STEMME S10-VT User manual

Maintenance Manual STEMME S10-VT Date of Issue: Jan. 01, 1998 Page ii

Amendment No.: 10 date: Dec. 14, 2001

A4011121_B23.doc Doc. No. A40-11-121

0.1 Record of Amendments

Any amendments of this manual must be recorded in the following table, except for:

•installation status of optional equipment, for optional equipment refer to section 9,

•amendments of the original ROTAX Maintenance Manual for the ROTAX 914 F (refer to Annex E).

Any modification or correction within the approved sections must be signed by the Luftfahrtbundesamt (LBA).

Information about amendments which must be inserted in this Manual, are given in the "Record of

Airworthiness Directives and Service Bulletins" (refer to Annex B).

New or amended text of the latest amendment is marked on the revised pages by a black vertical line in the

RH margin. The numbers of last amendment included and the date of the latest amendment is shown on the

RH side of the page-headline.

The original ROTAX Maintenance Manual for the ROTAX 914 F (refer to Annex E) is separately revised by

ROTAX.

The inspector confirms by his signature:

•the correct insertion of amendments.

Am.

No.

pages removed

pages inserted

Date of

amendment

Date of

insertion

Signature

1

ii, iv, v, 3-31, 7-26

ii, iv, v, 3-31, 7-26

18.03.1998

2

ii, iv, v, 3-55, 7-33

ii, iv, v, 3-55, 7-33

23.03.1998

3

ii, iv, v, viii, 7-10 ··· 7-18

ii, iv, v, viii, 7-10 ··· 7-18

22.07.1998

4

ii, iv, 3-9, 3-10, 3-14

ii, iv, 3-9, 3-10, 3-14

12.08.1998

5

ii, iv, 3-19, 5-6, 7-13

ii, iv, 3-19, 5-6, 7-13

29.10.1998

6

ii, iv, 3-50, 3-51

ii, iv, 3-50, 3-51

15.04.1999

7

ii, iv, 3-15

ii, iv, 3-15

03.08.1999

8

i, ii, iv...viii, 2-2, 3–16;

3-24...3-27, 3-55, 4-1, 4-2,

5-6, 5-9, 5-10, 6-8, 6-9,

6-13, 7-5, 7-11,

7-19...7-23, 7-28, 7-29,

8-2, 9–3; 11-1,

Cover Annex A,

Cover Annex C

i, ii, iv...viii, 2-2, 3–16;

3-24...3-27; 3-55, 4-1, 4-2,

5-6, 5-9, 5-10, 6-8, 6-9,

6-13, 7-5, 7-11, 7-19, 7-20,

7-21.1, 7-21.2, 7-22, 7-23,

7-28, 7-29, 8-2, 9–3; 11-1,

Cover Annex A,

Cover Annex C

11.11.1999

9

ii, iv, v, 4-1, 4-2, 4-3

ii, iv, v, 4-1, 4-2, 4-3

06.12.2000

10

i, ii, iv, v, 3-15, 3-32, 3-44,

3-45, 4-1, 4-2, 5-3, 5-4,

5-5, 5-8, 5-9, 8-7, 9-1, 9-2

i, ii, iv, v, 3-15, 3-32, 3-44,

3-45, 4-1, 4-2, 5-3, 5-4, 5-5,

5-8, 5-9, 8-7, 9-1.1, 9-1.2,

9-2

14.12.2001

Maintenance Manual STEMME S10-VT Date of Issue: Jan. 01, 1998 Page iii

Amendment No. 23 Date: Jan. 29, 2015

A4011121_B23.doc Doc. No. A40-11-121

Am.

No.

pages removed

pages inserted

Date of

amendment

Date of

insertion

Signature

11

iii, iv, 4-1, 4-2, 4-3

iii, iv, 4-1, 4-2, 4-3

27.01.2003

12

iii, iv, 4-1, 4-2, 4-3

iii, iv, 4-1, 4-2, 4-3

16.03.2005

13

iii, iv, v, 4-1..4-3, 5-8,

9-1.1, 9-1.2, 9-2..9-4

iii, iv, v, 4-1..4-3, 5-8, 9-1.1,

9-1.2, 9-2..9-4

25.05.2005

14

i, iii..v, viii, 1-1, 3-17,

3-19..3-21, 3-37, 3-38, 3-40,

4-1..4-3, 5-2, 6-9, 6-13,

7-9..7-17, 7-23, 7-32, 10-1,

Annex E

i, iii..v, viii, 1-1, 3-17,

3-19..3-21, 3-37, 3-38, 3-40, 4-

1..4-3, 5-2, 6-9, 6-13, 7-9..7-

17, 7-23, 7-32, 10-1, Annex E

30.11.2007

15

iii..vi, 1-2, 4-1..4-3

iii..vi, 1-2, 4-1..4-3

30.11.2008

16

iii, iv, 4-1..4-3

iii, iv, 4-1..4-3

24.02.2010

17

iii, iv, 4-1, 4-3

iii, iv, 4-1, 4-3

10.01.2011

18

iii, iv, v, vii, 5-1, 5-2,

cover sheet Annex E

iii, iv, v, vii, 5-1, 5-2,

cover sheet Annex E

07.06.2011

19

iii, iv, 4-1...4-3

iii, iv, 4-1...4-3

04.04.2012

20

iii, iv, 4-1…4-3, 5-5

iii, iv, 4-1…4-3, 5-5

13.08.2012

21

iii, iv, vi…viii, 4-1…4-3,

5-1…5-10

iii, iv, vi…viii, 4-1, 4-2,

5-1…5-11

15.10.2012

22

iii, iv, v, 3-3, 3-31, 3-50, 5-4,

6-7, 7-6, 7-26, 7-29, 7-30,

9-1.2, 9-2, 9-3, 9-4

iii, iv, v, 3-3, 3-31, 3-50.1,

3-50.2, 5-4, 6-7, 7-6, 7-26,

7-29, 7-30, 9-1.2, 9-2, 9-3,

9-4

Jan. 10, 2014

23

i, iii … viii, 4-1…4-2,

5-1…5-11, 7-23

i, iii … ix, 4-1…4-4, 5-1…5-21,

7-23

29.01.2015

Maintenance Manual STEMME S10-VT Date of Issue: Jan. 01, 1998 Page iv

Amendment No. 23 Date: Jan. 29, 2015

A4011121_B23.doc Doc. No. A40-11-121

0.2 List of Effective Pages

This list is only valid for the Serial No. specified on title page. The list contains all amendments of the

Maintenance Manual, effective until final approval of this Serial No. Amendments added later must be

recorded.

