Stealth Acoustics LineaResponse LRX-83 Instruction Manual

Full instructions, installation videos, tips,

troubleshooting, and more available at:

StealthAcoustics.com/invisible-speakers/how-to-install

Quick Start Installation Guide

For New Construction and Retrofit Installations

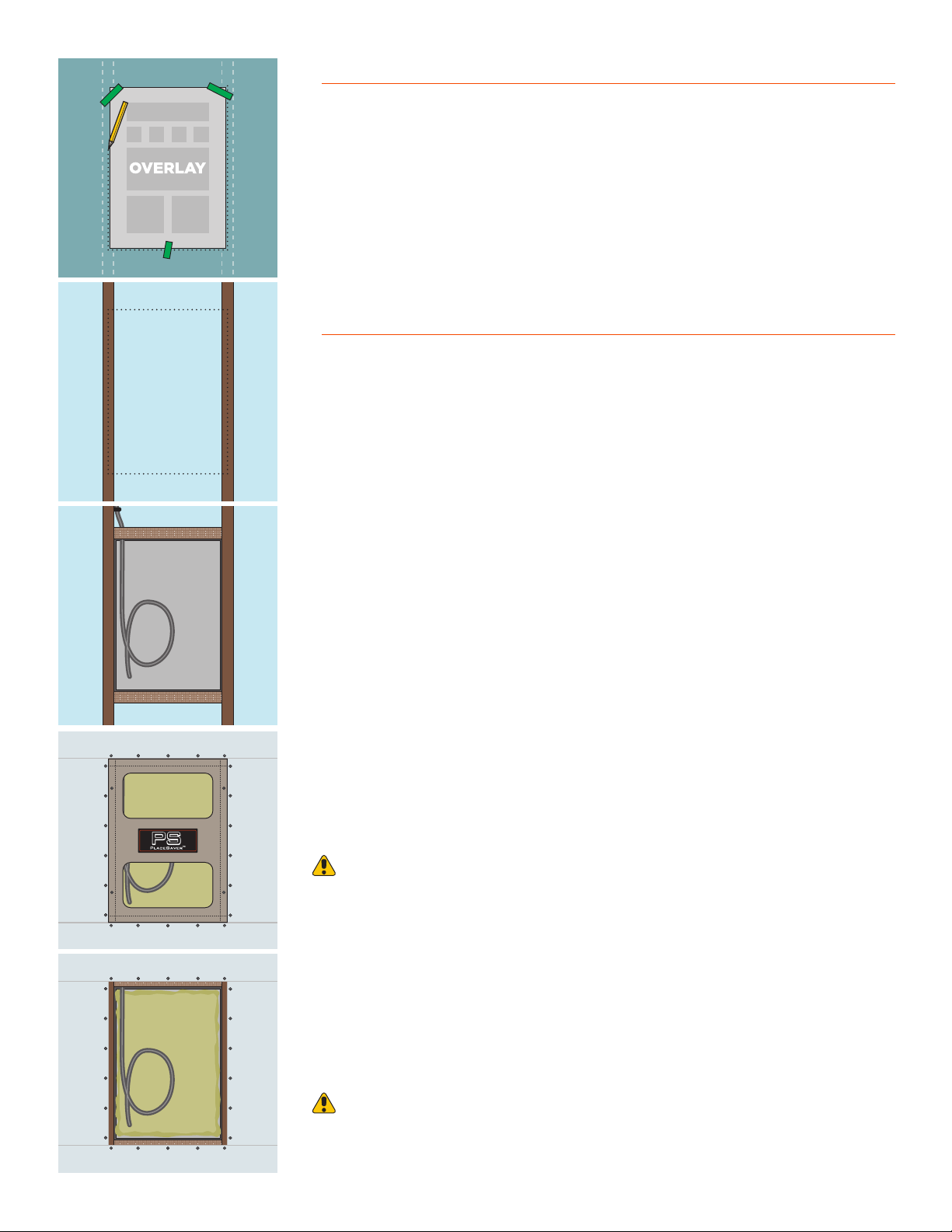

RETROFIT INSTALLATION

Installing a Stealth Acoustics Invisible Speaker into an already finished wall is

similar to making a wallboard patch.

Remove the overlay sheets that comes attached to the face of each speaker

and temporarily attach them to the walls to assist in planning speaker

placement.

