StoneAge NAV-100 User manual

PL 613 REV G

(10/2019)

NAVIGATOR (NAV-100) &

CONTROL BOX (CB-NAV)

USER MANUAL

2866-795-1586 • WWW.STONEAGETOOLS.COM

MANUFACTURER’S INFORMATION................................................................ 3

SPECIFICATIONS ........................................................................................ 3

DESCRIPTION OF EQUIPMENT AND INTENDED USE ................................... 3

KEY FEATURES........................................................................................... 3

CE DECLARATION OF CONFORMITY........................................................... 4

WARNING AND SAFETY INSTRUCTIONS ....................................................... 5

OPERATOR TRAINING................................................................................. 5

PERSONAL PROTECTIVE EQUIPMENT REQUIREMENTS.............................. 5

PRE-RUN SAFETY CHECK .......................................................................... 6

SYSTEM ASSEMBLY - OVERVIEW .................................................................. 8

NAVIGATOR (NAV-100) SET-UP........................................................................ 10

PIPE MOUNTING OPTIONS

QUARTER PLATE FLANGE MOUNT SET-UP ................................................... 14

STRAP MOUNT ASSEMBLY SET-UP - OPTIONAL........................................... 17

TIGHT PIPE FLANGE JOINT ATTACHMENT OPTIONS.................................... 20

CONTROL BOX SET-UP ................................................................................... 22

OPERATION...................................................................................................... 24

MAINTENANCE AND TROUBLESHOOTING .................................................... 25

STORAGE AND HANDLING ............................................................................. 25

ABX-PRO ROLLER REPLACEMENT................................................................ 26

ROLLER REMOVAL INSTRUCTIONS ............................................................ 26

ROLLER INSTALLATION INSTRUCTIONS...................................................... 27

PART DIAGRAMS ............................................................................................. 28

TERMS AND CONDITIONS .............................................................................. 42

TABLE OF CONTENTS

3

866-795-1586 • WWW.STONEAGETOOLS.COM

MANUFACTURER’S INFORMATION

DESCRIPTION OF EQUIPMENT AND INTENDED USE

The Navigator NAV-100 is a hose feed device designed to quickly

and safely clean a broad range of pipes with or without a ange.

The Navigator NAV-100 mounts to pipes from 2 inches (51 mm) to 4

inches (102 mm) in diameter. The Navigator NAV-100 will clean past

multiple bends and elbows using hose rotation and StoneAge’s proven

self-rotary tools. Standard safety practices should still be followed, but

the Navigator NAV-100 allows the user to be stand away from the

pipe entrance and be shielded from a tool.

KEY FEATURES:

Navigator NAV-100

• Modular, lightweight design

• Quick install

• Optional Strap Mount Assembly accommodates a wide variety of

pipes

Control Box CB-NAV

• Small, lightweight, ergonomic design that includes a

portable oor stand and lter-regulator-lubricator assembly

• 10’ (3048 mm) umbilical allows user to move with the controls

• Drive controls: forward/reverse hose feed, rotate drum

• Pneumatic dump control switch

StoneAge Inc.

466 S. Skylane Drive

Durango, CO 81303, USA

Phone: 970-259-2869

Toll Free: 866-795-1586

www.stoneagetools.com

StoneAge Europe

Unit 3 Crucible Business Park

Woodbury Lane, Norton, Worcester,

Worcestershire, WR5 2DQ

United Kingdom

Phone: +44 (0) 1684 892065

SPECIFICATIONS

Hose Feed Rate 2.7 in/s to 32 in/sec (69 mm/s to 813 mm/s)

Cleans Minimum Pipe Size 2 in (51 mm)

Cleans Maximum Pipe Size 4 in (102 mm)

Hose Size - 4 layer hose Outside Diameter range ø.39 in - ø.50 in

Hose Drum Connection End 9/16”-18 Type M Female Swivel

Air Connection to Control Box Chicago Style twist-claw tting

Tool Connection End

(Recommended for BA or BT tools) 3/8”-24 UNF RH HP Male Fitting (Blast-pro®or equivalent)

Control Box to Navigator Air Connections 1/2” JIC (x2), 1/4” JIC (x2)

Main Water Inlet Size 1” Type M comes standard. Other adapters are available

Maximum Air Supply Pressure 125 psi (0.86 MPa)

System Operating Pressure 80 psi (0.55 MPa) minimum, 100 psi (0.7 MPa) maximum

Recommended Operational Temperature Range 32°F to 140°F (0°C to 60°C)

WEIGHTS DIMENSIONS

Navigator NAV-100 Not including hoses 75 lbs (34 kg)

35”L x 21”W x 24”H

(890 mm x 533 mm x 610 mm)

Snout 5 lbs (2 kg)

72”L x 2”DIA.

(1829 mm x 51 mm)

CB-NAV Control Box 26 lbs (12 kg)

14”L x 14”W x 18” - 28”H

(356mm x 356mm x 457mm - 711mm)

HOSE DRUM CAPACITY

Maximum Hose Lengths

Size Length

4/4 110ft

5/4, 6/4 100ft

This manual must be used in accordance with all applicable national laws. The manual shall be regarded as a part of the machine and shall

be kept for reference until the nal dismantling of the machine, as dened by applicable national law(s).

Updated manuals can be downloaded at:

https://www.stoneagetools.com/manuals

4866-795-1586 • WWW.STONEAGETOOLS.COM

EU DECLARATION OF CONFORMITY

Manufacturer: StoneAge Incorporated

466 South Skylane Drive

Durango, CO 81303

USA

Authorized Representative: StoneAge Europe

Unit 3 Crucible Business Park

Woodbury Lane, Norton, Worcester,

Worcestershire, WR5 2DQ

United Kingdom

Steve Ellis, Director StoneAge Europe

Declare that: Navigator (NAV-100) and Control Box (CBX-NAV)

for high pressure water cleaning of system parts.

Is compliant with the following Directives and Standards:

Directive 2006/42/EC (Machinery Directive)

EN ISO 12100:2010 (E) Safety of machinery – General principles for design – Risk assessment and risk reduction

The Technical File for Navigator (NAV-100) and Control Box (CBX-NAV) is maintained at:

StoneAge Incorporated, 466 South Skylane Drive, Durango, CO 81303, USA and was compiled by the Engineering Manager.

The Technical File is available through the Authorized Representative.

This Declaration of Conformity is issued under the exclusive responsibility of StoneAge Incorporated.

________________________________________ 02/11/2019

StoneAge Incorporated, Durango, CO, USA Date

Adam Markham, Engineering Manager, Robotics

5

866-795-1586 • WWW.STONEAGETOOLS.COM

NOTES

This page is intentionally left blank.

6866-795-1586 • WWW.STONEAGETOOLS.COM

OPERATOR TRAINING

Managers, Supervisors, and Operators MUST be trained in Health

and Safety Awareness of High-pressure Water Jetting and hold a

copy of the Water Jetting Association (WJA) Code of Practice, or

equivalent (see www.waterjetting.org.uk).

Operators MUST be trained to identify and understand all applicable

standards for the equipment supplied. Operators should be trained

in manual handling techniques to prevent bodily injury.

Operators MUST read, understand, and follow the Operational and

Training Requirements (Section 7.0) of WJTA-IMCA’s Recommended

Practices For The Use Of High-pressure Waterjetting Equipment, or

equivalent.

Operators MUST read, understand and follow the Warnings,

Safety Information, Assembly, Installation, Connection, Operation,

Transport, Handling, Storage, and Maintenance Instructions detailed

in this manual.

StoneAge has designed and manufactured this equipment

considering all hazards associated with its operation. StoneAge

assessed these risks and incorporated safety features in the design.

