3

It’s Time To Sharpen when …

• The saw does not cut in a straight line.

• The cutters are not properly sharpened.

• The chain chatters and jumps - the depth gauge needs

adjustment.

• You are getting fine sawdust instead of wood chips.

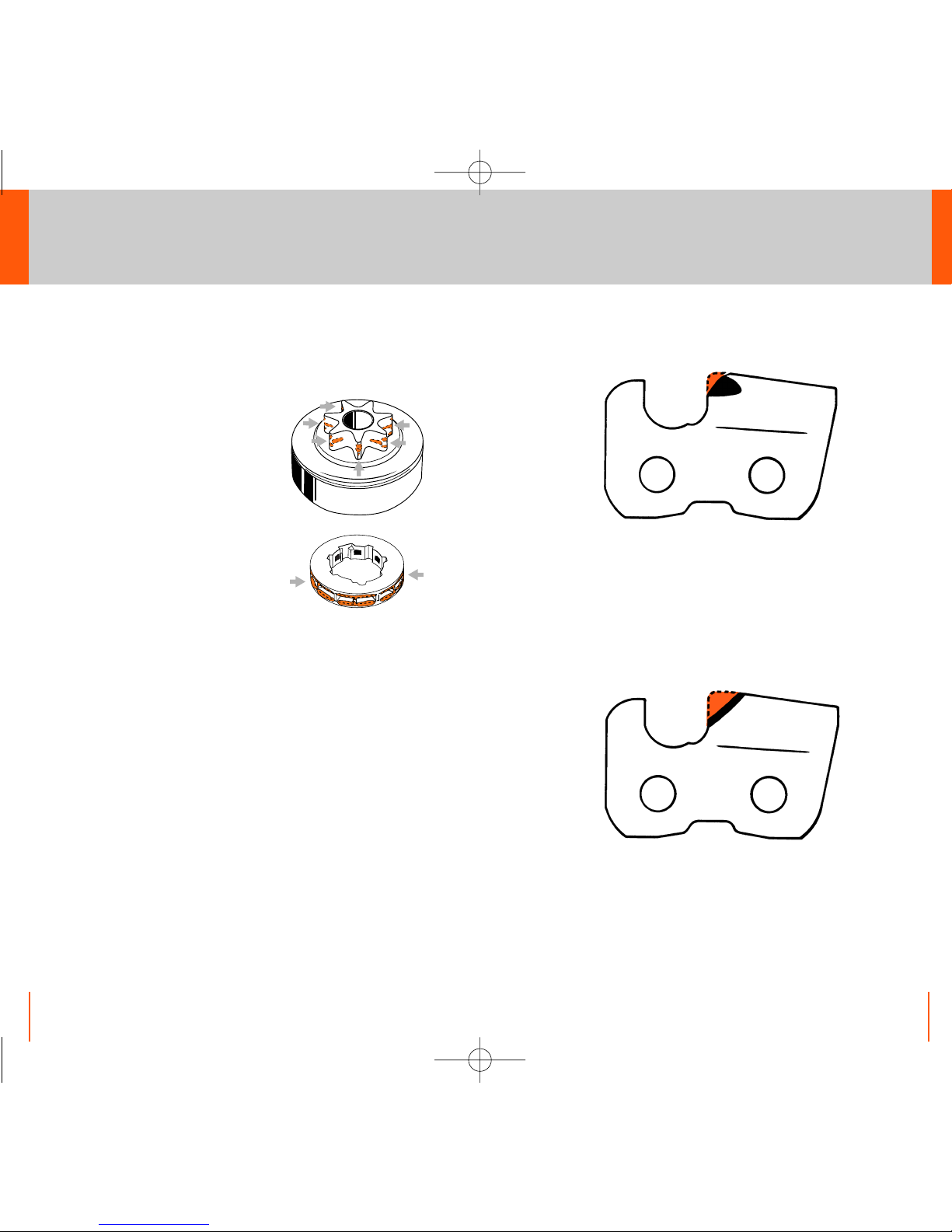

Construction of STIHL Saw Chain