Page

Am. No.

Date

i

23

29.01.2015

ii

10

14.12.2001

iii

23

29.01.2015

iv

23

29.01.2015

v

23

29.01.2015

vi

23

29.01.2015

vii

23

29.01.2015

viii

23

29.01.2015

ix

23

29.01.2015

1-1

14

30.11.2007

1-2

15

30.11.2008

2-1

2-2

8

11.11.1999

2-3

3-1

3-2

3-3

22

10.01.2014

3-4

3-5

3-6

3-7

3-8

3-9

4

12.08.1998

3-10

4

12.08.1998

3-11

3-12

3-13

3-14

4

12.08.1998

3-15

10

14.12.2001

3-16

8

11.11.1999

3-17

14

30.11.2007

3-18

3-19

14

30.11.2007

3-20

14

30.11.2007

3-21

14

30.11.2007

3-22

3-23

Page

Am. No.

Date

3-24

8

11.11.1999

3-25

8

11.11.1999

3-26

8

11.11.1999

3-27

8

11.11.1999

3-28

3-29

3-30

3-31

22

10.01.2014

3-32

10

14.12.2001

3-33

3-34

3-35

3-36

3-37

14

30.11.2007

3-38

14

30.11.2007

3-39

3-40

14

30.11.2007

3-41

3-42

3-43

3-44

10

14.12.2001

3-45

10

14.12.2001

3-46

3-47

3-48

3-49

3-50.1

22

10.01.2014

3-50.2

22

10.01.2014

3-51

6

15.04.1999

3-52

3-53

3-54

3-55

8

11.11.1999

4-1

23

29.01.2015

4-2

23

29.01.2015

4-3

23

29.01.2015

4-4

23

29.01.2015

Page

Am. No.

Date

5-1

23

29.01.2015

5-2

23

29.01.2015

5-3

23

29.01.2015

5-4

23

29.01.2015

5-5

23

29.01.2015

5-6

23

29.01.2015

5-7

23

29.01.2015

5-8

23

29.01.2015

5-9

23

29.01.2015

5-10

23

29.01.2015

5-11

23

29.01.2015

5-12

23

29.01.2015

5-13

23

29.01.2015

5-14

23

29.01.2015

5-15

23

29.01.2015

5-16

23

29.01.2015

5-17

23

29.01.2015

5-18

23

29.01.2015

5-19

23

29.01.2015

5-20

23

29.01.2015

5-21

23

29.01.2015

6-1

6-2

6-3

6-4

6-5

6-6

6-7

22

10.01.2014

6-8

8

11.11.1999

6-9

14

30.11.2007

6-10

6-11

6-12

6-13

14

30.11.2007

7-1

7-2

Maintenance Manual STEMME S10-VT Date of Issue: Jan. 01, 1998 page v

Amendment No.: 23 Date: Jan. 29, 2015

A4011121_B23.doc Doc. No. A40-11-121

7-3

7-4

7-5

8

11.11.1999

7-6

22

10.01.2014

7-7

7-8

7-9

14

30.11.2007

7-10

14

30.11.2007

7-11

14

30.11.2007

7-12

14

30.11.2007

7-13

14

30.11.2007

7-14

14

30.11.2007

7-15

14

30.11.2007

7-16

14

30.11.2007

7-17

14

30.11.2007

7-18

3

22.07.1998

7-19

8

11.11.1999

7-20

8

11.11.1999

7-21.1

8

11.11.1999

7-21.2

8

11.11.1999

7-22

8

11.11.1999

7-23

23

29.01.2015

7-24

7-25

7-26

22

10.01.2014

7-27

7-28

8

11.11.1999

7-29

22

10.01.2014

7-30

22

10.01.2014

7-31

7-32

14

30.11.2007

7-33

2

23.03.1998

8-1

8-2

8

11.11.1999

8-3

8-4

8-5

8-6

8-7

10

14.12.2001

9-1.1

13

25.05.2005

9-1.2

22

10.01.2014

9-2

22

10.01.2014

9-3

22

10.01.2014

9-4

22

10.01.2014

10-1

14

30.11.2007

11-1

8

11.11.1999

Page

Am. No.

