Sterling Power PCU1210 User manual

Sterling Power Products

Pro Charge Ultra

PCU Series Handbook

Optional

Remote control

with 10m cable

(Part No PCUR)

Part No:

PCU1210

PCU1220

PCU1230

PCU1240

PCU1250

PCU1260

PCU2420

PCU2430

PCU3620

PCU4815

PRIDE IN PERFORMANCE

Colours in use

Sterling Red

RAL 3003

90% Black

White

www.sterling-power.com

www.sterling-power-usa.com

Warranty (5 years return to factory)

Copyright © 2021

Sterling Power

All Rights Reserved

RoHS

compliant

RoHS

compliant

BC

To Standards:

UL 1236 SB

CSA C22.2-107.2

Tested to CE standards

EN 55014-1:2017

EN 55014-2:2015

EN 61000-3-2:2014

EN61000-3-3:2013

EN 60335-1:2019

EN 60335-2-29:2018

EN 62233:2008

EN ISO 13297

Small Craft Directive

Global input AC/DC battery charger

Marine grade

50% Black for subtitles + bottom right

90% Black for body

RAL 3003 R134 G26 B34

Text, by and large, is size 9.

Table of Contents

Welcome

Legal Guidelines

Safety Guidelines

Understanding your PCU Pt.1

Understanding your PCU Pt.2

Installation

First Start-Up, Battery Type Select

Commands, Remote Pt.1

Remote Pt.2

Troubleshooting, Maintenance

Cable Recommendations

Dimensions / Small

Dimensions / Large

Dimensions / Remote

Notes

Introduction

Pg.2 01

Pg.3 02

Safety and Legal

Pg.4 01

Pg.5 02

Product Information

Pg.6 01

Pg.7 02

Pg.8 03

Pg.9 04

Pg.10 05

Pg.11 06

Pg.12 07

Miscellaneous

Pg.13 01

Pg.14 02

Pg.15 03

Pg.16 04

Pg.17 05

INTRODUCTION TABLE OF CONTENTS

INTRODUCTION

Contents page

Welcome

Legal Guidelines

Safety Guidelines

Installation

Functions and Features

Integrated Protections

Troubleshooting

Specifications and Recommendations

Introduction

01

02

Safety and Legal

01

02

Product Information

01

02

03

04

05

INTRODUCTION TABLE OF CONTENTS

INTRODUCTION 01

STERLING

POWER

PCU Top Functions:

1) 11 preprogrammed battery curves including LiFePO4.

2) 1 custom set, can be set from charger, no need for computer.

3) 2 x digital meters for current and voltage measurement.

4) 1 x power meter to show what reserve power left on the unit.

5) Active PFC, up to 0.99 pf, ensuring efficient power conversion

6) Synchronized rectification output as opposed to diode output (+10% efficiency)

7) High voltage de-sulphation cycle.

8) New, low activity, standby mode to increase battery life.

9) Battery health program.

10) Multiple speed fan control to reduce unnecessary fan noise.

11) Primary (processor digitally controlled) and an emergency backup.

12) 32 LED information panel.

13) Internal scan and systems check.

14) Remote control.

15) Small footprint and light weight.

16) Include battery temperature sensor.

17) USA CEC listed (default setting is on, CEC can be turned off). CEC

regulation stipulates that the charger is only on when necessary. This

reduces AC power consumption and lowers operational costs, while

maintaining healthy batteries. Refer to sterling-power.com/pages/cec

for the most up to date information regarding CEC modes + functionality.

18) % power reduction to allow unit to work with restricted input power.

19) Conforms to A.B.Y.C. drip test. Waterproof when water is dropped directly on

to the top of the unit ( +/ - 17 degrees ) if installed correctly (vertically).

20) The printed circuit boards are conformal coated for high humidity operations.

Consider

Grey

Divider

Charge Current

60.0

60.3

61.0

A

Operation Voltage Range

90

270

Vac

Operation Frequency Range

45

65

Hz

AC Low Voltage Protection

80

90

Vac

PFC (230V Input)

95

%

Efficiency (at Flooded)(230Vac)

88.5

%

Full Load Input Current (110/230V)

10.1/4.8

A

Line Regulation at Full Load

2

%

Load Regulation (10%-100% Load)

3

%

Ripple & Noise (r.m.s)

50

mV

Current Drain

5

mA

Ground Leakage Current

0.75

mA

Volt meter Accuracy

±(1.5%+2digits)

Amp meter Accuracy (0-10A)

±(1%+5digits)

Amp meter Accuracy (10-60A)

±(1%+2digits)

High DC Voltage Protection

16.2

17.0

V

Withstanding Test (Input v.s Output) (15mA)

3000

VAC

Withstanding Test (Input v.s Housing) (10mA)

1500

VAC

Insulation Resistance (500Vdc)

100

MΩ

STERLING

POWER

01

02

50% Black for subtitles + highlight

90% Black for body

RAL 3003 R134 G26 B34

Text, by and large, is size 9.

INTRODUCTION WELCOME

Contents page

Welcome

Legal Guidelines

Safety Guidelines

Installation

Functions and Features

Integrated Protections

Troubleshooting

Specifications and Recommendations

Introduction

01

02

Safety and Legal

01

02

Product Information

01

02

03

04

05

INTRODUCTION TABLE OF CONTENTS

INTRODUCTION 01

STERLING

POWER

Welcome to the Sterling Power Products Owners Handbook for the product series ‘PCU’, shorthand for ‘Pro

Charge Ultra’. This is our flagship global input AC/DC battery charger, with many variants available.

Please take your time to read and fully understand the contents of this Handbook. These guidelines are

developed with your safety and the products performance in mind and failure to follow or understand these

guidelines may lead to voiding the product warranty or even leading to damage or injury for you or your setup.

If you are unsure of any step or guideline then please consider reaching out to Sterling via our web contact form

or our phone service and we shall offer our support.

Thank you for joining the Sterling family and we hope to serve your travels well.

Throughout this manual we will make reference to this PCU as a 12V unit. We have a variety of PCU voltage

variants in the 24V, 32V, 36V, and 48V regions. Please ensure your charger is correct for your battery voltage,

and please adjust our readings accordingly. For example, if we talk about 14.4V on our 12V unit, the equivalent

at 24V will be 28.8V. The equivalent at 36V will be 43.2V. The equivalent at 48V will be 57.6V.

This manual must be read throughout before installing this electronic device. Do not lose these instructions -

keep them safe. The most up to date instructions can be found on the Sterling Power website. Please refer to the

latest instruction manual before contacting Sterling. At Sterling, we endeavour to include all of the product

information that we can think of into the manual.

Installation of the electronic device must be carried out by qualified and trained personnel only. The personnel

must be familiar with the locally accepted guidelines and safety measures.

Your safety is Sterling’s top priority. Please follow all precautions to keep yourself safe. If you believe your unit

requires repair then please contact Sterling or your distributor. Do not attempt to service the unit yourself.

Using a PCU1260 as flagship reference, all other variants pro-rata:

Welcome

12V, 24V, 36V, 48V

Using this Handbook

Safety

Specifications

INTRODUCTION

12V / 60A model, all other units pro rata.

Input voltage range 90-270V 45-65 Hz

AC Low Voltage Protection <85V +/-5V

Power Factor at 230V 0.976

Efficiency 90.4%

Full load current (110/230V) 9.8/4.6A

Total Harmonic Distortion 2.4% voltage

Total Harmonic Distortion 2.4% current

Load Regulation (10%-100%) 3%

Ripple noise (R.M.S.) 50mV

Ground leakage 0.5 mA

Current Drain 5 mA

High DC Voltage Protection 16.2-17V

Generator/ mains power (watts), Continuous

12V 20A approx 350W

12V 30A approx 500W

12V 40A approx 600W

12V 50A approx 750W

12V 60A approx 900W

24V 20A approx 600W

24V 30A approx 900W

32V 20A approx 900W

36V 20A approx 900W

48V 15A approx 900W

Requested power may be up to double for startup.

Voltmeter accuracy +/- 1%

Ammeter accuracy +/- 1%

STERLING

POWER

02

03

SAFETY AND LEGAL

Your 100 % satisfaction is our goal. We realise that every customer and circumstance is unique. If you have a

problem, question, or comment please do not hesitate to contact us. We welcome you to contact us even after

the warranty and return time has passed.