StoneAge WILL NOT accept responsibility for the results of misuse.

IT IS THE RESPONSIBILITY OF THE INSTALLER/OPERATOR

to conduct a job specic risk assessment prior to use. Job specic

risk assessment MUST be repeated for each different set up,

material, and location.

The risk assessment MUST conform to the Health and Safety at

Work Act 1974 and other relevant Health and Safety legislation.

The risk assessment MUST consider potential material or substance

hazards including:

• Aerosols

• Biological and microbiological (viral or bacterial) agents

• Combustible materials

• Dusts

• Explosion

• Fibers

• Flammable substances

• Fluids

• Fumes

• Gases

• Mists

• Oxidizing Agents

WARNING AND SAFETY INSTRUCTIONS

PERSONAL PROTECTIVE EQUIPMENT REQUIREMENTS

Use of Personal Protective Equipment (PPE) is dependent on

the working pressure of water and the cleaning application.

Managers, Supervisors, and Operators MUST carry out a job

specic risk assessment to dene the exact requirements for PPE.

See Protective Equipment for Personnel (Section 6) of WJTA-

IMCA’s Recommended Practices For The Use Of High-pressure

Waterjetting Equipment for additional information.

Hygiene - Operators are advised to wash thoroughly after all

waterjetting operations to remove any waterblast residue which may

contain traces of harmful substances.

First aid provision - users MUST be provided with suitable rst aid

facilities at the operation site.

PPE may include:

• Eye protection: Full face visor

• Foot protection: Kevlar® brand or steel toe capped,

waterproof, non-slip safety boots

• Hand protection: Waterproof gloves

• Ear protection: Ear protection for a minimum of 85 dBA

• Head protection: Hard hat that accepts a full face visor and

ear protection

• Body protection: Multi-layer waterproof clothing approved for

waterjetting

• Hose protection: Hose shroud

• Respiratory protection: May be required; refer to job specic

risk assessment

The

NAVIGATOR NAV-100

has the potential to

cause serious injury if ngers, hair, or clothing

become caught between the drive rollers of

the drum assembly.

KEEP HANDS CLEAR

OF ROLLERS

The

ABX-PRO Tractor

has the potential to

cause serious injury if ngers, hair, or clothing

become caught between the hose rollers of

the ABX-PRO Tractor.

DO NOT OPERATE WITH THE HOUSING

DOORS OPEN. ENSURE THAT ALL FOUR

DOOR PINS ARE

SECURED PRIOR TO

OPERATION.

Maximum operating air pressure is 100

psi (0.7 MPa). Never exceed 125 psi (0.86

MPa) supply pressure. Exceeding 125 psi

(0.86 MPa) supply pressure may result in

injury to the Operator and/or damage to the

equipment

SAFETY LABEL DEFINITIONS

Replacement labels can be ordered through Stoneage

®

. See part diagrams for label locations and replace when necessary.

7

866-795-1586 • WWW.STONEAGETOOLS.COM

WARNING AND SAFETY INSTRUCTIONS WARNING AND SAFETY INSTRUCTIONS

WARNING

Operations with this equipment can be potentially hazardous. Caution

MUST be exercised prior to and during machine and water jet tool

use. Please read and follow all of these instructions, in addition to

the guidelines in the WJTA Recommended Practices handbook,

available online at www.wjta.org. Deviating from safety instructions and

recommended practices can lead to severe injury and/or death.

• Do not exceed the maximum operating pressure specied for

any component in a system.

• The immediate work area MUST be marked off to keep out

untrained persons.

• Inspect the equipment for visible signs of deterioration, damage,

and improper assembly. Do not operate if damaged, until

repaired.

• Make sure all threaded connections are tight and free of leaks.

• Users of the Navigator NAV-100 MUST be trained and/

or experienced in the use and application of high-pressure

technology and cleaning, as well as all associated safety

measures, according to the WJTA Recommended Practices for

the use of High-pressure Waterjetting Equipment.

• An anti-withdrawal device (back-out preventer) MUST be used

at all times. The back-out prevention device is located on

the Splash Guard of the Navigator NAV-100. The adjustment

instruction is located in the “ProDrive Set-up” section of this

manual.

• The Control Box should be located in a safe location where the

Operator has good visibility of the pipe and hose. The Navigator

NAV-100 and Control Box MUST be supervised at all times and

should never be left unattended.

• Always de-energize the system before servicing or replacing any

parts. Failure to do so can result in severe injury and/or death.

PRE-RUN SAFETY CHECK

Refer to WJTA-IMCA’s, Recommended Practices For The Use Of

High-pressure Waterjetting Equipment and/or The Water Jetting

Association’s, WJA Code of Practice for additional safety information.

• Complete a job specic risk assessment and act on the resulting

actions.

• Adhere to all site specic safety procedures.

• Ensure the waterblasting zone is properly barricaded and that

warning signs are posted.

• Ensure the work place is free of unnecessary objects (e.g. loose

parts, hoses, tools).

• Ensure all Operators are using the correct Personal Protective

Equipment (PPE).

• Check that the air hoses are properly connected and tight.

• Check all hoses and accessories for damage prior to use. Do

not use damaged items. Only high quality hoses intended for

waterblast applications should be used as high-pressure hoses.

• Check all high-pressure threaded connections for tightness.

• **Ensure that an anti-withdrawal device (back-out

preventer), and all other applicable safety devices are

installed and set-up properly.**

• Test the Control Box before operating the Navigator NAV-100 with

high-pressure water to verify the control valves move the hose in

the intended direction, and that the dump valve and hose clamp

are working properly.

• Ensure that Operators never connect, disconnect, or tighten

hoses, adapters, or accessories with the high-pressure water

pump unit running.

• Ensure no personnel are in the hydroblasting zone.

