Steiner 75-71215B4 Application guide

OPERATION / PARTS MANUAL

MAN 4175237

Rev. A 07-2017

MODEL:

75-71215B

450 CAB KIT

www.steinerturf.com

CALIFORNIA

Proposition 65 Warning

Diesel engine exhaust and some of

itsconstituentsareknown tothe State

of California to cause cancer, birth

defects and other reproductive harm.

Californie Proposition 65

Avertissement

Les échappements des moteurs diesel

et certains de leurs composés sont

reconnus par l’Etat de Californie pour

être cancérigènes, provoquer des

défautscongénitaux etd’autresdangers

en matière de reproduction.

ADVERTENCIA

AVERTISSEMENT

WARNING

The engine exhaust from this product

containschemicalsknown totheState

of California to cause cancer, birth

defects or other reproductive harm.

California Advertencia

de la Proposicion 65

ElestadodeCaliforniahacesaber que

los gases de escape de los motores

dieselyalgunos desus componentes

producen cáncer, defectos de

nacimiento y otros daños en el

proceso de reproducción humana.

L’

é

mission du moteur de ce mat

é

riel

contient des produits chimiques que

l’Etat de Californie consid

è

re

ê

tre

canc

é

rig

è

nes, provoquer des d

é

fauts

cong

é

nitaux et d’autres dangers en

mati

è

re de reproduction.

El estado de California hace saber

que los gases de escape de este

producto contienen productos

quÍmicos que producen cáncer,

defectosde nacimientoy otrosdaños

en el proceso de reproducción

humana.

CALIFORNIA

Proposition 65 Warning

Battery posts, terminals, wiring

insulation, and related accessories

contain lead and lead compounds,

chemicals known to the State of

California to cause cancer and birth

defects or other reproductive harm.

WASH HANDS AFTER HANDLING.

1

CAB IMPORTANT MESSAGE

Thank you for purchasing this Schiller Grounds Care, Inc. product. You have purchased a world class product, one of the best designed

and built anywhere.

This machine comes with an Owner / Operator's Manual and an Illustrated Parts Manual. The useful life and good service you receive from

this machine depends to a large extent on how well you read and understand these manuals. Treat your machine properly, lubricate and

adjust it as instructed, and it will give you many years of reliable service.

Your safe use of this Schiller Grounds Care, Inc. product is one of our prime design objectives. Many safety features are built in, but we

also rely on your good sense and care to achieve accident-free operation. For best protection, study the manuals thoroughly. Learn the

proper operation of all controls. Observe all safety precautions. Follow all instructions and warnings completely. Do not remove or defeat

any safety features. Make sure those who operate this machine are as well informed and careful in its use as you are.

See a Schiller Grounds Care, Inc. dealer for any service or parts needed. Schiller Grounds Care, Inc. service ensures that you continue to

receive the best results possible from Schiller Grounds Care, Inc. products. You can trust Schiller Grounds Care, Inc. replacement parts

because they are manufactured with the same high precision and quality as the original parts.

Schiller Grounds Care, Inc. designs and builds its equipment to serve many years in a safe and productive manner. For longest life, use this

machine only as directed in the manuals, keep it in good repair and follow safety warnings and instructions. You'll always be glad you did.

Schiller Grounds Care, Inc.

One Bob Cat Lane

Johnson Creek, WI 53038-0469

07-2017

TABLE OF CONTENTS FIGURES PAGE

INTRODUCTION, SPECIFICATIONS, ACCESSORIES ...........................................................................................1

SAFETY.....................................................................................................................................................................2

ASSEMBLY ..........................................................................................................................................................3-10

PARTS SECTION....................................................................................................................................................11

MOUNTING KITASSEMBLY................................... FIGURE 1..............................................................................12

KIT HARDWARE..................................................... FIGURE 2..............................................................................13

FRONT VIEW ASSEMBLY...................................... FIGURE 3..............................................................................14

REAR VIEW ASSEMBLY ........................................ FIGURE 4..............................................................................15

HEADLINER ASSEMBLY........................................ FIGURE 5..............................................................................16

WIRE HARNESS..................................................... FIGURE 6..............................................................................17

RIGHT SIDE ASSEMBLY........................................ FIGURE 7........................................................................18, 19

LEFT SIDE ASSEMBLY........................................... FIGURE 8........................................................................20, 21

ROOF ASSEMBLY ..................................................FIGURE 9........................................................................22, 23

ACCESSORIES

WATER HEATER KIT 75-71221

QUICK DISCONNECT HEATER HOSE KIT 75-71229

FRONT WORK LIGHTS- HALOGEN 75-71222

FRONT WORK LIGHTS - LED 75-71309

REAR WORK LIGHT - LED 75-71310

SAFETY BEACON LIGHT KIT 75-71223

CENTER MOUNT BRACKET OPTION FOR BEACON LIGHT 4174404

CIRCULATION FAN KIT 75-71224

DUAL EXTERIOR MIRROR KIT 75-71225

INTERIOR MIRROR 75-71226

SPECIFICATIONS

Overall Height (Installed)......................................... 77"

Overall Width........................................................... 44.5"

Cab Weight.............................................................. 180lbs.

