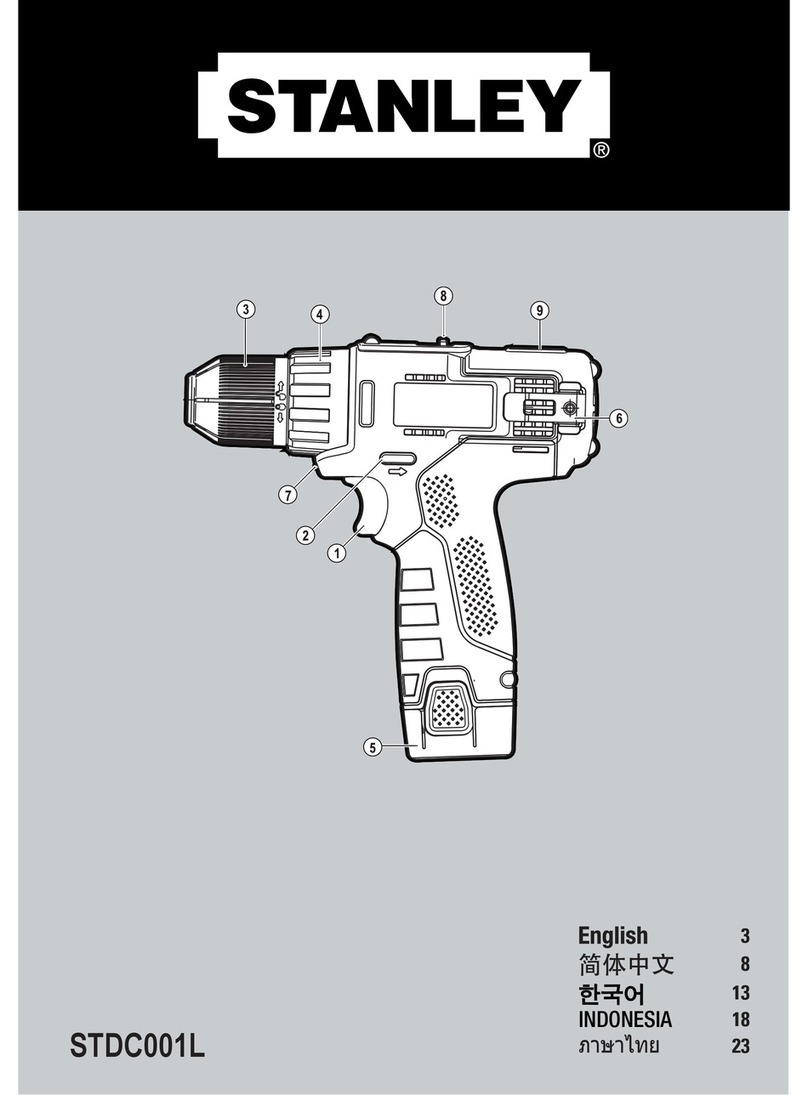

DL07ModelSticker

ModelNo.

Dl07

StanleyHydraulicTools

3810SENaefRd

Milwaukie,Oregon97267

15-45lpm/4-12gpm

140bar/2000psi

®

*Notallstickersarefurnishedonalltoolmodels.

Consultpartslistandmodelnumberfordetails.

Correctlyconnecthosestotoolports.Donotexceedspecifiedflowor

pressure.Improperhandling,useormaintenancecancausealeakor

burstthatcanresultinoilinjectiontothebody.Failuretoobservethese

precautionsmayresultinseriouspersonalinjury.

WARNING

58862

PressureWarning

Sticker

28788

ManualSticker

WARNING

ReadownersmanualandensurethatyouPhavebeen

properlytrainedtoworkonorParoundelectriclines.Failureto

usehydraulicPhoselabeledandcertifiedas

non-conductivePmayresultindeathorseriouspersonalinjury.

58864

ElectricalWarningSticker

FORUSEONOPENCENTERANDCLOSED

CENTERHYDRAULICSYSTEMS,"SETFOR

PROPERSYSTEMBEFOREUSE"

OC/CC

11354

OC/CCSticker

8GPM/30LPM

1000RPMAT

RATEDNO-LOADSPEED

29148

RPMSticker