Date

cover sheet

Annex A

8

11.11.1999

cover sheet

Annex B

cover sheet

Annex C

8

11.11.1999

cover sheet

Annex D

cover sheet

Annex E

18

07.06.2011

Maintenance Manual STEMME S10-VT Date of Issue: Jan. 01, 1998 Page vi

Amendment No. 23 Date: Jan. 29, 2015

A4011121_B23.doc Doc. No. A40-11-121

0.3 Contents

0.1 Record of Amendments ii

0.2 List of Effective Pages iv

0.3 Contents vi

1. General Remarks on Maintenance 1-1

1.1 Conversion table 1-2

1.2 Abbreviations 1-2

2. Brief Description and Technical Data 2-1

3. Description of Assemblies 3-1

3.1 Airframe, Primary and Secondary Structure 3-1

3.1.1 Wing 3-1

3.1.2 Fuselage 3-1

3.1.3 Tail Unit 3-2

3.2 Cockpit3-2

3.2.1 General 3-2

3.2.2 Control Elements and Instruments 3-3

3.3 Flight Control System 3-8

3.4 Power Plant (Fig. 3.4.a) 3-17

3.4.1 Engine 3-17

3.4.2 Lubrication System 3-19

3.4.3 Cooling System 3-19

3.4.4 Air Induction System 3-20

3.4.5 Engine Exhaust incl. Turbocharger and Attachment 3-20

3.4.6 Fuel System (Fig. 3.4.6) 3-21

3.4.7 Engine Controls and Instrumentation 3-23

3.4.8 Fire Protection 3-23

3.4.9 Engine Cowlings 3-23

3.4.10Propeller (Fig. 3.4.10.a/b/c) 3-24

3.4.11Power Transmission 3-27

3.4.12Front gear 3-27

3.4.13Operation Mechanism of the Propeller Folding System 3-28

3.4.14Operating Media 3-29

3.5 Landing Gear 3-31

3.5.1 Main Landing Gear (Fig. 3.5.1) 3-31

3.5.2 Tail Wheel 3-31

3.6 Flight Control Instruments, Pitot Static System (Fig. 3.6.a,b) 3-33

3.7 Electrical System 3-35

3.7.1 General 3-35

3.7.2 Wiring 3-35

3.7.3 Bus-Structure of the Electrical System 3-35

3.7.4 Structure of Grounding 3-36

3.7.5 Generation of Electric Energy 3-36

3.7.6 Engine Electric 3-37

3.7.7 Engine Monitoring 3-37

3.7.8 Instruments on the Instrument Panel 3-38

3.7.9 Warning, Caution and Status Lights on the Instrument Panel: 3-38

3.7.10Fuses and Circuit Breakers (CB´s): 3-39

3.7.11Switches on the Instrument Panel: 3-39

3.7.12Variable Pitch Propeller 3-41

3.7.13Main Landing Gear 3-41

3.7.14Landing Gear Warning System 3-41

3.7.15Avionics 3-41

3.8 COM and NAV Equipment 3-55

3.9 Oxygen System 3-55

Maintenance Manual STEMME S10-VT Date of Issue: Jan. 01, 1998 Page vii

Amendment No. 23 Date: Jan. 29, 2015

A4011121_B23.doc Doc. No. A40-11-121

4. Airworthiness Limitations Section 4-1

4.1 General4-2

4.2 Maintenance Limitations 4-2

4.2.1 Paint Finish 4-2

4.3 Component Replacement and Overhaul Limitations 4-3

4.4 Structural Limitations 4-4

5. Time Limits / Maintenance Checks 5-1

5.1 Overhaul and Replacement Schedule 5-2

5.2 Pre-Flight Inspections 5-5

5.2.1 Rubber Hose and Clamp Integrity 5-5

5.3 Periodical Inspections 5-5

5.3.1 Inspection Intervals 5-5

5.3.2 General Remarks on Periodic Inspections 5-7

5.3.3 Additional Calendar-Related Inspections 5-7

5.3.4 Unscheduled Maintenance 5-8

5.3.5 Special Conditions and Cautionary Notice 5-8

5.3.6 General Remarks on Maintenance 5-9

5.3.7 Inspection Groups and Maintenance Criteria 5-10

5.3.8 Other Particulars of Maintenance 5-12

5.4 Check List for Periodical Inspections 5-13

5.4.1 General 5-13

5.4.2 Wings and Fuel System Components in the Central Wing 5-13

5.4.3 Front Fuselage 5-14

5.4.4 Cockpit 5-14

5.4.5 Center Fuselage (except for fairings) 5-14

5.4.6 Tail Boom 5-15

5.4.7 Empennage 5-15

5.4.8 Fuel System Components in the Fuselage 5-15

5.4.9 Engine and Engine Mountings 5-16

5.4.10Lubrication System 5-16

5.4.11Cooling System (Liquid Cooling, Ram Air Cooling) 5-16

5.4.12Air Induction System 5-17

5.4.13Engine Controls & Monitoring 5-17

5.4.14Center Fuselage Fairing, Engine Cowlings and Fire-Wall 5-17

5.4.15Propeller 5-17

5.4.16Drive Shaft with Front Gear 5-18

5.4.17Main Landing Gear 5-18

5.4.18Tail Wheel 5-19

5.4.19Flight Instrumentation and Pressure Systems 5-19

5.4.20Electric System (except for engine and TCU) 5-19

5.4.21COM and NAV Equipment 5-20

5.4.22Oxygen Equipment 5-20

5.4.23Completition works 5-20

5.5 Special Inspections 5-21

5.5.1 Inspection Following a Heavy Landing or a Wing Tip Landing 5-21

5.5.2 Inspection Following an Impact to the Rotating Propeller 5-21

6. Maintenance Instructions, Tolerances, Adjustment Data for the Aircraft 6-1

6.1 General Remarks 6-1

6.2 Towing on ground, Jack Points and Lifting 6-1

6.3 Determination of Empty Weight and Corresponding Centre-of-Gravity; Weight Limits 6-2

6.4 Flight Control System 6-7

6.4.1 Deflection of Control Surfaces, Control System Friction, and Control Forces 6-7

6.4.2 Masses and Moments of Control Surfaces 6-8

6.4.3 Free Play in Flight Control System 6-8

6.5 Lubrication 6-9

Maintenance Manual STEMME S10-VT Date of Issue: Jan. 01, 1998 Page viii

Amendment No. 23 Date: Jan. 29, 2015

A4011121_B23.doc Doc. No. A40-11-121

6.5.1 General Remarks 6-9

6.5.2 Lubrication Plan 6-10

6.6 Surface of Composite Structures 6-11

6.7 Drainage and Ventilation Holes 6-12

6.8 Tightening Torques of Screwed Joints: 6-13

7. Maintenance Instructions, Tolerances and Adjustment Data for Assemblies /

Equipment 7-1

7.1 Airframe 7-1

7.1.1 Wing 7-1

7.1.2 Fuselage 7-2

7.1.3 Empennage 7-3

7.2 Cockpit 7-5

7.2.1 Canopy 7-5

7.2.2 Equipment and Systems 7-6

7.3 Controls 7-7

7.3.1 Controls in Fuselage 7-7