2

CAB

MODEL NUMBER: This number appears on

sales literature, technical manuals and price lists.

SERIAL NUMBER: This number appears only

on your unit. Use this number when ordering

parts or seeking warranty information.

SAFETY

NOTICE !!!

Unauthorizedmodicationsmaypresentextreme

safety hazards to operators and bystanders and

could also result in product damage.

Schiller Grounds Care, Inc. strongly warns against,

rejects and disclaims any modications, add-on

accessories or product alterations that are not

designed,developed,testedandapprovedbySchiller

GroundsCare,Inc.'s Engineering Department. Any

Schiller Grounds Care, Inc. product that is altered,

modiedorchangedinanymannernotspecically

authorized after original manufacture–including the

additionof“after-market”accessoriesorcomponent

partsnotspecicallyapprovedbySchillerGrounds

Care, Inc.–will result in the Schiller Grounds Care,

Inc. Warranty being voided.

Any and all liability for personal injury and/or

property damage caused by any unauthorized

modications,add-onaccessoriesorproductsnot

approved by Schiller Grounds Care, Inc. will be

considered the responsibility of the individual(s) or

company designing and/or making such changes.

Schiller Grounds Care, Inc. will vigorously pursue

full indemnification and costs from any party

responsibleforsuchunauthorizedpost-manufacture

modicationsand/oraccessories shouldpersonal

injury and/or property damage result.

This symbol means:

ATTENTION!

BECOME ALERT!

Your safety and the safety of others is involved.

Signal word defi nitions:

The signal words below are used to identify levels

of hazard seriousness. These words appear in this

manualandonthesafetylabelsattachedtoSchiller

Grounds Care, Inc. machines. For your safety and

thesafetyofothers,readandfollowtheinformation

given with these signal words and/or the symbol

shown above.

DANGER indicates an imminently hazardous

situationwhich, ifnot avoided, WILL result in death

or serious injury.

WARNING indicates a potentially hazardous

situation which, if not avoided, COULD result in

death or serious injury.

CAUTIONindicatesapotentiallyhazardoussituation

which,ifnotavoided,MAY resultinminorormoderate

injury. It may also be used to alert against unsafe

practices or property damage.

CAUTION used without the safety alert symbol

indicates a potentially hazardous situation which, if

not avoided, MAY result in property damage.

10 degree maximum angle of operation of power

unit with weather cab installed.

3

CAB ASSEMBLY

Read these instructions and identify all com-

ponents. Please retain these instructions for

future reference and parts ordering information.