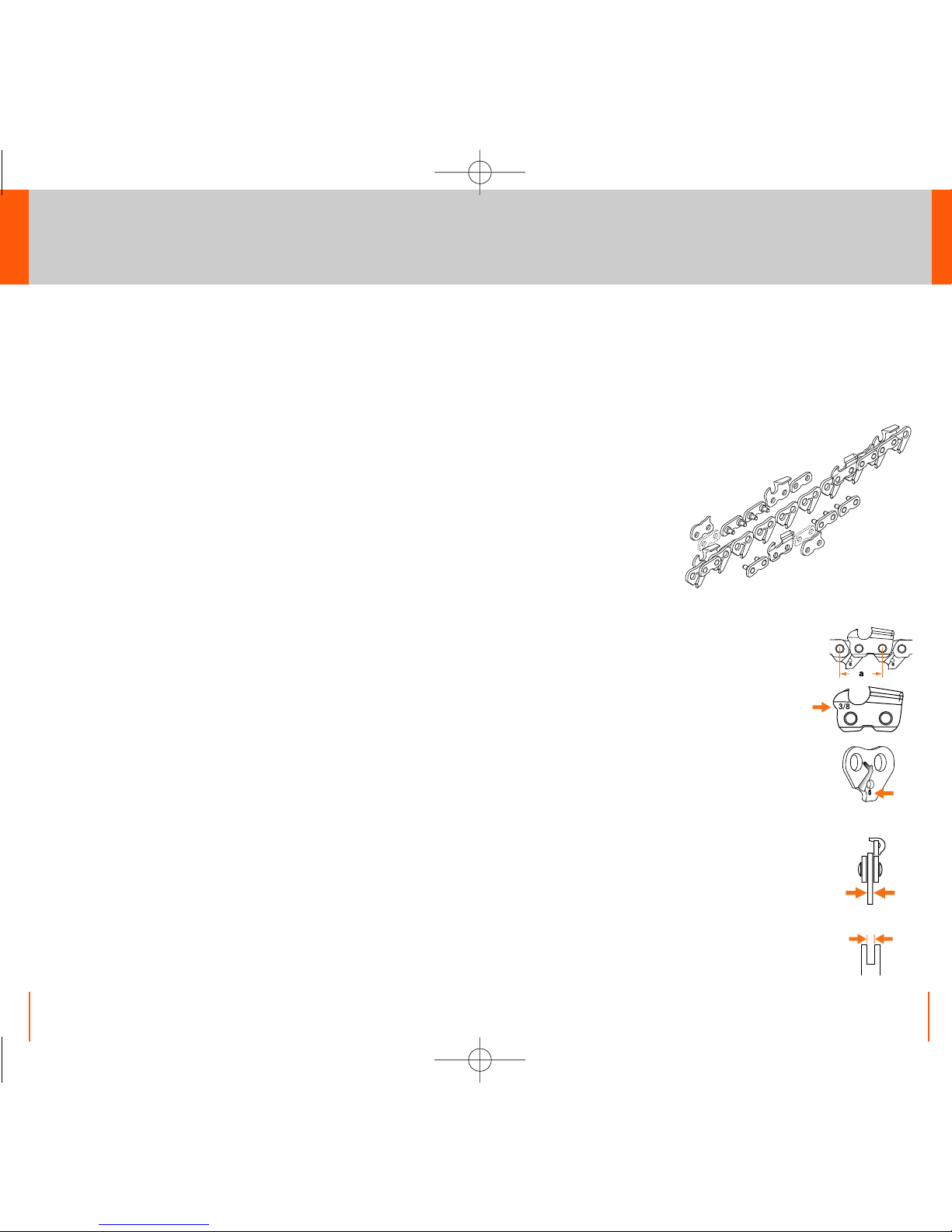

STIHL saw chains are 3-link

chains and are always

assembled in the same

basic pattern. The

illustration shows the

component parts of

a typical chain.

The important characteristics which

define a chain are the chain pitch, drive

link gauge and chain length.