Product Warranty:

Each product manufactured by Sterling Power comes with at least a 2 year limited factory warranty. Certain

Products have a warranty period of time greater than 2 years. Each product is guaranteed against defects in

material or workmanship from the date of purchase. At our discretion, we will repair or replace free of charge any

defects in material or workmanship that fall within the warranty period of the Sterling Power product. The

following conditions do apply:

- The original receipt or proof of purchase must be submitted to claim warranty. If proof cannot be located a

warranty is calculated from the date of manufacture.

- Our warranty covers manufacture and material defects. Damages caused by abuse, neglect, accident,

alterations and improper use are not covered under our warranty.

- Warranty is null and void if damage occurs due to negligent repairs.

- Customer is responsible for inbound shipping costs of the product to Sterling Power either in the USA or

England.

- Sterling Power will ship the repaired or warranty replacement product back to the purchaser at their cost.

If your order was damaged in transit or arrives with an error, please contact us ASAP so we may take care of the

matter promptly and at no expense to you. This only applies for shipping which was undertaken by our company

and does not apply for shipping organised by yourself. Please do not throw out any shipping or packaging

materials. All returns for any reason will require a proof of purchase with the purchase date. The proof of

purchase must be sent with the returned shipment. If you have no proof of purchase call the vendor who supplied

you and acquire the appropriate documentation.

To make a claim under warranty, call our customer care check telephone numbers on www.sterling-power.com

or www.sterling-power-usa.com. We will make the best effort to repair or replace the product, if found to be

defective within the terms of the warranty. Sterling Power will ship the repaired or warranty replacement product

back to the purchaser, if purchased from us.

Please review the documentation included with your purchase. Our warranty only covers orders purchased from

Sterling Power. We cannot accept warranty claims from any other Sterling Power distributor. Purchase or other

acceptance of the product shall be on the condition and agreement that Sterling Power USA LLC and Sterling

Power LTD shall not be liable for incidental or consequential damages of any kind. Some states may not allow

the exclusion or limitation of consequential damages, so, the above limitations may not apply to you.

Additionally, Sterling Power USA and Sterling Power LTD neither assumes nor authorizes any person for any

obligation or liability in connection with the sale of this product. This warranty is made in lieu of all other

obligations or liabilities. This warranty provides you specific legal rights and you may also have other rights,

which vary from state to state. This warranty is in lieu of all other, expressed or implied.

Copyright © 2021 Sterling Power. All rights reserved.

Reproduction, transfer, distribution or storage of part or all of the contents of this document is strictly prohibited. If

you wish to use all of this document, or excerpts from it, Sterling Power must be contacted.

Sterling Power can not accept liability for:

Ÿconsequential damage due to use of this device

Ÿpossible errors in the manuals and the results thereof

Please do not modify the device unless you have been instructed to do so by Sterling Power directly. Product

modification shall be done at Sterling, when needed. Warranty shall be voided if personal attempts are made to

modify the device, without Sterling’s approval.

Warranty and Terms

Copyright and Plagiarism

Liability

Device Modification

LEGAL GUIDELINES

SAFETY AND LEGAL 01

50% Black for subtitles + highlight

90% Black for body

RAL 3003 R134 G26 B34

Text, by and large, is size 9.

SAFETY AND LEGAL

Your 100 % satisfaction is our goal. We realise that every customer and circumstance is unique. If you have a

problem, question, or comment please do not hesitate to contact us. We welcome you to contact us even after

the warranty and return time has passed.

Each product manufactured by Sterling Power comes with at least a 2 year limited factory warranty. Certain

Products have a warranty period of time greater than 2 years. Each product is guaranteed against defects in

material or workmanship from the date of purchase. At our discretion, we will repair or replace free of charge any

defects in material or workmanship that fall within the warranty period of the Sterling Power product. The

following conditions do apply:

- The original receipt or proof of purchase must be submitted to claim warranty. If proof cannot be located a

warranty is calculated from the date of manufacture.

- Our warranty covers manufacture and material defects. Damages caused by abuse, neglect, accident,

alterations and improper use are not covered under our warranty.

- Warranty is null and void if damage occurs due to negligent repairs.

- Customer is responsible for inbound shipping costs of the product to Sterling Power either in the USA or

England.

- Sterling Power will ship the repaired or warranty replacement product back to the purchaser at their cost.

If your order was damaged in transit or arrives with an error, please contact us ASAP so we may take care of the

matter promptly and at no expense to you. This only applies for shipping which was undertaken by our company

and does not apply for shipping organised by yourself. Please do not throw out any shipping or packaging

materials. All returns for any reason will require a proof of purchase with the purchase date. The proof of

purchase must be sent with the returned shipment. If you have no proof of purchase call the vendor who supplied

you and acquire the appropriate documentation.

To make a claim under warranty, call our customer care check telephone numbers on www.sterling-power.com

or www.sterling-power-usa.com. We will make the best effort to repair or replace the product, if found to be

defective within the terms of the warranty. Sterling Power will ship the repaired or warranty replacement product

back to the purchaser, if purchased from us.

Please review the documentation included with your purchase. Our warranty only covers orders purchased from

Sterling Power. We cannot accept warranty claims from any other Sterling Power distributor. Purchase or other

acceptance of the product shall be on the condition and agreement that Sterling Power USA LLC and Sterling

Power LTD shall not be liable for incidental or consequential damages of any kind. Some states may not allow

the exclusion or limitation of consequential damages, so, the above limitations may not apply to you.

Additionally, Sterling Power USA and Sterling Power LTD neither assumes nor authorizes any person for any

obligation or liability in connection with the sale of this product. This warranty is made in lieu of all other

obligations or liabilities. This warranty provides you specific legal rights and you may also have other rights,

which vary from state to state. This warranty is in lieu of all other, expressed or implied.

Copyright © 2021 Sterling Power. All rights reserved.

Reproduction, transfer, distribution or storage of part or all of the contents of this document is strictly prohibited. If

you wish to use all of this document, or excerpts from it, Sterling Power must be contacted.

Sterling Power can not accept liability for:

Ÿconsequential damage due to use of this device

Ÿpossible errors in the manuals and the results thereof

Please do not modify the device unless you have been instructed to do so by Sterling Power directly. Product

modification shall be done at Sterling when needed. Warranty shall be voided if personal attempts are made to

modify the device without Sterling’s approval.

Warranty and Terms

Copyright and Plagiarism

Liability

Device Modification

LEGAL GUIDELINES

SAFETY AND LEGAL

STERLING

POWER

01

04

SAFETY AND LEGAL

Your Sterling Power product should only be utilised for it’s designated purpose. Use the Sterling Power Pro

Charge Ultra ONLY :

For AC to DC power conversion

With fuses protecting both the AC/DC cables

In a well ventilated, dry, dust-free and condensation free environment

When the Owners Handbook has been read and wholly understood

Ensure that the mains supply and battery leads are disconnected before transporting or moving the unit. No

liability can be accepted for damage in transit once equipment has been unpackaged. Store the product in a dry

environment, between –20°C to 60°C.

Refer to the battery manufacturer's manual for information on transportation, stowage, charge rates, recharging

and battery disposal for your battery care.

The device must be switched off during maintenance and all cables removed from the direct feed to or from the

unit. It must also be protected against unexpected switching off. Remove battery connections and ensure unit is

off. If repair is required, only use original parts. Unauthorised attempts to repair Sterling units will lead to the

warranty being voided. Only someone with adequate understanding of electronics and the unit itself should

attempt a repair.

Ensure your connections are good and clean and aim to protect your unit from humidity and water ingress.

Electrical appliances can be heavy. Please do not lift heavy units unassisted.

Ensure that your product is correct for your intent. 110V/240V, 12V/24V/48V. Incorrect use can lead to damage.

Orientation is not critical to unit function, however may affect water ingress rating.

Isolate AC wires during install.

Connect AC to a Residual Circuit Breaker (RCD) and current overload trips.

Sterling recommend Multi Core Tri Rated AC cable

Install device in a well ventilated space for cooling purposes.

Do not expose the unit to snow, rain, water, spray, condensation, pollution etc, unless it is a waterproof unit. If it is

a waterproof unit, only expose it to situations it is correctly rated for.

Do not cover or obstruct the ventilation.

Device connects to common negative. Common negatives must be earthed.

In case of fire, use fire extinguisher equipment suitable for electrical fires.

Avoid all possibilities of reverse polarity or short circuiting.

Check cabling and connections frequently and ensure the connections are sufficient.

Always protect DC and AC cabling with the appropriate fusing.