MACHINE PREPARATION

1. Remove all attachments if present.

2. With the engine off, disconnect the battery using

the battery main disconnect switch on the back

of the battery compartment. Figure 1

3. Remove the two bolts Aand nuts Bsecuring the

reverse control pedal on the tractor. Figure 2

4. RemovetheoorplatebyremovingfourboltsC.

Figure 3

FIGURE 1

FIGURE 2

FIGURE 3

4

CAB

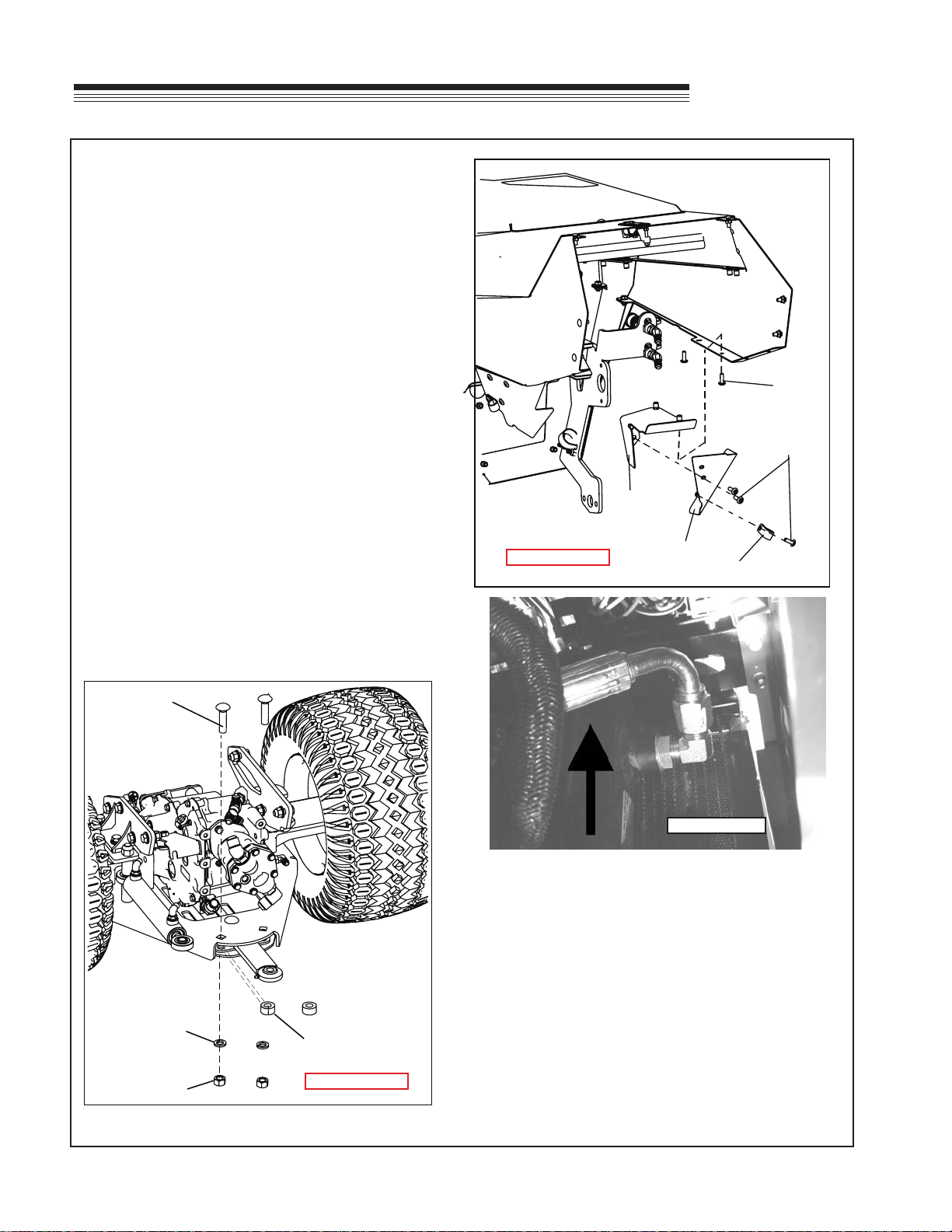

FRONT MOUNT INSTALLATION:

5. Secure the two front mount brackets (Item 7)

to the bottom of the machine using hardware.

Torque to 70 ft-lb (95n-m). Figure 4

(2) 1/2" X 1.50" long bolts (Item 16)

(2) 1/2" nylon nuts (Item 17)

(3)1/2"largeODatwashers(Item 31)

two on right side one on outside left side

(1)1/2"smallODatwasher (Item 15)

one on inside left side.

6. Secure the brackets to the side of the machine

using hardware. Torque to 70 ft-lb (95n-m).

Figure 4

(4) 1/2" x 1.25 long bolts (Item 26)

(4) 1/2" nylon nuts (Item 17)

(4)1/2"smallODatwashers (Item 15)

7.Reinstalltheoorplatewithhardwareremovedin

Step 4.

8. Reattach the reverse control pedal using

hardware removed in Step 3.

PUMP COVER FILLER PANEL INSTALLATION:

9. Remove the four mounting screws Dsecuring the

rear pump cover on the steering tower. Unplug

the two wires from the accessory plug in the

pump cover storage area. NOTE the polarity of

the connections. Figure 5 & 6

FIGURE 5

FIGURE 6

FIGURE 4

ASSEMBLY

5

CAB

10. On the inside of the removed pump cover, install

thetopllerplate (Item 5) using two .25 x .75

screws (Item 27) and two locking nuts. (Item 23)

Install the screws from the outside inward.

Figure 7

11.Installthellerdashbottom (Item 4) using two

.25 x .75 screws (Item 27) and two locking nuts

(Item 23). Install screws from outside in.

Figure 8

DASH FILLER PANEL INSTALLATION:

12.OpenthehoodandattachtheLHdashller

mount (Item 12)tothehoodusingtheLHller

dash bracket (Item 11) and two .25 x .75 screws

(Item 27). The screws will go up from the bottom

of the mount, through the hood, and screw into

thellerbracket.Tightenbothscrews.Figure 9

13.InstalltheLHdashllerassembly(Item 8) to

theLHdashllermountinstalledinStep12

using three .25 x .75 screws (Item 27). Tighten

screws. Install one Insulated hose clamp (Item

21)totheLHdashllerassy (Item 8) using one

.25 x .75 screw (Item 27). Figure 9

FIGURE 8

FIGURE 7

FIGURE 9

11

27

27

12

8

21

ASSEMBLY

6

CAB

14.InstalltheRHdashllermountingbracket(Item

9) using two .25 x .75 screws (Item 27) Bracket

should sit on top of the hood rail with hardware

going through hood then into bracket. Figure 10

If you don't have enough room, you may have to

rotate the hydraulic cooler hose on the oil cooler

inward and upward (clockwise) towards the cen-

ter of the machine. Figure 11

15.InstalltheRHdashllerassembly(Item 10) to

theRHdashllermountinstalledinStep14

using two .25 x .75 screws (Item 27). Tighten

screws. Install one Insulated hose clamp (Item

21)totheRHdashller (Item 10) using one .25

x.75 screw (Item 27). Figure 10

OSCILLATION STOP INSTALLATION:

16. Locate and remove the existing bushings E.

They are retained by two 5/8" carriage bolts F,

lock washers Gand nuts H. You should be able

to access from the bottom of the machine on the

front side of the steering link. Slide oscillation

stops (Item 1) in and attach with existing

hardware. Figure 12

FIGURE 12

FIGURE 10 10

27

27

9

21

FIGURE 11

F

G

H

E / 1

ASSEMBLY

7

CAB

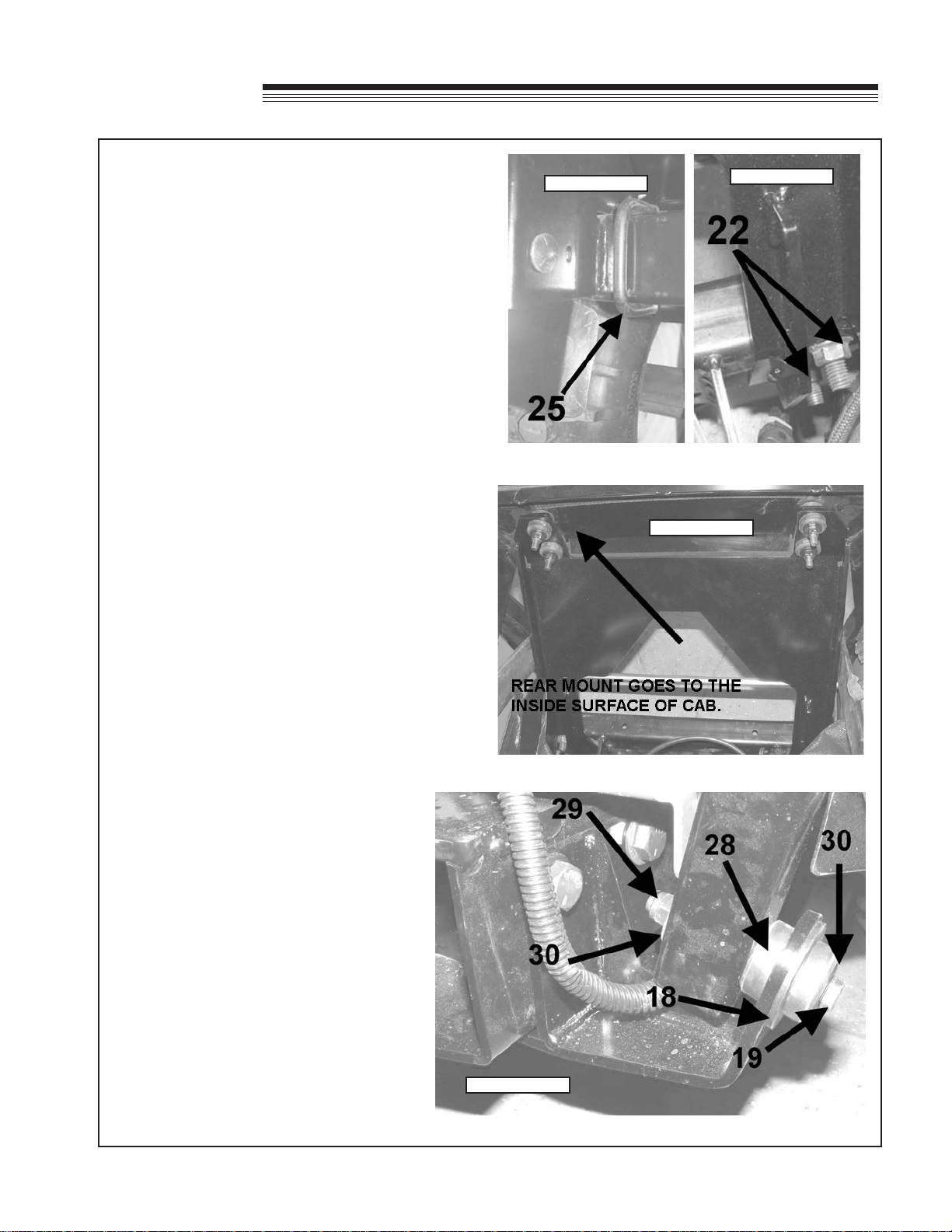

REAR MOUNT INSTALLATION:

17. Loosely secure the Rear Mounting Bracket (Item

6) to the machine as shown in Figure 13 & 14

using hardware:

(2) 1/2" U-bolts (Item 25)

(4)1/2"serratedangenuts(Item 22)

DO NOT TIGHTEN AT THIS TIME!