8866-795-1586 • WWW.STONEAGETOOLS.COM

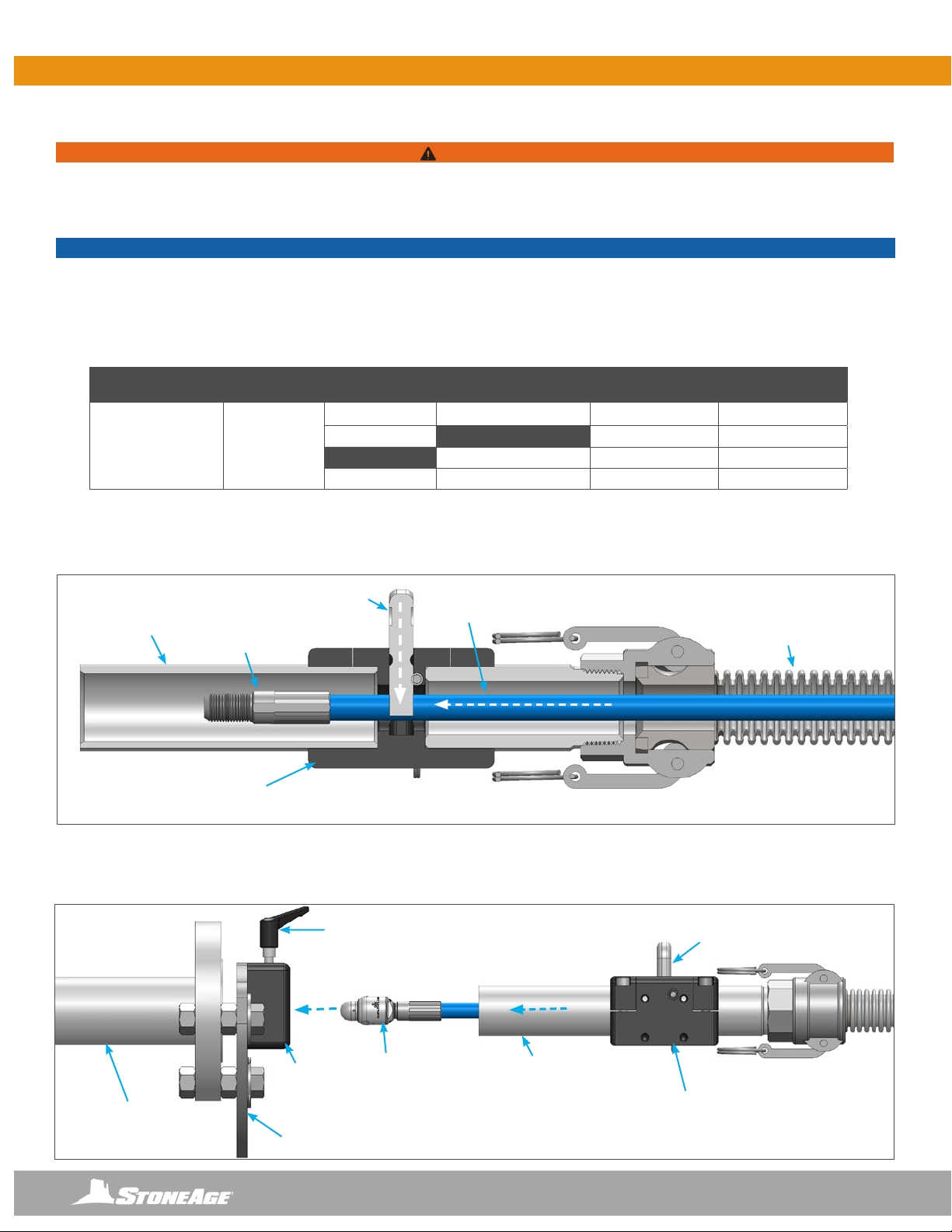

SNOUT

BOP 090

NAVIGATOR OPTIONAL

PIPE MOUNT ITEMS

NAVIGATOR PIPE ATTACHMENT AND BACKOUT

PREVENTION ASSEMBLIES

SYSTEM ASSEMBLY - OVERVIEW

BOP 010-2-4 QTR

QUARTER PLATE FLANGE MOUNT

BOP 030 COLLET

BLOCK ASSEMBLY

BOP 081-6

SNOUT TUBE

BOP 084

THREADED SNOUT TUBE

BOP 085

CAMLOCK

FF-121-XXX

COLLET

RECOMMENDED COLLET SIZES ARE

LOCATED IN THE “PART DIAGRAM“

SECTION AT THE BACK OF THIS MANUAL

Pipe shown

for graphic

representation only.

Not included in

assembly.

