© copyright Sti Srl - Rev. 0607 Vietata la divulgazione c/o riproduzione anche parziale

18

8. MAINTENANCE

►Always unplug the appliance before cleaning or servicing operations on the machine

For the safety of the operator and to secure always perfect performances, the following controls and servic-

ing is recommended :

8.1 After each use

To clean the flexible hose and the used extension units, suck in a small quantity of clear water. Doing so

you keep the conducts clean inside and prevent deposits and bad smells.

Unhook the dirt bucket, empty it and rinse it carefully.

8.2 Periodically

Check regularly that the power cord does not present any signs of wear or ageing. If it is damaged, it is

absolutely necessary to replaced it immediately by the same type of power cord, before using the appli-

ance again.

This operation must be made by properly qualified persons.

8.3 Cleaning the boiler

• The cleaning of boiler is advisable at least every 200 working hours.

• The machine has to be cold and the electrical plug disconnected. With a wrench n°22 open the

stopper under the machine and empty completely all remaining water in the boiler. When the boiler

is empty, close the stopper carefully but without exceeding.

• Control visually or with a rod the remaining water quantity in the cold water tank: for about 0.3 litter

water take 0.3 litter vinegar (or a recommended descaler).

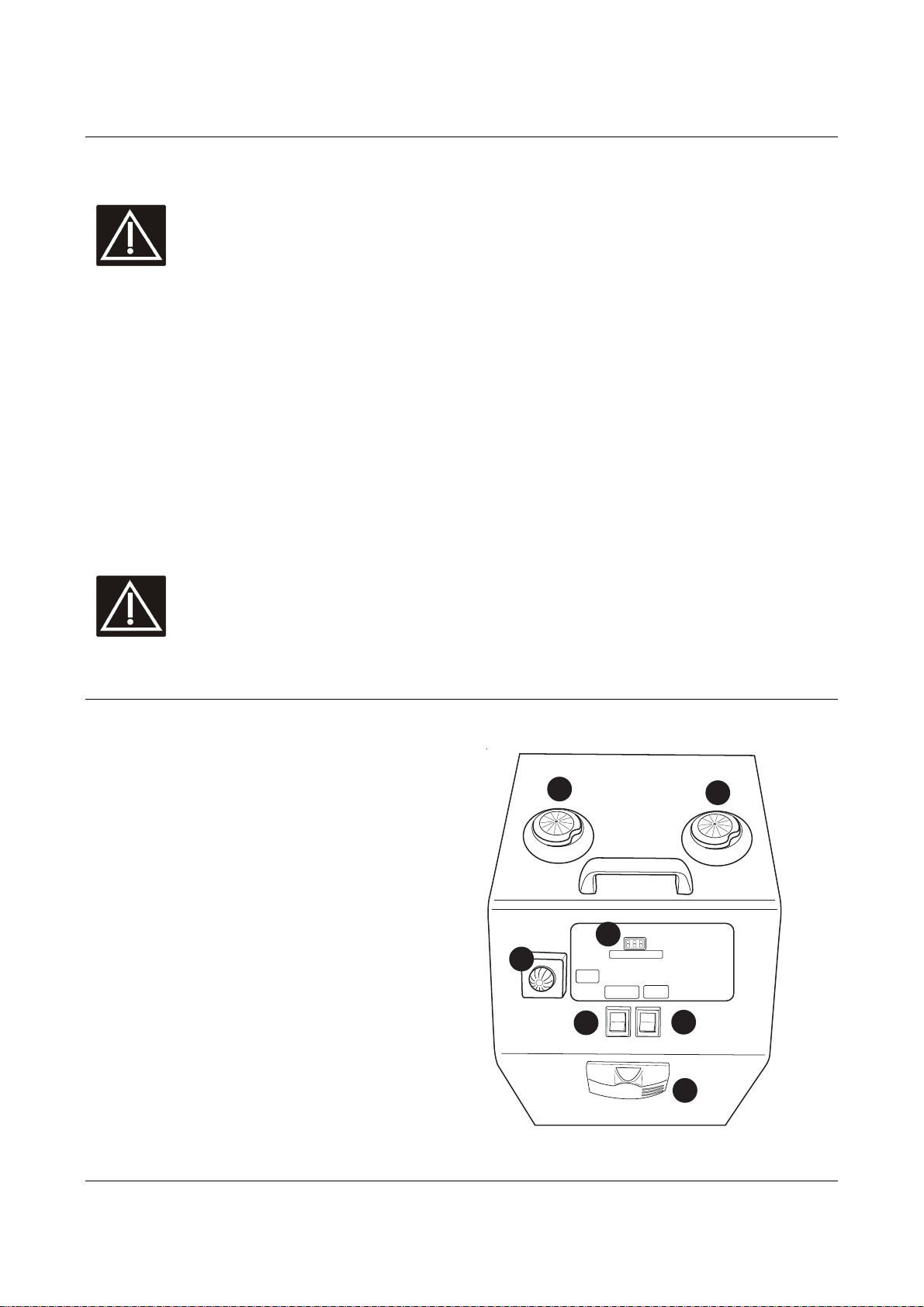

• Connect the electrical plug, switch on the switch (1).

• Wait until the pump finishes to fill the boiler and goes out. Switch off the machine, disconnect the

electrical plug and leave the machine for 8 hours.

• Empty the loose limestone in the solution and rinse the boiler proceeding as above described.

• Fill the cold water tank with clean water and switch on the machine. For about 10 minutes use

steam with care, because it will have a sharp smell because of the remaining vinegar in the boiler

and in the conducts.

• When the operation boiler cleaning is completed, to start the appliance again, follow the instruc-

tions explained under Starting.

►

When the pump is filling the boiler, it’s recommended to control if the stopper under

the machine is leaking