7.3.2 Controls in the Wing 7-7

7.3.3 Controls in Tail Cone/Vertical Tail 7-8

7.3.4 Deflection of Control Surfaces, Control System Friction, Control Forces 7-8

7.3.5 Slackness of Control System Bearings 7-8

7.4 Powerplant 7-9

7.4.1 Engine 7-9

7.4.2 Lubrication System 7-12

7.4.3 Cooling System 7-12

7.4.4 Air Induction System 7-13

7.4.5 Exhaust System 7-14

7.4.6 Fuel System 7-15

7.4.7 Engine Controls / Monitoring 7-16

7.4.8 Fire Protection 7-17

7.4.9 Cowlings 7-18

7.4.10Propeller 7-19

7.4.11Drive Shaft System 7-23

7.4.12Front Gear, Mounting and Support 7-24

7.4.13Propeller Operation 7-25

7.5 Landing Gear 7-26

7.5.1 Main Landing Gear 7-26

7.5.2 Tailwheel 7-30

7.6 Flight Control Instruments and Pitot and Static Pressure System 7-31

7.6.1 Calibration of Stall Warning System: 7-31

7.6.2 Maintenance on the Static Pressure System 7-31

7.7 Electrical System 7-32

7.7.1 General 7-32

7.7.2 Batteries 7-32

7.7.3 Grounding 7-32

7.7.4 E-Box 7-32

7.8 Communication and Navigation Equipment 7-33

7.9 Oxygen Equipment 7-33

8. List of Placards and their Positions 8-1

9. Equipment 9-1

9.1 Minimum Equipment List 9-1

9.2 Supplementary Equipment 9-2

9.3 Additional Equipment and Systems 9-2

Maintenance Manual STEMME S10-VT Date of Issue: Jan. 01, 1998 Page ix

Amendment No. 23 Date: Jan. 29, 2015

A4011121_B23.doc Doc. No. A40-11-121

9.3.1 Additional Equipment 9-2

9.3.2 Optional Systems 9-4

10. List of Special Tools 10-1

11. List of Maintenance Documents for Parts Being Approved Independently from

the Aircraft. 11-1

Annex A: Supplementary Instructions for Maintenance and Care, Maintenance Instructions

Annex B: Service Bulletins, Airworthiness Directives

Annex C: Documents (Inspection and Operation Reports)

Annex D: Maintenance and Inspection Forms.

Annex E: Maintenance Manual (Line Maintenance) for ROTAX Engine Type 914 Series

Maintenance Manual STEMME S10-VT Date of Issue: Jan. 01, 1998 Page 1-1

Amendment Nr. 14 Date: Nov. 30, 2007

A4011121_B23.doc Doc. No. A40-11-121

1. General Remarks on Maintenance

The legal owner of the STEMME S10-VT is obliged to ensure that, according to the specific national laws and

regulations, the maintenance of the aircraft follows the instructions of this manual. Among others, there are

scheduled maintenance,

adjustments,

exchange of fluids and lubricants,

exchange of parts after expiry of their service life,

minor repairs.

Any maintenance work must be documented (a/c logbook).

The manufacturer has to be informed immediately in case of any change of ownership. The message must

be confirmed by the manufacturer, so that all information concerning airworthiness (AD´s, SB´s) can be given

to the legal owner.

For maintenance work the following documents are relevant:

1. This Maintenance Manual for the powered glider STEMME S10-VT,

2. STEMME - "Flight Manual for the powered glider STEMME S10-VT",

3. ROTAX - "Maintenance Manual (Line Maintenance) for ROTAX Engine Type 914 Series”,

4. ROTAX - "Maintenance Manual (Heavy Maintenance) for ROTAX Engine Types ROTAX 912 and 914

Series”,

5. ROTAX - "Operating Manual“ ROTAX 914 F,

6. ROTAX - "Installation Manual“ ROTAX 914 F,

7. ROTAX - "Main Overhaul Manual“ ROTAX 914 F,

8. ROTAX - "Spare Parts List“ ROTAX 914 F,

9. STEMME Doc. No. A26-11AM-M: Technical Specification of the ROTAX 914 F2/S1,

10.Maintenance instructions for the "L'Hotellier" quick-disconnects in flight control system,

11.Manufacturer's documents referring to the equipment listed in the equipment list of the corresponding S/N,

12.SB´s published by STEMME, ROTAX and manufacturer of other equipment installed,

13.Maintenance Instructions from STEMME,

14.Service Information's from ROTAX.

The amount and kind of maintenance work depend on the a/c utilisation, the climate, airfield conditions,

storing facilities and other factors, irrespective of the periodic checks. E. g., in sandy environs it might be

necessary to clean all filters before every commencement of operation; on the other hand in coastal or in

rainy regions it is important to take more care of the conservation of the a/c. The instructions in this manual

are valid under normal conditions and use.

Use only spare parts from the manufacturer or according to the manufacturer's requirements.

NOTE: Materials required and recommended procedures for minor repairs on composite materials are

indicated in the repair guide "Minor repair to components of fibrous composite material" in Annex A of

this Maintenance Manual.

In case of any incident endangering airworthiness the manufacturer must be informed immediately.

Maintenance work must be performed by qualified personnel.

NOTE: This Maintenance Manual does not include instructions for assembly, daily inspection and Pre-flight

inspection, which are provided in section 4 "Normal Operating Procedures" of the Flight Manual. To

perform these procedures, the Flight Manual must be available to the maintenance personnel.

Maintenance Manual STEMME S10-VT Date of Issue: Jan. 01, 1998 Page 1-2

Amendment Nr. 15 Date: Nov. 30, 2008

A4011121_B23.doc Doc. No. A40-11-121

1.1 Conversion table

For the conversion of technical data the following factors have been used:

1 lb.

