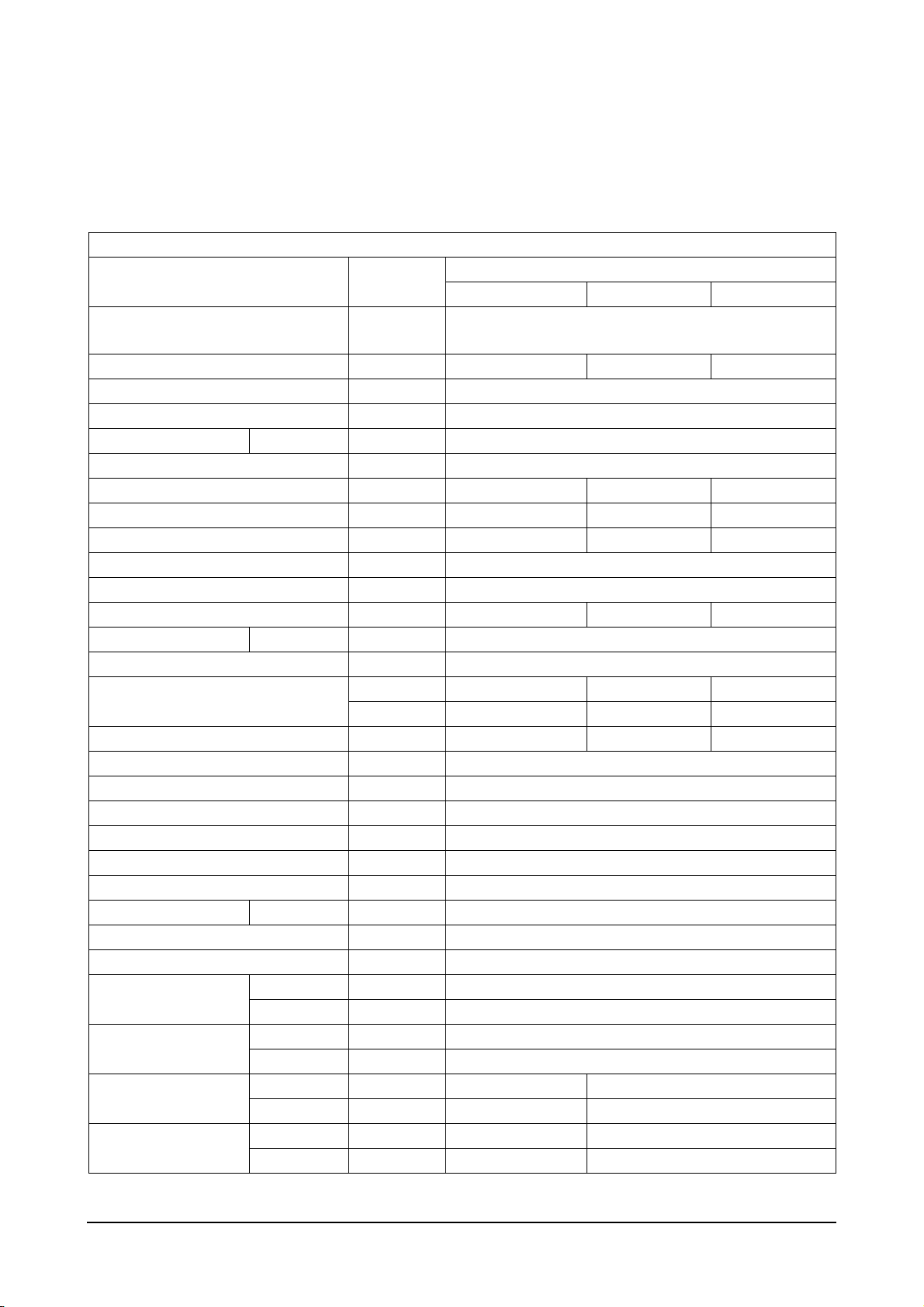

CONTENTS

1. SPECIFICATION ......................................................................................................................... 1

1.1. Engine Specification ........................................................................................................................... 1

1.2. Engine Aspects ................................................................................................................................... 5

1.3. Engine Performance Curve ................................................................................................................ 8

1.4. Engine Model & Serial Number .......................................................................................................... 9

2. SAFETY REGULATIONS.......................................................................................................... 11

2.1. General Notes .................................................................................................................................. 11

2.2. Regulations Designed to Prevent Accidents with Injury to Persons ................................................. 11

2.3. Regulations Designed to Prevent Damage to Engine and Premature Wear .................................... 13

2.4. Regulations Designed to Prevent Pollution ...................................................................................... 14

2.5. Notes on Safety in Handling Used Engine Oil .................................................................................. 14

3. COMMISSIONING AND OPERATION...................................................................................... 15

3.1. Inspections before Operation ........................................................................................................... 15

3.2. Starting ............................................................................................................................................. 22

3.3. Engine Break-in ................................................................................................................................ 23

3.4. Inspections after Starting .................................................................................................................. 25

3.5. Check after Initial 50 Hours Operation. ............................................................................................ 26

3.6. Operation In Winter .......................................................................................................................... 26

3.7. Tuning the Engine ............................................................................................................................ 27

4. GENERAL INFORMATION ....................................................................................................... 29

4.1. General Repair Instructions .............................................................................................................. 29

4.2. Periodical Inspection & Maintenance ............................................................................................... 30

4.3. Cooling System ................................................................................................................................ 31

4.4. Lubrication System ........................................................................................................................... 37

4.5. Intake & Exhaust System ................................................................................................................. 41

4.6. Fuel System ...................................................................................................................................... 43

4.7. Electric System ................................................................................................................................. 48

4.8. Valve Clearance ............................................................................................................................... 48

4.9. When the Engine is Sunk ................................................................................................................. 49

5. MAIN ACCESSORY PARTS..................................................................................................... 51

5.1. Reduction Gear ................................................................................................................................ 51

5.2. Front Power Take Off ....................................................................................................................... 53

5.3. Propeller Selection ........................................................................................................................... 60

5.4. Electric System ................................................................................................................................. 61

6. DISASSEMBLY AND ASSEMBLY OF MAJOR COMPONENTS ............................................ 64

6.1. Disassembly ..................................................................................................................................... 64

6.2. Inspection ......................................................................................................................................... 74

6.3. Engine Re-assembly ........................................................................................................................ 93

6.4. Trial Test after Maintenance ........................................................................................................... 112