Star EV BN72-14-AC-D Instruction Manual

Owner’s Manual and Service Guide

Enclosed Bus:

BN72-14-AC-D and BN72-11-AC-D (Wheelchair Accessible)

2

Thanks for buying the Star EV Enclosed Bus. This manual contains

information you will need for proper operation, maintenance, and

care of your Enclosed Bus. A thorough understanding of these simple

instructions will help you to obtain maximum enjoyment from your

new Star EV.

If you have any questions about the operation or maintenance of

your Enclosed Bus, please consult your Star EV dealer.

Read and understand this manual completely before operating your

Star EV.

This manual should be considered a permanent part of your Enclosed

Bus and should remain with the vehicle when lending or resold.

3

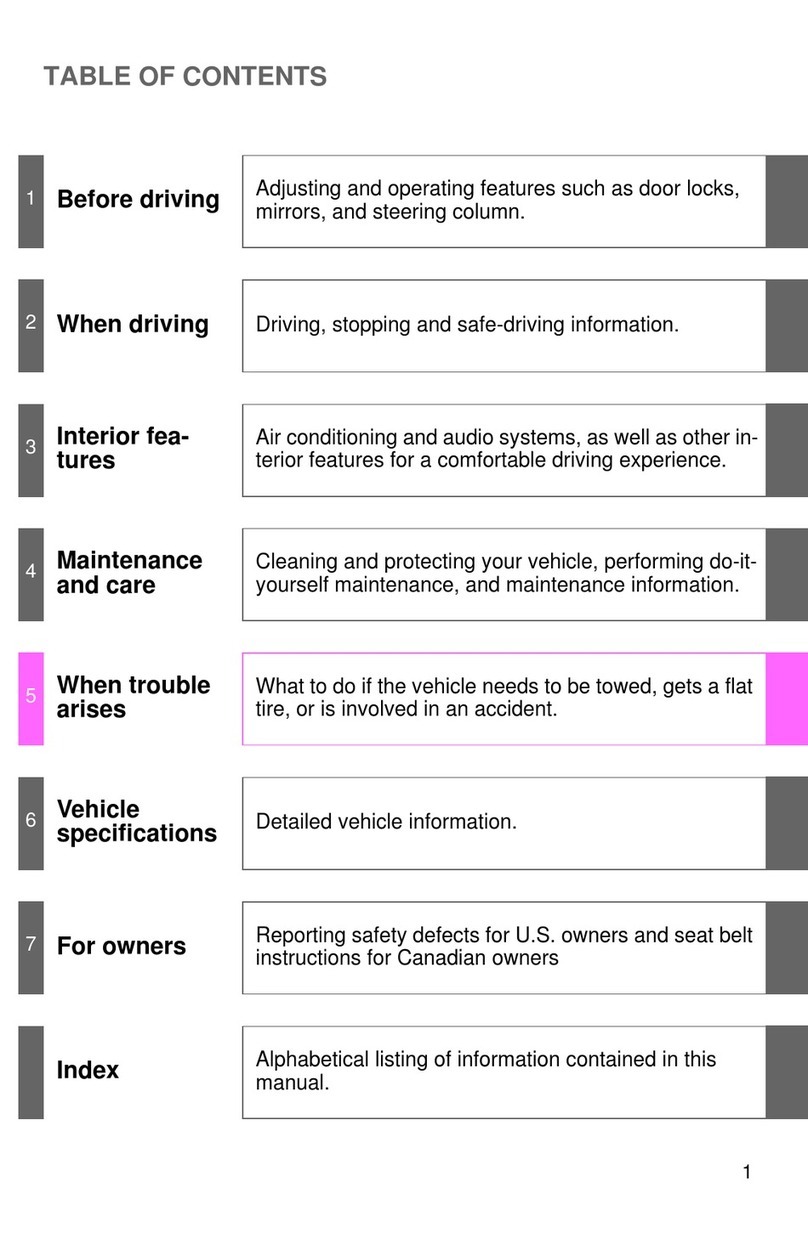

Vehicle Specifications

Operation

Important labels

Functions

Operational Process

Safety

Maintenance

Battery maintenance

Traction/motor maintenance

Speed controller maintenance

Brake system maintenance

Lubrication

General maintenance notes

Periodic maintenance

Storage

Troubleshooting

Electrical Diagrams

Table of Contents

4

4

5

6

7

8

12

13

13

14

14

14

17

17

21

4

1: Vehicle Specifications

1: Operation

Important Labels

Please read the following labels carefully before operating the vehicle, and prompt-

ly replace any labels which become unreadable or removed.