0.4536 kg

1 lbf ft

1.356 Nm

1 dr.

1.772 g

1 hp

0.7457 kW

1lbf =1 lb.(wt)

4.45 N

1 kts

1.852 km/h

1in.

25.4 mm

1 mph

1.609 km/h

1ft.

0.3048 m

1 Imp.gal.

4.546 l

1 sqft.

0.0929 m2

1 US gal.

3.785 l

100 fpm

0.5081 m/s

1 p.s.i.

0.06895 bar

1.2 Abbreviations

The following abbreviations are being used for clarity:

a/c

aircraft

AUW

all-up-weight

CB

circuit breaker

CFRP

carbon-fibre-reinforced-plastic

CG

centre-of-gravity

CHT

cylinder head temperature

DCDI

dual capacity discharge ignition

GFRP

glass-fibre-reinforced-plastic

KIAS

knots indicated airspeed

LH

left hand

MAP

manifold pressure

OAT

outside air temperature

RH

right hand

RPM

revolutions per minute

PPC

propeller pitch control

TCU

turbo charger control unit

Maintenance Manual STEMME S10-VT Date of Issue: Jan. 01, 1998 Page 2-1

Amendment Nr. 0 Date: --

A4011121_B23.doc Doc. No. A40-11-121

2. Brief Description and Technical Data

The STEMME S10-VT is a twin-seat high performance powered sailplane with an innovative propulsion

concept and a sophisticated aerodynamic design. The wing is a carbon fibre reinforced composite design.

The fuselage is manufactured as a hybrid construction (carbon, kevlar, glass) with an extremely rigid central

steel tube framework. The seats are arranged side by side and equipped with dual controls.

The wing is attached to the fuselage in the upper third section of the fuselage behind the cockpit. The wing

consists of a one-part central wing equipped with flaps and Schempp-Hirth air brakes as well as two outboard

wings with continuous ailerons. The tail unit is designed as a T-tail.

The two-leg landing gear is electrically operated and is equipped with hydraulic disc brakes. The tail wheel is

steered with the pedals.

The engine is located in the fuselage in the central steel tube framework near the aircraft centre of gravity.

The engine power is transmitted via an internal gear, a freewheel clutch, a composite drive-shaft and a front

reduction gear to a foldable propeller in the fuselage nose. The electrically operated variable pitch propeller

with two blades can be folded and completely covered by a retractable nose cone ("propeller dome") for

soaring.

One fuel tank is located in each outboard area of the central wing. Engine fuel supply is by two electrically

driven pumps (1 main, 1 aux) for each wing tank, which can be selected with a fuel selector switch for supply

from the left tank, both tanks or from the right tank.

Technical Data (general drawing see Fig. 2.a)

Wing

wing span

23.00 m

75.5 ft.

central wing span

9.90 m

32.5 ft.

wing area

18.74 m²

201.7 sqft.

aspect ratio

28.22

dihedral angle

0.75°

sweep of central wing leading edge

0°

sweep of outboard wing leading edge up to the bend

0°

airfoil: laminar profile

HQ41/14.35

Air Brakes (two-storey Schempp-Hirth air brakes on wing upper side only)

length

1.50 m

59 in.

area

0.22 m²

2.37 sqft.

maximum height above wing upper side

0.16 m

6.3 in.

Wing Flaps

span

4.39 m

14.4 ft.

area

0.75 m²

8.07 sqft.

flap positions:

-10°, -5°, 0°, +5°, +10°, L (+16°)

Ailerons

span

5.80 m

19 ft.

area

0.68 m²

7.32 sqft.

Fuselage

length

8.42 m

27.6 ft.

width

1.18 m

3.9 ft.

cockpit width

1.16 m

3.8 ft.

cockpit height

0.93 m

3.1 ft.

height of tail unit

1.75 m

5.7 ft.

Maintenance Manual STEMME S10-VT Date of Issue: Jan. 01, 1998 Page 2-2

Amendment Nr. 8 Date: Nov. 11, 1999

A4011121_B23.doc Doc. No. A40-11-121

Vertical Tail

height

1.60 m

5.2 ft.

total area

1.51 m²

16.25 sqft.

area of rudder

0.52 m²

5.60 sqft.

airfoil

FX 71-L-150/35

Horizontal Tail

span

3.10 m

10.2 ft.

total area

1.46 m²

15.72 sqft.

area of elevator

0.36 m²

3.88 sqft.

aspect ratio

6.58

airfoil

FX 71-L-150/25

Landing Gear

2 main wheels with brake discs, rim of wheel

127x127-30

tire size: (standard/wide tire)

5.00-5 / 6.00-5

wheel track: (standard/wide tire)

1.15 m / 1.16 m

3.77 ft / 3.8 ft.

tail wheel (steerable), tire size

210 x 65

wheel base

5.46 m

17.9 ft.

Power-Plant

engine

ROTAX 914 F2/S1

T/O-power (115%, max 5 minutes)

at 5800 RPM

84.5 kW

113.2 hp

max continuos power (100%)

at 5500 RPM

73.4 kW

98.4 hp

gear transmission ratio front gear

i = 1.109

gear transmission ratio engine-gear

i = 0.412

Variable-Pitch Propeller

Model

STEMME 11 AP

diameter extended

DPA = 1.63 m

63.4 in

mass of the propeller (incl. outer-casing of

needle bearing and rubber buffers)

mP= 9350 g

20.61 lbs

overall mass of propeller blade

mB= 650 g ± 10 g

1.433 lbs ± 0.022 lbs

max. propeller RPM

nP = 2.650 RPM

propeller pitch T/O position

P= 17.65°

cruise position

P= 24.05°

max. current consumption of the resistor element

Imax = 10 A

Weights (see also figures 6.3a/ 6.3.b and form "Weight and Balance Report")

maximum allowable weight

850 kg

1874 lbs

empty weight, including minimum equipment

660 kg1)

1455.1 lbs1)

maximum weight of non-supporting parts

570 kg

1257 lbs

total useful load (occupants, fuel, baggage)

190 kg1)

419 lbs1)

1) Load distribution according to Weight & Balance, refer to Flight Manual. Empty weight of 660 kg / 1455 lbs

is without optional equipment. Useful load is reduced by additional equipment.