INSTALLING THE CAB:

18. Flip the seat forward on the machine and lower

the ROPS upper hoop.

Using a spreader bar or lifting strap and overhead

crane or forklift, carefully raise the cab and remove

the crating and pallet. Locate the lifting strap at the

location of the roof brackets on the upper sides.

19. Lower the cab onto the tractor and align the front

mount holes of the cab tubes with the holes on

the front mount brackets installed in Step 7. The

rear mount may need to be tilted forward as you

lower the cab to allow it to pass to the inside of

the rear cab wall. Figure 15

20. Secure the front of the cab to the front mounts

installed in Step 4 using hardware:

Figure 16

(2) rubber isolators (Item 28)

(2)3/4"atwashers (Item 18)

(2) 3/8" x 3.50" bolts (Item 19)

(2) 3/8" nylock nuts (Item 29)

(4)3/8"atwashers (Item 30)

Torque to 30 ft-lb (41 N-m)

FIGURE 13 FIGURE 14

FIGURE 15

FIGURE 16

ASSEMBLY

8

CAB

21. Install the rubber isolators (Item 28) onto the

rear mount bracket. Secure the rear mounting

bracket to the back of the cab using hardware:

Figure 17

(4) 3/8" X 2.50" long bolt (Item 14)

(4) 3/8" nylock nuts (Item 29)

(4)3/8"atwashers(Item 30)

Torque to 30 ft-lb (41 N-m)

22. Tighten the nuts on the U-bolts for the rear mount

installed in Step 17.

23. Attach the two "P" clamps supplied on the 96"

bungee cord to the machine at the foot panel

using hardware:

Figure 18

(2) .75" long bolts (Item 24)

(2)1/4"angednuts(Item 23)

24. Remove screws (Item 27 ) from "P" clamps

(Item 30) on each side that were attached to

thefrontllerpanelsinSteps13and14.Slide

bungee cord into the clamp and attach bolt and

clamptofrontllerpanelsasshowninFigure 19

& 20

FIGURE 17

FIGURE 18

FIGURE 19

FIGURE 20

ASSEMBLY

9

CAB

25. Remove black plug from the 5/16" hole in the

middle top of the instrument panel. Install the

bungee cord guide (Item 2) with one screw (Item

20)andangenut(Item 23). Figure 21 & 22

ELECTRIC HOOK-UP:

26.Locate main harness secured to the front left cab

tube.

27. Open the hood of the machine. Route the cab

wire harness up to the bulk head area of the

tractor in front of the instrument panel.

28.Attachthetwopoleatconnectoronwire

harness to the accessory harness connector J

from the machine. Attach the red wire with the

ring terminal labeled "Battery +12VDC" to the

40 amp circuit breaker at the bulk head on the

terminal with the double wire attached K.Figure

23

29. Reset the battery disconnect at the back of the

battery box. Figure 1

30. Close the hood of the machine and turn ignition

key on and start machine.

31. Check operation of front wiper: HI, LO, and OFF.

When the switch on the wiper motor is turned off,

wiper will run for a short period of time and then

stop or park itself. Wiper should turn off when

machine key is turned off.

32. If switch panel has no power, check the breaker

located on the red wire of the cab harness.

Reset breaker if needed. Figure 24

33. Check operation of the dome light. ON/OFF.

Dome light should go off when machine key is

turned off.

FIGURE 21

FIGURE 22

FIGURE 23

FIGURE 24

ASSEMBLY

10

CAB

34. Coil excess wire harness and secure using

nylon ties. Make sure to leave enough room for

complete front travel of machine. Avoid any HOT

or MOVING parts. DO NOT SECURE WIRE

HARNESS TO HIGH PRESSURE FUEL LINES!

35. Reconnect the accessory plug with the two wires

(Red +, Black -) before installing pump cover.

Reinstall the top screws of the pump cover

assembly removed in Step 9. Install lower center

frontller (Item 3) over the bottom of the pump

cover attach with two .25 x .75 screws (Item 27).

Figure 25

36.Tiptheseatupandinstallunderseatsealller

assembly (Item 13) textured side up. The

sealwilltovertheradialbearingsuspension

doughnuts. Figure 26.

37. Lower the seat to normal position to help position

the Velcro into place for the battery box and

fuel tank before removing the liner and applying

adhesive.

38. Peel off the liner on the PSAVelcro strips and

attach to the rear wall of the cab and to the

fenders. Apply pressure to the Velcro to get

good adhesion.