• Security Warning label under the dashboard

• Warning label under the dashboard

• Warning label beside the parking brake handle

Enclosed Bus BN72-14-AC-D-M and BN72-11-AC-D-Wheelchair-M (Wheelchair Accessible

model)

Passengers 14 / Wheelchair: 11+ wheel-

chair Body Material Fiberglass with steel frame

and aluminum doors

Battery System Twelve 6 V (72 V) batteries,

Trojan T-105 Front Suspension Independent suspension, coil

over shocks

Motor Power 9.5 hp AC motor Rear Suspension

Integral rear axle, coil spring

non-independent suspension,

hydraulic shock absorber

Controller Power 550 A Curtis AC controller Steering System Rack and pinion power

steering

Top Speed 19 mph Brake System

Front and rear drum, hydraulic

brake, mechanical parking

brake

Load Capacity 2200 lbs / Wheelchair: 1900 lbs Tire Size 155 R 12 DOT tire

Dimensions

203” x 61” x 82” (L x W x H)

Wheelchair: 207” x 61” x 82” (L

x W x H)

Tire Pressure 65 psi

Weight w/ Batteries 3100 lbs Wheel Type 12” aluminum

Ground Clearance 5.5” Roof Fiberglass

Turning Radius 20 Windshield AS1, DOT automotive wind-

shield

Wheel Base 108” / Wheelchair: 104” Drive Train Automatic drive system

Top Climbing Grade 20% Voltage Reducer 30 A, 72 V to 12 V reducer

included

Warranty One year bumper-to-bumper warranty, less wear items; two year Trojan battery war-

ranty, based on date code

5

Functions

Power key: Controls the power supply of the whole vehicle. When the key is inserted

into it and turned clockwise, it will switch on the lights, horn, and the control sys-

tem; when the key is turned back, the power will be switched o.

Acceleration pedal: Controls the speed. It should be depressed slowly. The vehicle

speeds up with the gradual stepping-down, and reaches the full speed when the

pedal is stepped to the bottom. The 4

vehicle slows down when the pedal is released gradually. When the pedal is fully

released, electric brake works.

Service brake pedal: Decelerate the vehicle.

F/R switch: This switch is a three-position button. Depressing the upper part (F)

makes the vehicle move forwards while depressing the lower part (R) makes the

vehicle move backwards, and the middle is neutral. NOTE: The buzzer will sound

when the lower part of this button is depressed to give warning to the people

around your electric vehicle.

Hand-brake lever: Parks and brakes the vehicle.

Steering wheel: Controls the driving direction.

Light switch: Controls light system, including turning signals and headlight (in-

cludes high beam and lower beam).

Wiper and horn switch: Controls the wiper and horn.

Emergency stop switch: Stops the power of the whole vehicle in case of emergency.

NOTE: Before you switch on the vehicle, always check the status of this switch to

6

make sure that it is in the OFF position.

Combination meter: This meter shows information including lights, speed, range,

hand brake, and battery power.

Operational Process

Starting the vehicle

1. Select F for Forward or R for Reverse from F/R Button.

2. Switch on power with key.

3. Release the handbrake lever.

4. Depress the acceleration pedal smoothly.

WARNING: If you switch on Power Key first before selecting Forward or Reverse on

F/R Button, the vehicle will not run.

Stopping the vehicle

1. Step Service Brake Pedal to decelerate the vehicle until it stops completely

and shi F/R button to Neutral position.

2. Engage the handbrake lever to park the vehicle.

3. Release the service brake.

4. Switch o all lights.

5. Switch o the power key and take out the key.

Charging

CAUTION: There are two dierent kinds of chargers for this vehicle. One is an exteri-

or charger and the other is a built-in (on-body) charger. Before you use the charger,

read the charger operation manual.

7

• Explosive hydrogen gas is produced while battery is charged. Only charge

the battery in well-ventilated areas.

• Before using the charger, check if the battery charger you are using is cor-

rectly rated for your local AC electricity network.

• Do not disconnect the DC output cord from the battery receptacle when

the charger is ON, otherwise an arc could occur which may cause an ex-

plosion.

