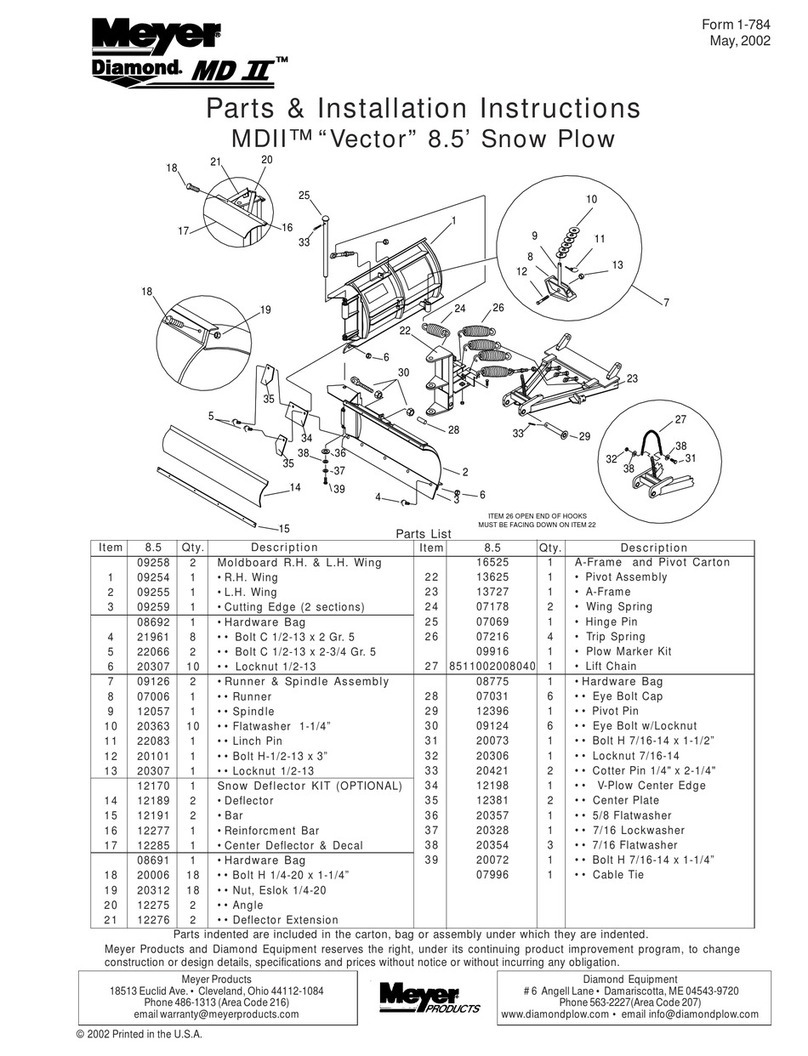

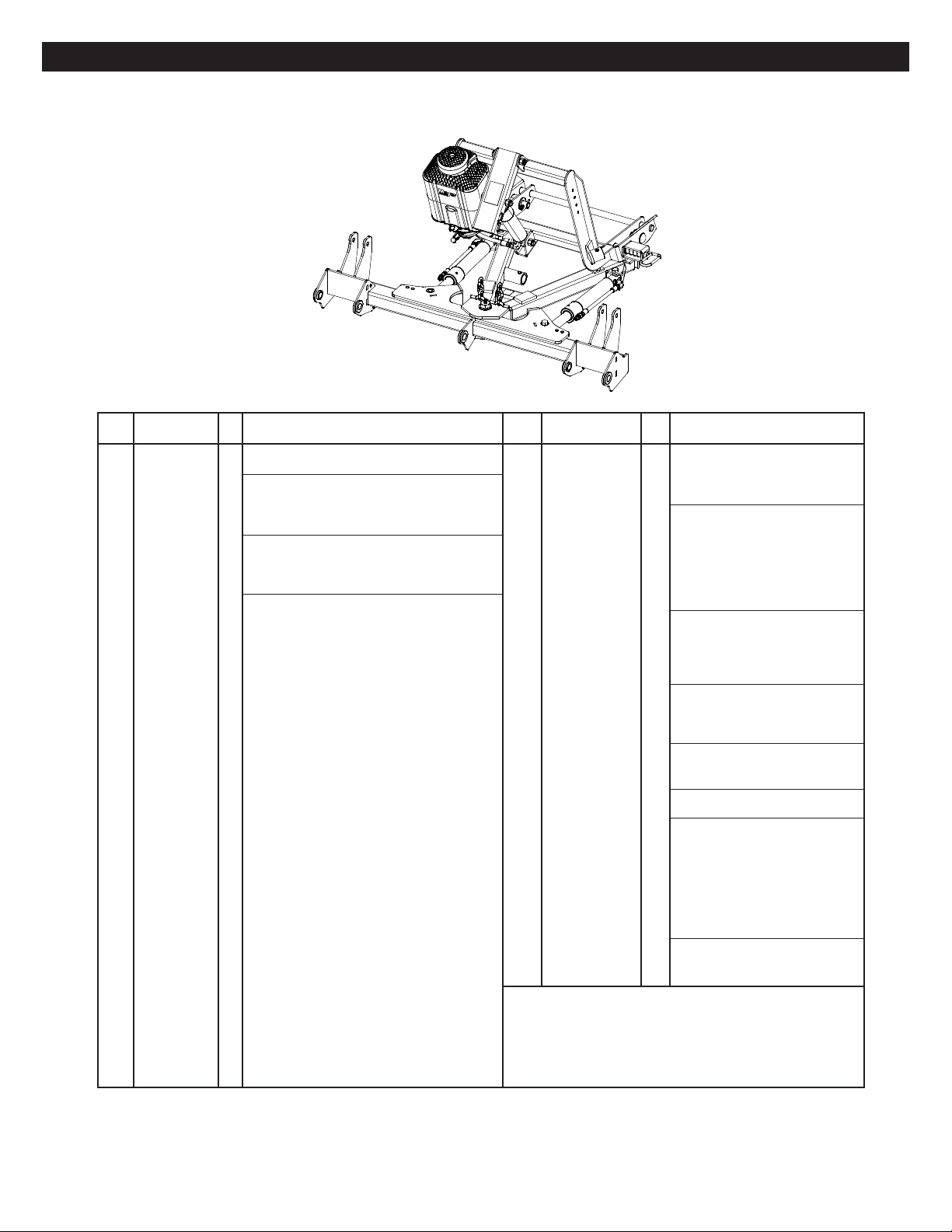

Parts Diagram

Parts List

Parts indented are included in the carton, bag or assembly under which they are indented.

E-72 PKG

Item Part No. Qty. Description

41325 1 LP 7.5-9.0 E58H Plus Mount Assy.

1 05815 1 Lift Ram 1.75 x 8”

07708 1 • L.H. Ram with Hose & Fittings

2 05877 1 •• Ram (1-1/2” x 10”)

3 22866 1 •• SAE Mx3/8 90 Degree Elbow

4 22885 1 •• Hose 1/4 x 54”

07709 1 • R.H. Ram with Hose & Fittings

2 05877 1 •• Ram (1-1/2” x 10”)

3 22866 1 •• SAE Mx3/8 90 Degree Elbow

4 22884 1 •• Hose 1/4 x 33”

5 11859 2 • Blue Handle Pin

6 12750 1 • Pivot Bar Lot Pro

7 13333 1 • E-72 Mounting Bracket

8 13940 1 • A-Frame Lot Pro Plus

8a 21541 2 • Chain 5/16 x 38” Gr. 43

8b 8518001026 2 • U-Bolt 7/16-14

8c 20306 4 • Locknut 7/16-14

9 15645 1 • Lift Unit Cover