SYSTEM ASSEMBLY - OVERVIEW

BOP 050 STRAP MOUNT PIPE

ATTACHMENT ASSEMBLY BOP 012 SPLASH PLATE

9

866-795-1586 • WWW.STONEAGETOOLS.COM

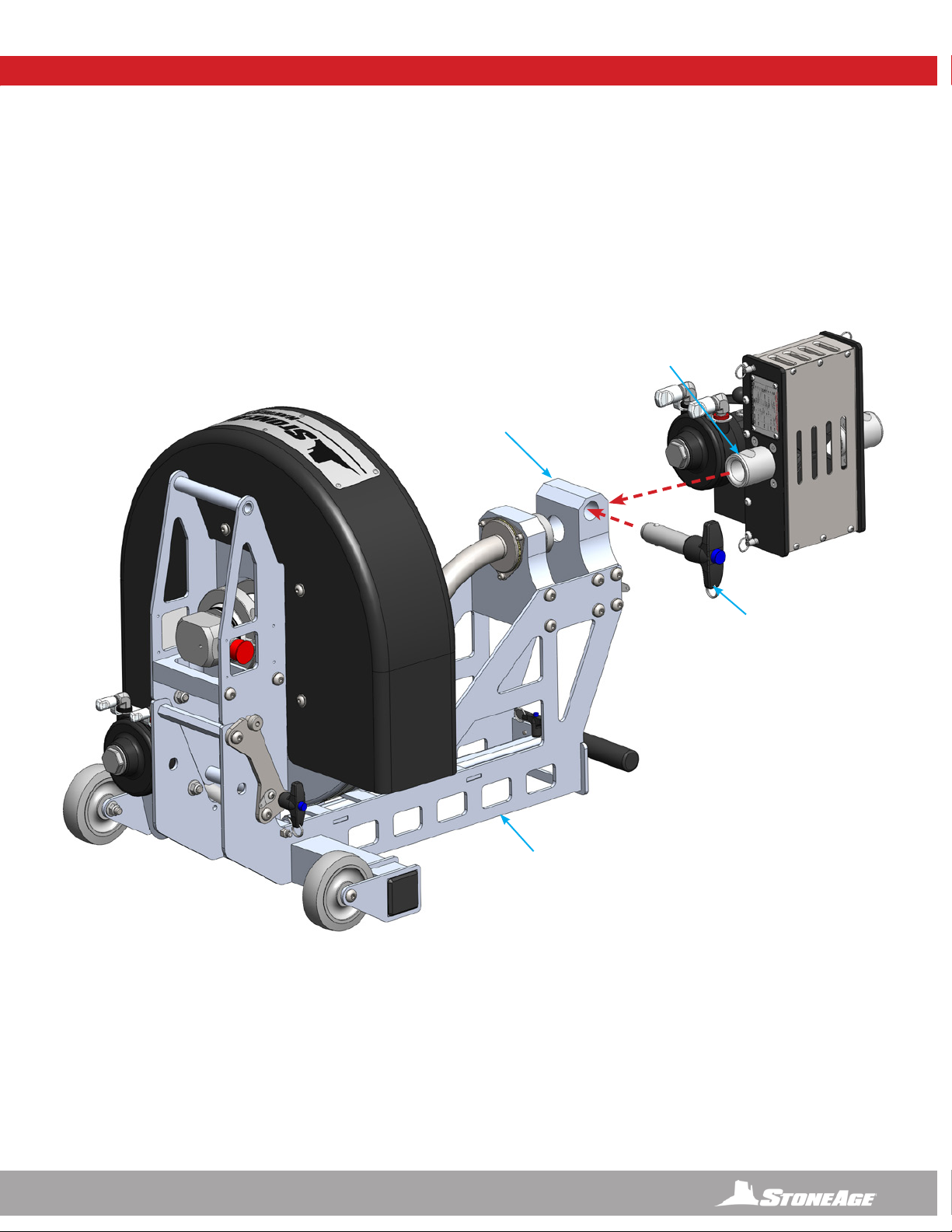

SYSTEM ASSEMBLY - OVERVIEW

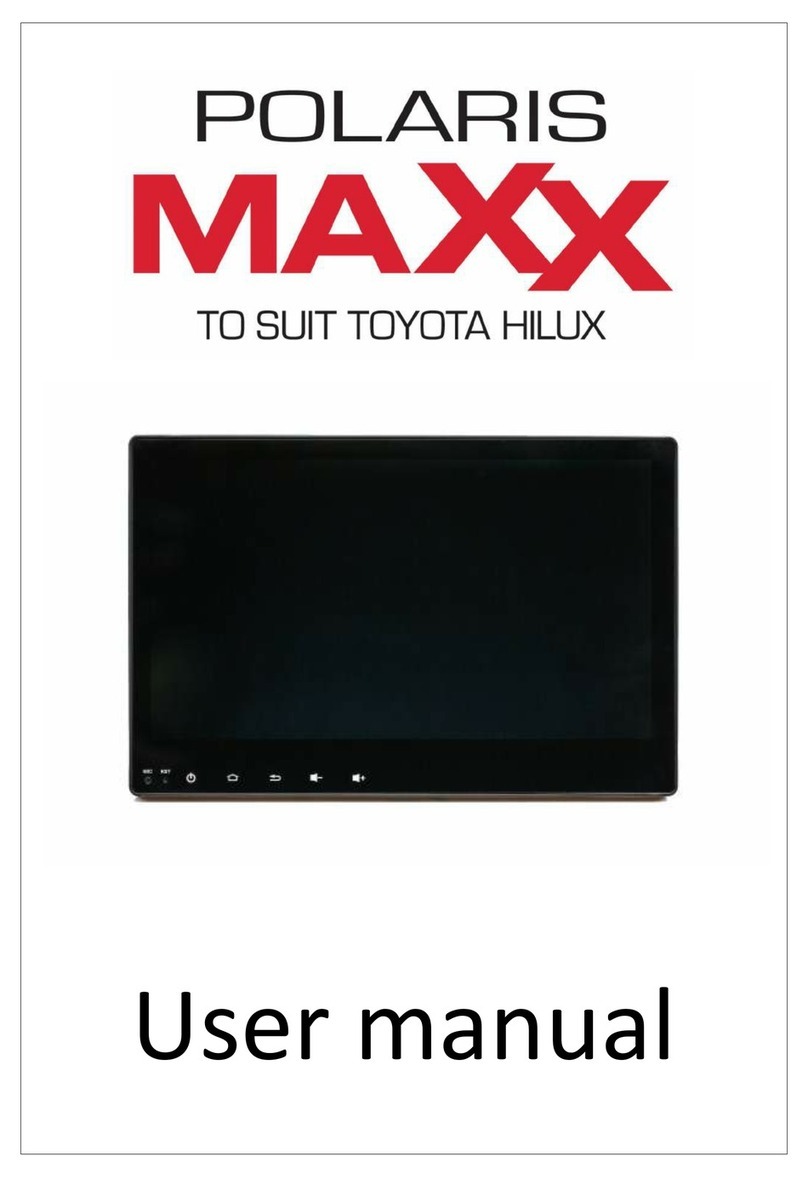

ABX-PRO

TRACTOR ASSEMBLY

DRUM FRAME

ASSEMBLY

BASE FRAME

ASSEMBLY

ELBOW

NAVIGATOR WITH CONTROL BOX ASSEMBLY

(NAV-100 AND CB-NAV)

FORWARD AND REVERSE

SPEED CONTROLS

ADJUSTABLE

HEIGHT STAND

18 IN -28 IN

(457mm - 711mm)

CONTROL BOX ASSEMBLY

(CB-NAV)

1/4” REEL TO AND FROM

DRUM ROTATION MOTOR

CONNECTIONS

FILTER,

REGULATOR,

LUBRICATOR (FRL)

1/2” HOSE

FORWARD AND

REVERSE CONNECTIONS

TO ABX-PRO

REMOTE

CONTROL BOX REMOTE CONTROL

BOX TETHER

10 FT (3048 mm)

10 866-795-1586 • WWW.STONEAGETOOLS.COM

NAVIGATOR SET-UP

1. Remove Quick Release Pin from Base Frame Assembly. Install the Hose Drum Assembly onto the Base Frame Assembly by placing

the shoulder screw heads into the notches on the Joint Plates and inserting the Quick Release Pin through the holes in the Joint

Plates. (Figure 1)

HOSE DRUM ASSEMBLY TO BASE FRAME ASSEMBLY

HOSE DRUM

ASSEMBLY

JOINT

PLATES

QUICK

RELEASE PIN

BASE FRAME

ASSEMBLY

FIGURE 1

11

866-795-1586 • WWW.STONEAGETOOLS.COM

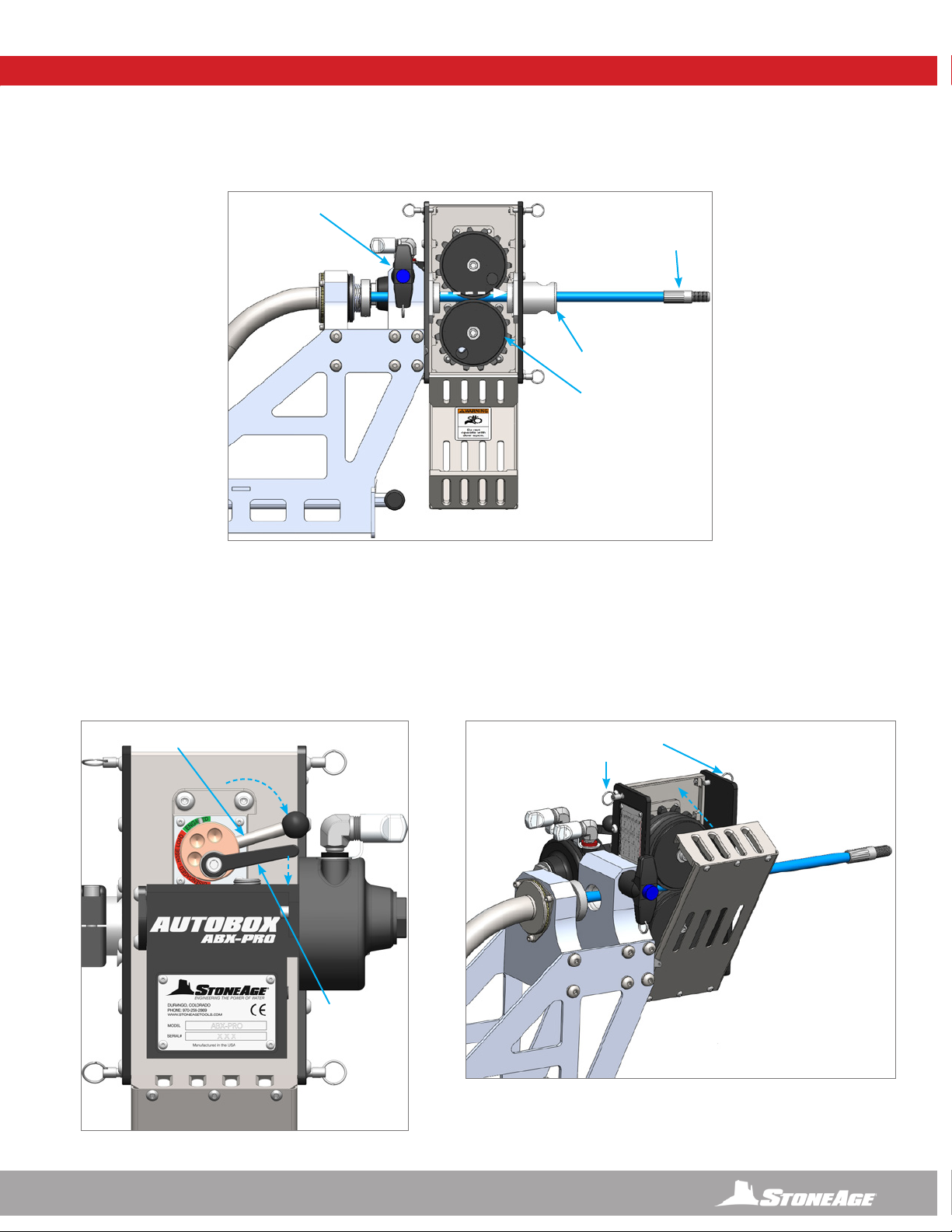

NAVIGATOR SET-UP

FIGURE 2

ABX-PRO PRODRIVE TO BASE FRAME ASSEMBLY

NAVIGATOR SET-UP

QUICK

RELEASE PIN

2. Remove Quick Release Pin from Base Frame Assembly, Install the ABX-PRO PRODRIVE onto the Base Frame Assembly by sliding the