• Do not open the housing of the charger. Only a qualified electrician should

open the housing of the charger.

• The charger should be stored in safe and dry room with good ventilation.

The charger should be packed properly if not used for long time.

2: Safety

The driver should have a good knowledge of the operation system of the vehicle

and its features while following rules for safe operation. WARNING: Drive the vehi-

cle o streets unless it is allowed.

• The vehicle cannot be overloaded, or the motor will be damaged. An over-

loaded vehicle can lose control and its life will be shortened.

• Unqualified persons are prohibited to drive the vehicle.

• Make sure this vehicle runs in its rated climbing ability.

• Don’t overtake other vehicles at crossroads, in blind areas or in other dan-

gerous zones.

• Keep your entire body inside the vehicle, keep seated and holding on while

the vehicle is moving.

• Do not start the vehicle until all occupants are securely seated.

• Keep your hands on the steering wheel and your eyes on the path ahead.

• Always back out the vehicle slowly and watch the back carefully.

• Avoid starting and stopping suddenly.

• Avoid turning the vehicle too sharply at high speeds.

• Always drive slowly up and down slopes.

• Do not make any modification or addition which may aect the capacity

or safety.

• Do not allow children to play in the vehicle. Children should be seated be-

tween adults and protected while the vehicle is moving.

8

3: Maintenance

Battery Maintenance

WARNING: Battery electrolyte is poisonous and dangerous, may cause severe

burns, injury, etc.. Always wear protective clothing, gloves, and goggles when han-

dling batteries, electrolyte, and charging your battery.

KEEP OUT OF REACH OF CHILDREN.

Cleaning

• The exterior of the battery, the connection wires and bolts should always

be kept clean and dry. When cleaning, make sure all vent caps are tightly

in place. Clean the battery top with a cloth or brush and solution of bak-

ing soda and water. When cleaning, do not allow any cleaning solution or

other foreign matter to get inside the battery. This should be done every

week.

• Clean battery terminals and the inside of cable clamps using a post and

clamp cleaner. Clean terminals will have a bright metallic shine. This

should be done whenever necessary.

• Reconnect the clamps to the terminals and thinly coat them with petro-

leum jelly (Vaseline) to prevent corrosion.

• WARNING: Before you disconnect any battery cable from any terminal on

the battery, always remove the power by disconnecting the main battery

cable from the controller.

• Checking the terminals and nuts: The connection of the battery should al-

ways be kept in good condition. Check every week on whether any battery

cable terminal or nut has become loose in order to prevent any damage to

terminals. Check the status of the battery cable weekly. A damaged bat-

tery cable should be replaced immediately.

• Foreign matter: Do not place any objects on the battery and do not con-

nect the positive pole to the negative pole. This may cause a short circuit

and sparking.

Recharging

• As long as you use the vehicle, regardless of how long you have used it,

the battery should be recharged fully on the same day. Any delay in re-

charging will negatively aect the battery. The lead-acid battery does not

develop a memory, so need not be fully discharged before recharging.

9

• If the vehicle is going to be kept unused for a long time, the battery should

be fully recharged first. Aer that, the battery should be fully recharged

every two weeks.

• When driving, the driver should always be aware of the drop level of the

battery power from the battery power meter. Any drop means the battery

power is diminishing. The driver can estimate the distance needed to be

taken, and recharge the battery at a proper time in case the vehicle cannot

get back to the recharging station in time for recharging.

• WARNING: Make sure the battery is recharged before the battery power

meter shows 20% power is le inside the battery. An over-discharged bat-

tery will have a very short service life and will make recharging diicult.

• WARNING: During recharge, the vehicle should be parked in a well-venti-

lated area with the fill caps tightly secured. Keep far away from any flame

and sparks to avoid any explosion or fire that could cause physical injury

or damage to the property.

• During recharge, if the vehicle had doors, keep the doors open. Li the seat

bottom to keep the battery compartment open to the air.

Watering

Flooded batteries need water. More importantly, watering must be done at the

right time and in the right amount or else the battery's performance and longev-

ity suers. Water should always be added aer fully charging the battery. Prior to

charging, there should be enough water to cover the plates. If the battery has been

discharged partially or fully, the water level should also be above the plates. Keep-

ing the water at the correct level aer a full charge will prevent having to worry

about the water level at a dierent state of charge.