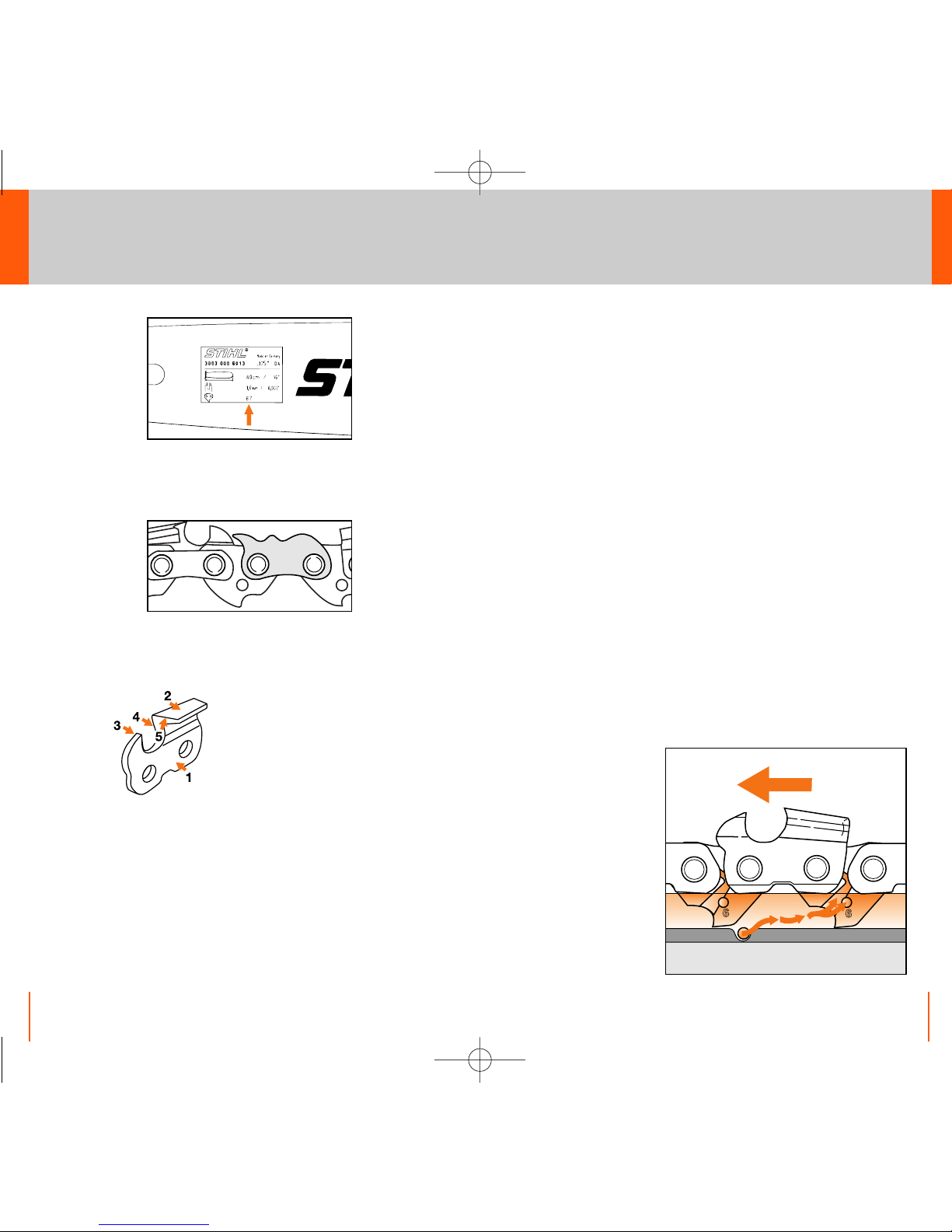

Pitch is the distance between the centers

of any three rivets and dividing the

measurement by two. The result is the

pitch in inches (e.g. 3/8”). The pitch size in

inches is stamped on each depth gauge.

Drive link gauge As the engine turns the

sprocket, it engages the drive links and

propels the chain. The drive link must

match the width of the guide bar groove

so that the chain exactly fits the bar. This

measurement is quoted in inches or

millimeters of the thickness of the bottom

of the drive link. There are chains with

drive link gauges of .043” (1.1 mm), .050”

(1.3 mm), .058” (1.5 mm) and .063” (1.6

mm). The last digit of the measurement in

millimeters is stamped on every drive link.