Guide Tube into the Drive Mounting Block and inserting the Quick Release Pin. (Figure 2)

BASE FRAME

ASSEMBLY

DRIVE

MOUNTING

BLOCK

GUIDE TUBE

12 866-795-1586 • WWW.STONEAGETOOLS.COM

1. Connect the female hose end to the hose connection tube and wind the hose in the direction of the arrow inside the drum. (Figure 1)

NAVIGATOR SET-UP

ECCENTRIC

LEVER

HOSE

CONNECTION TUBE

DIRECTIONAL

ARROW

ELBOW

FIGURE 1

2. Load the hose into the ABX-PRO tractor by releasing the Adjustable Handle and rotating the Cam Lever counterclockwise until the

Indicator Pin is in the “Disengaged” position. This will open up the space between the rollers to allow for the hose to slip between

them. (Figure 2)

CAM LEVER

ADJUSTABLE

HANDLE

INDICATOR

PIN

FIGURE 2

LOADING THE HIGH-PRESSURE HOSE

NOTICE

Only high quality hoses intended for waterblast applications should be used as high-pressure hoses. Pressure rating of high-pressure hoses

MUST NEVER be exceeded. Do not use a shrouded hose or hose with a steel protective cover. This will cause severe damage to the Rollers.

13

866-795-1586 • WWW.STONEAGETOOLS.COM

NAVIGATOR SET-UP NAVIGATOR SET-UP

3. With the Rollers open, slip the hose through the Drive Block, Rollers and Guide Tube. Be sure to pull enough extension to feed through

the Snout. (Figure 3)

FIGURE 3

MALE

HOSE

END

ROLLERS

GUIDE

TUBE

DRIVE

BLOCK

4. Rotate the Cam Lever clockwise to the “Engaged” position to tighten the Idler Roller down onto the hose. Push the Adjustable Handle

down to tighten the bushing assembly. (Figure 4)

5. Push the back cover back into the closed position and secure the two Quick Release Pins on the top of the ABX-PRO AUTOBOX®

PRODRIVE TRACTOR. (Figure 5)

FIGURE 4

FIGURE 5

QUICK RELEASE

PINS

CAM

LEVER

ADJUSTABLE

HANDLE

“ENGAGED”

14 866-795-1586 • WWW.STONEAGETOOLS.COM

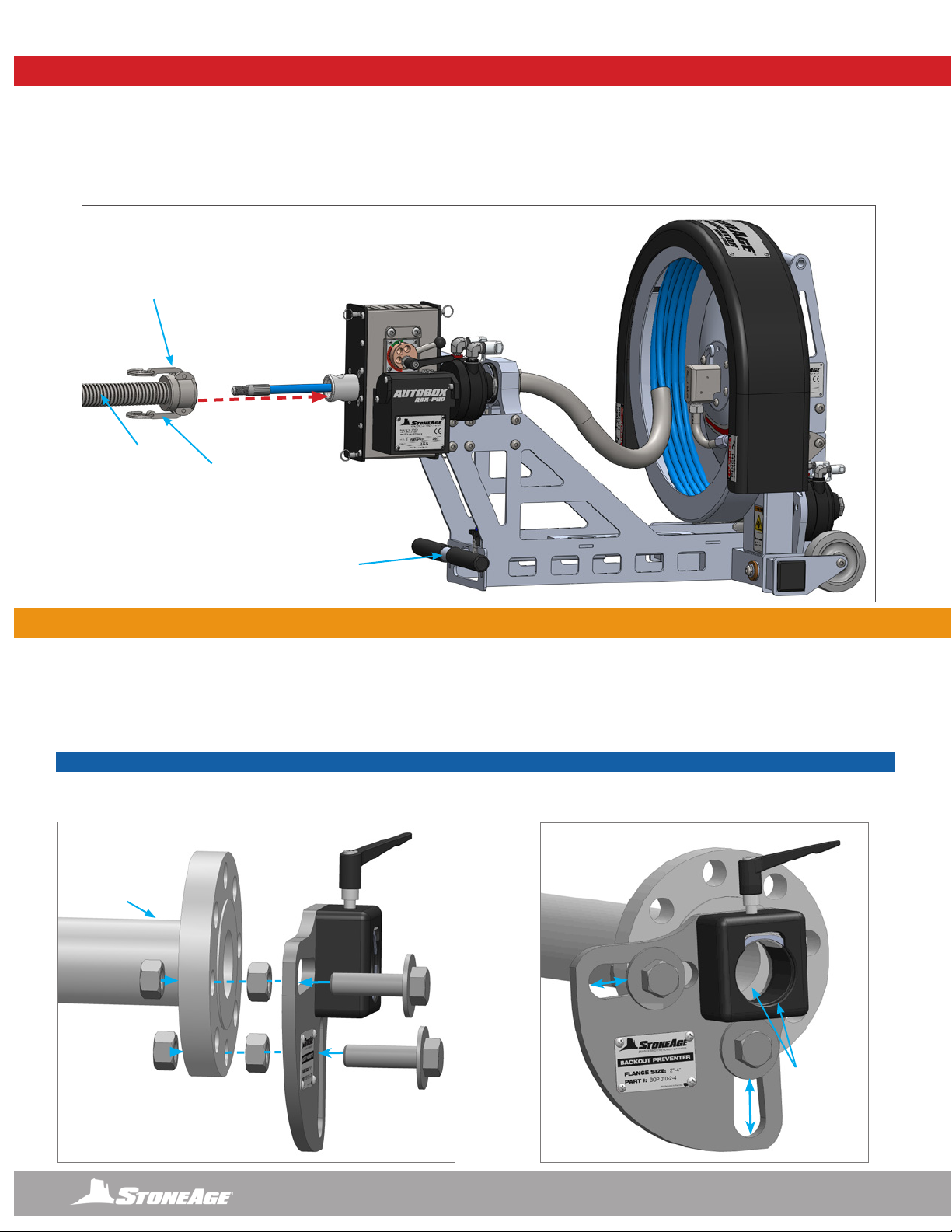

SNOUT ASSEMBLY TO ABX-PRO PRODRIVE

SNOUT

ASSEMBLY

1. Pull on the Camlock Release Rings and slide the Camlock onto the male end of the ABX-PRO PRODRIVE. Push the Camlock pins

back to lock into place. (Figure 1) Pull on the Snout Assembly to make sure it is secured. Feed the rest of the hose through the Snout

Assembly and leave enough length to feed through a pipe ange attachment.

NAVIGATOR SET-UP

BASE FRAME

ASSEMBLY

CAMLOCK

END

CAMLOCK

RELEASE RING

FIGURE 1

QUARTER PLATE FLANGE MOUNT (BOP 010-2-4 QTR) TO PIPE

1. Attach the Quarter Plate Flange Mount to the pipe ange using the fasteners that were removed from the ange joint. The nuts shown

between the pipe ange and the Quarter Plate Flange Mount are to allow for drainage. Other spacer options are acceptable. (Figure 1)

2. Adjust the Quarter Plate Flange Mount by sliding it along the slots to center the inside diameter of the Hinge Clamp with the inside

diameter of the pipe. Tighten all hardware to secure in place. (Figure 2)

FIGURE 1 FIGURE 2

USE FASTENERS

REMOVED FROM THE

FLANGE JOINT

ALIGN INSIDE

DIAMETERS

Pipe shown

for graphic

representation only.