Ensure the unit is adequately and safely mounted to prevent displacement and damage.

Always use a professional to install electrical products.

Ensure the product is correctly set up for your battery.

Keep out of reach of children

All electrical appliances carry the risk of electrical shock. This equipment is designed to be used in combination

with a permanent energy source (the battery). Always turn the AC power off and disconnect the battery before

performing any maintenance or inspection.

Do NOT remove the panelling to inspect the internals unless expressly told to by Sterling. This is not a product

designed to be user-serviced.

Do NOT use the device in situations where there is danger of gas / dust / vapour explosions, or around potentially

flammable produce.

Product Guidelines

Transport and Storage

General Maintenance

Safety Precautions

WARNING :

SAFETY GUIDELINES

SAFETY AND LEGAL

STERLING

POWER

02

05

The top vent on the PCU is the hot air exhaust. The PCU is a self-cooling product with a powerful fan that keeps

the internal electronics cool and safe. The flow of air enters through by the red end-cap and is exhausted out of

the top vent.

The PCU has four screw mount positions. Use these to mount your unit securely to a stable support.

Section three has three LEDs. AC Power, Auto Temp Control and Active PFC.

ŸThe AC power LED shows when AC power is connected. The LED will be illuminated solidly when AC is live

and the unit is ONLINE. The LED will flash intermittently (One second ON, one second OFF) if AC is live but

the unit is OFF. Push SETUP + Enter to turn the unit ONLINE again

ŸThe Auto Temp Control LED will be illuminated if the battery temperature sensor is installed and correctly

fitted to the PCU. If this is not illuminated, either your battery temperature sensor is not fitted or it is not fitted

correctly. If no sensor is detected the unit will default to a 20 deg.C charge curve.

ŸThe active PFC LED will be illuminated when Power Factor Correction is enabled.

UNDERSTANDING YOUR PCU, PT.1

Pro Charge Ultra Diagram

1.

2.

3.

GLOBAL AC Input & Active Power Factor Correction

OK

CHARGER MODE

AC Power

Auto Temp Control

Active PFC

Multi Speed Fan

Volts Amps

AUTO CONSERVATION MODES

Fault

Absorption

Stand-by Battery Health Program

Fast Charge Float

DC Output Fault

DC Low Voltage

DC High Voltage Trip

High Charger temp trip

Check Fan

De-sulphation

1 2 3

SETUP

ENTER

CHARGE INFORMATION

Open lead acid

Sealed lead acid

A.G.M

GEL

Calcium / Custom

Lithium (LiFePO4)*

System self test Battery Type

Charger Output

0% 100%

Progressive DIGITAL software control Charger / Powerpack

Preset 1

Preset 2

Sterling Power

1) Ammeter, shows the total current being

produced by the charger.

2) Voltmeter, showing the average voltage being

produced by the charger.

3) Power meter, shows the % power being produced

by the unit and the remaining power available.

4) AC power, shows the AC power is connected and

the product is live. LED flashes if power is available

but the unit is switched off (see on/off later) push

buttons. Setup and up arrow for 5 secs to activate.

5) Auto temp control, shows the battery temp sensor

is connected and operational. If sensor not

connected then the unit will default to a 20 deg C / 69

F charge curve.

6) Shows that the active PFC (Power Factor

Correction is on).

7) Fan speed control, varies depending on temp, 3

speeds.

8) Standby, charger power system power

requirement very low, unit on low float voltage to

prolong battery life.

9) Fast charge unit on constant current mode.

10) OK, unit operating within normal parameters

11) Fault, fatal fault, needs to be returned for repair.

12) Battery type selector, shows which battery

charger curve in operation (adjustable).

13) Buttons to select charge options (see later in

instructions) also used to switch unit off or on in

conjunction with the setup button (see 14).

Off select button press down button for 5 seconds.

On select button press up button for 5 seconds.

14) Button to enter selections. Also, use to switch

unit on/off in conjunction with the up or down button.

15) Battery health program, unit doing a 21 day de-

sulphation cycle.

16) , charger on initial charge cycle.Absorption

17) De-sulphation cycle operational. For safety

reasons only available when on open lead acid

battery type.

18) Float, unit on float charge or power pack mode,

main charge complete.

19) DC output service, output working correctly.

20) DC output low voltage warning, either batteries

are very low / more power is being taken than the

charger can supply / or the charger is defective.

21) High voltage trip, the unit is defective and

tripped itself, or a high back DC voltage has been

detected, like a wind generator reg gone defective.

22) High charger temp, if the unit is positioned in too

hot an environment and over heated, or the fans

have failed.

23) Check fans, if LED on, fans are defective.

24) Case screws to access the wiring of the product.

Battery type High Charge V Float Charge V Maintenance V High Charge V Float Charge V Maintenance V

Flooded/Open Lead acid 14.8 13.6 12.8 14.7 13.4 12.8

Sealed Lead acid 14.4 13.6 12.8 14.6 13.4 12.8

AGM Lead acid 14.3 13.3 13.0 14.6 13.6 13.0

GEL Lead acid 14.0 13.7 13.2 14.4 13.8 13.2

LiFePO4-Lithium 14.2 13.8 13.2 14.4 13.8 13.2

Calcium / Custom 15.1 13.6 13.2 Your choice see custom setup in instructions

Equalization / Desulph 15.5 15.5 15.5 15.5

Preset 1 Profiles Preset 2 Profilesx 2 all voltages for 24V unit x 2.66 for 32 V x 3 for 36V x 4 for 48V

1

**Label simplified for clarity,

**Red endcap removed for demonstration.

2

3

5

7

8

9

11

6

4

10

GLOBAL AC Input & Active Power Factor Correction

OK

CHARGER MODE

AC Power

Auto Temp Control

Active PFC

Multi Speed Fan

Volts Amps

AUTO CONSERVATION MODES

Fault

Absorption

Stand-by Battery Health Program

Fast Charge Float

DC Output Fault

DC Low Voltage

DC High Voltage Trip

High Charger temp trip

Check Fan

De-sulphation

1 2 3

SETUP

ENTER

CHARGE INFORMATION

Open lead acid

Sealed lead acid

A.G.M

GEL

Calcium / Custom

Lithium (LiFePO4)*

System self test Battery Type

Charger Output

0% 100%

Progressive DIGITAL software control Charger / Powerpack

High Voltage AC Low Voltage DCWARNING

www.sterling-power-usa.com

Preset 1

Preset 2

www.sterling-power.com

*Lithium must be used in conjunction

with a lithium balancing system.

Safety Certified by: TUV

Built and tested to

UL 1236 SB

CSA C22.2-107.2

RoHS

compliant

CEC

approved

Pro Charge ULTRA

Sterling Power

Warm air

out

Cooling

Air flow

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

Quick LED feature guide

Lithium battery Use

this charger must not be used to

charge lithium battery cells by itself

( ie lithium cells only with no BMS ) .

You cannot charge lithium cells on

their own. You must have a

B M Sattery anagement ystem

attached to built into the or

batteries for safety.

No Battery charger can act as a BMS,

that is an independent operation

for Lithium batteries .

Figure 3.01A

RATING

RATING

LNG

-

+++

12 13 14 15 16 17

PRODUCT INFORMATION

PRODUCT INFORMATION

STERLING

POWER

01

06

To case ground

UNDERSTANDING YOUR PCU, PT.2

Section 4 is comprised of two screens. The ‘Volts’ screen will display the average voltage being produced by the

charger, as felt on the output terminals. The ‘Amps’ screen will display the total current being produced by the

charger.

This is the grounding terminal and connects to the rear grounding panel of the PCU. This should be connected to

your vehicles chassis to maximise safety.

Section 6 covers the ‘Multi Speed Fan’ and the ‘Charger Output’ LEDs.

ŸMulti Speed Fan LEDs will display to communicate the fan speed control. This will vary depending on

temperature and has three speeds.

ŸCharger Output LEDs will display the percentage power output of the PCU. If it is displaying at 50%, the unit

is only outputting 50% of its rating. At 100% it is outputting 100% of its rating.

Section 7 covers the Auto Conservation Modes and Charge Modes.

ŸThe Stand-By LED will be illuminated when the unit has AC power input, but is not needed to charge any

batteries. This may happen due to no batteries being connected for a long period of time or all of the batteries

attached are sufficiently full and have been on float for long periods of time.