Pitch a/2

Drive link gauge

Bar groove width

2

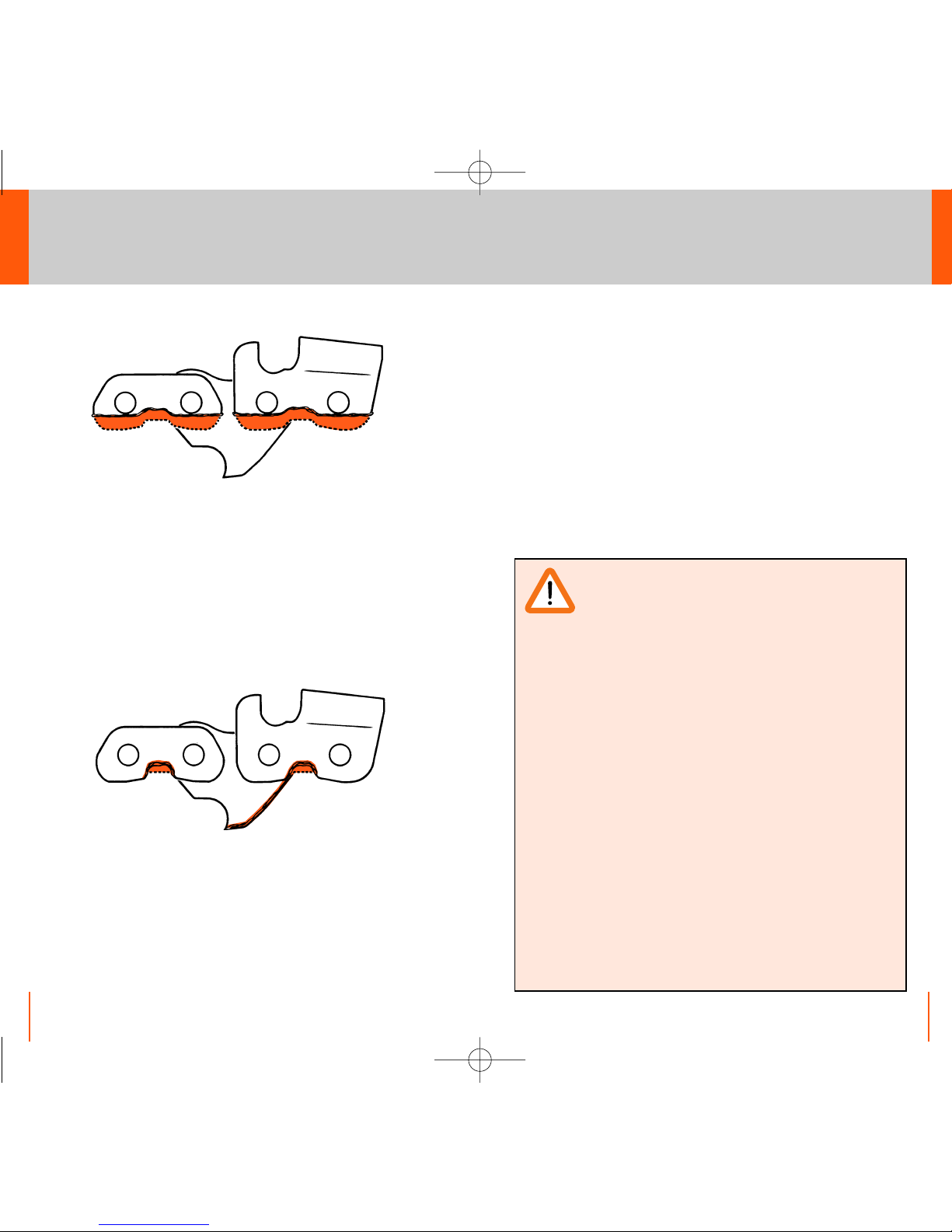

The occurrence called “kickback” can cause serious

or fatal injuries. Always read your Owner’s Manual

carefully before using your saw. In the U.S.A., STIHL has

developed a color code system using green and yellow to

help you select a powerhead, bar and chain combination

that complies with the kickback requirements of ANSI

Standard B 175.1. Ask your STIHL dealer about safe

operating procedures and the advantages of the STIHL

Quickstop®chain brake, STIHL reduced kickback bars,

and STIHL low kickback saw chains.