Inflight Centre of Gravity range

In-flight Centre-of-Gravity range aft of datum

(central wing leading edge, see section 6.3)

254 - 420 mm

10 in. - 16.5 in.

For more technical data, please refer to the Flight Manual.

Following figure shows a 3-view plan of the S10-VT.

Maintenance Manual STEMME S10-VT Date of Issue: Jan. 01, 1998 Page 2-3

Amendment Nr. 0 Date: --

A4011121_B23.doc Doc. No. A40-11-121

Fig. 2.a: 3-View Plan of the S10-VT

Maintenance Manual STEMME S10-VT Date of Issue: Jan. 01, 1998 Page 3-1

Amendment Nr. 0 Date: --

A4011121_B23.doc Doc. No. A40-11-121

3. Description of Assemblies

3.1 Airframe, Primary and Secondary Structure

The Primary Structure includes:

wing spars, root ribs, and wing spar boxes

wing shells

central fuselage framework

tail boom and vertical stabiliser

front section of fuselage

horizontal stabiliser

fittings

The Secondary Structure includes:

control surfaces

cowlings, cooling air system ducts, cockpit components

3.1.1 Wing

Structural design: Carbon fibre reinforced plastic (CFRP) sandwich shell, CFRP spars.

The wing consists of three sections: a central wing with a span of 9.90 m / 32.5 ft. and two outboard wing

sections with a span of 6.55 m / 21.5 ft. each. Attachment of the central wing to the fuselage is by means of

four sliding bolts, attachment of the outboard wings to the central wing is with one sliding bolt each.

A removable fairing covers the wing/fuselage combination. Beneath the fairings, free access to the wing

attachment, the control system joints and the combined aileron/flap controls is possible. For disassembly, the

central wing has to be lifted vertically.

The flaps extend to the total span of the central wing and the ailerons to the total span of the outboard wings.

The controls of flaps and ailerons are interconnected, the ailerons acting as differential flaps and the flaps

acting as differential ailerons. The flap deflection is reduced from the inner to the outer wing, the aileron

deflection is reduced from outer to the central wing and from up to down deflections.

Two-storey Schempp-Hirth air brakes are installed on the centre wing upper side.

The slots of flaps and ailerons are sealed with elastic adhesive tape and a skid layer on the upper side of the

wing and with a textile tape (elastic adhesive tape and skid layer optional) on the lower side.

A boundary layer turbulator (adhesive 60° zigzag tape, leading edge at 69% of chord, 12 x 0.5 mm / 0.47 x

0.02 in.) on the wing lower side ensures a defined flow transition.

3.1.2 Fuselage

The fuselage is a modular construction of three assemblies with bolted joints: the front fuselage section

(CFRP-Kevlar-fibreglass construction), the centre fuselage framework and the tail boom (CFRP

construction).

Loads from the fuselage front section, the wing, the landing gear, the power-plant and the tail unit are

transmitted by the central fuselage framework.

The centre fuselage framework is covered by self-supporting fairings (upper fairing and engine cowlings) of

GFRP-sandwich. The attachment of the fairings is by means of camlocks, which can be easily opened with a

screw-driver. The upper fairing includes an oil service access, which can be opened without a tool.

Maintenance Manual STEMME S10-VT Date of Issue: Jan. 01, 1998 Page 3-2

Amendment Nr. 0 Date: --

A4011121_B23.doc Doc. No. A40-11-121

3.1.3 Tail Unit

Horizontal Tail

T-arrangement, easy removable (simple spring-bolt connection),

Stabiliser as sandwich construction of CFRP, elevator made of CFRP.

Elevator slots sealed by elastic tape.

Boundary layer turbulator (adhesive 60° zigzag tape, leading edge at 65% of chord, 12 x 0.5 mm / 0.47 x

0.02 in.) on upper and lower side for defined flow transition.

Vertical Tail

Stabiliser as a sandwich construction of CFRP, rudder as a sandwich construction of GFRP,

rudder slot sealed by elastic tape with integrated zigzag turbulator (combi-tape),

COM antenna integrated in rudder.

3.2 Cockpit

3.2.1 General

The two seats are arranged side by side. The GFRP seat back rests are multi-adjustable. Each seat is

equipped with 4-point seat belts and a central harness.

Dual controls are provided. Between the seats a console covers systems and the drive shaft tunnel. The

mushroom-style panel arrangement has three separate areas: LH side, centre and RH side.

The one-piece canopy is hinged at the front and held in opened position by gas springs. Three canopy locks

on both, left hand and right hand side, are operated by one locking lever on each side. One lock to improve

canopy emergency jettisoning ("Roeger-hook") is installed in the rear upper canopy frame, to be operated by

the handle next to it.

Emergency jettisoning: open both locking levers on sides and pull the red T-shaped handle on the instrument

panel for emergency jettisoning. The canopy hinge opens and is lifted by a gas spring by approximately

100 mm / 4 in. The Roeger hook must remain closed, since it is the axis of rotation until the canopy is

jettisoned.

The cockpit is ventilated via two nozzles (LH and RH side) in the instrument panel. The canopy ventilation is

via openings in the canopy frame. The cockpit heating is by power-plant waste heat (optional equipment).

Maintenance Manual STEMME S10-VT Date of Issue: Jan. 01, 1998 Page 3-3

Amendment Nr. 22 Date: Jan. 10, 2014

A4011121_B23.doc Doc. No. A40-11-121

3.2.2 Control Elements and Instruments

3.2.2.1 Cockpit controls at the airframe

Following overview includes the controls at the airframe.