ŸThe Battery Health Program LED will illuminate if the charger is in Open Lead Acid maintenance, and will

cause it to run a desulphation cycle once every 21 days.

ŸThe Fast Charge, Absorption, Float and De-sulphation LEDs will illuminate to display which stage of the

charging cycle the PCU is presently in. These tell you what your charger is presently attempting to do.

Section 8 covers the Fault LED section. These LEDs will illuminate to display when a fault is ongoing with your

unit, and what the likely culprit will be. Please consult the troubleshooting section of this handbook, or consider

contacting Sterling support.

Section 9 covers the Setup/Enter, Up arrow and Down arrow buttons. This is the main user interface and these

buttons are how you will control and customise your PCU.

Section 10 highlights the available battery types, and the battery type presently selected. This is useful for

choosing battery types and to know what charge profile you are presently using. The battery types translate to

the following voltages.

Section 11 indicates the PCU endcap, typically red in colour, or grey for older units. It has been ‘removed’ in this

demonstration to help with clarity and to show you what is underneath.

This area is for the 3 core AC connection. Left to right is for Live, Neutral and Ground/Earth. Accessible by

removing the white cover. Only connect AC wires when the AC connection is isolated. When cables are

connected, replace the white cover.

The black port is for the Pro Charge Ultra Remote, product code : PCUR.

The grey port is for the TEMP1 temperature sensor. This allows the PCU to give you your battery temperature

readings. It also causes the PCU output voltage to vary by 0.018V per degree Celsius either side of 20C. If your

batteries are warmer, we decrease the charge voltage. If they are colder, we increase the voltage. This connects

to the negative battery stud. This will also cause the PCU to trip to OFF if the battery terminal reaches 50degC.

This area is for the positive line DC connections.

This is the negative line DC connection.

These fuses are for the negative line of the PCU. Inspect these if the PCU is unresponsive.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

1) Ammeter, shows the total current being

produced by the charger.

2) Voltmeter, showing the average voltage being

produced by the charger.

3) Power meter, shows the % power being produced

by the unit and the remaining power available.

4) AC power, shows the AC power is connected and

the product is live. LED flashes if power is available

but the unit is switched off (see on/off later) push

buttons. Setup and up arrow for 5 secs to activate.

5) Auto temp control, shows the battery temp sensor

is connected and operational. If sensor not

connected then the unit will default to a 20 deg C / 69

F charge curve.

6) Shows that the active PFC (Power Factor

Correction is on).

7) Fan speed control, varies depending on temp, 3

speeds.

8) Standby, charger power system power

requirement very low, unit on low float voltage to

prolong battery life.

9) Fast charge unit on constant current mode.

10) OK, unit operating within normal parameters

11) Fault, fatal fault, needs to be returned for repair.

12) Battery type selector, shows which battery

charger curve in operation (adjustable).

13) Buttons to select charge options (see later in

instructions) also used to switch unit off or on in

conjunction with the setup button (see 14).

Off select button press down button for 5 seconds.

On select button press up button for 5 seconds.

14) Button to enter selections. Also, use to switch

unit on/off in conjunction with the up or down button.

15) Battery health program, unit doing a 21 day de-

sulphation cycle.

16) , charger on initial charge cycle.Absorption

17) De-sulphation cycle operational. For safety

reasons only available when on open lead acid

battery type.

18) Float, unit on float charge or power pack mode,

main charge complete.

19) DC output service, output working correctly.

20) DC output low voltage warning, either batteries

are very low / more power is being taken than the

charger can supply / or the charger is defective.

21) High voltage trip, the unit is defective and

tripped itself, or a high back DC voltage has been

detected, like a wind generator reg gone defective.

22) High charger temp, if the unit is positioned in too

hot an environment and over heated, or the fans

have failed.

23) Check fans, if LED on, fans are defective.

24) Case screws to access the wiring of the product.

Battery type High Charge V Float Charge V Maintenance V High Charge V Float Charge V Maintenance V

Flooded/Open Lead acid 14.8 13.6 12.8 14.7 13.4 12.8

Sealed Lead acid 14.4 13.6 12.8 14.6 13.4 12.8

AGM Lead acid 14.3 13.3 13.0 14.6 13.6 13.0

GEL Lead acid 14.0 13.7 13.2 14.4 13.8 13.2

LiFePO4-Lithium 14.2 13.8 13.2 14.4 13.8 13.2

Calcium / Custom 15.1 13.6 13.2 Your choice see custom setup in instructions

Equalization / Desulph 15.5 15.5 15.5 15.5

Preset 1 Profiles Preset 2 Profilesx 2 all voltages for 24V unit x 2.66 for 32 V x 3 for 36V x 4 for 48V

GLOBAL AC Input & Active Power Factor Correction

OK

CHARGER MODE

AC Power

Auto Temp Control

Active PFC

Multi Speed Fan

Volts Amps

AUTO CONSERVATION MODES

Fault

Absorption

Stand-by Battery Health Program

Fast Charge Float

DC Output Fault

DC Low Voltage

DC High Voltage Trip

High Charger temp trip

Check Fan

De-sulphation

1 2 3

SETUP

ENTER

CHARGE INFORMATION

Open lead acid

Sealed lead acid

A.G.M

GEL

Calcium / Custom

Lithium (LiFePO4)*

System self test Battery Type

Charger Output

0% 100%

Progressive DIGITAL software control Charger / Powerpack

High Voltage AC Low Voltage DCWARNING

www.sterling-power-usa.com

Preset 1

Preset 2

www.sterling-power.com

*Lithium must be used in conjunction

with a lithium balancing system.

Safety Certified by: TUV

Built and tested to

UL 1236 SB

CSA C22.2-107.2

RoHS

compliant

CEC

approved

Pro Charge ULTRA

Sterling Power

Warm air

out

Cooling

Air flow

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

Quick LED feature guide

Lithium battery Use

this charger must not be used to

charge lithium battery cells by itself

( ie lithium cells only with no BMS ) .

You cannot charge lithium cells on

their own. You must have a

B M Sattery anagement ystem

attached to built into the or

batteries for safety.

No Battery charger can act as a BMS,

that is an independent operation

for Lithium batteries .

PRODUCT INFORMATION

PRODUCT INFORMATION

STERLING

POWER

02

07

Battery type High Charge V Float Charge V Maintenance V High Charge V Float Charge V Maintenance V

Flooded/Open Lead acid 14.8 13.6 12.8 14.7 13.4 12.8

Sealed Lead acid 14.4 13.6 12.8 14.6 13.4 12.8

AGM Lead acid 14.3 13.3 13.0 14.6 13.6 13.0

GEL Lead acid 14.0 13.7 13.2 14.4 13.8 13.2

LiFePO4-Lithium 13.8 13.8 13.8 14.6 14.6 14.6

Calcium / Custom 15.1 13.6 13.2 CUSTOM

Equalization / Desulph 15.5 15.5 15.5 15.5

Preset 1 Profiles Preset 2 Profilesx 2 all voltages for 24V unit x 2.66 for 32 V x 3 for 36V x 4 for 48V