10 15634 1 • Cover Strap

11 16006 1 • Lift Ass’y. (Unit only)

12 19365 1 • Lift Frame

13 19370 1 • Clevis

14 19592 1 • Lift Arm

15 20029 4 • Bolt H 5/16-18 x 1-1/2” Gr. 2

16 20049 2 • Bolt H 3/8-16 x 1” Gr. 2

17 20146 1 • Bolt H 5/8 - 11 x 3-1/4” Gr. 5

18 20147 2 • Bolt H 5/8 - 11 x 3-1/2” Gr. 5

19 20150 2 • Bolt H 5/8 - 11 x 4-1/2” Gr. 5

20 20152 1 • Bolt H 5/8 - 11 x 5” Gr. 5

21 20153 1 • Bolt H 5/8 - 11 x 5-1/2” Gr. 5

22 20304 4 • Locknut 5/16-18

23 20309 7 • Locknut 5/8-11

24 20327 2 • Lockwasher 3/8”

25 20331 2 • Lockwasher 5/8”

26 20406 3 • Cotter Pin 3/16 x 1-1/2”

27 20420 2 • Cotter Pin 1/4 x 2”

28 22245 1 • Crank Stand

29 22274 1 • Slotted Nut 1-8

30 22398 1 • King Bolt 1-8 x 5-1/2”

31 22436 2 • Pin 1 x 3”

32 22692 1 • Plow Side Harness

33 22866 1 • SAE Mx3/8 90 Degree Elbow

34 22883 1 • Hose 1/4 x 22”

