STM 17004501 User manual

AC BARREL PUMP MOTOR

USER’S MANUAL

MODEL NUMBER: 17004501, 17004502

WARNING: Read carefully and understand all INSTRUCTIONS before operating.

Failure to follow the safety rules and other basic safety precautions may result in serious

personal injury.

1 of 4

AC BARREL PUMP MOTOR

USER’S MANUAL

MODEL NUMBER

17004501 & 17004502

A. SAFETY

All safety instructions must be observed and followed.

Before Using

1.There is high speed rotating components.Failure to follow the safety instructions may lead to serious injury.All safety instructions must

be observed and followed strictly.

2.

Before installing and starting the barrel pump, the related engineer must have the considerable qualification and is familiar with this manuals.

3.The installation and maintenance must according to the current machinery and electrical standard strictly.

4.The spare parts life time will be limited by wear and corrosion.The failure is affected by operating environment. The user has the

responsibility to operate in accordance with the regulations. The regular maintenance and spare parts change should be performed

regularly. Stop the pump when the pump under irregularity and obviously dangerous status.

5.The pump should install the detection alarm system when it was installed at the location where may cause the failure or personal injury.

Using

1.

Wear protective clothing,goggles and in accordance with the safe production routine when operate the corrosive and hazardous substance.

2. It is prohibited to use plastic or aluminum alloy pump pipe and the non-explosion proof motor when transferring the flammable liquids.

3. Carry flammable liquids, the earth wire must be installed,electrostatic protection device and conductive hose must be used when

transferring the flammable liquids.

4. Make sure the pump head insert to the liquids completely before using.Also all the connectors connect tightly.Without leakage and fall

out dangerous situation.

5.The suitable flexible pipe must be used during transferring high temperature liquids.

6. Attention to the pumped liquids temperature, viscosity and density do not exceed the stated upper limit.

7. Install the filters in the pump tube bottom when transport the liquids with impurity or solids.To avoid the blocking, please check and

clean it regularly.

8.

Make sure the motor under close status before power on.Never leave the pump unattended and never operate the motors without pump.

9. Do not touch the tube bottom after switching on the electric or air source.The impeller under high speed rotating may lead to

equipment damage and personal injury.

Make sure the pump tube working under vertical position. Never upend or lay flat after using. Pay attention to the residual liquids may

lead to injury or cause environmental damage.

PUMP MODEL

17004501

17004502

ELECTRICAL POWER

Current

AC

AC

Voltage(V)

230

120

Power (W)

450

450

Load Speed

(RMP)

Rated Speed

(RMP)

3000~11000

3000~11000

20000

20000

B. MACHINE DESCRIPTION

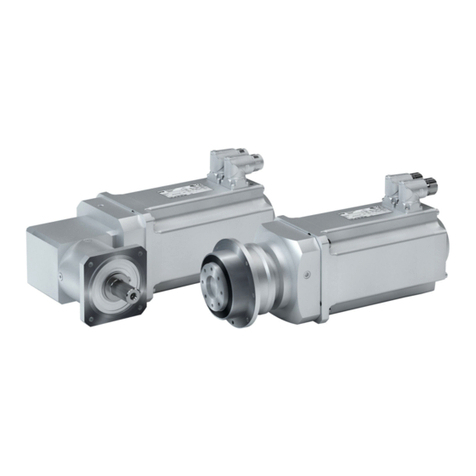

MOTOR: AC series motor with the overheating protection components, Quick coupling adapter,Automatic positioning coupling and

Adjustable speed switch.

ATTENTION!

• Never operate the motors without pump.

• Never leave the pump unattended.

• Never run dry of the pump.

• The pump should not be immersed deeper into the liquid than the outlet connection.

C.TECHNICAL DATA

C1. Electrical Data

D. OPERATING CONDITIONS

D1. Environmental Conditions

Electro-Motor operating environment:-25~40˚C

D2. Power Supply

Make sure that the supply voltage corresponds to the voltage indicated on the rating plate.

ATTENTION!

Power from lines with values outside the indicated limits can damage the electrical components.

2 of 4

AC BARREL PUMP MOTOR

USER’S MANUAL

F. INSTALLATION

MODEL NUMBER

17004501 & 17004502

Check if the packing was damaged before opening. Make sure no missed spare parts.

Safety Check

Make sure that the supply voltage corresponds to the voltage indicated on the rating plate.

7.1 Motor Installation

1. Pump tube check: Make sure every joint part no looseness.The coupling and shaft could be rotated flexible.

2. Motor Check: Make sure the power cable complete, switch in good condition. Dry running for several minutes to check if the motor

workable. Do not put hands to the motor output shaft.