It is recommended that batteries be checked once a month until you get a feel for

how oen you must water your batteries. Important things to remember:

• Do not let the plates get exposed to air. This will damage (corrode) the

plates.

• Do not fill past the water level in the filling well to the cap. This most likely

will cause the battery to overflow acid, consequently losing capacity and

causing corrosion.

• Do not use water with a high mineral content. Use distilled or de-ionized

water only.

WARNING: The electrolyte is a solution of acid and water so skin contact should be

avoided.

10

Watering procedure

1. Open the vent caps and look inside the fill wells.

2. Check electrolyte level; the minimum level is at the top of the plates.

3. If necessary add just enough water to cover the plates at this time.

4. Put batteries on a complete charge before adding any additional water

(refer to the Charging section).

5. Once charging is completed, open the vent caps and look inside the fill

wells.

6. Add water until the electrolyte level is 1/8" below the bottom of the fill

well.

7. A piece of rubber can be used safely to help determine this level.

8. Clean, replace, and tighten all vent caps.

CAUTION: Never add acid to a battery.

Testing: Visual inspection alone is not suicient to determine the overall health of

the battery. Both open-circuit voltage and specific gravity readings can give a good

indication of the battery's charge level, age, and health. Routine voltage and gravi-

ty checks will not only show the state of charge but also help spot signs of improper

maintenance, such as undercharging and over-watering, and possibly even locate

a bad or weak battery. The following steps outline how to properly perform routine

voltage and specific gravity testing on batteries.

Specific Gravity Test (Flooded batteries only)

1. Do not add water at this time.

2. Fill and drain the hydrometer 2 to 4 times before pulling out a sample.

3. There should be enough sample electrolyte in the hydrometer to com-

pletely support the float.

4. Take a reading, record it, and return the electrolyte back to the cell.

5. To check another cell, repeat the 3 steps above.

6. Check all cells in the battery.

7. Replace the vent caps and wipe o any electrolyte that might have been

spilled.

8. Correct the readings to 80° F:

• Add .004 to readings for every 10° above 80° F.

• Subtract .004 for every 10° below 80° F.

9. Compare the readings.

10. Check the state of charge using the table below.

If any specific gravity readings register low then follow the steps below.

11

1. Check voltage level(s).

2. Perform equalization charge. Refer to the Equalizing section for the proper

procedure.

3. Take specific gravity readings again.

If any specific gravity reading still registers lower than the factory specification of

1.277+/- .007 then one or more of the following conditions may exist:

1. The battery is old and approaching the end of its life.

2. The battery was le in a state of discharge too long.

3. Electrolyte was lost due to spillage or overflow.

4. A weak or bad cell is developing

5. Battery was watered excessively previous to testing.

Batteries in conditions 1 - 4 should be taken to a specialist for further evaluation or

retired from service.

Open-Circuit Voltage Test

For accurate voltage readings, batteries must remain idle (no charging, no dis-

charging) for at least 6 hrs, preferably 24 hrs.

1. Disconnect all loads from the batteries.

2. Measure the voltage using a DC voltmeter.

3. Check the state of charge with the table below.

4. Charge the battery if it registers 0% to 70% charged.

If battery registers below the Table 1 values, the following conditions may exist:

• The battery was le in a state of discharge too long.

• The battery has a bad cell.

Batteries in these conditions should be taken to a specialist for further evaluation

or retired from service.

