Stork RSI User manual

STORK RSI®

printhead

User Manual

(as from Q400)

User manual RSI 2

Disclaimer

The material in this manual is believed adequate for the intended use of the

system. If the system, or its individual modules or procedures, are used for

purposes other than those specified herein, confirmation of their validity and

their suitability must be obtained. Stork Prints B.V. warrants that the material

itself does not infringe any known patents. No further warranty is expressed or

implied.

Copyright

All technical and technological information contained in this manual, including

any drawings and technical specifications provided by us, shall remain our

property and may not be used (other than for the operation of this product),

copied, multiplied, passed on or communicated to a third party without our

prior written permission.

Stork Prints B.V.

Raamstraat 1-3

P.O. Box 67

5830 AB Boxmeer, The Netherlands.

tel. +31(0) 485 599555

fax +31(0) 485 572282

E-mail: [email protected]

©2004 Stork Prints B.V.

Stork Prints B.V. 8000000EN-04-2

User manual RSI 3

Contents

Disclaimer................................................................................................................2

Copyright .................................................................................................................2

Contents ..................................................................................................................3

i General introduction to the operating instructions.............................................5

ii How to use the user manual..............................................................................6

iii Notes to the user...............................................................................................7

iv Notational Conventions.....................................................................................8

vSafety................................................................................................................9

vi Technical Specifications..................................................................................11

1. Introduction ............................................................................................................12

1.1. Mechanical/Pneumatic Components .............................................................................12

1.1.1. Frame 12

1.1.2. Shielding and Protection 13

1.1.3. Screen Holder 13

1.1.4. Squeegee Suspension 13

1.1.5. Squeegee holder 14

1.1.6. Screen drive 14

1.1.7. Pneumatic Box 14

1.1.8. Auxiliary and/or optional Equipment 15

1.1.8.1. Ink Supply System 15

1.1.8.2. Squeegee set-up tool 15

1.1.8.3. Automatic Ink Level Control System (ILCU). 15

1.1.8.4. Automatic Register Control System (optional) 15

1.2. Electrical Functions........................................................................................................15

1.2.1. Supply Voltages 15

1.2.2. Component Parts 16

1.2.2.1. Control Panel 16

1.2.2.2. Motor Control Unit 18

1.2.2.3. Drive Motor 18

1.2.2.4. Speed Reference Encoder 18

1.2.2.5. Screen Position Detector 18

1.2.2.6. Pressure Switch 18

1.2.2.7. Printing Release Valve 18

2. Preparation for printing...........................................................................................19

2.1. Squeegee Preparation...................................................................................................19

2.1.1. Introduction 19

2.1.2. Procedure 19

2.2. Installing a Screen..........................................................................................................21

2.2.1. Introduction 21

2.2.2. Preparing the printhead for use 21

2.2.3. Inserting a Screen 22

2.2.4. Fitting the Squeegee Holder 23

2.2.5. Setting Gap between Screen and Impression Roller 24

2.2.6. Setting the Squeegee Height 24

2.2.7. Setting the Squeegee Pressure 25

2.2.8. Connecting the ink supply 25

2.2.9. Inserting the flexible tube into the pump head 26

3. Operating the printhead .........................................................................................29

3.1. Operators Responsibility................................................................................................29

3.2. Starting Criteria..............................................................................................................29

3.3. Initial Action....................................................................................................................29

3.4. Confirm the screen size .................................................................................................29

Stork Prints B.V. 8000000EN-04-2

User manual RSI 4

3.5. Slow rotation. .................................................................................................................30

3.6. Ink Supply.......................................................................................................................31

3.7. Moving the squeegee / printhead into the printing position ...........................................31

4. Fine adjustments to the printhead..........................................................................33

4.1. Length Registering.........................................................................................................33

4.1.1. Course pre-alignment. 33

4.1.2. Fine adjustment. 33

4.2. Lateral Registering.........................................................................................................33

5. Automatic Ink Level Control system.......................................................................35

5.1. Function of the automatic ink level control system. .......................................................35

5.2. Installation of the sensor................................................................................................35

5.3. Adjust the ink level.........................................................................................................36