Not included in

assembly.

QUARTER PLATE FLANGE MOUNT ASSEMBLY SET-UP - INCLUDED

NOTICE

If the cleaning tool diameter is larger than the inside diameter of the snout tubes, the high pressure hose will need to be fed through the

Quarter Plate Flange Mount before installing the tool on the male hose end. Skip to the next page if this is necessary.

15

866-795-1586 • WWW.STONEAGETOOLS.COM

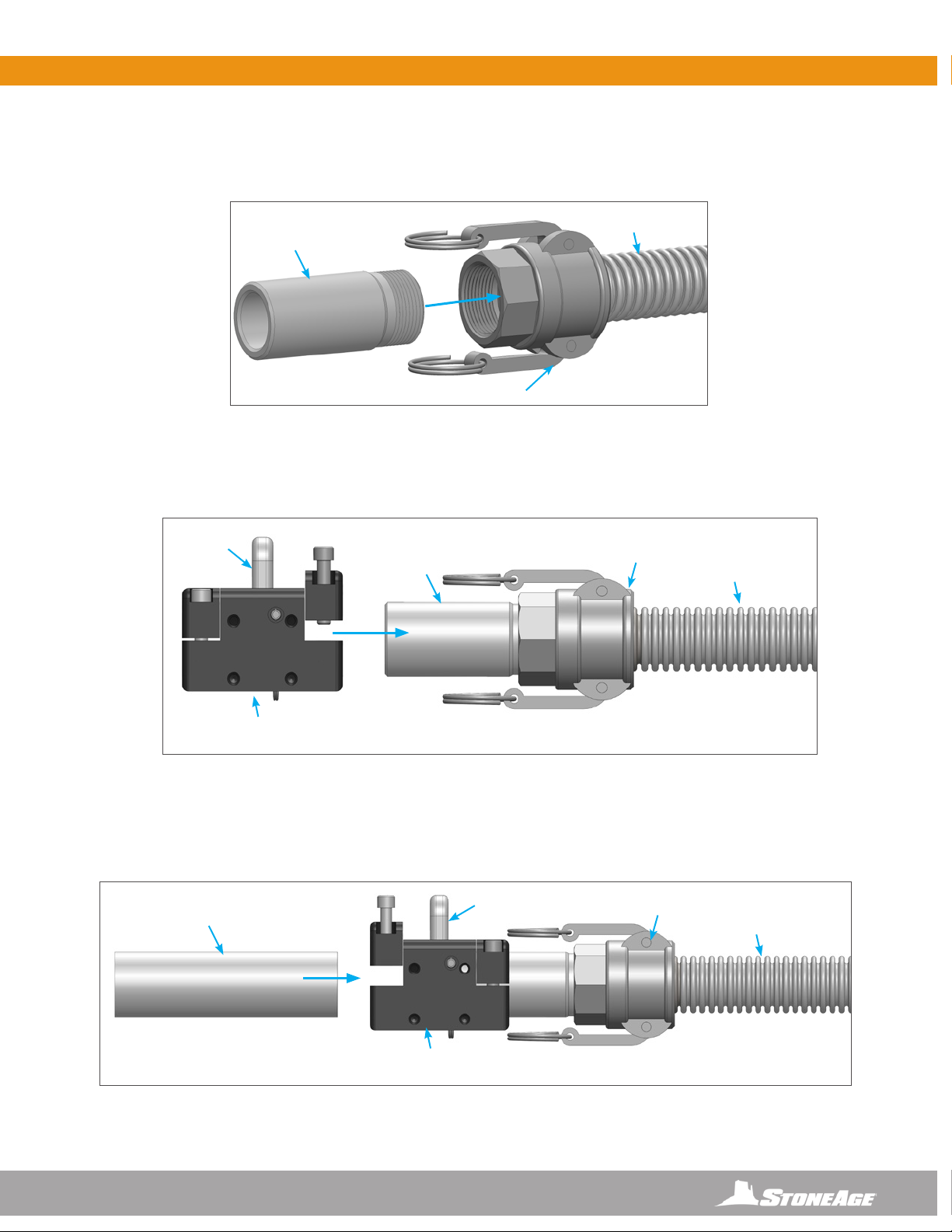

QUARTER PLATE FLANGE MOUNT ASSEMBLY SET-UP - INCLUDED

SNOUT CONNECTION AND BACKOUT PREVENTION ASSEMBLY

3. Thread the BOP 084 Threaded Snout Tube into the BOP 085 Camlock at the end of the BOP 090 Snout. (Figure 3)

4. Loosen the two screws on the collet cap block and slide the BOP 030 Collet Block Assembly onto the BOP 084 Threaded Snout Tube.

Push the Collet Block until it stops on the Snout Tube, then tighten the two screws securely. (Figure 4)

5. Loosen the two screws on the collet cap block and slide the BOP 081-6 Snout Tube into the BOP 030 Collet Block Assembly.

Push the Snout Tube until it stops in the Collet Block Assembly, then tighten the two screws securely. (Figure 5)

FIGURE 3

FIGURE 4

FIGURE 5

SNOUT

BOP 090

SNOUT

BOP 090

BOP 084

THREADED SNOUT

TUBE

BOP 084

THREADED SNOUT

TUBE

BOP 030 COLLET

BLOCK ASSEMBLY

BOP 030 COLLET

BLOCK ASSEMBLY

BOP 081-6

SNOUT TUBE

BOP 085

CAMLOCK

BOP 085

CAMLOCK

FF-121-XXX

COLLET

FF-121-XXX

COLLET SNOUT

BOP 090

BOP 085

CAMLOCK

16 866-795-1586 • WWW.STONEAGETOOLS.COM

QUARTER PLATE FLANGE MOUNT ASSEMBLY SET-UP - INCLUDED

MALE

HOSE END

BOP 010-2-4 QTR

QUARTER PLATE FLANGE MOUNT

ADJUSTABLE

HANDLE

TOOL

Pipe shown for graphic

representation only.

Not included in assembly.

HIGH PRESSURE

HOSE

SECTION VIEW

HINGE

CLAMP

6. Remove the Quick Release Pin and the Collet from the Collet Block Assembly. Push the Male Hose End past the Collet and reinsert

the Collet and Quick Release Pin. Test the collet by pulling the hose in the reverse direction of installation to ensure the Male Hose

End does not back out past the Collet. (Figure 6)

7. Attach desired tool onto the male hose end (Stoneage® Beetle®shown for reference). SEE THE APPLICABLE TOOL MANUAL

FOR INSTALLATION INSTRUCTIONS. Loosen the adjustable handle on the Hinge Clamp. Feed the high pressure hose with tool and

Snout Tube into the Quarter Plate Flange Mount. Tighten the adjustable handle to secure. (Figure 7)

BOP 030 COLLET

BLOCK ASSEMBLY

BOP 030 COLLET

BLOCK ASSEMBLY

BOP 081-6

SNOUT TUBE

FF-121-XXX

COLLET

SNOUT

BOP 090

FF-121-XXX

COLLET

FIGURE 7

FIGURE 6

BOP 081-6

SNOUT TUBE

POLY ROLLER

ABX-PRO HOSE O.D. SPIR STAR PARKER COLLET SIZE

STONEAGE

PART NUMBER

PRO 174-46

ø0.46 IN.

0.39 - 0.50 IN.