PRODUCT INFORMATION

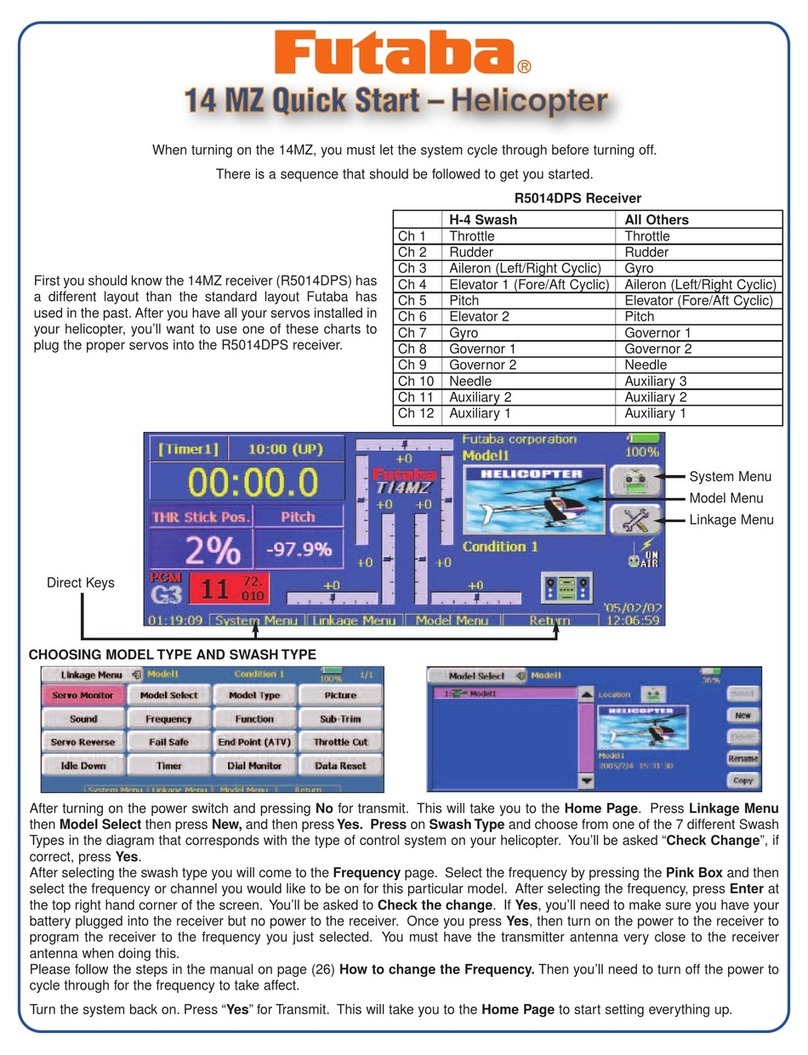

All electrical installations should be carried out by a professional electrician. Electricity does have the potential to

kill you. Ensure your input and output voltage needs are correct for the model you have before continuing.

Sterling do not provide, by default, the cable necessary for your installation. We are of the belief that every install

is unique to the client and as such we cannot presume. Ensure that your cable thickness is sufficient and safe for

the current expected to move through it and ensure that you fuse your cable, to the rating of the cable when

connecting to a battery.

This product has a high heat tolerance and can be installed in an engine room. The PCU should be installed

vertically for efficient convection air-flow and also to ensure that it keeps its drip-proof rating. The PCU can work

from any position or angle, however the main benefits arise from vertical installs.

This product is ignition protected and can be installed near the batteries, however, always ensure general safety

when in a work or power environment.

Ensure, when wall mounting, that the screws are correctly sized and sufficiently strong to support the unit.

Ensure the unit is firmly mounted and ensure the structure the unit is mounted to is strong enough to support the

unit for extended periods of time.

Ensure that, when mounted, you do not obstruct the cooling vents.

Ensure your AC input is isolated/disconnected until the installation is complete.

1) Unscrew the PCU endcap to get access to the cable connections and place aside.

2) Unscrew and remove the left hand side AC protection cover.

3) Using either ring or spade connections connect your AC cable. The live (Brown/Black) wire connects into the

left hand connection point, the neutral (Blue/White) connects to the middle connection point, the ground (Green)

connects to the right hand connection point.

4) Return the AC protection cover and screw it securely in to protect the connections and any future users from

accidental AC shock.

Red cable refers to positive (+) cable, black cable refers to negative (-) cable. Utilise 6mm ring terminals for these

connections on the bolt terminal PCUs, ferrules or neat copper for the screw terminals on the 10A variant.

1) Ensure the AC input to the PCU is OFF.

2) Connect the positive terminals from your batteries to their chosen positive output from the PCU using correctly

sized red cable.

3) Connect the common negative cable to the negative terminal of the PCU

4) Ensure all connections are firm, tight and secure. Loose connections can lead to a gradual build-up of heat

and cause damage to cables or the PCU itself. A buildup of heat at a connection point is indicative of a bad

connection or termination.

Installation Preface

Mounting

Installation Instructions

AC Install

DC Install

Figure 3.03A

INSTALLATION

PRODUCT INFORMATION

+

_

12V/24V/36V/48V bank +

_

12V/24V/36V/48V bank +

_

12V/24V/36V/48V bank

AC circuit breaker

DC fuse

20% larger

amperage than

charger output

DC fuse

20% larger

amperage than

charger output

DC fuse

20% larger

amperage than

charger output

RATING

RATING

LNG

-

+++

Battery type High Charge V Float Charge V Maintenance V High Charge V Float Charge V Maintenance V

Flooded/Open Lead acid 14.8 13.6 12.8 14.7 13.4 12.8

Sealed Lead acid 14.4 13.6 12.8 14.6 13.4 12.8

AGM Lead acid 14.3 13.3 13.0 14.6 13.6 13.0

GEL Lead acid 14.0 13.7 13.2 14.4 13.8 13.2

LiFePO4-Lithium 14.2 13.8 13.2 14.4 13.8 13.2

Calcium / Custom 15.1 13.6 13.2 Your choice see custom setup in instructions

Equalization / Desulph 15.5 15.5 15.5 15.5

Preset 1 Profiles Preset 2 Profilesx 2 all voltages for 24V unit x 2.66 for 32 V x 3 for 36V x 4 for 48V

STERLING

POWER

03

08

PRODUCT INFORMATION

Upon powering up the Pro Charge Ultra (PCU) for the first time the default settings to take note of are:

1) The PCU will be in the Californian Energy Commission compliant ‘bc’ mode and

2) The PCU battery type will be set to ‘Sealed Lead Acid’.

By default the PCU will be in ‘bc’ mode, battery charger mode. This mode is standard as it complies with the CEC

regulations on battery chargers and makes the PCU legal to be sold in California and other territories with similar

rulings. The ‘bc’ charge mode will only output a charge voltage when a 11V DC signal is detected at the terminals.

The bc charge mode also ensures that the unit goes to sleep if the batteries it is charging are full (float stage of

charging with very low, under 5A, current draws from the battery) for 72 hours, to preserve power. This should

lower electricity costs and ensure healthy long term care for your batteries.

The alternative is PS mode, power supply mode. Power supply mode has the output terminals consistently ‘live’,

turning the PCU into a power pack, even without having a battery bank connected. The charger will still maintain

its multi stage charge performance, even in PS mode (IE, Fast charge, absorption, float, etc).

To put the PCU into PS mode, turn the PCU on and, after displaying 888 on the displays to show that it has

completed its startup sequence correctly, the screens will display ‘bc’. Simply press the up or down arrow while

‘bc’ is shown and the screen should then show ‘PS’. Press setup/enter to confirm.

If the Sealed Lead Acid default charge profile is unsuitable for your batteries please consider changing the

charge profile to the closest recommended charge profile, or setting up your own custom charge profile.

Our charge profiles are solely averages based on research done at the time. Not all sealed lead acid batteries

will want our ‘Sealed’ profile. Not all AGM batteries will want our AGM profiles. Cross reference our available

profiles with your battery specification sheet and choose the most suitable.

Charging a battery at an incorrect voltage could cause damage or degradation to your system. If you are unsure,

please consult your battery manufacturer. If you are charging multiple battery banks that all have different

chemistries and recommended charge voltages, please charge all banks at the lowest common charge

voltages.

This is a lithium safe charger, HOWEVER, ensure that your lithium cells are protected by a battery management

system (BMS) either internally or externally.

To change the existing charge profile;

1) Press and hold the Setup/Enter button for 6 seconds before releasing the button.

2) The current battery type and the Voltage and Amperage displays will all flash. The Voltage screen is now

displaying the High Voltage (absorption voltage) for the chosen profile, the Amperage screen is showing the Low

Voltage (float voltage) for the chosen profile.

3) Using the up and down arrows, cycle through the available charge profiles until your target profile is selected.

4) To confirm this profile either press the Setup/Enter button or leave the device for 30 seconds.

In the instance that an existing battery type profile is unsuitable;

1) Follow the instructions above to choose a battery type and select the Custom option as your battery type.

2) The fast charge and absorption LEDs will flash to indicate the unit is in adjustment mode.

3) The left display will flash, and the right hand display will go blank. Press the up and down arrows to adjust the

displayed voltage on the left screen from 12.6V to 15.1V to choose your target high voltage/absorption voltage.

Press Setup/Enter to confirm.

4) The left display will then go blank and the right display will begin flashing. Press the up and down arrows to

adjust the displayed voltage on the right screen from 12.6V to 15.1V to choose your target low voltage/float

voltage. Press Setup/Enter to confirm.