12

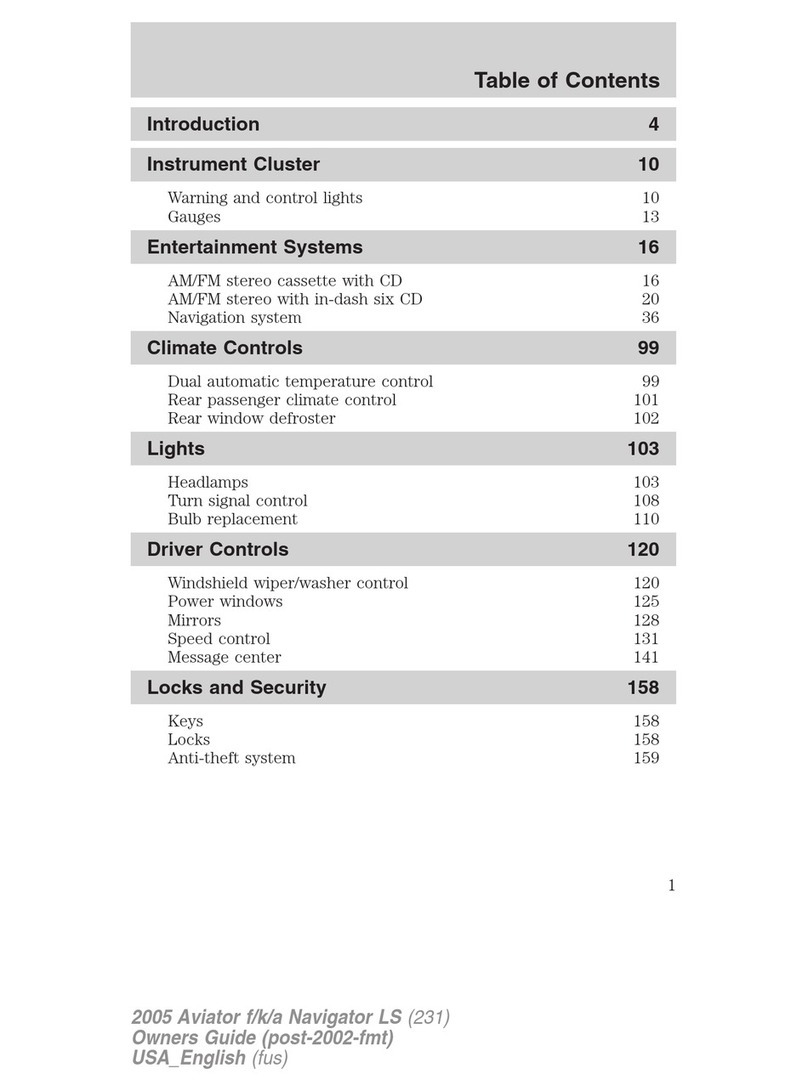

Percentage of

Charge

Specific Gravity

Corrected to 80° F

Open circuit voltage

6 V 8 V 12 V 24 V 36 V 48 V

100% 1.277 6.37 8.49 12.73 25.46 38.20 50.93

90% 1.258 6.31 8.41 12.62 25.24 37.85 50.47

80% 1.238 6.25 8.33 12.50 25.00 37.49 49.99

70% 1.217 6.19 8.25 12.37 24.74 37.12 49.49

60% 1.195 6.12 8.16 12.24 24.48 36.72 48.96

50% 1.172 6.05 8.07 12.10 24.20 36.31 48.41

40% 1.148 5.98 7.97 11.96 23.92 35.87 47.83

30% 1.124 5.91 7.88 11.81 23.63 35.44 47.26

20% 1.098 5.83 7.77 11.66 23.32 34.97 46.63

10% 1.073 5.75 7.67 11.51 23.02 34.52 46.03

State of charge as related to specific gravity and open circuit voltage

Battery Installation

Tighten the battery cables to battery terminals with torque of 95 - 105 lbs. in. (10.7

- 11.9 N.M.) Make sure there is nothing else between the battery cable lug and

battery terminal post.

WARNING: When working with the battery, DO NOT put wrenches or any other

metal objects across the battery terminals, otherwise, an arc can occur, and it may

cause explosion of the battery and physical injury.

Battery should be installed or replaced only by a qualified electrician.

Traction/Motor Maintenance

The motor is designed for use up to 4000 feet above sea level and in a temperature

between -15° F and 105° F.

Never keep the motor running idly. Any mud, sand, and other clinging objects

should be cleaned away.

Check the carbon brush every three months. To change a worn or weakened car-

bon brush, press spring.

Troubleshooting for Motor (DC Motor only)

Warning: Only a qualified electrician should change and adjust the carbon brush.

13

Symptoms Possible Causes

All copper plates turn black The pressure of brush is incorrect.

The commutator turns black in a

certain order and in groups

Short circuit in the commutator or armature coil; poor welding or

disconnection between the commutators and the armature coil.

The commutator turns black The central line of the commutator deviates or its surface is not

round and smooth.

The brush wears out, turns colors and

become broken

The motor vibrates; the clearance between the brush and its holder

is too big; the clearance between the brush and commutators is

too big; the mica between dierent commutators extrudes; the

brush is made by wrong materials; the brush is the wrong type.