Figure 27 & 28

FIGURE 25

FIGURE 28

FIGURE 27

FIGURE 26

ASSEMBLY

11

CAB

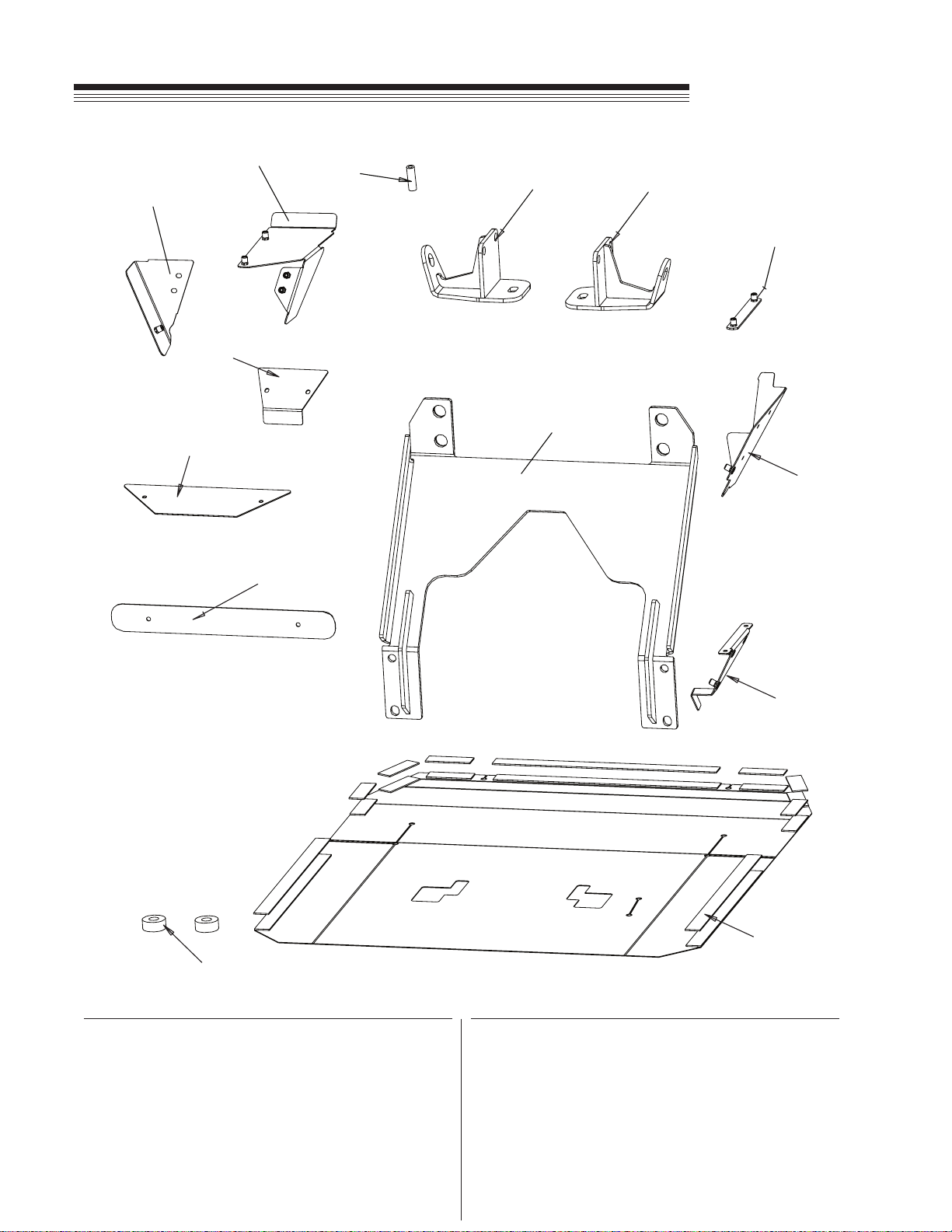

PARTS

SECTION

12

CAB

MOUNTING ASSEMBLY

FIGURE 1

ITEM PART NO. DESCRIPTION QTY ITEM PART NO. DESCRIPTION QTY

77

2

3

4

5

1

6

10

8

9

12

13

11

1 4175238-12 STOP, OSCILLATION 2

2 4171878-5 S-SPACER-CORD GUIDE 1

3 4175238-1 FILLER, LWR FRONT, CNTR 1

4 4175238-2 FILLER DASH, BOTTOM 1

5 4175238-3 FILLER, TOP, CUBBY HOLE 1

6 4171878-6 S-WLDMNT, REAR MOUNT 1

7 4171878-7 S-WLDMNT, FRONT MOUNT 2

8 4175238-4 ASSY, FILLER, DASH LH 1

9 4175238-5 ASSY, FILLER, DASH RH 1

10 4175238-6 ASSY, FILLER, DASH FRNT RH 1

11 4175238-7 ASSY,BRKT,DASH FILLER LH 1

12 4175238-8 ASSY, MOUNT, DASH, FILLER LH 1

13 4175238-13 S-ASSY,UNDER SEAT FILLER 1

13

CAB HARDWARE

FIGURE 2

ITEM PART NO. DESCRIPTION QTY ITEM PART NO. DESCRIPTION QTY

14 4171015-96 S-BLT, HHCS .375 X 2.5 4

15 4171878-20 S-WSHR, .50 TYPE AN 5

16 4171878-16 S-BLT, HHCS .5 X 1.5 2

17 4171878-18 S-NUT, NYLOCK .5 6

18 4171015-98 S-WSHR, FLAT .75 2

19 4171015-99 S-BLT, HHCS .375 X 3.5 2

20 4171878-17 S-SCREW, PH .25X.25 1