9.9 - 12.7 MM

4/4 2440D-025 0.438 in. / 11.0 mm FF 121-438

5/4 0.460 in. / 11.7 mm FF 121-460

2440D-03 0.484 in. / 12.3 mm FF 121-484

6/4 2440D-04 0.516 in. / 13.0 mm FF 121-516

SNOUT CONNECTION AND BACKOUT PREVENTION COLLET

NOTICE

The NAVIGATOR NAV-100 comes with one customer specied FF 121-XXX Collet installed in the BOP 030 Collet Block Assembly. It is

necessary to change the Collet size when changing to a different diameter hose. There are additional roller and collet sizes beyond the list

below that are only to be used when operating the ABX-PRO as part of the ABX-PRO-100 PRODRIVE Assembly. THE REPLACEMENTS

SHOWN IN THE CHART BELOW ARE THE ONLY SIZES TO BE USED WITH THE NAVIGATOR ASSEMBLY. Additional information on the

ABX-PRO-100 PRODRIVE Assembly can be found in the ABX-PRO-100 PRODRIVE manual at WWW.STONEAGETOOLS.COM.

WARNING

Prior to use, always test the backout preventer to ensure the tool does not pass backward through the Collet Block Assembly. Failure to do

so can result in severe injury and/or death. It is the responsibility of the user to select proper collet sizing to assure the end of the hose will

not pass through the Collet. Use the chart below in to select proper collet size.

17

866-795-1586 • WWW.STONEAGETOOLS.COM

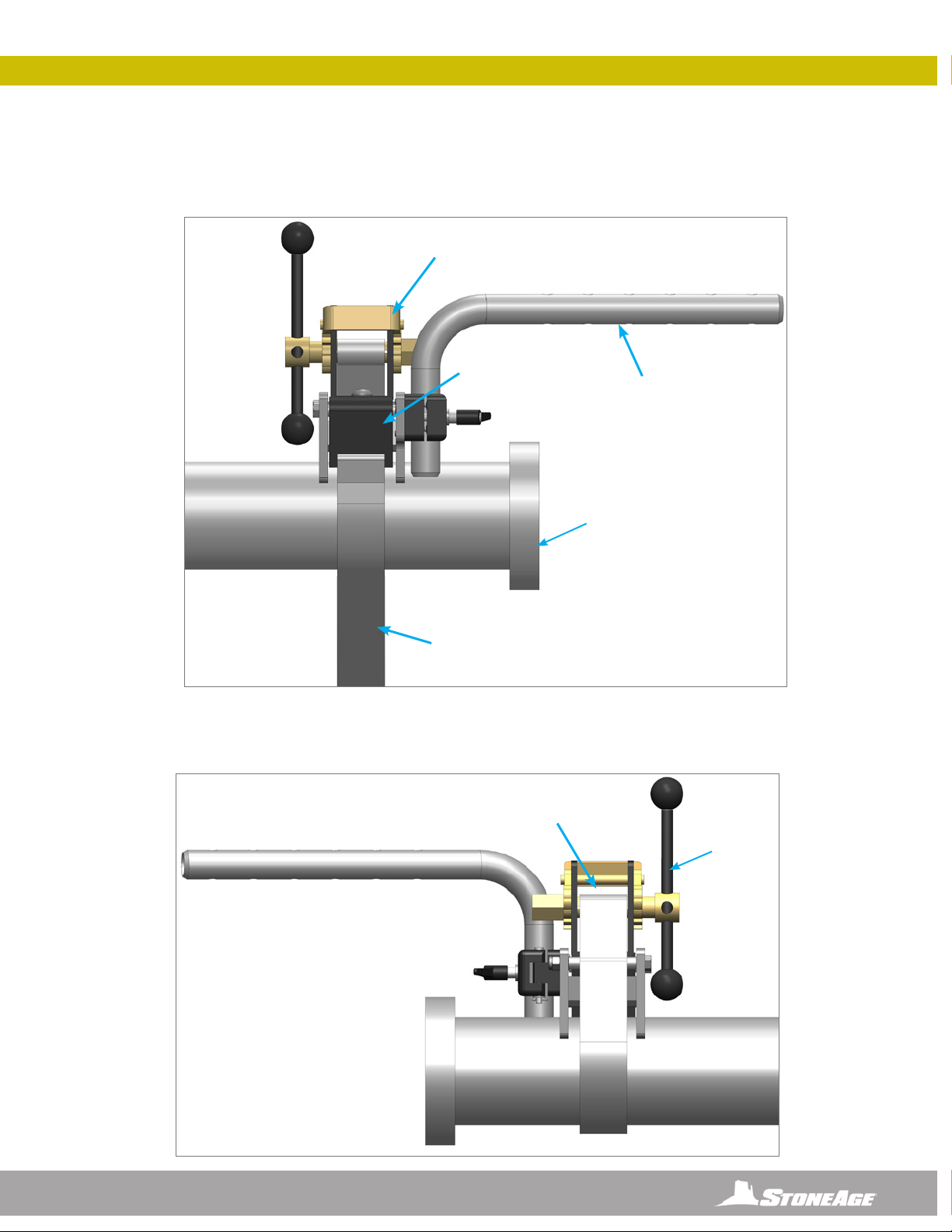

STRAP MOUNT ASSEMBLY SET-UP- OPTIONAL

The Strap Mount Assembly (BOP 050) is designed for pipes that do not have anges.

1. Attach the strap end to the strap capture bar and wrap the strap around the pipe towards the Winch Assembly. (Figure 1)

2. Pull excess strap through the Winch Assembly and tighten down with the Ball End Handle. (Figure 2)

FIGURE 1

FIGURE 2

STRAP END TO

CAPTURE BAR

MALE

POSITIONER

BAR

WINCH

ASSEMBLY

STRAP

BALL END

HANDLE

PULL EXCESS

STRAP THROUGH

STRAP MOUNT ASSEMBLY (BOP 050) - MALE POSITIONER SIDE

Pipe shown for graphic

representation only.

Not included in assembly.

18 866-795-1586 • WWW.STONEAGETOOLS.COM

FIGURE 3

3. Release the Adjustable Handle on the BOP 070 Hinge Clamp to access the 4 socket head cap screws. Locate the side of the BOP

030 Collet Block Assembly with 4 threaded holes. Orient the Hinge Clamp so that the hinge is on the right. Fasten the Hinge Clamp

Assembly to the Collet Block Assembly using the 4 supplied socket head cap screws. (Figure 3)

4. Insert the BOP 058 Female Positioner Assembly into the Hinge Clamp Assembly. This can be done in the open or closed position and

is designed to be adjustable based on the size of the pipe. (Figure 4)

5. Close the Hinge Clamp Assembly and tighten the Adjustable Handle. To Install the BOP 012 OPTIONAL Splash Plate loosen the two

bolts on the collar, slide it onto the BOP 081-6 Snout Tube and hand tighten the collar bolts when in position. (Figure 5)

STRAP MOUNT ASSEMBLY (BOP 050) - FEMALE POSITIONER SIDE

BOP 030 COLLET

BLOCK ASSEMBLY

BOP 058 FEMALE

POSTIONER

ASSEMBLY

SOCKET HEAD CAP

SCREWS (4)

BOP 070

HINGE CLAMP

ASSEMBLY

BOP 070

HINGE CLAMP

ASSEMBLY

COLLAR

COLLAR

BOLTS

ADJUSTABLE

HANDLE

FF-121-XXX

COLLET

FIGURE 4 FIGURE 5

ADJUSTABLE

HANDLE

*OPTIONAL BOP 012

SPLASH PLATE

STRAP MOUNT ASSEMBLY SET-UP- OPTIONAL

19

866-795-1586 • WWW.STONEAGETOOLS.COM

STRAP MOUNT ASSEMBLY SET-UP- OPTIONAL

5. Attach desired tool onto the male hose end (Stoneage® Beetle®shown for reference). SEE THE APPLICABLE TOOL MANUAL

FOR INSTALLATION INSTRUCTIONS. Connect the Male and Female Positioner Arms. Select the appropriate positioning holes and

insert the Quick Release Pin through both arms. (Figure 7)