Once the approximate speaker locations have been selected, use a stud

finder to locate the nearest framing cavity and drill test holes to verify. Align

the sides of the overlay sheet so they are centered over the existing framing

members and use the overlay as a template to cut the wallboard to the size

of the speaker. The finished opening should be 16” width centered on the

framing studs.

SPEAKER INSTALLATION

1. FRAMING, BACK BOXES AND PLACESAVERS™

For retrofit and for new construction, it is recommended to add cross

member framing above and below the speaker opening so that the speaker

may be attached on all four sides.

Back boxes are recommended. MBA and MBX back boxes should be installed

flush with the framing. See the instructions with MBC back boxes for proper

installation. BX back boxes are installed at the same time as the speaker

panel and instructions are covered below.

In new construction, PlaceSavers™ are installed when the job is pre‑wired.

Center the PlaceSaver™ on the framing and attach with provided hardware.

This reserves the exact space for the speaker during the wallboard installation

preventing the speaker panel itself from exposure the harsh construction

environment. Using PlaceSavers™ will save you time and money.

2. WIRING

Install regular speaker wiring and attach it securely to the studs. Be sure to

feed the wire through the knockout hole in the back box. It is recommended

to use a wire clamp to secure the wire at the knockout leaving sucient

slack length to be able to connect to the speaker panel when installed.

For runs of 50 feet (15m) or less, use 16 gauge wire.

For runs longer than 50 feet (15m), use 14 gauge wire.

3. BX BACK BOXES

BX Back Boxes install directly onto the Invisible Speaker frame before the

speaker frame is installed into the wall. First, insert the back box speaker

wires into the binding posts on the speaker crossover, noting proper polarity

and then install the box directly to the back of the speaker panel using the

provided screws in the pre‑drilled holes.

Use only the provided screws as other screws may cause damage to the

speaker.

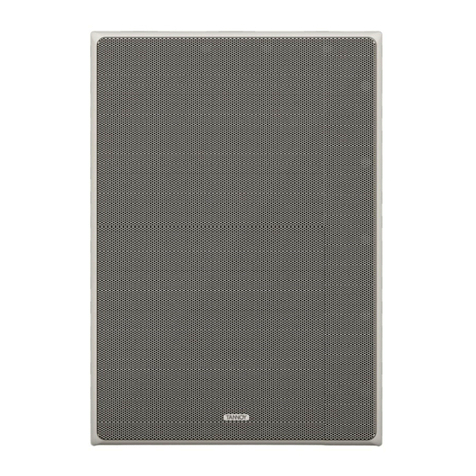

4. SPEAKER ALIGNMENT AND TEST FIT

After the wallboard has been installed, remove the PlaceSaver™.

Correct registration is achieved when the perimeter screw flange of the

speaker is flush with the adjoining wallboard allowing the face of the speaker

to protrude approximately 1/16" (2mm) beyond the wallboard. This creates a

recess for the seam tape which prevents sanding back into the tape during

the finishing process.

If necessary, shim the screw flange out flush with the wallboard by layering

the provided self‑adhesive shims around the perimeter of the rear of the

speaker (shims should cover the screw holes).

It is critical to add the correct number of shims so that the wallboard and

flange surfaces are flush with one another. If the speaker is recessed in

relation to the wallboard excessive material build-up on the surface of the

speaker can occur during the finishing process which may lead to poor

sound quality and possible premature failure.

PLAN LOCATION

FRAMING

MBX & WIRE

PLACESAVER THEN DRYWALL

REMOVE PLACESAVER

16" OC

5. CONNECT SPEAKER WIRES

Insert the speaker wires into the binding posts on the speaker crossover (or

BX back box) noting proper polarity.

For smaller gauge wires, bend the exposed wire back upon itself prior to

insertion to make better contact with the binding posts.

6. SPEAKER MOUNTING

Attach the speaker panel screw flanges directly to the structural framing

using the provided wallboard screws. The panels have been pre‑drilled with

the proper number of holes. Be sure that all of the screws are installed and

that they hold securely to the framing.

Do not use nails.

7. RECHECK SPEAKER REGISTRATION

Now that the speaker is secured, recheck that the outer flange of the speaker

is flush with the surrounding wallboard.

Place a 4‑foot straight edge across middle of the speaker to verify that the

speaker face protrudes approximately 1/16" (2mm) beyond the wallboard in

each direction.

Check that the speaker is not warped from strain caused by uneven

framing. A warped speaker frame will cause the speaker face to bulge.

Having the correct registration minimizes the amount of joint compound that

might be built up over the face of the speaker during the finishing process.