21 4171878-8 S-CLIP, HOSE, CLAMPING 4

22 4171878-22 S-NUT,HEX FL .50-13 NC 4

23 4171878-21 S-NUT, FL HEX .25 7

24 4171015-102 S-BLT, HHCS .75 2

25 4171878-25 S-UBOLT, .5X3X3.5 2

26 4171878-19 S-BLT-HHCS, .50 X 1.25 4

27 4175238-9 MSCR..25-20NC X.750 TH TORX 17

28 4171015-94 S-MOUNT, RUBBER 6

29 4171015-97 S-NUT, NYLOCK .375 6

30 4171015-95 S-WSHR.375 12

31 4171878-23 S-WASHER 3

16

28

30

14

15

31

29

17

18

19 21

22

20

24

25

23

26

27

14

CAB

FRONT VIEW ASSY

FIGURE 3

ITEM PART NO. DESCRIPTION QTYITEM PART NO. DESCRIPTION QTY

1 4171015-110 S-VINYL RETAINER 2

2 4171878-11 S-VINYL, LOWER FRONT LH 1

3 4171878-10 S-VINYL, LOWER FRONT RH 1

4 4171015-59 S-WINDOW, FRONT TEMPERED 1

5 4171015-111 S-SCREW, SELFTAP .25 X .75 14

6 4171878-12 S-VINYL, LWR FRONT CENTER 1

7 4171878-15 ASSY-BUNGEE CORD 30" 1

8 4171878-14 ASSY-BUNGEE CORD 96" 1

9 4171015-112 S-BASE 1

10 4171015-80 S-ASSY, ROOF 1

11 4171878-8 S-CLAMP-CLIP, HOSE 2

12 64163-02 WSHR .321/.328X.593/.608X11GA2

13 4171015-44 S-RUBBER WINDSHEILD 118" 1

14 4171015-68 S-CORD, .313 EPDM RUBBER 1

MATCH DRILL

.219 HOLES (14)