In Canada, STIHL saw chain meets kickback

requirements of CSA Standard Z62.3 M1990 when tested

on a representative sample of chain saws.

Chain Care Rules

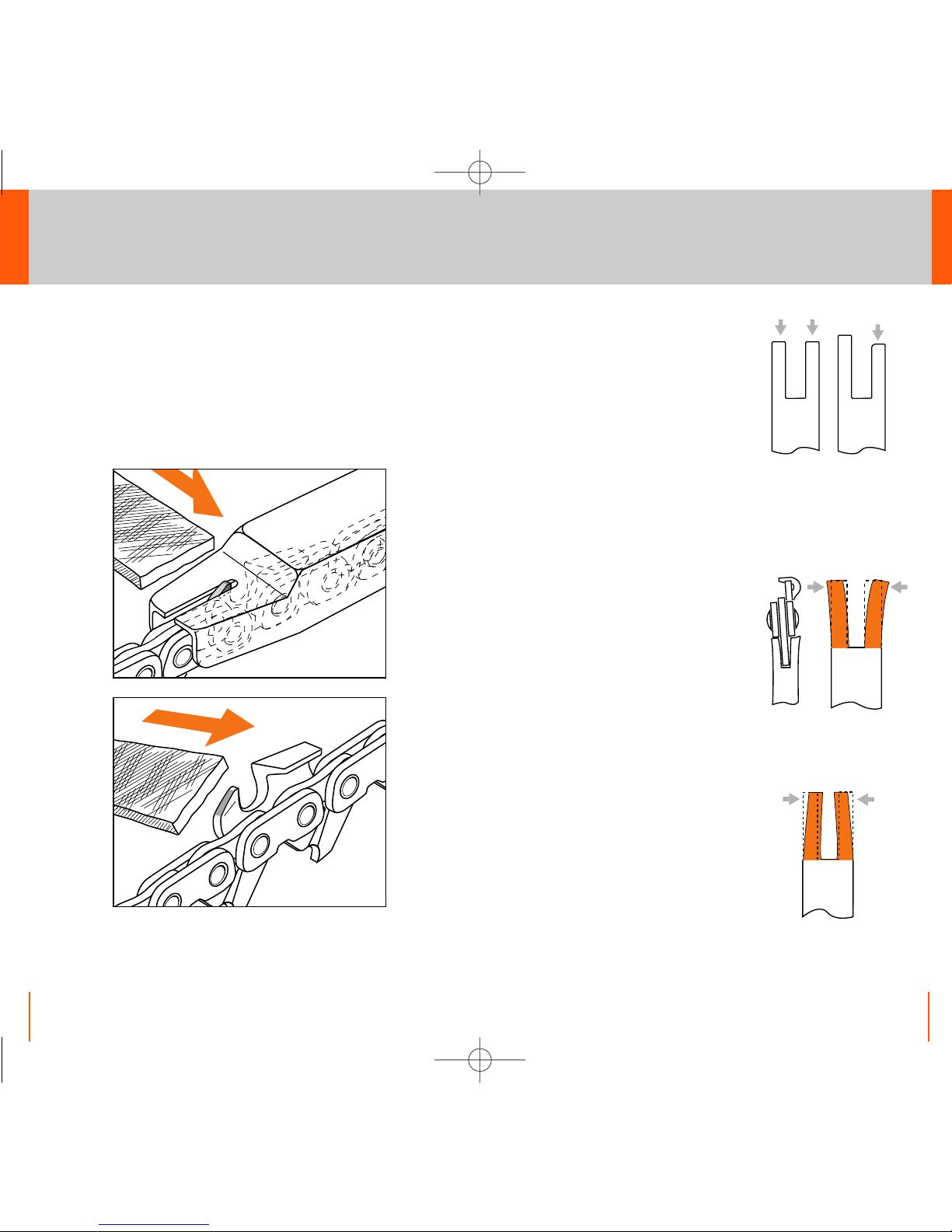

1. Avoid hitting dirt, rocks or any other abrasive material

while cutting.