Big sparks

The motor is overloaded; the commutators are not clean, round

or smooth; mica or some commutators extrude; the brush is not

ground properly; the brush is the wrong type; the brush is jammed

in the brush holder; the brush holder become loose or vibrating;

the polarity and sequence of magnetic poles is wrong.

The brush and its wires get hot Big sparks of the brush; poor contact between brush and so wires.

The brush is noisy The surface of the commutators is not smooth.

Speed Controller

Speed Controller Maintenance

The speed controller of the vehicle is wholly imported, which adopts high frequen-

cy MOS technology to realize the control of speed, torque and brake with smooth-

ness, silence, and high energy eiciency.

When the vehicle starts, the controller will inspect signals from the accelerator.

If signal exceeds 20%, the HPD (protection unit in the controller) will prohibit the

output of the controller. The controller will self-check when the vehicle is running.

If any defect inspected, the controller will stop the vehicle to protect the operator

and the vehicle.

Brake System Maintenance

Depress the brake pedal with a force of 65 lbs. The pedal travel shouldn’t exceed

2/3 of the full free pedal travel.

The clearance for the brake plate is self-adjusted. Under a force of around 45 lbs,

the parking brake handle should be fixed in one gear from 5 to 10 ratchets. When

the brake handle is released completely, the brake function will stop. Inspect and

change brake shoe, and add lubrication into the brake bearing periodically.

14

Lubrication

Use 901 vehicle brake oil DOT3 as brake oil. Use 1L of 85W/90GL lubrication oil

for gear box. Use 1L of 90GL hypoid gear oil for the rear axle. Lubrication points:

steering gears, horizontal bars, steering ball joints, and bearings.

General Maintenance Notes

• To avoid any damage on the brake shoe, the handbrake should be re-

leased to its bottom before staring the vehicle.

• The lubricant for rear power assembly must be applied and changed as

per user’s manual.

• The brake system must be adjusted once every 3 months.

• The electricity system must be checked once every 3 months (especially

main circuit) for its fastening parts and wiring connections. Meanwhile

the contactor should be checked. Any defective parts should be replaced

immediately. Dust should be cleaned with low pressure air.

• The electric contactors easily become hot if their mutual contact is not

in good condition, so special attention should be paid regularly to the

electric contactors.

• When changing a fuse, make sure that the new fuse is right in rated cur-

rent.

• Disconnect the positive pole from the battery when maintenance is done.

• Never step the accelerator hard and frequently, which may shorten the

life of the controller.

• It is prohibited to pour any other liquids (such as battery additives, min-

eral water and tap water) into the battery. Only distilled water should fill

battery.

•

Periodic Maintenance

• Check if the contact between contacting points of the contactor is in good

condition, check for any mechanical sticking or jamming.

• Check if the micro switch in the accelerator can be switched on and o

properly.

• Check if the switch for the turn signal can be switched on and o proper-

ly.

15

• Check if all the connections between the motor, the battery, and the con-

troller are in good condition.

Use the following cleaning procedure for routine maintenance:

1. Turn the power key to OFF position.

2. Remove power by disconnecting the battery.

3. Discharge the capacitors in the controller by connecting a load (such as a

contactor coil or a horn) across the controller’s B+ and B- terminals.

4. Remove any dirt or corrosion from the connector areas. The controller

should be wiped clean with moist rag. Dry it before reconnecting the bat-

tery. The controller should not be subjected to pressured water flow from

either a standard hose or a power washer.

5. Make sure the connections are tight, but do not over-tighten them.

NOTE: All above checks should be performed with the power o. Above checks

shall be carried out once every 3 months; aer the power is turned o, the

wave-filter capacitor in the controller unit should continue discharging for a few

minutes more; don’t wash the electrical parts with water. You can remove dust

with a brush or high–pressure air.

Periodic Maintenance Chart

WARNING: Make sure to turn o the power key and apply the park brake when

you do the maintenance unless specified.