First Start-Up

Charge Modes

bc Mode

PS Mode

Battery Types

Battery Type Select

Battery Type Profiles

Custom Battery Type

FIRST START-UP, BATTERY TYPE SELECT

PRODUCT INFORMATION

Remote page ->

SHAREV

SHAREV SHARE EV

SHAREV

Battery type High Charge V Float Charge V Maintenance V High Charge V Float Charge V Maintenance V

Flooded/Open Lead acid 14.8 13.6 12.8 14.7 13.4 12.8

Sealed Lead acid 14.4 13.6 12.8 14.6 13.4 12.8

AGM Lead acid 14.3 13.3 13.0 14.6 13.6 13.0

GEL Lead acid 14.0 13.7 13.2 14.4 13.8 13.2

LiFePO4-Lithium 13.8 13.8 13.8 14.6 14.6 14.6

Calcium / Custom 15.1 13.6 13.2 CUSTOM

Equalization / Desulph 15.5 15.5 15.5 15.5

Preset 1 Profiles Preset 2 Profilesx 2 all voltages for 24V unit x 2.66 for 32 V x 3 for 36V x 4 for 48V

STERLING

POWER

04

09

SHAREV

PRODUCT INFORMATION

WARNING, HIGH VOLTAGE

Desulphation/Equalisation can only be activated from the open lead acid battery type. Only use this mode if your

batteries are safe to be desulphated. Running this cycle on most battery types will cause serious damage.

1) While in the open lead acid battery type, hold Setup/Enter for five seconds and push the up/down arrows until

the ‘De-sulphation’ LED is flashing

2) Once the ‘De-sulphation’ LED is flashing, hold the up and down arrows together for 3 seconds.

3) The desulphation phase will begin and will last for 240 minutes. During this phase the batteries will be

charged at 15.5V. When the phase is complete it will return to the open lead acid battery type.

To adjust the output power of the PCU in increments of 25%;

1) Hold down the up and down arrow for >20 seconds,

2) The left hand display will show ‘PL’ for Power Level, and the right hand display will show 100, for 100%.

3) Press the up or down arrows to adjust this power level to your target, then press enter to confirm.

If no selection is made within 15 seconds, the PCU will default to 100% power.

To run the PCU through an auto-diagnosis;

1) Press and hold all face buttons simultaneously for ten seconds and then release (Setup/Enter, Up, Down)

2) The ‘System self test’ LED will flash intermittently until the test is complete.

3) ‘OK’ or fault LEDs will display. Cross reference with troubleshooting section if unit displays fault.

To return your PCU to factory default settings;

1) Enter the battery type select setting by holding down Setup/Enter for >6S

2) Press the down arrow all the way to the custom setting, and then press down once more. ‘FAC dEF’ will display

on the two screens for Factory Default.

3) Press Setup/Enter to confirm. The charger will then restart.

The PCUR is the PCU remote control, allowing greater access to information and superior control over the PCU

and its functions.

It is made up of four individual loose parts. 1x housing plate, 2x wing plates and 1x main remote.

It connects to the PCU via the ‘Remote’ port, utilising an Rj12 connector. Standard remote length of cable is 10M

and can be adjusted at the users discretion.

Commands for the PCUR follow on the next page.

Desulphation / Equalisation

Power Level Adjustment

Self-Test Sequence

Factory Reset

PCU Remote, PCUR

PCUR

COMMANDS, REMOTE PT.1

PRODUCT INFORMATION

Remote page ->

Pro Charge Ultra

Remote : PCUR

STERLING

POWER

05

10

PRODUCT INFORMATION

The following commands are exclusively for the PCU remote (PCUR);

If the PCU has valid AC input and is online, the PCUR should turn on as soon as it is connected to the PCU via the

remote lead. It will then display the Sterling Power website and the PCU product code it is connected to. It will

then display the Charger Status screen until changed further.

To toggle the back-light on and off, press the On/Off button for about one second.

To toggle the power of the PCU on and off, hold the On/Off button for >4 seconds. While ‘off’, the PCU will display

0.0 and 0.0, and the PCUR will display ‘Standby’.

To toggle the audible alarm on and off, press the ‘Alarm’ button for one second.

By pressing the Setup/Enter button you will enter ‘Screen Select’, which begins with the ‘Scrolling’ option.

Pressing the up or down arrows will allow you to cycle through these following screens. Press enter to confirm.

Automatically scrolls through all of the below screens, showing each screen for four seconds at a time.

Displays the charger product code.

Displays what charge mode the unit is in (Charge, Conditioning or Ready), the output voltage and the output

current.

Displays the currently chosen battery type.

Displays the time left to complete the ‘Absorption’ stage.

Displays the recorded run time for this charge session.

Displays the chosen power level (25%, 50%, 75%, 100%), and the expected max current/voltage for absorption.

With a battery temperature sensor fitted (product code TEMP1), displays the battery temperature.

Displays the PCU hardware temperature, in Fahrenheit and Celsius.

Displays the PCU transformer temperature, in Fahrenheit and Celsius.

Identifies faults, from ‘Over Voltage’, ‘Under Voltage’ or ‘Battery Over Temperature’.

Displays the Sterling Power website, www.Sterling-Power.com.

Displays the overall unit run-time.

Displays what software version is presently running on the unit.

If you wish to force the PCU into float mode, hold the down arrow for ten seconds. The charger will remain in float

mode until the PCU is restarted or until the battery voltage connected drops to 12.35V, for 12V batteries.

To adjust the power level of the PCU remotely,

1) Hold down both the up and down arrows for 15+ seconds

2) The remote will display the power level customisation screen. Press the up and down arrows to change the

output level displayed and then press the Setup/Enter key to confirm. If no decision is made within 15 seconds,

the PCU will return to 100% output.

3) Once confirmed, the remote will display the ‘Power Level’ screen from above, until changed.

To run a PCU Self Test from the remote, hold down the Setup, Up and Down keys for over five seconds and then

release. The PCUR will beep to signify the start of the test, and show the results in a few seconds.

To return the PCU to factory default settings, hold down the Alarm, Setup, Up and Down keys for over three

seconds and release. The remote will show a confirmation and the PCU will reset to factory default settings.

PCU Remote Commands

First Start-up

Backlight On/Off

PCU Output On/Off

Alarm On/Off

Screen Options

Scrolling

Charger Name

Charger Status

Bat Type Select

Time to Absorb

Run Time

Power Level

Bat Temperature

Charger Temp.

Transformer Temp.

Faults

Company Informat

Total Run Time

SoftwareRevision

Force to Float

Power Level Adjust

System Self Test Remote

PCU Factory Reset

REMOTE PT.2

PRODUCT INFORMATION

Remote page ->

STERLING

POWER

06

11

TROUBLESHOOTING, MAINTENANCE

PRODUCT INFORMATION

In the instance that your fault light is displaying, please cross reference the fault LED with the following list, and

hopefully the problem can be isolated and ideally solved.

This indicates a potential reverse polarity situation. Please check your DC fuses are intact and correctly

installed, and ensure that the positive (RED+) and negative (BLACK-) cables are correctly installed, particularly

the correct way around.

This indicates your DC system voltage is lower than the PCU requires in order to engage on BC mode. At 12V

the low voltage trip is 11V. At 24V it is 22V, and so on. Please charge your batteries to over 11V using another

charge source, or put the PCU into power supply mode. If your batteries refuse to hold charge, consider

replacing your batteries.

This indicates a high DC voltage on the output, independent from the PCU. This could be caused by a failed

alternator, solar panels, wind generators etc. A DC voltage above 16.2V (for 12V) is at risk of tripping this fault.

Please use a voltmeter and the process of gradually isolating your charge sources to isolate exactly what is

causing this high voltage output, and then please either remove this from your system, or repair it.

This indicates that the charger has shut down due to an over-temperature situation. This unit will conform and

operate comfortably at up to an ambient temperature of ~50degC. Operation at higher temperatures will still

occur, but at a reduced efficiency. Please ensure that the PCU cooling ventilation is unobstructed and that the

fan itself is running. If the fan is obstructed, please solve the obstruction. If the fan is not running, contact Sterling.

If the room is over 50degC please consider improving ventilation or cooling.

This implies a potential fan failure. Please ensure that the cooling fan is unobstructed. The fan should perform a

self test during the startup sequence. Persistent or recurring fan problems may indicate a servicing requirement.

This implies general faults, including a possibility that the internal DC fuse has blown. Please contact Sterling for

servicing options.

This LED implies that the PCU is scaling back performance due to the high internal or ambient temperature.

Thermal control. Please see ‘Charger High Temp Trip’ above for reference on how to improve this.

If the above tests do not lead to a solution, or your unit continues to display faults, please contact Sterling for a

review of your unit.