5.4. Ink level control in production.........................................................................................38

5.4.1. Ink supply by hand 38

5.4.2. Automatic ink supply 38

5.4.2.1. Switch on the ILCU 38

5.5. Pressure switch type PSE300........................................................................................39

5.6. Regulate of the ILCU......................................................................................................39

5.7. Adjust valve “B” en check the reduce valve...................................................................39

5.8. Adjust valve “C”..............................................................................................................39

5.9. Maximum adjust PSE300...............................................................................................39

5.10. Save the settings............................................................................................................39

6. Removing a screen from the printhead..................................................................40

6.1. Ink supply Control ..........................................................................................................40

6.2. Putting the squeegee / printhead in Non-printing Position.............................................40

6.3. Removing the squeegee holder.....................................................................................41

6.4. Opening the Screen Holder............................................................................................41

6.5. Removing the Screen.....................................................................................................42

6.6. Cleaning the screen and squeegee holder....................................................................42

7. Adjustments ...........................................................................................................43

7.1. Initial Check....................................................................................................................43

7.2. Adjusting the Gap between Screen and Impression Roller...........................................43

7.3. Adjusting the Squeegee.................................................................................................44

8. Optional automatic register control system............................................................46

8.1. Choose web cylinder comparison or web web comparison...........................................46

8.2. Web-Cylinder comparison mode....................................................................................46

8.3. Web-Web comparison mode..........................................................................................47

8.4. Pre-conditions ................................................................................................................47

8.5. Start the Web-Cyl comparison mode.............................................................................47

8.6. Start the Web-Web comparison mode...........................................................................48

8.6.1. Change or edit more parameters in Web-Web comparison mode 48

8.7. Web Capture button.......................................................................................................49

8.8. Monitoring the RCS........................................................................................................49

8.9. Compensating linear errors............................................................................................50

9. Printmark scanners................................................................................................51

9.1.1. Installation 51

9.1.2. Setting the switching threshold 52

9.2. Some important notes regarding the positioning of the print mark scanners: ...............52

9.3. Web-Cyl comparison mode............................................................................................52

9.4. Web-Web tracking mode................................................................................................53

9.5. Parameter ‘Pscan’ and ‘Sscan’......................................................................................53

9.6. Parameter Sc_pm..........................................................................................................54

9.7. Print mark scanner capture inputs.................................................................................54

9.8. Print mark scan errors....................................................................................................54

10. Annex 1 Pneumatic plan (ILCU).............................................................................56

11. Annex 2 Manual PSE300.......................................................................................57

Stork Prints B.V. 8000000EN-04-2

User manual RSI 5

i General introduction to the operating

instructions.

• Any technical and technological information contained in these operating

instructions, as well as any drawings and technical specifications made

available by us remain our property and shall not to be used (other than for

the operation of this installation), copied, multiplied, handed over or

communicated to third parties without our prior written consent.

• The data published in these operating instructions have been based on the

most recent information. They are provided subject to alterations.

• We reserve the right to change the design and/or construction of our

products at any time without being obliged to adapt earlier supplies

accordingly.

• These operating instructions contain useful and important information

allowing your installation to be properly operated and maintained. They

also contain important instructions for preventing possible accidents and

serious damage prior to commissioning and during operation of the

installation, thus ensuring as safe and trouble free an operation of your

installation as possible. Carefully read the instructions prior to putting the

installation into operation, familiarise yourself with the functioning and

operation of your installation and strictly adhere to the instructions given. In

this respect we would emphasise the importance of training in the correct

handling of the installation. It is essential that these operating instructions

are kept in a fixed place in the vicinity of the installation.

• This installation, just like other installations, also requires periodic

maintenance. The chapter “spare parts” provides you with the required

information on spare parts identification. It is intended for your technical

and servicing personnel and for those who are responsible for spare parts

ordering.

• Should you have any further questions or wish to receive additional

explanation regarding specific matters concerning your installation, please

do not hesitate to contact us.