This 1/16" (2mm) protrusion of the speaker face will become invisible after

the seams are properly finished and joint compound is feathered out from

the speaker appropriately.

Note: The typical installations shown above are provided as guidelines. For

your installation, the number and thickness of shims needed may dier due to

variances in wallboard material and other construction variables.

5/8” Wallboard

Structural

Framing

Speaker Frame

1/8” (4mm)

Shim

Speaker

Face

Screw

Flange

Joint

Compound

Seam

Tape

5/8” (16 MM) WALLBOARD

Install with screw flange flush to wallboard.

Speaker face to protrude by 1/16” (2mm) so

plaster can be feathered away from speaker.

1/2” Wallboard Speaker Frame

Structural

Framing

No Shims

Typically

Required

Speaker

Face

Screw

Flange

Joint

Compound

Seam

Tape

1/2” (13 MM) WALLBOARD

Install with screw flange flush to wallboard.

Speaker face to protrudes by 1/16” (2mm) so

plaster can be feathered away from speaker.

8. TEST SPEAKER SOUND

Before proceeding to wall finishing, test each speaker with music or pink

noise from an amplified sound source at listening volume to ensure full

speaker functionality.

Make note of sound coming from the high/mid/low frequency drivers of

each speaker and listen for any rattling or vibration.

Now is the time to correct any potential issues.

CHECK

REGISTRATION

SHIM IF NECESSARY

CONNECT WIRING

ATTACH SPEAKER

TEST WITH AMP

1/16"

(2mm)

GAP

WALL FINISHING

9. SEAM FINISHING

After the registration and sound check, seam finishing can proceed. The

speaker panel should be finished in place similar to any other piece of

wallboard.

Self‑adhesive nylon mesh tape is recommended due to its ease of use,

however paper tape is also acceptable.

Use only air-dry joint compounds and plasters for seam finishing. Do not

use chemically curing joint compound.

For best results, we recommend at least three light applications of joint

compound, sanding between coats.

Allow 24 hours between each application of joint compound for complete

drying. Failure to allow the joint compound to completely dry between

applications may result in fine hairline cracking around the speaker. If

this occurs, repair the crack using standard wall finishing techniques. The

crack will not reappear.

The joint compound should be spread beginning 2”‑3” in from the speaker

edge and then feathering outward 16”‑20” in order to achieve a smooth, flat

transition.

It is important that enough joint compound be applied around the speaker

to make a very gradual transition from the surface of the wallboard to the

face of the speaker panel. Every situation is dierent, but it will normally take

at least a 16”‑20” (30cm) fan of joint compound around the perimeter of the

panel to create a flat‑looking transition.

Be sure to feather the joint compound away from the speaker as to not build

up more than the maximum allowed 1/16" (2 mm) of joint compound over

the face of the speaker panel.

Stealth Acoustics speakers do not require a skim coat to attain a smooth

finish. However, some advanced finishing techniques and materials such as

Venetian plaster or heavy plaster coats may require skimming over the front

of the speaker. In these situations, it may be necessary to shim the speaker

proud of the surrounding wallboard so that we avoid build‑up of more than

1/16" (2 mm) in thickness on the face of the speaker.

10. SAND SMOOTH

Sanding is the last important step before the painting begins. This can make

or break the quality of the installation.

When sanding, imperfections in the application of the joint compound may

appear. If so, additional joint compound and sanding may be needed to

create a seamless transition.

Best practice may include the use of a flashlight to shine sheer light down

the wall or ceiling in order to identify high/low spots in the finish work.

11. PAINT AND FINISH

Once sanding is complete the face panel is ready for painting.

Light “orange peel” texture, light knock‑down texture, wallpaper, veneer, or

level 5 finish may be applied.

Heavy knock down or trowel finishes are not recommended. Stealth

Acoustics speaker face panels are engineered for optimum audio

performance with no more than 1/16” (2mm) of any material applied to

the surface of the speaker. To exceed the 1/16” (2mm) limitation will cause

degradation of audio quality.

StealthAcoustics.com

T 888.865.6800 | F 360.424.8872

A Division of Dimensional Communications, Inc.

1220 Anderson Road | Mount Vernon, WA 98274

SEAM TAPE

JOINT COMPOUND

SAND BETWEEN COATS

INSPECT FINISH WHEN DRY

PRIME & PAINT

©2021 Stealth Acoustics REV 21.04

This manual suits for next models

1

Table of contents