3. Put the motor coupling is directed at the pump tube. Make sure the pump tube head insert to the motor head completely.

4.The motor and pump tube position could be adjusted by 360°.Put the pump tube adjusted to the suitable position and lock the nut to

finish the installation. It is recommended that the pump exports away from the motor power cable.

7.2 Start

Make sure all the joint parts without leakage.The tube outlet must be fixed well so to avoid pressure leaking.

F7. Electrical Connections

• Terminal strip box complete of:

- ON/OFF switch;

- Speed regulating knob switch

- Speed regulating circuit board

• 5M Power cable

ATTENTION!

IT IS THE INSTALLER’S RESPONSIBILITY TO PREFORM THE ELECTRICAL CONNECTIONS WITH RESPECT FOR THE APPLICABLE

REGULATIONS.

G. DAILY USE

Long time continuous running may cause motor overheating, the overheating protection system will cut the power automatically.The

motor can be restarted work again after cooling down by pressing the on/off button.

ATTENTION!

The suggested duty cycle is 2 hours. Do not exceed one hour when the environment temperature more than 30˚C

Please change the electric brush every 250-300hours

H. NOISE LEVEL

Under normal working conditions the noise emission from all models does not exceed the valve of 80 db at a distance of 1 meter from

the electric pump.

I. DISPOSING OF CONTAMINATED MATERIALS

In the event of maintenance or demolition of the machine, do not disperse contaminated parts into the environment.

Refer to local regulations for their proper disposal.

E. MOVING AND TRANSPORT

The pump tube and motor adopt the carton box packing.There is enough protection packing material inside.However, never knock on,

heavy load by the non-normal external force.Please transport and stacking as per packing indication. Keep drying and anti-corrosion of

the stacking place.

AC Switch

M

Speed

regulating

circuit

board

K: DIAGRAM & PARTS LIST

No.

1

2

3

4

5

6

7

8

No.

9

10

11

12

13

14

15

16

Description

Tapping screw

Speed control knob

Switch block

Head cover

Tapping screw

Rotary knob connector

Toggle switch

Description

Lining

Speed control circuit board

Motor shell

Tapping screw

The handle cover

Binding post

Wire pressing piece

Cable shield

Qty.

3

1

1

Countersunk head tapping screws

2

1

2

1

1

Qty.

1

1

1

3

1

1

1

1

No.

17

18

19

20

21

22

23

24

Description

Motor

Cable

Coupler

Bottom cover

Flat gasket

Spring washer

Bolt

Tapping screw

Qty.

1

1

1

1

3

3

3

8

3 of 4

AC BARREL PUMP MOTOR

USER’S MANUAL

MODEL NUMBER

17004501 & 17004502

J. PROBLEMS AND SOLUTIONS

PROBLEM POSSIBLE CAUSE CORRECTIVE ACTION

No ow rate or small ow rate

Vibration, Big noise

Pump tube leakage

Without opening the electric or air source

Motor failure, do not rotating

Outlet close

Too big pump lift

Too big liquids viscosity

Liquids draining out

The inlet block o

Liquids draining out

Motor overload

Sliding bearing damage

Coupling wear

Seal ring wear

Circuit failure

Long time working of the motor, overheating

protection, electric brush damage

Open the power and air source

Motor Check

Open the outlet valve

Short the transportation distance and height

Check the type with supplier

Stop the pump

Clean the inlet

Stop the pump

Check the liquids viscosity and pump lift

Change the sliding bearing and seal ring

Change the coupling

Change the seal ring

Check the circuit

Restart the motor after cooling down

Change the electric brush

4 of 4

AC BARREL PUMP MOTOR

USER’S MANUAL

MODEL NUMBER

17004501 & 17004502

1

3

2

4

5

6

7

8 9

10

11

12 13

14

115 17

16

18

19

20

21 22

23

24

This manual suits for next models

1

Table of contents

Popular Engine manuals by other brands

Briggs & Stratton

Briggs & Stratton 120000 Operating & maintenance instructions

Doosan

Doosan V158TI Operation & maintenance manual

Xray

Xray NT18 0.8cc Instruction and safety manual

Saito

Saito FA-30S(H) instruction manual

WEG

WEG W21 Instructions manual for installation, operation and maintenance

Grin Technologies

Grin Technologies GMAC installation guide

Scania

Scania DI13 series Operator's manual

ZIEHL-ABEGG

ZIEHL-ABEGG ZA top SM250.60B Original operating instructions

Texas Instruments

Texas Instruments AMIC110 ICE user guide

Atlas Imperial Diesel Engine

Atlas Imperial Diesel Engine Engine Operator instructions

EuroLite

EuroLite MD-3010 user manual

Tecumseh

Tecumseh SPECTRA 37 Service and repair manual