• Finally, we would point out that any guarantee issued for your installation

will become null and void and that you shall indemnify us against any

product liability claims filed by third parties if:

• The servicing and maintenance jobs have not been performed strictly in

accordance with the instructions, repairs have not been carried out by our

personnel or carried out without our prior written consent;

• The installation has been changed without our prior written consent;

• Non-original Stork parts or lubricants other than those specified have been

used;

• The installation has been used inexpertly, incorrectly, carelessly or not in

line with its nature and/or destination.

• The General Terms of Delivery already in your possession are applicable.

Stork Prints B.V. 8000000EN-04-2

User manual RSI 6

ii How to use the user manual

Who Should Read This Manual

The Stork Prints RSI printhead User Manual is intended for use by those

people who will use the RSI Printhead to print an image.

Organisation

This manual is organised as follows:

Chapter 1 INTRODUCTION describes the main parts of the printhead.

Chapter 2 PREPARATION FOR PRINTING describes how to install a

screen in the printhead.

Chapter 3 OPERATING THE PRINTHEAD describes how to use the

printhead to print an image.

Chapter 4 FINE ADJUSTMENTS TO THE PRINTHEAD explains the

control options for operator use.

Chapter 5 INK LEVEL CONTROL SYSTEM describes how to operate this

system.

Chapter 6 REMOVING A SCREEN FROM THE PRINTHEAD explains the

steps to be taken to remove a screen from the printhead at the

end of printing.

Chapter 7 ADJUSTMENTS explains the adjustments of the printhead

during commissioning and normal production.

Chapter 8 OPTIONAL AUTOMATIC REGISTER CONTROL SYSTEM

describes how to operate and (if ordered separately) install this

system.

Chapter 9 Annex Pneumatic plan / Manual DP-M2.

Stork Prints B.V. 8000000EN-04-2

User manual RSI 7

iii Notes to the user

This manual is for the Stork RSI printhead.

It contains information for using that equipment. It also contains important

instructions to prevent accidents and serious equipment damage.

Before you begin to use the product, read this manual carefully to familiarise

yourself with the construction of the product.

When using the machine, follow the instructions precisely.

If you have any questions or need further details of specific matters

concerning this product, please do not hesitate to contact Stork.

The information contained in this manual is based on the latest information. It

is provided subject to alterations.

We reserve the right to change the construction and/or configuration of our

products at any time without being obliged to adjust earlier supplies

accordingly.

Although we have made every effort to make this manual as accurate and

complete as possible, there may be some errors and omissions.

If you do find any errors or omissions, please bring them to our attention so

that we may correct them. In this way we hope to improve our product

documentation for the benefit of ourselves and our clients.

Please send your corrections and comments to our Customer Service

Department.

Stork Prints B.V.

P.O. Box 67

5830 AB Boxmeer, The Netherlands.

tel. +31(0) 485 599555

fax +31(0) 485 572282

E-mail: [email protected]

©2004 Stork Prints B.V.

Stork Prints B.V. 8000000EN-04-2

User manual RSI 8

iv Notational Conventions

This document contains several types of messages to emphasise information

or point out potential risks to personnel or equipment. A sample of each

message type follows:

NOTE:

Notes provide additional information, such as expanded explanations, hints, or

reminders.

CAUTIONS:

Cautions point out procedures that you must follow precisely to avoid damage

to equipment, loss of data, or corruption of files in software applications.

WARNINGS:

Warnings point out procedures that you must follow precisely to avoid

personal injury.

ITALICS:

If a sentence is italicised, this is extra information to clarify the statement

preceding it.

Stork Prints B.V. 8000000EN-04-2

User manual RSI 9

v Safety

General Precautions

Personnel using the printhead should be thoroughly familiar with all aspects of

its operation. To ensure the safety of personnel, read this section carefully

before beginning to work.

Additionally, to promote safety awareness, operators should periodically

review the basic precautions outlined in the following subsections.

Personnel who are using the printhead should be know the regulations of the

ink supplier. Follow up the instructions of the ink supplier exactly.

Cleaning of the equipment, release of ink, should also been done according to

the instructions of the ink supplier.

WARNING: The screen is fragile. Take special care when touching it. If the

screen breaks, it will have sharp edges.

Specific precautions

Safety instructions, which are applicable to a specific piece of the

printhead, are given at the beginning of any paragraph where that

equipment is used.

