strada Aquatherm STA140UC User manual

0

Technical Manual

Manual must be completed by Installer and left with Home Owner

28/03/19

1

Contents

Aquatherm: Schematic ........................................................................................2

Aquatherm: Connection Heights .........................................................................3

Technical Data .....................................................................................................3

Handling & Storage..............................................................................................4

Mains Water Supply ............................................................................................4

Discharge/Overflow Requirements .....................................................................4

Water Treatment.................................................................................................5

Commissioning.....................................................................................................6

Immersion Heaters ..............................................................................................8

Troubleshooting...................................................................................................9

Aquatherm Spares List.......................................................................................11

Commissioning Checklist ...................................................................................12

28/03/19

2

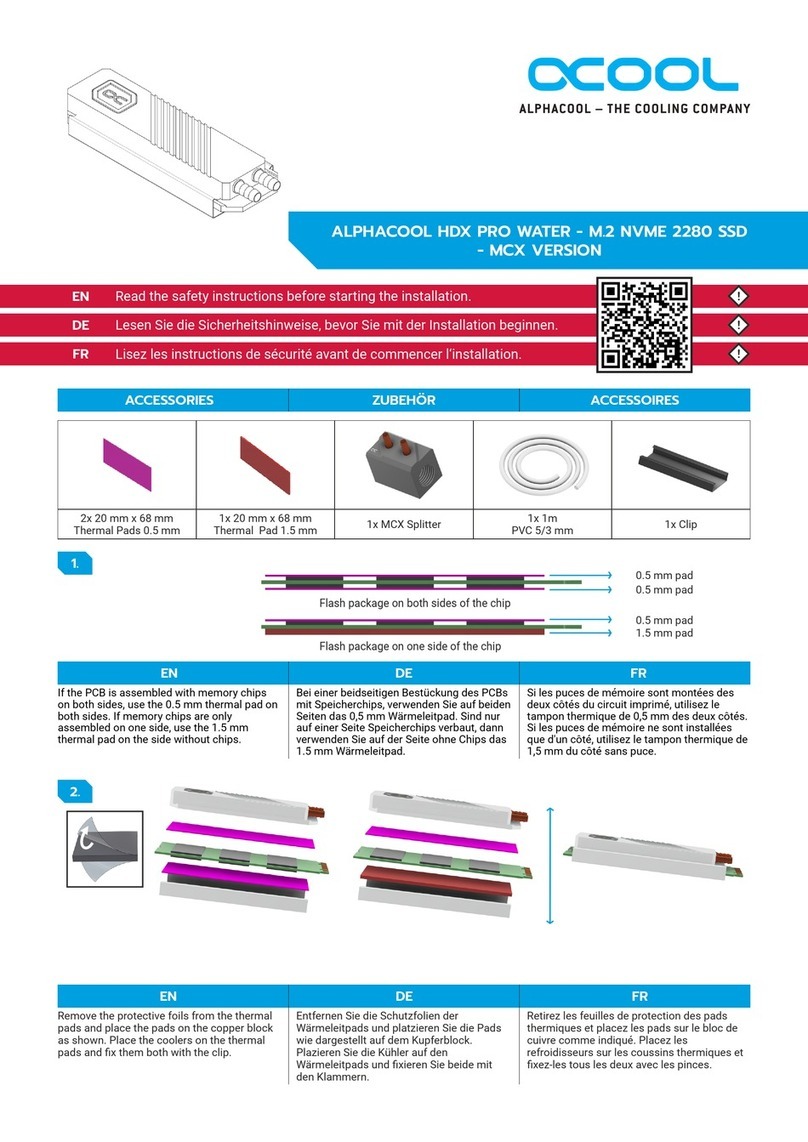

Aquatherm: Schematic

Immersion Heater

3kW

Drain

Cold Mains

Secondary Water

c/w Y Strainer

Hot Out

c/w Thermostatic

Mixing Valve

Boiler Coil

Return

High Efficiency

Secondary Coil

Ballvalve

Boiler

Control Stat

@75⁰C

Central

Heating Flow

& Return

Boiler Flow

Boiler Return

Boiler Coil Flow

28/03/19

3

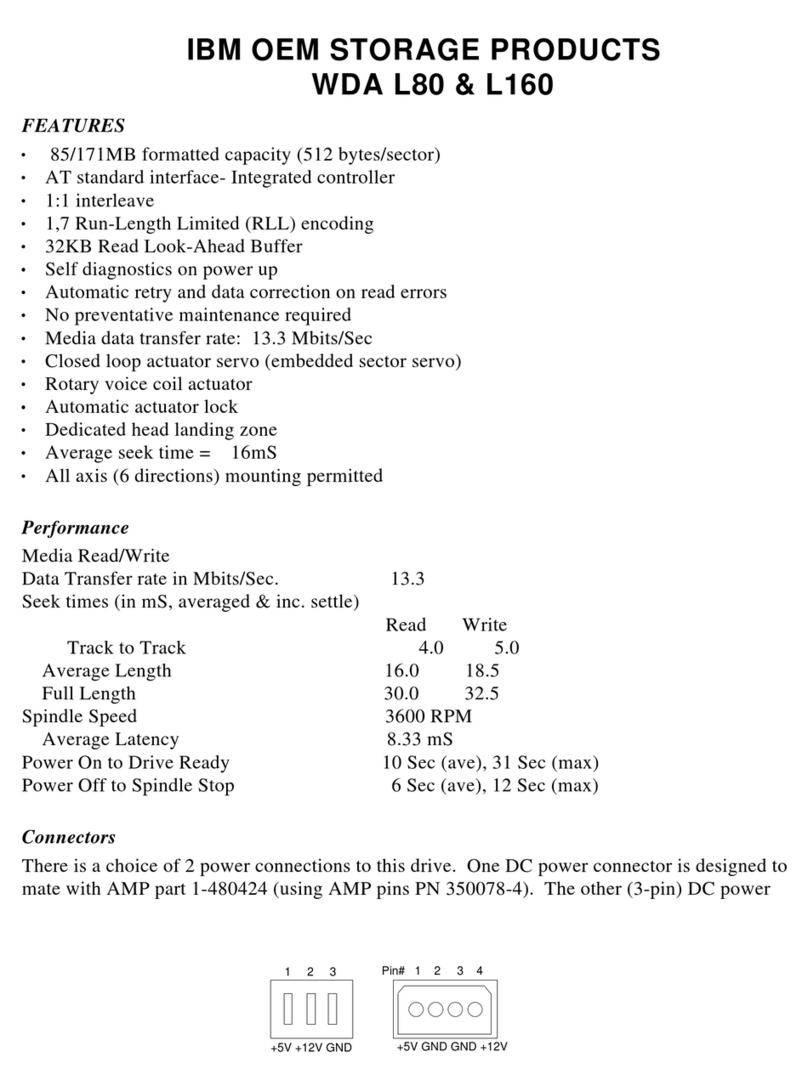

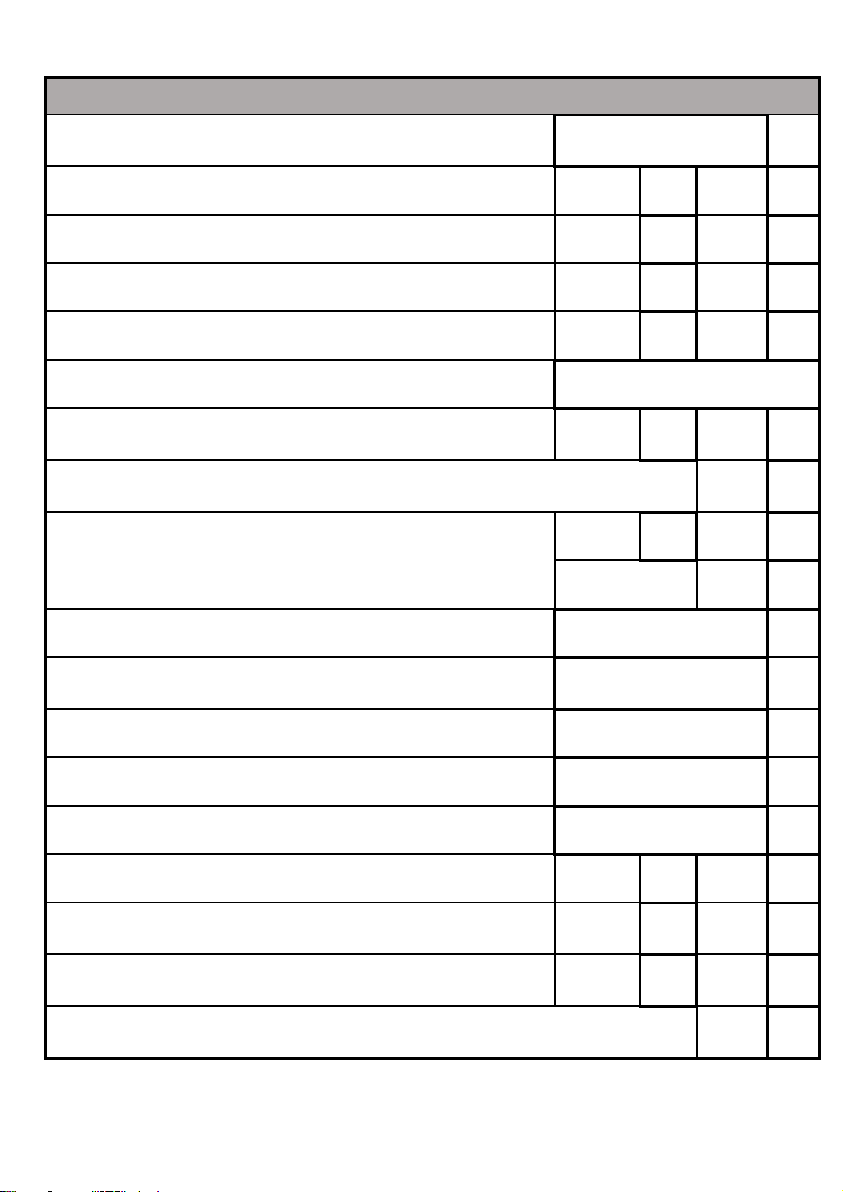

Aquatherm: Connection Heights

The connection heights shown below are taken from the ground (in mm).

Allow an additional 100mm to the diameter for external pipework connections.

Capacity (Litres)

140

160

180

210

Height

1250

1475

1500

1700

Diameter

570

570

570

570

Drain

95

95

95

95

Immersion Heater

160

160

160

160

Central Heating Flow

450

550

550

650

Central Heating Return

105

105

105

105

Boiler Flow

850

1075

1100

1300

Boiler Return

105

105

105

105

Boiler Coil Flow

555

555

555

555

Boiler Coil Return

105

105

105

105

Control Stat

340

300

300

350

Hot Out (Coil)

850

1075

1100

1300

Cold In (Coil)

350

495

520

720

Ballvalve

1180

1405

1430

1630

Technical Data

ERP / Heat Loss Data

Capacity (Litres)

140

160

180

210

Insulation Thickness (mm)

60

60

60

60

ERP Class

C

C

C

C

Standing Heat Loss (Watts)

74

78

82

87

Standing Heat Loss (kWh/day)

1.78

1.87

1.97

2.09

Tested in accordance with HWA Thermal Store Specification

28/03/19

4

Handling & Storage

DO NOT LIFT BY THE PIPEWORK as this can loosen off the pre-tested pipework

and may result in leaks.

Check the joints before filling with water in case anything has been loosened

in transit.

Any manual lifting will need to comply with the requirements of the Manual

Handling Operations Regulations issued by the Health & Safety Executive.

For installations on higher levels of properties such as the 4th floor it is

recommended move the tank vertically within a lift.

Mains Water Supply

The mains supply to the unit should ideally be in a minimum of 22mm diameter

but will work with 15mm if there is adequate pressure and flow rate.