This unit is solid state software controlled and designed with longevity and performance in mind, it does not

require constant adjustment or attention - however - the following items should be checked in order to encourage

the greatest long term performance of the unit.

On startup, ensure the front panel shows no fault LEDs.

Occasionally and procedurally ensure that the fuses (DC fuses next to the negative terminal on the PCU, and

your own installed fuses) are intact, and check their condition regarding discolouration and corrosion.

On startup, the PCU cooling fan will run a self test. Ensure that it is not obstructed or impeded by debris, the

sound should be obvious if something is in the way.

Occasionally check for signs of liquids that may have been running down your unit. Water stains, streaks, oil etc.

If evidence of liquids are found, please find the leak and fix the leak or move the charger to a safer place away

from the source of the liquid.

Check the battery charger terminals and battery terminals for corrosion monthly, clean as required. Also ensure

that all connections are tight and sufficient, and that there are no signs of heat-buildup over time. Loose

connections lead to a heat buildup due to inefficiency of contact, and this can rapidly lead to damage or fire risks.

Ensure your batteries are maintained as according to your battery manufacturers directions.

Check your wires for any burning, chafing or movement monthly. Degraded wires can become a fire risk, or even

an electrical hazard.

During the charge process, please monitor the temperature of your batteries. They should not ever be noticeably

hotter than the surrounding ambient temperature (unless they are heated batteries). If the batteries are hot to the

touch, they need immediate investigation and attention. Ensure the batteries are being charged at a safe

voltage. If the charge voltage is safe, the batteries are likely defective. Never walk away from warm/hot batteries

until a solution has been found, as there is a major problem. Turn the charge sources OFF.

Troubleshooting

DC Output Fault : RED

DC Low Voltage : AMBER

DC High Voltage Trip : RED

Charger High Temp Trip :

AMBER

Check Fan : RED

Fault : RED

Auto Temp Control : RED

OTHER

Maintenance

Fault Check

Fuse Check

Fan Check

Water Check

Terminal Inspection

Battery Maintenance

Wire Inspection

Battery Temperature Check

PRODUCT INFORMATION

Remote page ->

Charger Fault ( Service ) Conditions

LED Label LED Colour Fault

Reverse Polarity Red Indicates a reverse polarity situation

Check DC Connections, ensure positive + (RED) and negative - (Black and

/ or Yellow) connections are attached accordingly , also check DC fuses,

DC Volts Low Amber DC system V is less than 11V (x2 for 24v)

Wait for battery system voltage to rise over 11.0V and, if not, check and

replace defective batteries.

DC Volts High Red Indicates a high DC voltage from an external

source such as a failed alternator or wind

generator

Using a voltmeter check the voltage at the charger then switch off engine

(stop alternator) then other charging sources to establish what is causing

the high voltage.

Charger High Temp Amber Charger has shut down due to High temp

Generally this indicates that the unit has been installed in an area of very

high ambient temperature. This unit is designed to be used in a engine room

up to 45-50 Deg C, the unit will operate in higher ambient temperatures but

will reduce it performance off the product, We recommend an ambient off no

more than 50 Deg C. The other possibility is that the internal fan may have

failed, please listen to ensure the fan is running as one would expect the fan

to be on max speed in this fault condition so if quiet this could be the problem.

Check Fan Red Fan Failure

Ensure that the cooling fan can move freely and that no debris is blocking the

fan movement, the fan should come on during the start up sequence to prove

it works, any persistent fan problems may require servicing.

Fault Red Indicates a fault

Possible internal DC fuse blown, Please contact Sterling for service options.

Auto Temp Control Red Flash High Ambient causing power reduction

to sustain output.

See charger high temperature above.

MAINTENANCE

This unit is solid state software controlled and requires no constant

adjustments or attention, however, the following items should be checked:

1) On start up ensure the panel shows no fault LEDs.

2) On start up check the conditions of the fuses and ensure there is no

discolouration or corrosion round the fuse, also, check that the breaker will

manually trip and reset.

3) On start up check the fans cooling flow is not impeded by debris, keep

the area round the unit clear of items and dirt.

4) On Start up check for any traces of water / other liquids running down the

front of the unit or any evidence of this (water stains).

5) Do not use the charger, find the leak and fix the leak or remount the

charger to a safer place away from the water source.

6) Check the battery charger terminals and the battery terminals for

corrosion monthly, clean as required.

7) As per battery manufacturers’ instructions check and top up the batteries

with distilled water, as required monthly. Do not use tap or bottled water as

this will destroy the batteries.

8) Check the wires for any burning or chaffing, monthly. This is where the

wires pass through bulkheads. Repair / replace as required.

9) When the charger is on, feel the temperature of the batteries, they should

not be noticeably hotter than the surrounding ambient temperature.

If the batteries are hot to the touch then they need major investigation,

check the charger voltage is within parameters. If it is then the batterys must

be checked as they are probably defective.

Never walk away from warm-hot batteries as there is a

major problem, switch the charger off.

STERLING

POWER

07

12

CABLE RECOMMENDATIONS

MISCELLANEOUS

When choosing DC cable we must be aware that voltage drop is far more significant in long runs than it is with AC

cable. Ensure you only use high quality fire retardant cable.

The closer you install the charger to your batteries, the better your performance. You will save money on cable

and also see significantly improved charge performance, as the PCU will be able to maintain the charge voltage

to a superior degree. Do not use solid cable or speaker wire.

Cable Recommendations

AC CABLE, 230V

AC CABLE, 110V

DC CABLE

DC CABLE, m TO mm2

DC CABLE, ft TO AWG

MISCELLANEOUS

Remote page ->

Charger Fault ( Service ) Conditions

LED Label LED Colour Fault

Reverse Polarity Red Indicates a reverse polarity situation

Check DC Connections, ensure positive + (RED) and negative - (Black and

/ or Yellow) connections are attached accordingly , also check DC fuses,

DC Volts Low Amber DC system V is less than 11V (x2 for 24v)

Wait for battery system voltage to rise over 11.0V and, if not, check and

replace defective batteries.

DC Volts High Red Indicates a high DC voltage from an external

source such as a failed alternator or wind

generator

Using a voltmeter check the voltage at the charger then switch off engine

(stop alternator) then other charging sources to establish what is causing

the high voltage.

Charger High Temp Amber Charger has shut down due to High temp

Generally this indicates that the unit has been installed in an area of very

high ambient temperature. This unit is designed to be used in a engine room

up to 45-50 Deg C, the unit will operate in higher ambient temperatures but

will reduce it performance off the product, We recommend an ambient off no

more than 50 Deg C. The other possibility is that the internal fan may have

failed, please listen to ensure the fan is running as one would expect the fan

to be on max speed in this fault condition so if quiet this could be the problem.

Check Fan Red Fan Failure

Ensure that the cooling fan can move freely and that no debris is blocking the

fan movement, the fan should come on during the start up sequence to prove

it works, any persistent fan problems may require servicing.

Fault Red Indicates a fault

Possible internal DC fuse blown, Please contact Sterling for service options.

Auto Temp Control Red Flash High Ambient causing power reduction

to sustain output.

See charger high temperature above.

MAINTENANCE

This unit is solid state software controlled and requires no constant

adjustments or attention, however, the following items should be checked:

1) On start up ensure the panel shows no fault LEDs.

2) On start up check the conditions of the fuses and ensure there is no

discolouration or corrosion round the fuse, also, check that the breaker will

manually trip and reset.

3) On start up check the fans cooling flow is not impeded by debris, keep

the area round the unit clear of items and dirt.

4) On Start up check for any traces of water / other liquids running down the

front of the unit or any evidence of this (water stains).

5) Do not use the charger, find the leak and fix the leak or remount the

charger to a safer place away from the water source.

6) Check the battery charger terminals and the battery terminals for

corrosion monthly, clean as required.

7) As per battery manufacturers’ instructions check and top up the batteries

with distilled water, as required monthly. Do not use tap or bottled water as

this will destroy the batteries.

8) Check the wires for any burning or chaffing, monthly. This is where the

wires pass through bulkheads. Repair / replace as required.

9) When the charger is on, feel the temperature of the batteries, they should

not be noticeably hotter than the surrounding ambient temperature.

If the batteries are hot to the touch then they need major investigation,

check the charger voltage is within parameters. If it is then the batterys must

be checked as they are probably defective.

Never walk away from warm-hot batteries as there is a

major problem, switch the charger off.