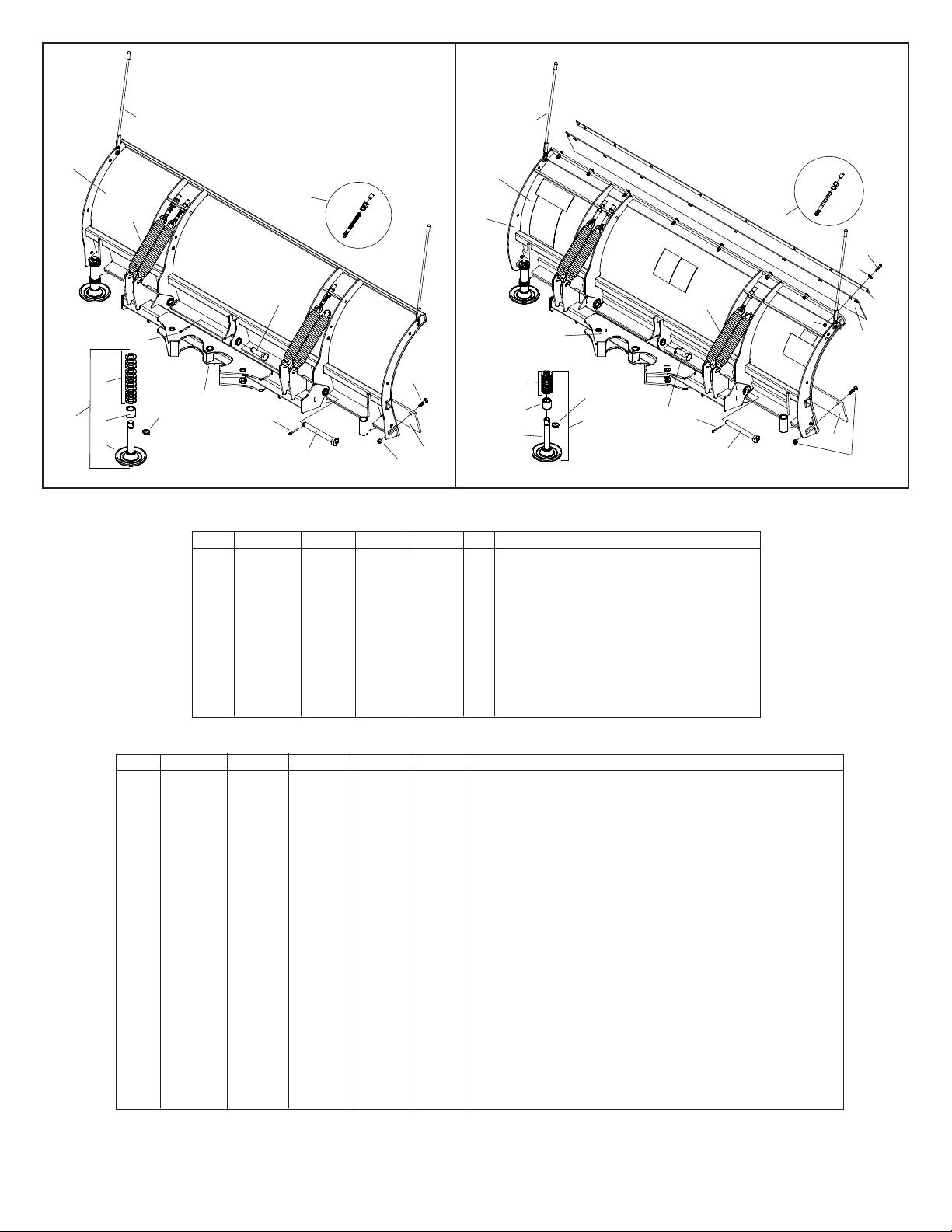

E-72 PKG

Item Part No. Qty. Description

41301 1 • Accessory Box

35 05024 1 •• Power Cable - 36”

36 07017 4 •• Trip Spring

07550 1 •• Nite Saber II Kit

08202 1 •• Plug Bracket Kit

37 19607 1 ••• Plug Bracket

38 19609 1 ••• Plate

39 20027 2 ••• Bolt H 5/16-18 x 1 Gr. 2

40 20326 4 ••• Lockwasher 5/16

41 20525 4 ••• Finish Nut 5/16-18

42 22658 2 ••• Bolt H 5/16-18 x 3 Gr. 2

09917 1 •• Plow Marker Kit

43 08214 2 ••• Plow Marker

44 20027 4 ••• Bolt H 5/16-18 x 1 Gr. 2

45 20304 4 ••• Locknut 5/16-18

46 20352 8 ••• Flatwasher 5/16”