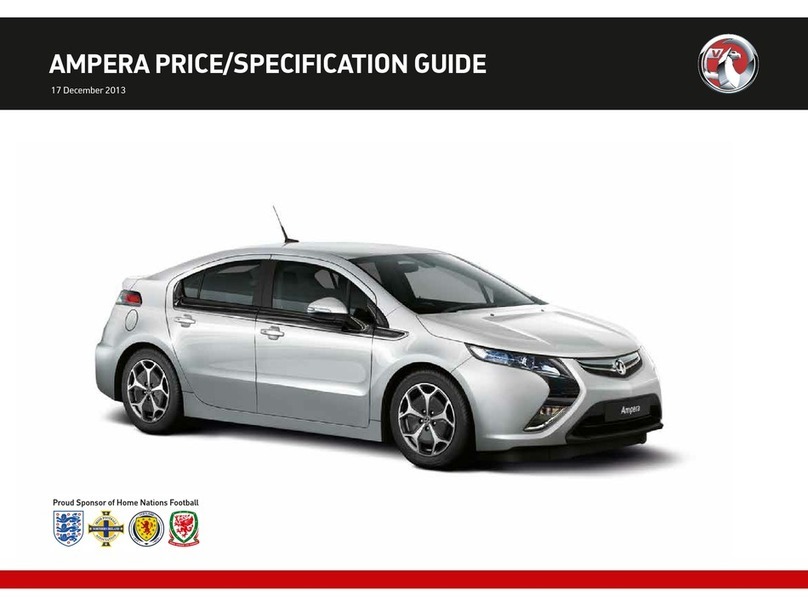

Item Descriptions Daily Weekly Monthly Quarterly Annually

Battery

Check the liquid level. Add distilled

water if necessary. ☑

Charge the battery. ☑

Tighten the nut on the battery

cable. ☑

Check if the battery is over-dis-

charged (the battery power meter

flashing).

☑

Check the liquid density of the

battery; standard density should be

1.275±0.005.

☑

Check if the battery is charged fully

by using the hydrometer and check-

ing the battery power meter.

☑

Clean the surface of battery. ☑

16

Item Descriptions Daily Weekly Monthly Quarterly Annually

Charger

Observe the charging status, check

if the charger plug becomes hot. ☑

Clean the surface of the charger. Do

not get any water inside the charger. ☑

Controller

Check if all terminals are tightened

properly. Do this aer the power

is o.

☑

Clean the surface of the controller. ☑

Check if the solenoid is in order,

checking its touching point. ☑

Motor

Check if any water gets in. Check if it

becomes too hot. ☑

Check if the carbon brush should be

replaced. (DC motor only) ☑

Check if the accelerator pedal works

well and if it can be released freely

and automatically.

☑

Chassis and

body

Check if the brake drum and shoe. ☑

Check if the hand brake functions. ☑

Check if the hose and tube for the

brake liquid leaking. ☑

Check if the brake liquid inside the

brake liquid tank is enough. ☑

Check the air pressure inside the

tire, check if the tire surface is worn,

and check if the nuts are tightened

properly.

☑

Check if the shock absorber has any

oil leaking, flat or abnormal noise. ☑

Check if there is oil leaking on the

gear box and the rear end. ☑

Add the lubricant inside the wheel

hub, steering system. ☑

Adjust the toe-in of the front end. ☑

Clean the body and seat. ☑

17

4: Storage

Follow the steps below when the vehicle is stored.

1. Check the liquid level inside the battery; recharge it fully before storing

the vehicle. WARNING: Charge the battery once a month if your vehicle

will be stored more than one month.

2. Turn the power key to OFF position, remove the key, and store the key in

a safe place.

3. Engage the handbrake.

4. Check the tire pressure to make sure its pressure is set to recommended

pressure.

5. Clean the exterior of the vehicle and apply a rust inhibitor.

6. Cover the vehicle with a breathable cover and store it in a dry, safe, and

well-ventilated place.

7. If you plan to store the vehicle for a longer time, check the liquid level

inside the battery and recharge the battery monthly.

5: Troubleshooting

There is no settled mode to diagnose and eliminate malfunctions. During main-

taining and checking, we suggest you first listen, then look and feel. Below is the

diagnoses and maintenance of some common malfunctions.