BEFORE RUNNING

POWER WIRE

RUN CROSS CORD THROUGH

THE LOOPS OF THE FRONT

CROSS VINYL - DO NOT RUN

THE LONG HOOD SEAL CORD

THROUGH THE CROSS VINYL

LOOPS - RUN THE LONG HOOD

SEAL CORD THROUGH SIDE

AND LOWER LOOPS OF FRONT

VINYL WINDOWS

SEE DETAIL F

1.14 REF

DETAIL F

4

3

1

12

5

14

11

7

9

1

8

12 3

9

11

23

6

10

13

15

CAB REAR VIEW ASSY

FIGURE 4

ITEM PART NO. DESCRIPTION QTYITEM PART NO. DESCRIPTION QTY

1 4171015-8 S-MOUNT, TEE HANDLE , RH 1

2 4171015-41 S-DOOR TRIM SEAL, 11/16 6" 2

3 4171015-34 S-TRIM SEAL, , 180 DEG 5" 2

4 4171769-09 NUT-FLG HEX .25 4

5 4171015-113 HHCS-.375 X 4.50 2

6 4171015-91 BOLT-TOREX BH .25 X .625 2

7 4171015-60 S-GLASS, REAR, TEMPERED 1

1

3

4

2

6

5

SEE DET

AIL D

7

5

13

8

12

10

99

11

DETAIL D

8 4171015-44 S-WINDOW TRIM SEAL, 11/16 11"1

9 4171015-28 S-WASHER, SHOULDER GLASS 4

10 4171015-35 S-WASHER,, .344 ID x 1.25 2

11 64229-02 NUT-NYLON LOCK 5/16-18 4

12 4171670-07 BLT-TORX HD 5/16-18 X 1-1/4 2

13 4171015-88 NUT-CNTRLCK, HEX .38 2

16

CAB

HEADLINER ASSY

FIGURE 5

ITEM PART NO. DESCRIPTION QTYITEM PART NO. DESCRIPTION QTY

1 4171769-01 PANEL-HEADLINER, SHORT 1

2 4171015-43 S-DOMELIGHT, 12 VDC 1

3 4171769-06 NUT-SERT 8-32 8

4 4171769-07 SCRW-MACH BH SOC 8-32 X .50 6

5 4171769-08 SCRW-MACH .25 X 1 PH PHIL 1

6 4171769-09 NUT-FL HEX .25 1

7 4171769-02 MOUNT-FUSE BLOCK 1

8 4171769-03 HOLDER-6 FUSE W/GROUND 1

9 4171670-09 SCRW-MACH SOC 8 X 1 2

10 4171769-10 NUT-SERT 10-24 2

11 4171015-1 COVER-FUSE 1

12 4171015-53 S-KNOB, BLACK, .875 DIA 10-24 2

13 4171769-11 PLUG-HOLE .63 1

14 4171769-12 PLUG-HOLE .25 3

15 4171769-13 GROMMET-SNAP UNIVERSAL 1 1

16 4171769-14 FUSE-7.5 AMP 1

17 4171769-15 FUSE-5 AMP 1

18 4171769-04 HARNESS-MAIN W/ RESET 1

19 4171015-56 HARNESS-MAIN HEADLINER 1

20 4171769-16 PLUG-HOLE .38 1

4

GROUND LOCATION

NO NUTSERTS IN TOP (4) HOLES

3

6 & 5

7

8

4

(FUSE COVER NOT SHOWN)

SEE DETAIL A

HOOK UP GROUND FROM BELOW

**DO NOT AT TACH OVER THE TOP**

17

9

(FUSE COVER NOT SHOWN)

DETAIL A

(5 AMP FOR

DOME LIGHT)

(7.5 AMP

FOR WIPER)

ALIGN BOTTOM 2 HOLES IN FUSE

BLOCK WITH BOTTOM 2 HOLES

IN MOUNT BRACKET

910

16

15

1

2 & 4

11 & 12

13

14

20

17

CAB WIRE ASSEMBLY

FIGURE 6

ITEM PART NO. DESCRIPTION QTY

WIRE No

. USED FOR WIRE SPECCOLOR LENGTH TERMINAL END 1 TERMINAL END 2

1 FUSE BLOCK GROUND STUD TO SWITCH PANEL GROUND STUD 16 GA GXL BLACK14.00" No.10 RING 1/4" RING

2WIPER +12V (FUSE TO JUMPER LOCATION) 16 GA GXL GREEN 32.00" BLADE 1/4" FEMALE 90 BLADE 1/4" MALE

3

WIPER -12V (FUSE GROUND BAR

TO JUMPER LOCATION) 16 GA GXL BLACK32.00" BLADE 1/4" FEMALE 90 BLADE 1/4" FEMALE

4WIPER +12V (JUMPER LOCATION TO WIPER MOTOR) 16 GA GXL GREEN 16.00" BLADE 1/4" FEMALEBLADE 1/4" FEMALE

5WIPER -12V (JUMPER LOCATION TO WIPER MOTOR MOUNT BOLT )16 GA GXL BLACK16.00" BLADE 1/4" MALE No.10 RING TERMINAL

6

DOME LIGHT +12V (FUSE

TO DOME LIGHT WHITE WIRE) 16 GA GXL WHITE 14.00" BLADE 1/4" FEMALE 90 BUTT, 16 GA BLUE

7

DOME LIGHT -12V (FUSE GROUND BAR

TO DOME LIGHT BLACK WIRE) 16 GA GXL BLACK14.00" BLADE 1/4" FEMALE 90 BUTT, 16 GA BLUE

DOME-

DOME+

WIPER+

WIPER-

F

MF

F

F

F

F

BLACK

WHITE

GREEN

BLACK

GROUND BLACK

No.10

FUSE BLOCK CONNECTION

S

7.5

A

5 A

M

DOME- BLACK

DOME+ WHITE

GRND STUD BLACK

TO 1/4"

HEADLINER

GROUND

STUD

F

DOME

LIGHT

+

+

BLACK

GREEN

WIPER-

BLACK

WIPER+

GREEN

TO

WIPE

R

MOTOR

JUMPER LOCATION

-12V

-12V

1

2

3

6

7

1

2

3

4

5

4

5

6

7

1 4171015-56 HEADLINER HARNESS ASSY 1

2 4171015-77 MAIN WIRE HARNESS ASSY 1

18

CAB

RIGHT SIDE ASSY

FIGURE 7

.25

27

31

32

34 28

35

18

17

12

30

41

33

26

29

SEE DETAIL E

SEE DETAIL G

9.00" - TRIM

TO FOLLOW SLOPE

SEE DETAIL A

10

8

7

DETAIL A

9

7

15

39

8

12

11

13

DETAIL E

24

21

25

16

20

22

19

23

DETAIL G

1

2

3

14

36

38

37

5

6

4

Table of contents

Other Steiner Snow Blower manuals