Minimum incoming mains pressure of 1.0 Bar and a minimum flow rate of 20

Litres/minute.Careful consideration should be made to ensure the pressure of

hot and cold supplies are balanced.

An incoming pressure of 2.1 Bar is the most optimal for performance.

If the incoming pressure exceeds 3 Bar, then a pressure reducing valve must be

fitted after the stopcock of where the incoming cold supply enters the property.

No Pressure Reducing Valve or Check Valve should be fitted within 2 metres of

the Cold Inlet to the tank.

If the flow rate exceeds 18 Litres per minute at any tap, it should be restricted

to maintain the performance of the system as a whole.

Discharge/Overflow Requirements

The Aquatherm is a Vented Thermal Store and therefore does not require safety

discharge from a Pressure and Temperature Relief Valve as highlighted in Part G of the

Building Regulations.

The overflow should be run in either 22mm copper tube or high temperature overflow

pipe with suitable supports.

28/03/19

5

Water Treatment

In accordance with the Building Regulations L1A: New Dwellings/ L1B: Existing

Dwellings, the requirements set out in the Domestic Building Services Compliance

Guide specify that “where the mains water hardness exceeds 200ppm provision should

be made to treat the feed water to water heaters and the hot water circuit of

combination boilers to reduce the rate of accumulation of lime scale”. In most instances

of this water condition, an inline Water Conditioner/Scale Inhibitor would be fitted to

the incoming mains.

The water quality shall be in accordance with European Council Directive 98/83/EC, or

revised version at the date of installation, and is not fed with water from a private

supply. Particular:

Chloride content: Max. 200 mg/l

Sulphate content: Max. 200 mg/l

Combination chloride/sulphate: Max. 300 mg/l (in total)

The tank is part of the primary system and, along with other parts of the primary circuit,

will require the application of a protective scale and corrosion inhibitor such as Fernox

to ensure adequate protection. This should avoid having corrosive material in the

primary system and remove any build-up of sludge which can reduce the performance

of the High Efficiency Heat Exchanger Coil.

The volumes and concentration of inhibitor required should be calculated in accordance

with the manufacturer’s instructions. Please ensure that the thermal store volume is

also included as well as the radiator and pipework volume.

If there are doubts regarding the quality of water being used to fill the tank, an inhibitor

should be added to the appliance when filling in line with the manufacturer’s

instructions for these products.

Please note that the primary water within the thermal store water is used as primary

storage and the domestic hot water is heated instantaneously by means of the High

Efficiency Heat Exchanger Coil. Therefore, treating the primary water will not have an

effect on the domestic hot water supply.

28/03/19

6

Commissioning

The below is a recommended guide of actions and checks that should be undertaken

during commissioning:-

DO

During commissioning, complete all relevant sections of the Commissioning

Checklist (Page 10-12). This must be completed during commissioning and left

with product to meet the Warranty conditions.

Check the incoming mains water pressure. If the incoming mains pressure is higher

than 3.0 Bar, fit a Pressure Reducing Valve set at 3.0 Bar maximum –recommended

2.1 Bar where the cold supply enters the property as this will create balanced

pressure throughout.

Ensure that connections are fitted in accordance with the sketch supplied

Ensure the drain is connected to allow draining of the unit if required. If a drain-

cock is fitted, we recommend a DZR fitting.

Fit the Overflow with Copper piping or high temperature plastic to the thermal

store system where required.

Ensure minimum of 225mm between the top of the tank and ceiling to allow access

to service the ball-valve if ever required.

Check that all pipework connections on the tank are tight with pipes fully inserted

following transit and handling.

Fill the tank via the ball-valve in the Feed & Expansion Tank.

Ensure the system is inhibited correctly –see page 6.

Check the water level in the Feed & Expansion Tank, and adjust ball-valve so water

is at lowest level.

On the Automatic Fill version, turn down servicing valve once system is initially filled

to where the warning/overflow pipe will cope with the discharge from a ball-valve

failure.

On the Manual Fill version, once the unit is filled through the pipework, close off

the isolation valve, disconnect the flexible hose from the pipework and cap the pipe

to avoid any dead legs.