47 11751 1 •• Light Bracket LH

48 11752 1 •• Light Bracket RH

49 11844 1 •• Receiver Tube Cap

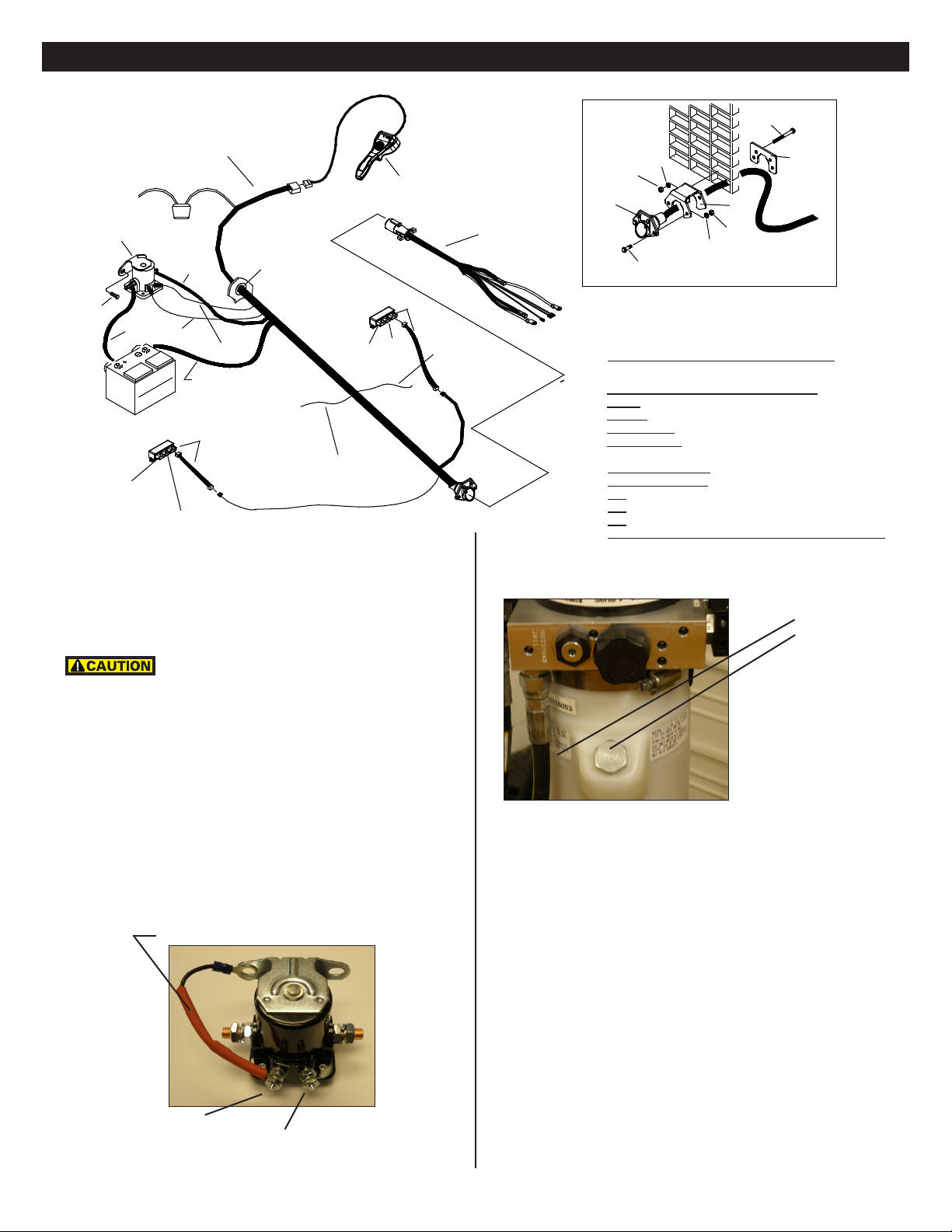

50 15370 1 •• Starter Solenoid - 12 volt

15787 1 •• Hardware Bag

51 21398 2 ••• S. Tap Screw 1/4 - 14 x 3/4”

52 21832 1 ••• Split Bushing

53 22690X 1 •• Optional Controller See Page 11

54 22691 1 •• Universal Truck Side Harness

41302 1 •• Hardware Bag

55 09124 4 ••• Eye Bolt

56 20028 4 ••• Bolt H 5/16-18 x 1-1/4 Gr. 2

57 20326 4 ••• Lockwasher 5/16”

58 20406 3 ••• Cotter Pin 3/16 x 1-1/2”

59 20525 4 ••• Finish Nut 5/16-18

60 22331 1 ••• Hex Head Pin 1 x 3-5/16”

61 22375 2 ••• Pivot Pin 1 x 8-3/4”

62 814000005 2 • Spring

63 8500003307001 2 • Bolt H 5/8-11 x 3 Full Thread

64 8501003013 4 • 5/8-11 Jam Nut

41325 E-72 EZ Build

(2)

Meyer Products LLC reserves the right, under its continuing product

improvement program, to change construction or design details,

specications and prices without notice or without incurring any obligation.