Battery type High Charge V Float Charge V Maintenance V High Charge V Float Charge V Maintenance V

Flooded/Open Lead acid 14.8 13.6 12.8 14.7 13.4 12.8

Sealed Lead acid 14.4 13.6 12.8 14.6 13.4 12.8

AGM Lead acid 14.3 13.3 13.0 14.6 13.6 13.0

GEL Lead acid 14.0 13.7 13.2 14.4 13.8 13.2

LiFePO4-Lithium 14.2 13.8 13.2 14.4 13.8 13.2

Calcium / Custom 15.1 13.6 13.2 Your choice see custom setup in instructions

Equalization / Desulph 15.5 15.5 15.5 15.5

Preset 1 Profiles Preset 2 Profilesx 2 all voltages for 24V unit x 2.66 for 32 V x 3 for 36V x 4 for 48V

DC installation (output from charger)

Choosing cable. unlike AC conductors, DC is very sensitive to voltage drop.

The longer the cable runs the larger the cable thickness needs to be. Ensure

only quality fire retardant cable is used.

Europe DC Charge cable size ( mm2 ) for cable length Fuse

Model 1m 2m 3m 4m 5m 6m

PCU1210 2.5 mm2 4 mm2 6 mm2 10 mm2 10 mm2 16 mm2 15A

PCU1220 4 mm2 10 mm2 16 mm2 16 mm2 25 mm2 25 mm2 30A

PCU1230 6 mm2 6 mm2 25 mm2 35 mm2 50 mm2 50 mm2 40A

PCU1240 10 mm2 16 mm2 25 mm2 35 mm2 50 mm2 50 mm2 50A

PCU1250 10 mm2 25 mm2 35 mm2 50 mm2 50 mm2 n/a 60A

PCU1260 16 mm2 25 mm2 50 mm2 50 mm2 n/a n/a 80A

PCU2420 4 mm2 10 mm2 16 mm2 16 mm2 25 mm2 25 mm2 30A

PCU2430 6 mm2 6 mm2 25 mm2 35 mm2 50 mm2 50 mm2 40A

PCU3620 4 mm2 10 mm2 16 mm2 16 mm2 25 mm2 25 mm2 30A

PCU4815 4 mm2 10 mm2 16 mm2 16 mm2 25 mm2 25 mm2 20A

USA DC Charge cable size ( AWG ) for cable length Fuse

Model 5 ft 10 ft 15 ft 20 ft 25 ft 30 ft

PCU1210 16 AWG 14 AWG 12 AWG 10 AWG 10 AWG 10 AWG 15A

PCU1220 14 AWG 10 AWG 10 AWG 8 AWG 6 AWG 6 AWG 30A

PCU1230 12 AWG 10 AWG 8 AWG 6 AWG 6 AWG 4 AWG 40A

PCU1240 10 AWG 8 AWG 6 AWG 6 AWG 4 AWG 4 AWG 50A

PCU1250 8 AWG 6 AWG 6 AWG 6 AWG 4 AWG 2 AWG 60A

PCU1260 8 AWG 6 AWG 4 AWG 4 AWG 2 AWG 2 AWG 80A

PCU2420 14 AWG 10 AWG 10 AWG 8 AWG 6 AWG 6 AWG 30A

PCU2430 12 AWG 10 AWG 8 AWG 6 AWG 6 AWG 4 AWG 40A

PCU3620 14 AWG 10 AWG 10 AWG 8 AWG 6 AWG 6 AWG 30A

PCU4815 16 AWG 14 AWG 12 AWG 8 AWG 6 AWG 6 AWG 20A

USA AC cable size ( AGM ) for cable length up to 50ft

Model 110 volt fuse/breaker 230 volt fuse/breaker

PCU1210 3 core 16 AWG 6 A 3 core 18 AWG 4 A

PCU1220 3 core 16 AWG 8 A 3 core 18 AWG 6 A

PCU1230 3 core 14 AWG 11 A 3 core 16 AWG 7 A

PCU1240 3 core 14 AWG 14 A 3 core 16 AWG 7 A

PCU1250 3 core 12 AWG 16 A 3 core 14 AWG 8 A

PCU1260 3 core 12 AWG 16 A 3 core 14 AWG 8 A

PCU2420 3 core 14 AWG 14 A 3 core 16 AWG 7 A

PCU2430 3 core 12 AWG 16 A 3 core 12 AWG 8 A

PCU3620 3 core 12 AWG 16 A 3 core 14 AWG 8 A

PCU4815 3 core 12 AWG 16 A 3 core 14 AWG 8 A

IMPORTANT

The closer to the batteries you fit the charger the better. Not only do you save

expensive cable you also get better performance from the charger. The cable

should be properly rated to 105 deg C fire resistant. Do not use solid cable or

speaker wire.

Europe AC cable size ( mm2 ) for cable length up to 15 m

Model 110 volt fuse/breaker 230 volt fuse/breaker

PCU1210 3 core 0.75 mm2 6 A 3 core 0.75 mm2 4 A

PCU1220 3 core 0.75 mm2 8 A 3 core 0.75 mm2 6 A

PCU1230 3 core 1.5 mm2 11 A 3 core 1.5 mm2 7 A

PCU1240 3 core 1.5 mm2 14 A 3 core 1.5 mm2 7 A

PCU1250 3 core 1.5 mm2 16 A 3 core 1.5 mm2 8 A

PCU1260 3 core 1.5 mm2 16 A 3 core 1.5 mm2 8 A

PCU2420 3 core 1.5 mm2 14 A 3 core 1.5 mm2 7 A

PCU2430 3 core 1.5 mm2 16 A 3 core 1.5 mm2 10 A

PCU3620 3 core 1.5 mm2 16 A 3 core 1.5 mm2 10 A

PCU4815 3 core 1.5 mm2 16 A 3 core 1.5 mm2 10 A

STERLING

POWER

01

13

198 mm

85 mm

90 mm

260 mm

85 mm

215 mm

90 mm

44 mm

1 3/4 inch

dimensions

in inches

and ( mm )

12V 10-40A

24V 20A

12V 50-60A

24V 30A

36V 20A

48V 15A

Cut out

90 x 62 mm

Unit Dimensions

PCU1210

PCU1220

PCU1230

PCU1240

PCU2420

DIMENSIONS / SMALL

198 mm 7 3/4 inch

85 mm

3 3/8 inch

90 mm

3 1/2 inch

260 mm

10 1/4 inch

85 mm

3 3/8 inch

215 mm

8 ½ inch

MISCELLANEOUS

MISCELLANEOUS

STERLING

POWER

02

14

90 mm

44 mm

1 3/4 inch

dimensions

in inches

and ( mm )

12V 10-40A

24V 20A

12V 50-60A

24V 30A

36V 20A

48V 15A

Cut out

90 x 62 mm

Unit Dimensions

PCU1250

PCU1260

PCU2430

PCU3220

PCU3620

PCU4815

DIMENSIONS / LARGE

198 mm 7 3/4 inch

85 mm

3 3/8 inch

90 mm

3 1/2 inch

260 mm

10 1/4 inch

85 mm

3 3/8 inch

215 mm

8 ½ inch

93 mm 130 mm 93 mm

315 mm

215 mm

198 mm

MISCELLANEOUS

MISCELLANEOUS

STERLING

POWER

03

15

52.5 mm

dimensions

in inches

and ( mm )

12V 10-40A

24V 20A

12V 50-60A

24V 30A

36V 20A

48V 15A

90mm

Unit Dimensions

PCUR

DIMENSIONS / REMOTE

198 mm 7 3/4 inch

85 mm

3 3/8 inch

90 mm

3 1/2 inch

260 mm

10 1/4 inch

85 mm

3 3/8 inch

215 mm

8 ½ inch

70mm

110mm

99mm

110mm

21mm

14mm

MISCELLANEOUS

MISCELLANEOUS 04

STERLING

POWER

16

dimensions

in inches

and ( mm )

12V 10-40A

24V 20A

12V 50-60A

24V 30A

36V 20A

48V 15A

NOTES

STERLING

POWER

198 mm 7 3/4 inch

85 mm

3 3/8 inch

90 mm

3 1/2 inch

260 mm

10 1/4 inch

85 mm

3 3/8 inch

215 mm

8 ½ inch

110mm

MISCELLANEOUS

MISCELLANEOUS 05

17

This manual suits for next models

11

Table of contents

Other Sterling Power Remote Control manuals