SAFETY PRECAUTI NS

Please read the following before installation.

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages that follow this

symbol to avoid possible injury or death.

This mark indicates procedures which, if improperly performed,

might lead to the death or serious injury of the user.

This mark indicates procedures which, if improperly performed, might

possibly result in personal harm to the user, or damage to property.

Notice is used to address practices not related to personal injury.

General Safety Precautions

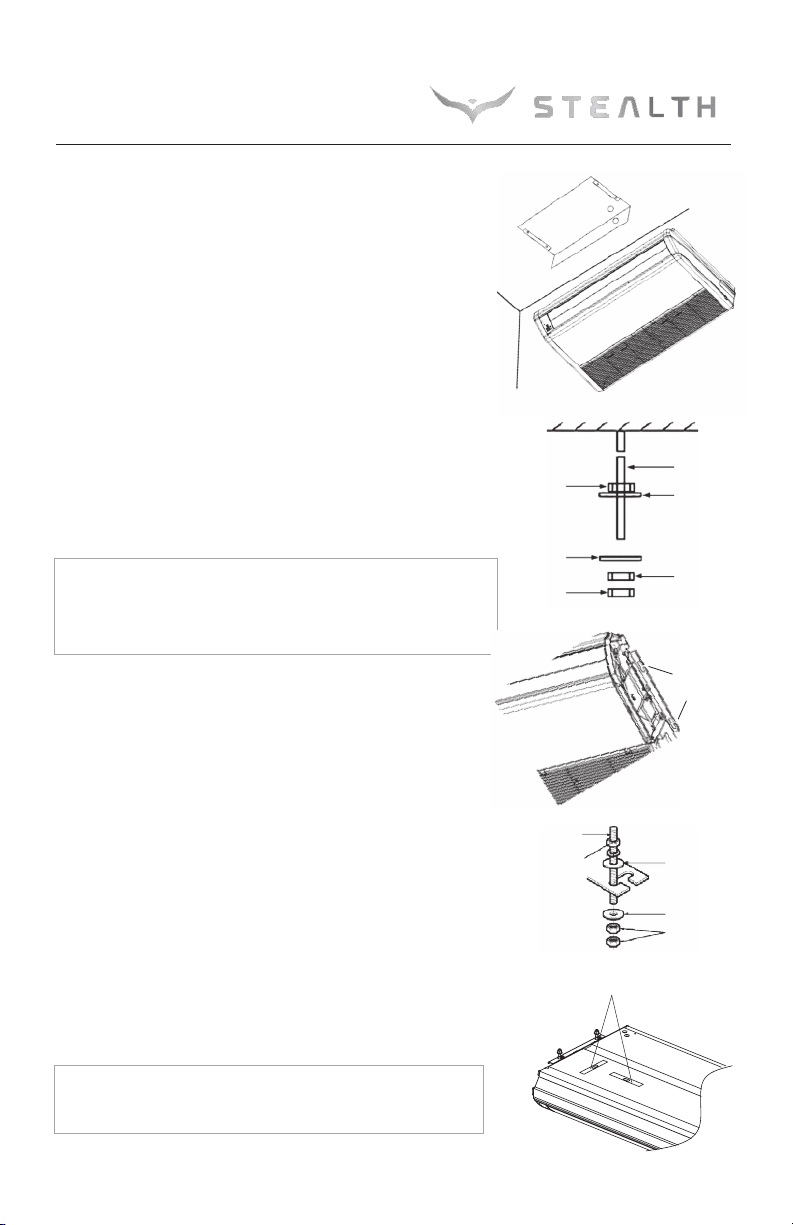

1. Instructions for installation and use of this product are provided by the manufacturer.

For proper operation, the system must be installed in accordance with this

installation manual.

2. Installation must be performed in accordance with local laws, regulations and

National Electrical Codes (NEC).

3. If there is a refrigerant leak while work is being carried out, ventilate the area.

Do not allow refrigerant to come in contact with a flame as it produces toxic gas.

4. Disconnect all electrical power to the indoor and outdoor units until the system is

ready for start-up and checkout.

5. When installing or repairing the system, use only R410A refrigerant. Do not

mix refrigerant with other gases. If air or other gas enter the refrigeration system,

the pressure inside the system may rise to an abnormally high value and cause

damage or injury.

This appliance is not intended for use by persons (including children) with reduced physical,

sensory or mental capabilities, or lack of experience and knowledge, unless they have been given

supervision or instruction concerning use of the appliance by a person responsible for their safety.

WARNING

CAUTION

NOTICE

WARNING

2