1. The vehicle doesn't move aer turning on the power key and stepping on accelerator pedal.

Malfunction Possible Reason Troubleshooting

Turn on power key,

voltmeter has no signal

Connector(s) in circuit is loose or open Tighten or connect

Fuse of controller or main circuit is open Change fuse

Battery cable(s) is loose or disconnected Tighten of change

Power key is broken Change

Voltmeter is broken Change

Battery terminals connect improperly Adjust

Turn on power key,

voltmeter has signal

Improper operating procedure Operate properly

Controller failure Check or change

Solenoid failure Check, repair, change

Accelerator failure Repair or change

Motor failure Repair or change

Parking brake doesn’t loosen Loosen parking brake

Over-heat protection Check, eliminate

18

2. Locking control when vehicle starts running, speed cannot be adjusted.

Malfunction Possible Reason Troubleshooting

Vehicle runs at full speed

when it starts

Terminals of solenoid stick together Check or repair

Controller failure Change

Potentiometer failure Repair or change

Vehicle stops immediately

aer it starts

Internal short of motor Repair or change

Motor is assembled too tight or blocked Repair or change

Controller failure Repair or change

Accelerator failure Repair or change

Normal power at low

speed, weak power at high

speed

Controller failure Check or change

Motor failure Check or change

Accelerator failure Check or change

3. Vehicle cannot change direction, only runs in one direction.

Malfunction Possible Reason Troubleshooting

Only runs in one direction F&R switch failure Change

Controller Failure Change

4. Possible reason and troubleshooting for malfunctions of mechanic system.

System Malfunction Possible Reason Troubleshooting

Transmission

system

Abnormal sound when

running

Clearance of rear axle decelerating

gear is too big, or the decelerating gear

is broken

Adjust, change

Transmission cross sha is worn out Change

Gear of transmission is worn out or

damaged Change

Flange bearing is damaged Change

Motor bearing is damaged Change

Gear liquid is deficient or empty Add gear liquid

Hard to shi gear, and/

or gear shi jumps in

dierent positions

Clutch cannot separate smoothly Adjust

Gear shi wire is damaged Change

Gear inside transmission case is worn

out Change

Orientation pin is loose Change

Steering system Steering heavy

Pressure of front tire is deficient Check the pres-

sure and inflate

Screw plug of redirector is too tight Adjust

Lack of lube in redirector Maintain/add

lube

Toe-in is abnormal Adjust

19

4. Possible reason and troubleshooting for malfunctions of mechanic system.

System Malfunction Possible Reason Troubleshooting

Steering

system

Steering heavy

Clearance of tension rod ball is too big Change

Steering knuckle and master pin is not lubri-

cated Add lube

Steering sha or its plastic cover is worn out Change

Unstable wheels

Rack of redirector is worn out Change redirector

Screw plug of redirector is too tight Adjust

Toe-in is adjusted improperly Adjust

Bearing of front wheel is worn out Change

Tie rod ball and joint is worn out Change tie rod

Redirector is loose Tighten

Driving

system

Deflected running

The pressure of the two front tires is dierent Inflate

Toe-in is too big or too small Adjust

Tightness of the le and right drum bearing of

front wheels is dierent Adjust

Brake of one wheel is too tight Adjust or change

Spring shock absorber is abnormal Change

Front suspension is loose Change

Abnormal tire fray

Tire pressure is abnormal Inflate

Toe-in is improper Adjust

Drum bearing loose Change

U type bolt of leaf spring is loose Tighten

Rim is distorted or frame is distorted Tighten

Brake force of each wheel is dierent Adjust

Overexerting accelerate or braking frequently Alter operation

Brake system

Brake fail

Master cylinder and/or wheel cylinder is dam-

aged or leaking oil

Check, eliminate,

change

Brake fluid is insuicient or empty Add fluid

Air enters into oil pipe Let air out

Free travel of brake pedal is too long or the

clearance of arrester is too big Adjust

Brake drum is worn out or distorted Change

Master cylinder leaks oil internally Change

Braking deviation

The clearance of le brake drum shoe and right

brake drum shoe is dierent Adjust

Oil is on one arrester’s brake shoe Dispose/change

Tire pressures are dierent Repair/change

One wheel cylinder’s piston is blocked Adjust

Wheels are aligned improperly Adjust

Brake drum becomes out of round Change

20

4. Possible reason and troubleshooting for malfunctions of mechanic system.

System Malfunction Possible Reason Troubleshooting

Brake system

Braking drag

Brake pedal has no free travel Adjust

Clearance between brake shoe and drum is too

small or releasing spring is disabled Adjust or change

Piston of wheel cylinder is ineective Check or change

Piston of master cylinder is ineective Change spring

Parking brake is ineective Change spring

Braking noise

Shoes distort Change

Brake facing wear out Change

Brake drum breach, scraped to uneven Change

This manual suits for next models

1

Table of contents

Other Star EV Automobile manuals