SAFETY WARNINGS

Read all safety warnings and instructions. Failure to follow the warnings and

instructions may result in injury and/or property damage. Save all warnings and

instructions for future reference.

The warning and safety instructions in this manual are not meant to cover all possible conditions and

situations that may occur. Common sense, caution and care must be exercised when operating or

cleaning tools and equipment. Always contact your dealer, distributor, service agent or manufacturer

about problems or conditions you do not understand before operating the product. Power tool means

two types of equipment: one with power cord and directly powered by external power supply and another

without power cord and powered by battery.

1

Keep children away from the work area. NEVER allow children to handle power tools.

DO NOT use a tool that is leaking air, has damaged or misssing parts, or that requires repairs. Before use,

verify that all screws are tightened.

NEVER attempt ro override the safety features of this tool.

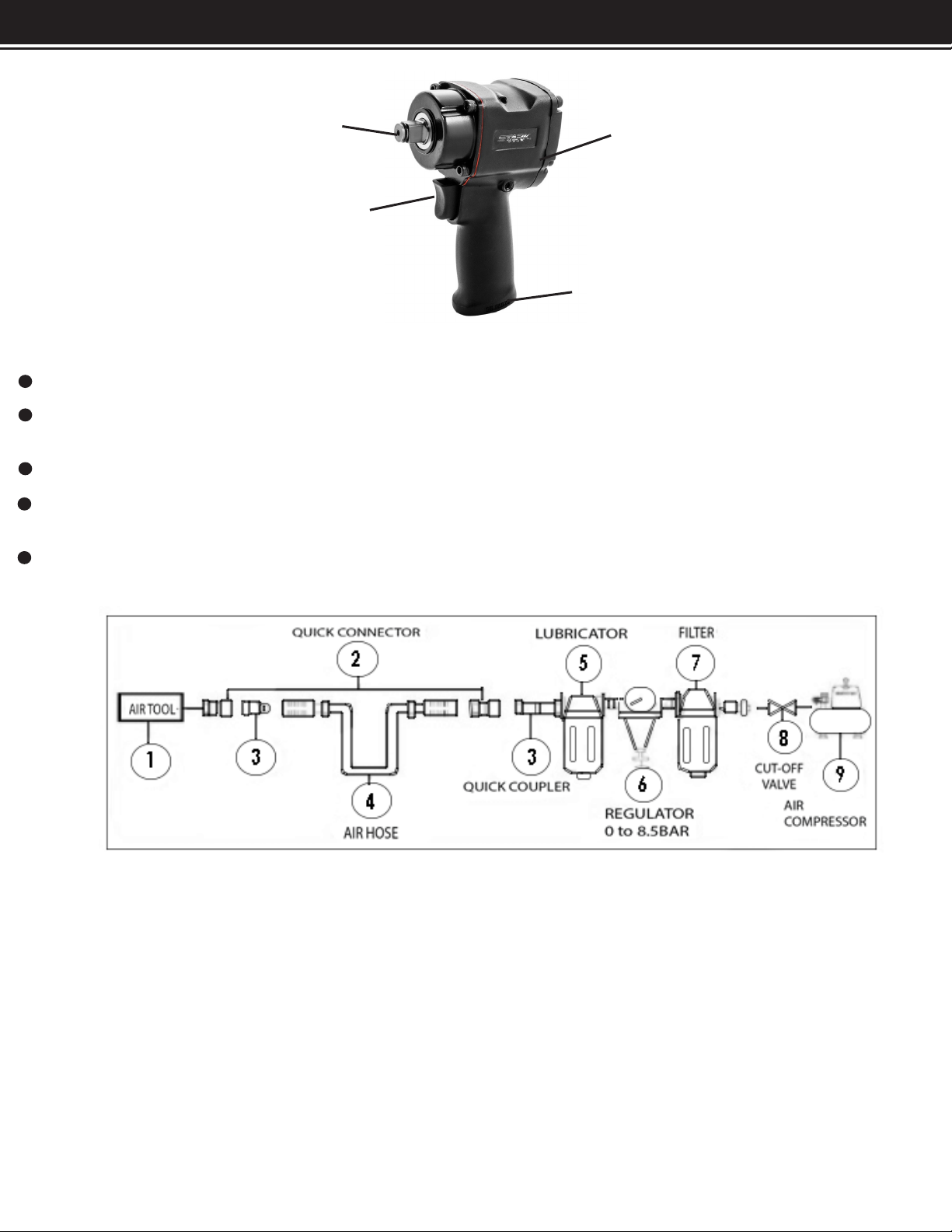

DO NOT use oxygen or any other combustible or bottled gas to power air powered tools. Failure to observe

this warning can cause an explosion and serious personal injury or even death. Use only the compressed air

to power air powered tools. Use a minimum od 25’ of hose to connect the tool to the compressor.

Risk of electric shock: Do not expose the tool to humid or wet environments. Store it indoors only.

Compressor must be grounded. Do not use any grounding adaptors.

Risk of personal injury: Do not direct compressed air from the air hose toward anyone.

Do not adjust the pressure switch of safety valve for any reason. They have been preset at the factory for this

compressor’s maximum pressure. Tampering with the pressure switch or safety valve may cause personal

injury or property damage.