DRIVE SIDE TUBE MOUNT AND BACKOUT PREVENTION COLLET

STRAP MOUNT ASSEMBLY SET-UP- OPTIONAL

FIGURE 6

TOOL

MALE HOSE

END

MALE

POSITIONER

ARM

FEMALE

POSITIONER

ARM

QUICK

RELEASE PIN

*OPTIONAL BOP 012

SPLASH PLATE

MALE

HOSE END

HIGH PRESSURE

HOSE

SNOUT

BOP 090

FF-121-XXX

COLLET

6. Remove the Quick Release Pin and the Collet from the Collet Block Assembly. Push the Male Hose End past the Collet and reinsert

the Collet and Quick Release Pin. Pull back on the hose to ensure the Male Hose End does not back out past the Collet. (Figure 6)

*OPTIONAL BOP 012

SPLASH PLATE

BOP 030 COLLET

BLOCK ASSEMBLY

BOP 081-6

SNOUT TUBE

FIGURE 7

Pipe shown for graphic

representation only.

Not included in assembly.

POLY ROLLER

ABX-PRO HOSE O.D. SPIR STAR PARKER COLLET SIZE

STONEAGE

PART NUMBER

PRO 174-46

ø0.46 IN.

0.39 - 0.50 IN.

9.9 - 12.7 MM

4/4 2440D-025 0.438 in. / 11.0 mm FF 121-438

5/4 0.460 in. / 11.7 mm FF 121-460

2440D-03 0.484 in. / 12.3 mm FF 121-484

6/4 2440D-04 0.516 in. / 13.0 mm FF 121-516

NOTICE

The NAVIGATOR NAV-100 comes with one customer specied FF 121-XXX Collet installed in the BOP 030 Collet Block Assembly. It is

necessary to change the Collet size when changing to a different diameter hose. There are additional roller and collet sizes beyond the list

below that are only to be used when operating the ABX-PRO as part of the ABX-PRO-100 PRODRIVE Assembly. THE REPLACEMENTS

SHOWN IN THE CHART BELOW ARE THE ONLY SIZES TO BE USED WITH THE NAVIGATOR ASSEMBLY. Additional information on the

ABX-PRO-100 PRODRIVE Assembly can be found in the ABX-PRO-100 PRODRIVE manual at WWW.STONEAGETOOLS.COM.

WARNING

Prior to use, always test the backout preventer to ensure the tool does not pass backward through the Collet Block Assembly. Failure to do

so can result in severe injury and/or death. It is the responsibility of the user to select proper collet sizing to assure the end of the hose will

not pass through the Collet. Use the chart below in to select proper collet size.

20 866-795-1586 • WWW.STONEAGETOOLS.COM

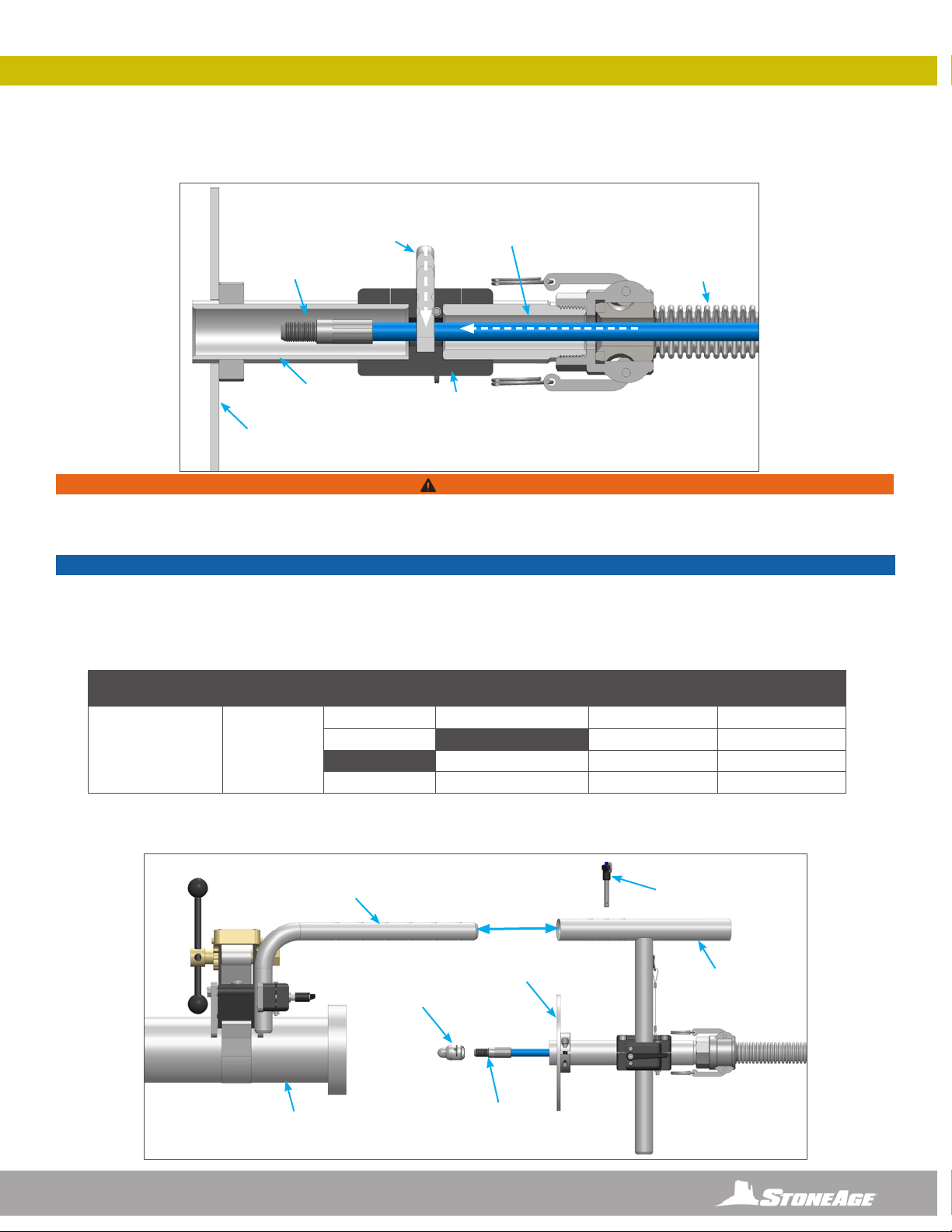

TIGHT PIPE FLANGE JOINT ATTACHMENT OPTIONS

QUARTER PLATE BOP

BOP 010-2-4 QTR

Pipe shown for graphic

representation only. Not

included in assembly.

(INCLUDED WITH NAVIGATOR PACKAGE)

TIGHT PIPE FLANGE JOINT ATTACHMENT OPTIONS

(NOT INCLUDED WITH NAVIGATOR PACKAGE)

BOP 012 SPLASH PLATE

BOP 050 STRAP

MOUNT ASSEMBLY

NAV-100 NAVIGATOR ASSEMBLY

WITH STRAIGHT MOUNTING OPTIONS

*THE MOUNTING OPTION BELOW IS USED ON FLANGED PIPES*

*THE MOUNTING OPTION BELOW IS USED ON FLANGELESS PIPES*

Pipe shown for graphic

representation only. Not

included in assembly.

This manual suits for next models

1

Table of contents