Watch out! Risk for turning en moving parts.

During moving of the substate, and/or printing with the printunit

there is a risk of body injury.

Watch out! Risk for voltage.

Watch out! Risk for stick / clamp.

Safety measures

• The equipment has been designed to meet with internationally accepted

safety regulations. Use the RSI unit only for the goal where for its disigned.

• Keep the RSI unit and his neighbourhood decently and clean.

• In spite of all precautions, be careful when working on the equipment.

• Abide by the Stork Prints safety regulations.

• Carry out of reparation and replacement is for bidden as has to be done by

the machine supplier.

• Observe all cautions or warnings, stated or implied, in the procedures.

• Do not wear rings, watches, neckties, or loose fitting clothing.

• If asked to do so, wear safety glasses, safety shoes.

Stork Prints B.V. 8000000EN-04-2

User manual RSI 10

• Unless specified otherwise, Disconnect, lock out, tag and try all

electrical connections before servicing the machine. Use extreme

caution to avoid electrical or mechanical injury.

• Unless specified otherwise, do not operate the equipment with covers and

panels removed.

• Never bypass or override equipment safety measures.

• Use sufficient personnel and/or lifting devices to move the equipment.

Work safely!

Stork Prints B.V. 8000000EN-04-2

User manual RSI 11

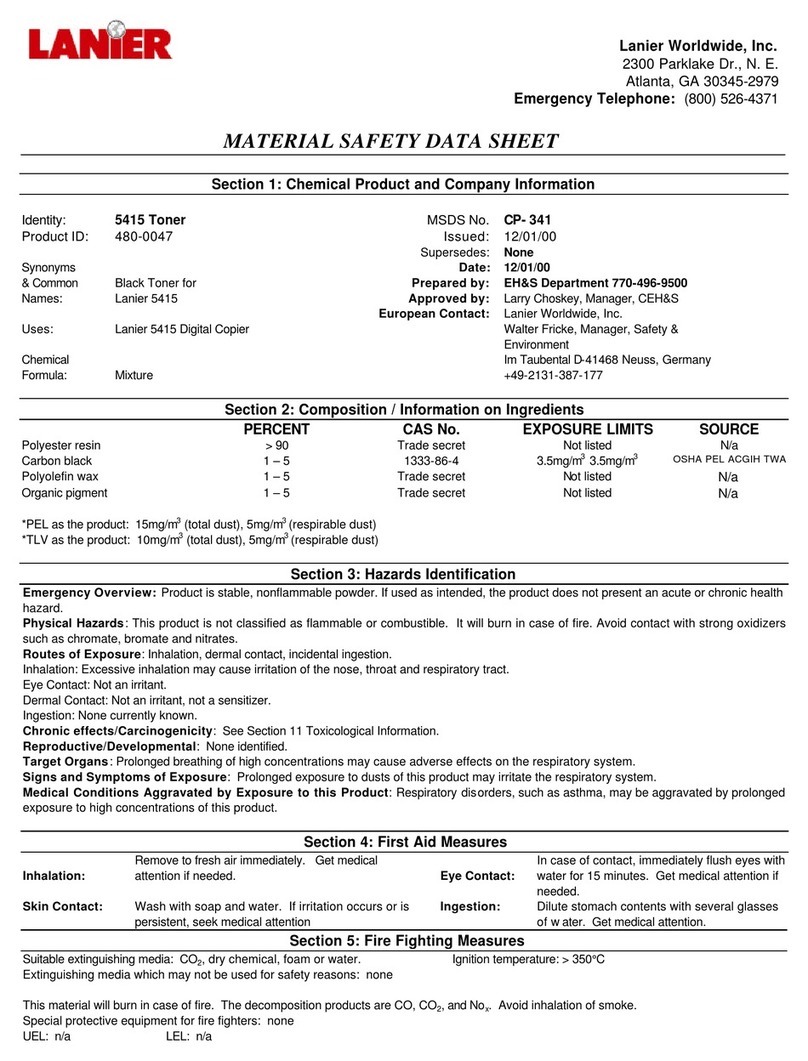

vi Technical Specifications

General Specifications

Maximum printingspeed : 150m/min (480ft/min)