2. Check the chain tension often. Never allow the chain

to sag. (See page 7).

3. Never force a dull chain to cut; it increases the risk of

injury and will damage the bar and chain.

4. Never install a new chain without replacing a worn

sprocket.

5.

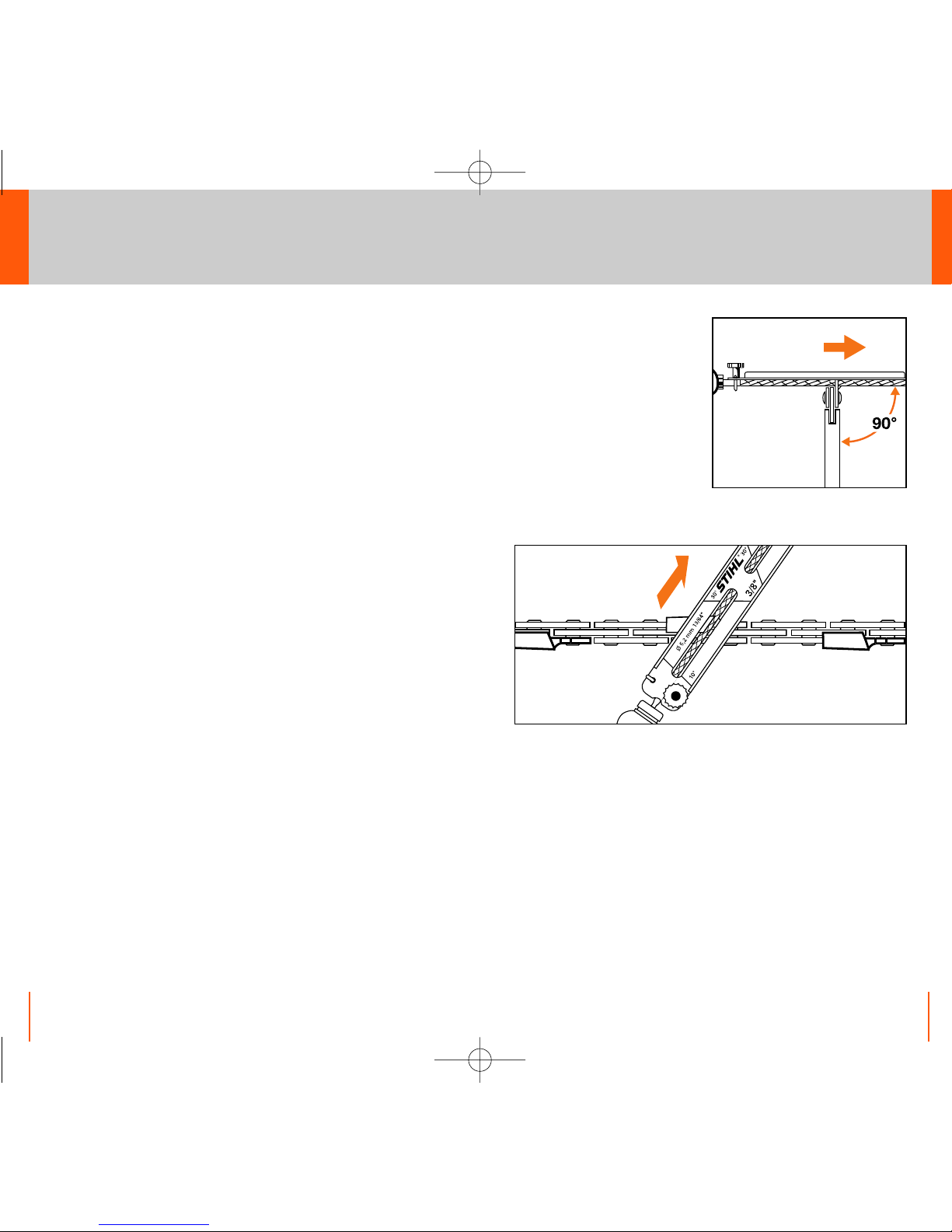

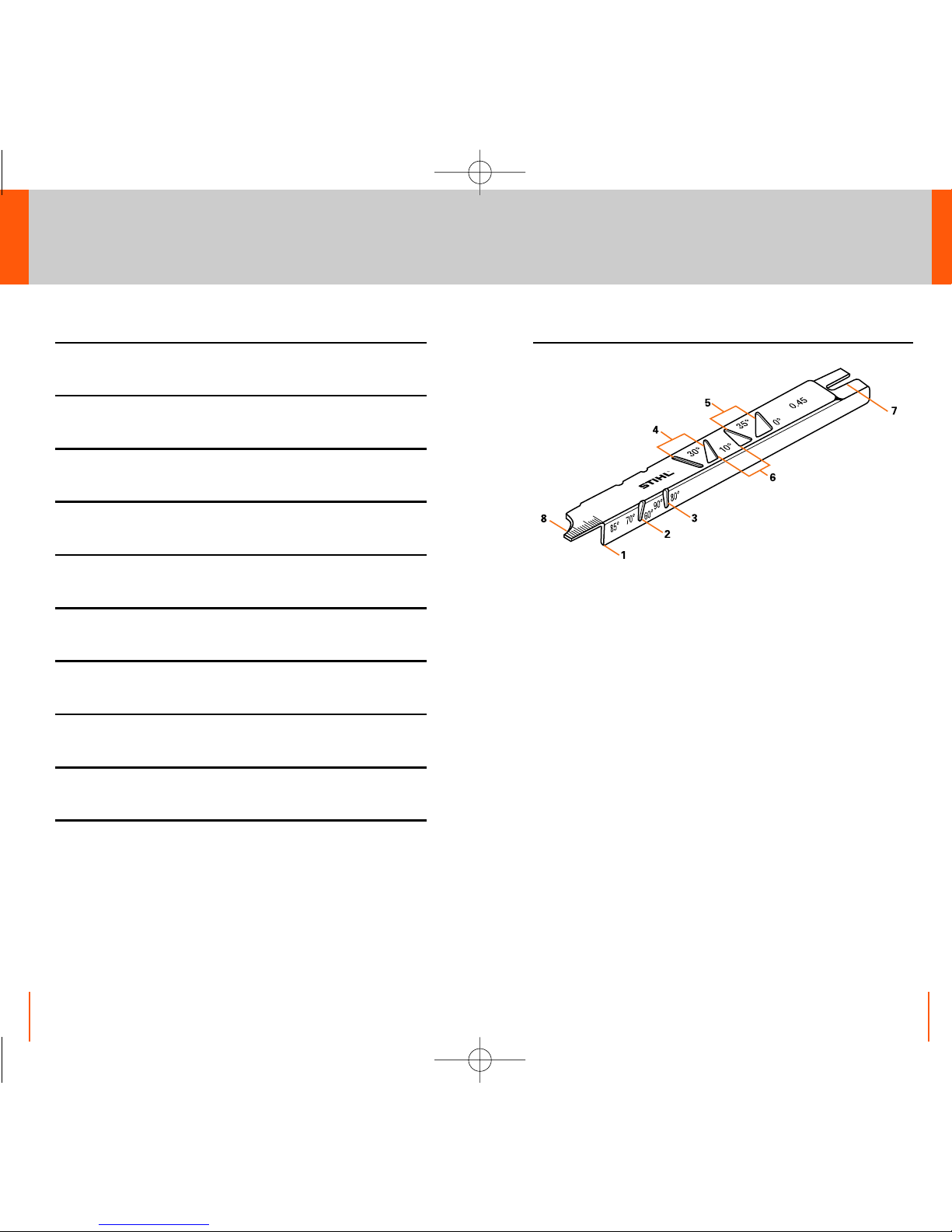

Always sharpen cutters to correct angles. (See pages 8-9).

6. Measure the depth gauges with every sharpening;

lower and re-profile as necessary. (See page 10).

7.

Check the entire chain often for visible wear or damage.

(See pages 13-16 for common wear problems).

8. Check the depth of the bar groove for proper drive

link clearance, examine the bar rails for even wear,

and clean bar groove.

9. Always wear gloves when handling chain.

10. Keep scabbard on the bar when the saw is not in use.

11. Make sure that your chain is always properly

lubricated. (See page 6).

Important Information