Check for leaks throughout the thermal storage system.

Run all taps and other hot outlets to remove all air from the system.

Immersion Heaters should be set at 70⁰C.

28/03/19

7

Boilers –Set the boiler pump to its highest setting. Set the Boiler Thermostat and

also the tank thermostat to maximum. Fire the boiler on HOT WATER ONLY setting

and wait until the boiler goes off. Turn the cylinder thermostat down slowly till it

clicks off, then turn it down by approximately 2⁰C. This should mean that the tank

thermostat controls the system. This can be checked by running off some of the

hot water, re-firing the boiler and checking that the tank thermostat is in control.

Ensure the store temperature is set to 75⁰C (70⁰C minimum and 80⁰C maximum)

on the store temperature gauge. This can be increased but consideration should be

made for the temperature and pressure rise, caused by “creeping”, where small

draw offs are present.

On installs where central heating is run from the tank, ensure that 500mm height

difference is in place between the highest point of the radiator circuit and the

bottom of the Feed & Expansion Tank.

Ensure that all exposed pipework on the tank is insulated to minimalise any heat

losses.

Ensure the Thermostatic Mixing Valve is adjusted to control the hot water outlet

temperature between 50 - 55°C (take shower differential into consideration).

Check the boiler pump setting is set as high as possible without emitting excessive

noise to prevent a boiler temperature differential of greater than 11°C.

If required, chlorinate the hot and cold water system in accordance with BS 6700

and Water Regulations. Please note that the whole of the domestic hot and cold

water systems must be adequately flushed after chlorination. Failure to do so will

cause damage to the exchangers/immersion heaters etc.

DON’T

Use a combined feed and vent.

Use tube smaller than 28mm between boiler and tank if the boiler exceeds an

output of 60,000 Btu (17kW).

Place any clothing or other combustible materials against or on the tank.

28/03/19

8

Immersion Heaters

Immersion Heaters should be set to ensure the reading on the Thermometer

reaches 75°C (maximum 80°C) once the unit is heated.

We would recommend setting the Immersion Heaters at 70°C and the high

limit at 90°C. This can be lowered or increased as required for the installation

requirements.

If in any doubt of how to set the Immersion or what temperature we would

advise for specific installations, please contact us on 01592 611123.

All Immersion Heaters should be wired by a qualified electrician as shown

below;

28/03/19

9

Troubleshooting

SYMPTOM

SOLUTION

The water at the tap

is lukewarm or cold.

1) Check the thermometer is showing the store temperature is at

or approaching 75°C- 80C.

2) If this is not the case, ensure that the boiler is firing, that the

control thermostat is set at 75⁰C and allow sufficient time for the

store to reach working temperature

The thermal store is

at 75°C and the

water at the taps is

still lukewarm or cold

1) If the store is at or approaching 75°C - 80C, check that the

Thermostatic Mixing Valve is correctly set. The maximum

temperature of water from the Mixing Valve should be about

55C.

2) If the valve is correctly set, check that the flow rate at any outlet

(e.g. bath tap) does not exceed 18 Litres per minute. If the flow

rate is too high then sufficient heat transfer inside may not be

occurring.

Turn the flow through the tap down or fit a suitable flow

restrictor and the temperature will increase.

3) If Stage 1 and 2 has not resolved the problem a competent

installer should check the mixing valve for blockages within the

internal filter of the mixing valve.

Not enough hot

water and less than

75°C on the

thermometer.

Check the heat sources and their input in (kW) to the store as this will

be lower than the kW output which will result in the store not

producing enough heat for the exchanger to provide heated mains

pressure water.

There is a brownish

tint to the mains

pressure hot water.

This could be a symptom with the heat exchanger coil leaking inside

the thermal store. An installer should have this tested. If this is the

case, pay attention to the Feed & Expansion Tank as the pressure

within the store will increase causing the tank to overflow continually.

28/03/19

10

Tank is set at 75°C

but the mains

pressure

temperature drops

quickly when running

a tap (e.g. bath)

1) If an inhibitor has been installed, check with the installer that it

has been installed at the correct proportion and checked at

appropriate frequencies.