Minimum printingspeed : 1,5 m/min (4,5 ft/min)

Webtension standard

rubber impressionroller : max. 0,3 N/mm (optional steel

impressionroller)

Print Accuracy : +/- 0,15 mm

Gearing : 1/8” (Option 1/6”)

Air pressure : 6 – 8 bar (87 – 116 PSI)

Air consumption : 0,6m3/hr

Electrical power : 1 kW

Main supply voltage : 3 x 230 VAC – 5% to 3 x 480 VAC + 10%

50/60 Hz ,Neutral, Ground.

Supply Graymills pump : 230 VAC 50/60 Hz ±5% (available at

MCU)

Sound level : less than 70 dB(A)

Sreen size related specifications

RSI®10“ 16“ 20“ 24“ (24“ + 40 mm

special)

Maximum Printing

Width 10“ 16“ 20“ 24“ 24“ + 40 mm

Maximum web

width 10.25“ 16.25“ 20.25“ 24.25“ 24.25“ + 40 mm

Repeat range 12-25¼“ 12-25¼“ 12-25¼“ 16-25¼“ 16-25¼“

Repeat increment 1/8“ (1/6“) 1/8“ (1/6“) 1/8“ (1/6“) 1/8“ (1/6“) 1/8“ (1/6“)

Stork Prints B.V. 8000000EN-04-2

User manual RSI 12

1.Introduction

A Rotary Screen printer uses a cylindrical RotaMesh®screen, a squeegee, an

impression roller, the substrate and ink.

The substrate passes between the screen and the impression roller. When the

screen begins to rotate with the screen and the squeegee in the print position,

the squeegee presses ink through the holes in the screen to transfer the

image onto the substrate.

This chapter describes the various mechanical/pneumatic and electrical

components of the printhead shown in figure 1.

figure 1 RSI®printhead

1.1. Mechanical/Pneumatic Components

• The printhead comprises the following mechanical

• components:

• Frame

• Shielding and protection

• Screen holder

• Squeegee suspension

• Squeegee

• Screen drive

• Pneumatic box

• Auxiliary and/or optional equipment

1.1.1. Frame

The frame comprises a steel box section containing the fixing points for the

impression roller, guide roller, spacing adjusters, tilting points, etc.

Stork Prints B.V. 8000000EN-04-2

User manual RSI 13

The base plate acts as the mechanical interface between the printhead and

any other machine upon which the printhead is to be mounted.

1.1.2. Shielding and Protection

On the print unit there is a rotatable protective shield. When a screen is to be

inserted or removed, the shield can be opened. Screen rotation can only

begin when the shield is closed, the screen is under tension and the screen

holder is closed.

1.1.3. Screen Holder

This is constructed from two holders coupled together by shafts. In each

holder there is a mechanism with three rollers controlling radial movements of

a screen, and two rollers which exert axial pressure upon the screen when the

two holders are pushed apart. Pneumatic cylinders are fitted at the end of the

shafts to pull the two holders apart.

The complete construction is pivoted in two places so that it can tilted.

Another pneumatic cylinder is used to tilt the complete assembly into either

the printing position where it rest on a variable position stop, or the free

position.

A graduated knob, at the operator’s side of the unit, allows the screen and

squeegee to be moved in the axial direction for alignment purposes.

A maximum positional change of 5 mm either side of the centre line is

possible. Two other graduated knobs, protruding from the rear of the

printhead, allow the operator to change the position of the screen relative to

the impression roller so that it is parallel and correctly spaced. Correctly

spaced means; the distance between the impression roller and the screen is

the same as the thickness of the substrate being printed upon.

The screen holder has four functions:

• Moving the screen so that it lies at the correct distance from, and parallel

to, the impression roller.

• Axial tension of the screen after the two halves of the holder have been

forced apart.

• Moving the screen into the printing or free position.

• Moving the screen in the axial direction for alignment purposes.

1.1.4. Squeegee Suspension

This consists of two arms to the left and right of the printing zone each of

which is constructed to accept an end of the squeegee holder. Each arm is

controlled by a pneumatic cylinder which allows the squeegee holder to be

moved to the printing or free position.