1.

Control Stick

Middle in front of each seat.

2.

Rudder Pedals

For each seat and adjustable. The pedals also steer the tail wheel,

which is coupled to the rudder via spring device.

3.

Airbrake Lever

For each seat LH side. Blue lever at LH cockpit side and on the centre

console between seats, respectively.

4.

Flap Lever

For each seat LH side. Black lever at LH cockpit side and on the centre

console, respectively. Indication of settings (-10, -5, 0, +5, +10, L) in

centre console. Unlocking is by moving lever to the right against spring

force, which locks the flap positions.

5.

Pedal Adjustment Handle

In front of each seat. Unlocking is by pulling the handle.

6.

Canopy Locks

Two white handles with red coloured ring, one on left and one on right

side of the canopy frame, to open and lock the canopy, and one white

handle at rear top, which keeps hold of the rear canopy at the first

moment of emergency canopy jettison ("Roeger-Hook").

7.

Brake Lever

Lever at LH control stick, at RH stick optional. Separate lever for parking

brake valve on the floor panel console in front of the LH control stick.

Hydromechanical brake system:

The brake lever can be locked with a pin for parking.

8.

Trim Lever

One green lever on centre console between seats. To trim push down

(unlock) and shift lever forward or aft. Locking is by a spring device.

9.

Throttle Lever

One black lever on centre console with two forward stops (for max.

continuous and max. T/O-power). It is coupled with a spring acting

forward in direction FULL POWER. Its position is fixed by friction discs,

which can be adjusted with a milled-nut on LH side of the centre

console.

10.

Choke Lever

Black lever on centre console, RH side of the throttle lever. It is coupled

with a spring acting rearward in direction CHOKE OFF. Its position is

fixed by friction discs, which can be adjusted with a milled-nut on RH

side of the centre console.

11.

Propeller Pitch Control

Switch on centre console. The forward position is the TAKE-OFF

position. A green light next to the switch indicates, if propeller pitch (not

switch) is in T/O-position.

12.

Fuel Cock

Red handle on the rear console between the seat back rests. Turning

handle horizontal (fuel cock CLOSED) cuts off the fuel supply between

tanks and carburetors.

NOTE: Throttle positions for 115% and 100% can be selected by feeling. The first stop is the 100% throttle

position. To select 115% the throttle lever must be moved through a throttle gate to the left and then

pushed to the next stop.

Maintenance Manual STEMME S10-VT Date of Issue: Jan. 01, 1998 Page 3-4

Amendment Nr. 0 Date: --

A4011121_B23.doc Doc. No. A40-11-121

3.2.2.2 Controls at Instrument Panel

The following overview includes controls at the lower area of the instrument panel. These elements are

included in Fig. 3.2.a "Arrangement of Elements on Instrument panel" (see section 3.2.2.3):

1.

Emergency Canopy Release

Red pull-handle on LH side of the switch panel. It is pulled for

emergency canopy jettisoning after opening the canopy locks on LH

and RH side of the canopy frame.

2.

Cowl Flap Reduction

Black T-handle on LH side of the lower middle section of the instrument

panel to reduce engine cooling in cruise condition. The foremost

position means cowl flaps fully OPEN, 5 settings aft are available to

reduce the opening of the cowl flaps.

3.

Propeller Dome Operation

Black handle in the middle foot of the instrument panel to open, close

and lock the propeller dome, linked to the engine electric master

switch. Unlock by lifting, lock by pushing down the handle. In the

forward position (Dome OPEN) the engine master switch comes ON

when the dome is LOCKED.

4.

Propeller Brake

Black T-handle on RH side of the cowl flap reduction to brake the

propeller to full stop after the engine is switched off in flight. Braking is

by pulling the handle.

5.

Propeller Positioning

Black T-handle on RH side of the propeller brake to position the

propeller so as it fits into the propeller dome contour. Operation is by

steady, not too fast pulling the handle to its stop.

6.

Air Vents

Two adjustable air vents for cockpit ventilation, one on LH and one on

RH side of the Instrument panel, are provided.

7.

Canopy Ventilation

Knob on RH side of the ignition/starter switch to ventilate the canopy.

The pulled position means canopy ventilation OPEN.

Maintenance Manual STEMME S10-VT Date of Issue: Jan. 01, 1998 Page 3-5

Amendment Nr. 0 Date: --

A4011121_B23.doc Doc. No. A40-11-121

3.2.2.3 Instrument Panel

Following description gives an overview of instruments, controls, monitor devices and CB´s installed on the

instrument panel. The positions of the elements is shown in Fig 3.2.a: "Arrangements of Elements on

Instrument Panel", valid for the serial number as indicated on the title page of this maintenance manual.

The flight control instruments include at least

1. one ASI (airspeed range 50 - 300 km/h / 27 - 162 kts)

2. one Altimeter

3. one magnetic compass.

These instruments are located directly in the view area of the PIC (in front of LH seat). Double-

instrumentation is possible to provide an optimum view on flight control instruments from the RH seat (e. g.

instruction flights).

Additional avionics may be installed on customer demands. Related Switches and CB´s are always located in

the same section of the instrument panel.

Engine monitoring includes at least:

tachometer,

oil pressure and oil temperature,

cylinder head temperature (CHT) LH and RH,

voltmeter and ammeter

fuel quantity in LH and RH wing tanks

Engine-elapsed-time-indicator

These instruments are located as a rule, with the exception of the engine-elapsed-time-indicator, in the RH

area of the panel, if not installed (i. e. with double-instrumentation) in the centre area. The engine-elapsed-

time-indicator is located on the centre console between the seats.

The red fire-warning light (test by pushing light for optic and acoustic signal) is adjacent to the engine

instrumentation.

The following warning and monitoring lights are combined in a group, arranged independently of its location

on the instrument panel. They inform the pilot about the proper condition of the a/c at a glance. The group is

always located at the upper instrument panel below the glareshield to allow for dazzle-free reading.