Risk of burns: The pump and manifold generate high temperatures, in order to avoid burns or other injuries,

do not touch the pump, manifold, or transfer tube while the compressor is running. Allow all parts to cool

before handling or servicing.

Conrm the regulator is adjusted so that the compressor outlet pressure is set lower than the maximum

operating pressure of the tool. Before starting the compressor, pull the ring on the safety valve to make sure

it moves freely. Drain water from the tank after each use.

Do not weld or repair the tank. Relieve all pressure in the hose before removing or attaching accessories.

ALWAYS ensure the work piece is rmly secured, leaving both hands free to control the power tool.

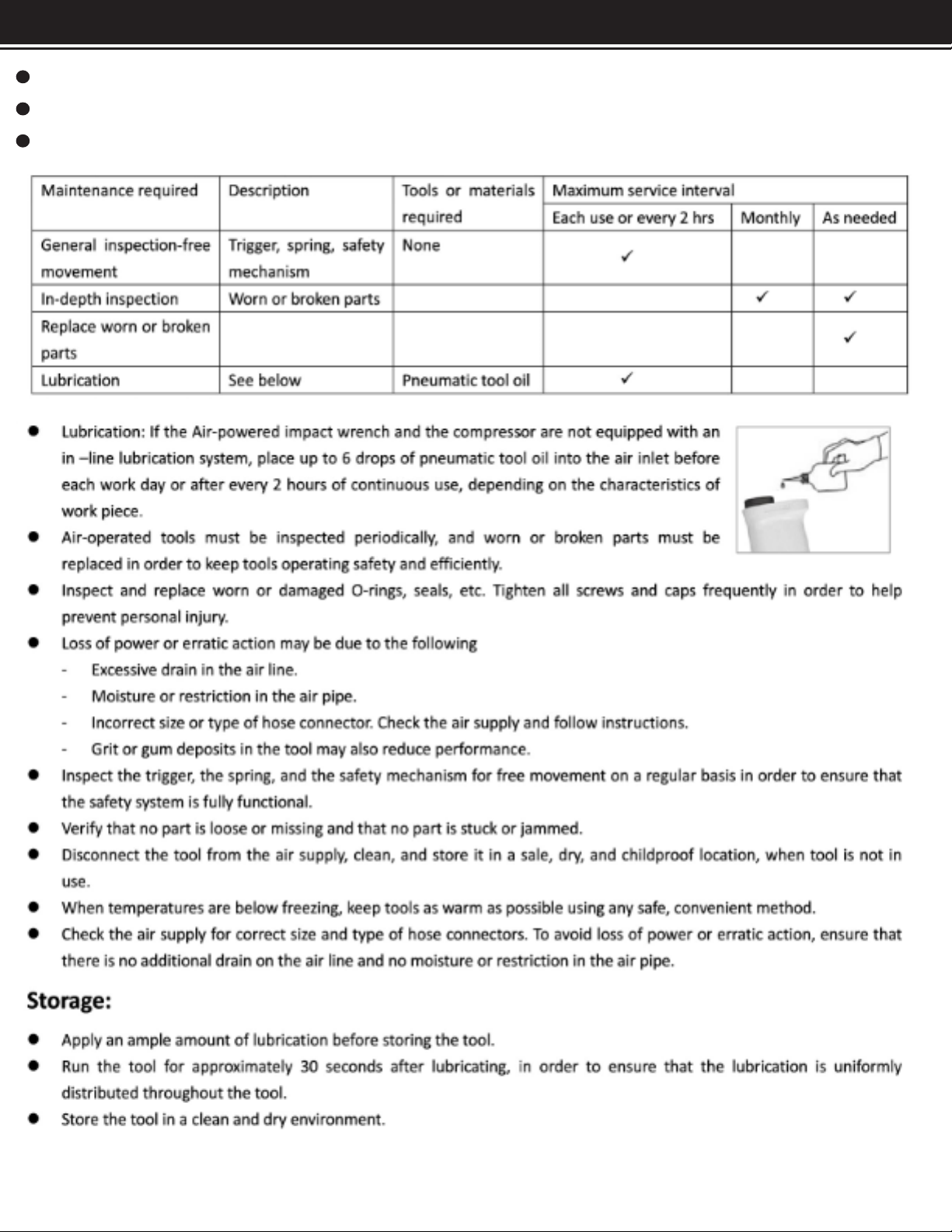

ALWAYS keep your air tool clean and lubricated. Daily lubrication is essential to avoid internal corrosion.

DO NOT overload the tool. Allow the tool to operate at its optimum speed for maximum eciency. Excessive

overload can cause the tool casing to split and may lead to excessive wear on moving parts.

Use only lightweight coil hoses for connecting the tool to the compressor coupling. Do not t quick change

couplings onto the tool. Vibration can lead to damage or failure of the coupling.

ALWAYS ensure the tool has stopperd before connecting it to the air supply.

Verify the grinding accessories that are used with this tool are rated at or above the tool’s speed rating

(8500RPM). Failure to properly match the accessory to the tool could result in serious injury.

Ensure the accessories are correctly and securely fastened before connecting the tool to air supply.

Locate the compressor in a well ventilated area. For cooling at a minimum of 12” away from the nearest wall.