The functions of the squeegee suspension are:

• Holding the squeegee holder so that it is always in the same starting

position.

• Moving the squeegee holder in and out of the printing position.

• Controlling the squeegee pressure by a variable position stop.

Stork Prints B.V. 8000000EN-04-2

User manual RSI 14

• Controlling the squeegee height by a graduated knob protruding from the

operating side of the printhead. This is done simultaneously left and right.

1.1.5. Squeegee holder

The squeegee holder presses ink through the screen (image carrier). A

squeegee, shown in figure 2, comprises:

• An extruded aluminium profile with a stainless steel pipe fitted at either end

to allow it to be fitted into the squeegee suspension units.

• Side plates which are used to keep the ink away from the end rings.

• A squeegee blade with a special tip along the edge, when necessary,

support blades.

figure 2 Squeegee

To ensure that the squeegee blade is positioned correctly in the squeegee

assembly, a special squeegee set-up tool is supplied. See § 1.1.8.2

1.1.6. Screen drive

Screen rotation is obtained from gear wheels mounted at either side of the

print unit. The gear wheels are connected by a common shaft which also

contains a coupling to compensate for gear wheel alignment differences at

either side of the screen. Primary drive to this system is supplied by a servo

motor.

The functions of the screen drive are:

• To ensure that the rotational speed of the screen is synchronised with the

speed of the substrate passing the screen.

• To ensure that the screen is rotated slowly to prevent leakage when the

unit is in the free position (not printing).

• To control the printing register of the screen so that the printed design is

correctly aligned with a previously printed design.

• To bring the screen in pre-register with the main printing machine.

1.1.7. Pneumatic Box

At the non-operating side of the printhead is a box containing the pneumatic

control valves and electrical terminals used in the pneumatic control circuit.

Stork Prints B.V. 8000000EN-04-2

User manual RSI 15

1.1.8. Auxiliary and/or optional Equipment

1.1.8.1. Ink Supply System

Ink is supplied to the printhead by means of a peristaltic pump.

A tube connects the pump to a small pipe at the operators side of the

squeegee.

1.1.8.2. Squeegee set-up tool

A special squeegee set-up tool is supplied with the printhead so that

squeegee blades can be accurately positioned in the squeegee holder.

Operating this tool is explained in § 2.1 Squeegee Preparation.

1.1.8.3. Automatic Ink Level Control System (ILCU).

With this system the ink level inside the screen can be controlled

automatically.

Depending on the ink level the ink supply is automatically started or stopped.

This makes operating the RSI printhead even easier and assures a very

constant print result.

For documentation/ information see chapter 5 Automatic Ink Level Control

system.

1.1.8.4. Automatic Register Control System (optional)

This system sees to it that the screen can keep a specific position relative to

the register or pre-printed mark on the substrate. The RSI than follows press

speed (standard) and stays in register automatically. This makes operating

the RSI printhead even easier and assures a very constant print result.

For documentation/ information see chapter 8 Optional automatic register

control system.

1.2. Electrical Functions

The following paragraphs describe the electrical functions and supply voltages

of the RSI printhead.

1.2.1. Supply Voltages

Power for the RSI printhead should be taken from a 3 phase 400 V 50/60 Hz,

Neutral and ground supply.

Each printhead has a consumption of approx. 1000 VA.

If an emergency stop button is pressed, the supply to the printhead is

interrupted after the main printing machine has stopped.

Auxiliary power is taken from a 230 VAC, 0,1 A supply.

This supply should not be interrupted if an emergency stop button is pressed.

All electrical connections should be in accordance with the electrical diagrams

produced by Stork.

Stork Prints B.V. 8000000EN-04-2

User manual RSI 16

1.2.2. Component Parts

In the printhead there are a number of discrete electrical components which

are:

• Control panel

• Motor control unit

• Drive motor

• Speed reference encoder

• Screen position detector

• Pressure switch

• Printing release valve

• Ink Level Control System

1.2.2.1. Control Panel

This panel is mounted at the front of the machine and is used by operators

and maintainers. Operators use it to synchronise the speed of the printhead

with the main machine, and to define the size of screen being used. See

figure 3. Service engineers can use the panel to observe and change various

system parameters.