Arrangement from left to right is:

A) red fuel pressure warning,

B) green status indication for fuel aux pump operation,

C) red warning light for manifold pressure (boost pressure),

D) yellow caution light for malfunction of TCU,

E) red warning light for malfunction external generator (battery charge control),

F) yellow caution light for malfunction of internal generator.

The landing gear position and warning indication is also located below the glareshield and consists of two

lights, indicating the situation with green ore red steady or flashing light.

Maintenance Manual STEMME S10-VT Date of Issue: Jan. 01, 1998 Page 3-6

Amendment Nr. 0 Date: --

A4011121_B23.doc Doc. No. A40-11-121

The following CB´s are combined in a group, arranged independently of its location at the panel:

master CB,

CB for external generator,

landing gear CB,

CB´s for main and auxiliary fuel pumps.

The lower, central section of the instrument panel comprises a row of levers and switches. Any switches,

except for avionics and a push button to select voltmeter indication of the additional battery voltage at the

lower RH panel, are systematically arranged here. The red handle for canopy emergency jettison is installed

LH of the row of switches. Sequence of levers and switches, starting from the left, is:

1. red handle for canopy emergency jettison,

2. landing gear lever with three positions (down: lowering, centre: neutral (electrically de-energised), up:

retraction),

3. battery selector switch (down: additional battery selected, up: main battery selected)

4. switch for auxiliary fuel pump,

5. fuel selector switch (positions "LEFT", "BOTH", "RIGHT")

6. electric master switch,

7. switch for external generator,

8. engine-back-up switch to bypass engine master switch in case of malfunction of the microswitch at the

propeller-dome (switch is guarded with a black protecting plate for unintended operation).

9. TCU emergency switch to isolate wastegate actuator and TCU control in case of malfunction (switch is

guarded with a red protecting plate for unintended operation),

The control elements for propeller and propeller-dome (propeller brake, propeller positioning and propeller

dome handle) are arranged below the row of switches in the centre console. In the same area the canopy

ventilation knob and the ignition/starter switch (positions OFF, Right, Left, BOTH and START) are installed.

The following figure "Arrangement of Elements on Instrument panel" shows layout and arrangement of the

instrument panel of the serial number as indicated on the title page, including control elements, monitoring

devices and CB´s.

Table of contents

Other STEMME Toy manuals

Popular Toy manuals by other brands

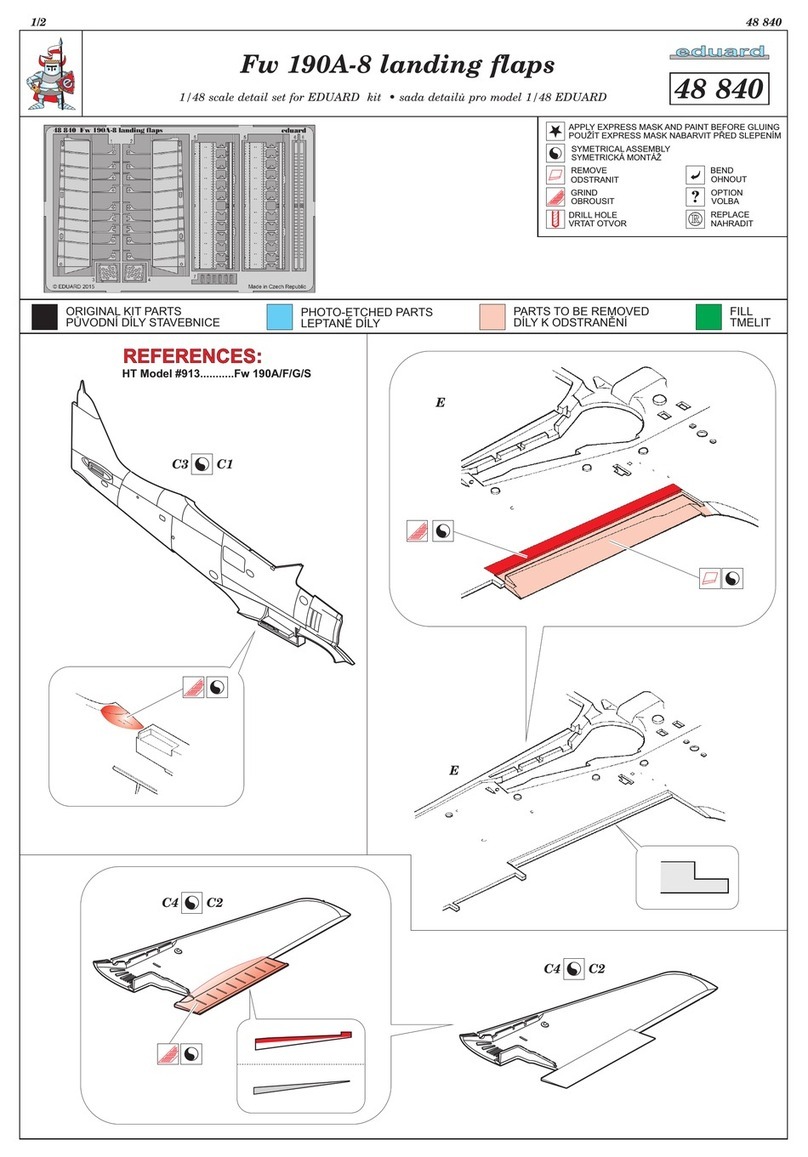

Eduard

Eduard Fw 190A-8 landing flaps manual

Hasbro

Hasbro TOYBOX TOOLS Playskool Chase 'n Go Ball... instruction sheet

Circuit Cubes

Circuit Cubes Whacky Wheels Getting started

Pheonix Model

Pheonix Model Cessna 182 instruction manual

Mattel

Mattel Barbie DHF08-BC70 instructions

Mattel

Mattel Hot Wheels DEADMAN'S CURVE instructions