2) The in-line strainer in the cold mains supply to the unit may be

choked and require cleaning.

3) Carefully check the hot water temperature flow into the mixing

valve. If it is very hot, it may be that the valve needs to be

checked / replaced. A competent installer should check the

mixing valve for blockages within the internal filter.

4) If the DHW Coil is giving an initial heat transfer and then fading,

this could be a sign of scale build up inside the Heat Exchanger

Coil, especially if in a known hard water area. A competent

installer would need to descale the DHW coil and check/fit

descaling equipment.

28/03/19

11

Aquatherm Spares List

Part Number

Description

SUTMIX1

22mm Thermostatic Mixing Valve

SUTVESS1

2 Litre Expansion Vessel

SUTSTAT1

Cylinder Thermostat

SUTSTRAINER1

22mm Y-Strainer

SUTBALL1

15mm Ballvalve

SUTFLOAT1

4.5” Plastic Float

28/03/19

12

Commissioning Checklist

THERMAL STORE MAINS PRESSURE HOT WATER STORAGE SYSTEM

COMMISIONING CHECKLIST

This Commissioning Checklist is to be completed in full by the competent person who

commissioned the storage system as a means of demonstrating compliance with the

appropriate Building Regulations and then handed to the customer to keep for future

reference.

Failure to install and commission this equipment to the manufacturer’s instructions may

invalidate the warranty but does not affect statutory rights.

Customer Name:

Telephone Number:

Address:

Aquatherm Make & Model:

Production Number:

Commissioned by (PRINT NAME):

Company Name:

Telephone Number:

Company Address:

Commissioning Date:

28/03/19

13

ALL SYSTEMS

What is the incoming static cold water pressure at the inlet

to the system?

Bar

If above 3.0 Bar, has a pressure reducing valve been fitted?

Yes

No

Has cold mains strainer been cleaned of installation debris?

Yes

No

Is the installation in a hard water area (above 200ppm)?

Yes

No

If yes, has a water scale conditioner/inhibitor been fitted?

Yes

No

What type of scale conditioner/inhibitor has been fitted?

Has flow rate been restricted to a maximum of 18 litres at

any one outlet?

Yes

No

Time and temperature controls have been fitted in compliance with Part L of

the Building Regulations?

Yes

Type of control system (if applicable)

Y Plan

S Plan

Other

What is the hot water thermostat set temperature?

⁰C

If fitted, what is the Immersion Heater thermostat

temperature?

⁰C

What is the hot water temperature at the nearest outlet?

⁰C

What store temperature is the unit sitting at? (Max 80⁰C)

⁰C

What is the maximum hot water temperature at taps?

⁰C

Is the cylinder solar (or other renewables) compatible?

Yes

No

If a manual fill, has any ball-valve been disconnected or

blanked?

Yes

No

Has the automatic fill flow rate been reduced to ensure the

overflow can cope?

Yes

No

All appropriate pipes have been insulated up to 1 metre or the point where

they become concealed?

Yes

28/03/19

14

ALL SYSTEMS PRIMARY SETTINGS (Indirect Heating Only)

Is the primary circuit a sealed or open vented system?

Sealed

Open

What is the maximum primary flow temperature?

⁰C

ALL INSTALLATIONS

The hot water system complies with the appropriate Building Regulations.

Yes

The system has been installed and commissioned in accordance with the

manufacturer’s instructions.

Yes

The system controls have been demonstrated and understood by the

customer.

Yes

The manufacturer’s literature, including this Checklist, has been explained

and left with customer.

Yes

Commissioning Engineer’s Signature:

Customer’s Signature:

(To confirm satisfactory demonstration and receipt of manufacturer’s literature)

0

0

Advanced Water Company

Unit D5 Enterprise Way

Vale Park

Evesham

Worcestershire

WR11 1GS

Tel: 01386 760066

Fax: 01386 760077

Email: sales@advancedwater.co.uk

This manual suits for next models

3

Table of contents