Stork Prints B.V. 8000000EN-04-2

User manual RSI 17

The control panel has the following control and monitoring functions:

1. Enter button (edit parameters) 14. Button down edit parameters

2. Printhead (release) indicator

(ready to print) 15. Button up edit parameters

3. LED web – cylinder comparison

mode 16. LED Register control error

4. Button web - cylinder

comparison mode 17. LED Register control printmark

captured

5. Cylinder released 18. LED cylinder – cylinder comparison

mode

6. Start (release) cylinder 19. Start web capture

7. Stop cylinder 20. Button cylinder – cylinder comparison

mode

8. Course pre-alignment control 21. LED cylider closed

9. LED pump on 22. LED squeegee, printhead open / close

10. LED pump automatic mode 23. Button squeegee, printhead open /

close

11. Manual on/off ink pump 24. Button cylinder open / close

12. Automatic mode ink pump 25. Register plus (increase slow rotation

13. LCD Display 26. Register min (decrease slow rotation)

13

14

15

16

17

18

2

1

3

4

5

6

7

8

9

10

11

12

20

19

26

25

24

23

22

21

figure 3 Operators Control panel

Stork Prints B.V. 8000000EN-04-2

User manual RSI 18

1.2.2.2. Motor Control Unit

This unit controls and monitors all electrical functions of the printhead.

1.2.2.3. Drive Motor

The motor is used to drive the screen so that it can be synchronised in speed

with the main printing machine.

1.2.2.4. Speed Reference Encoder

This encoder, mounted on the main machine, produces pulses proportional to

the main machine speed. The pulses are used to synchronise the printhead

with the main machine when printing.

1.2.2.5. Screen Position Detector

On each screen end-ring is a small cam which indicates where the screen

pattern starts. The detector sends a pulse to the drive unit each time the cam

passes, thereby defining the rotary position of the screen. This allows the

drive unit to bring the screen to the correct position after a short stop or a

period of slow operation.

1.2.2.6. Pressure Switch

A pressure switch is used first to detect whether or not the screen is stretched

and second whether or not the covers are closed.

1.2.2.7. Printing Release Valve

Before both the head and squeegee can be moved into the printing position,

the screen must be rotating and there must be web throughput by the main

machine.

When this is the case, printing release will be given.

Stork Prints B.V. 8000000EN-04-2

User manual RSI 19

2.Preparation for printing

2.1. Squeegee Preparation

2.1.1. Introduction

Before the printhead can be used, the operator must ensure that a suitable

squeegee is at hand. If a squeegee is not available for immediate use, one

may be constructed using the squeegee set-up tool as described below. The

squeegee set-up tool is shown in figure 4.

3

2

1

figure 4 Squeegee set-up tool

2.1.2. Procedure

Steps to follow:

1. Put the squeegee blade holder (3) into the squeegee set-up tool

according the figure 4 and fix its position with the clamps (1).

2. Disconnect clamp of squeegee blade holder. See figure 5.

figure 5 Clamp of squeegee blade

3. Pre-position support-and squeegee blade.

Stork Prints B.V. 8000000EN-04-2

User manual RSI 20

For standard application, 1 supportblade is used. (it depend on the application

who is printed)

The supportblade and the squeegeebalde needs to be parallel. Distance

between support blade and squeegee blade tip is 2mm. (see figure 6). Use

tape to fix the position.

figure 6 Squeegee- and support blade

1. Squeegee tip

2. Squeegee blade

3. Supportblade

4. Tape

4. Position the assembly of support- and squeegee blade in such a way that

it is centred in the squeegee set-up tool and the tip of the squeegee blade

is against the stop of the squeegee set-up tool . See figure 7. Mount the

squeegeeblade by means of the clamps (2).

Squeegee tip

Horizonta

l

stop

figure 7 position of the squeegeetip

5. Apply the side scrapers to the clamp See figure 8.

figure 8 clamp with side scrapers

Stork Prints B.V. 8000000EN-04-2

Table of contents