STRATOS HSSD User manual

Technical Manual

Issue 2.4

Quality system cert. no. 404

Assessed to ISO 9001

afp-813

World Patents Pending ©AirSense Technology Ltd. 1999

ISSUE 2.4

Page 2

TECHNICAL.MANUAL

Introduction 3

Background 4

Heat Detectors 4

Ionisation Detectors 4

General Optical Detectors 5

Beam Detectors 5

Light Scattering Detectors 6

Light Sensing Detectors 6

Point Detectors 7

High Sensitivity Aspirating Systems (a.k.a. Air Sampling Systems) 9

Specific types of Aspirating Systems. 11

Particle counters 12

Light scatter (mass detection) systems 12

Light sources 13

Absolute v. relative scaling 15

Absolute Scaling 15

Relative Scaling 16

Stratos-HSSD®17

Description 17

Histograms and Learning 17

Dust 19

Bargraph Scale 20

Power Supplies 21

Using an external power supply 21

Chart recorder analogue output 22

Examination of referencing systems 22

Stratos detector referencing 32

Local and remote referencing 34

Terminal board jumper link connections 35

Apollo Series 90 Interface 35

Autronica BNX-3 36

Thorn AM521 37

Remote control software 38

Using the remote control software 38

Setup menu 38

Demonstration and log menu 40

Diagnostic menu 41

Chart recorder format 42

Histogram format 43

Product id numbers 43

Remote monitor format 44

Remote monitor programming API 45

Chart recorder sample rates 46

PipeCAD™ for Windows 47

Sampling Pipe Modelling Program 47

System requirements 47

Installation 47

World Patents Pending ©AirSense Technology Ltd. 1995

Contents

Produced by AirSense Technology Publications.

Written by Mark Symonds - Technical Manager, Kit Girling, Technical Director

© AirSense Technology Ltd. 1999

No part of this Technical Manual may be reproduced, copied or transmitted by any

means without the express written permission of AirSense Technology Ltd.

TECHNICAL.MANUAL

World Patents Pending ©AirSense Technology Ltd. 1999

ISSUE 2.4 Page 3

TECHNICAL.MANUAL

Introduction There are now several air sampling smoke detection systems on the world Fire

Protection market that operate at ‘High Sensitivity’ levels as defined by the tests

described in BS6266 1992. The AirSense Technology Ltd Stratos-HSSD® detector is

at time of writing, the latest entry in this field, and is designed to overcome many of

the shortcomings found in other systems. In order to understand Stratos it is useful to

haveacursoryknowledgeofthefiredetectionsystemsthatprecededit,whetherpoint

detectors, large area detectors or other aspirating smoke detection systems.

It is a truism that early detection of fires is the key factor in preventing them from

developing. The earlier they are detected and extinguished, the less damage will be

caused. It is not until one looks at the evolution of detection systems that one can see

where such a simple truism can lead. The major requirement of any system is,

obviously, to detect fire, but, not quite so obviously, to not give a warning when no

fire occurs! The problem of unwanted alarms is a major one; for instance frequent call

outs to deal with non-existent fires can lead to a tendency for alarms to be ignored.

Unwanted alarms, from whatever cause, can largely negate the usefulness of any

alarm system and for this reason the ability to not give unwanted alarms must be rated

as high in importance as the ability to signal a true alarm.

United Kingdom

01462 440666

Netherlands

+31 1825 635696

Finland

400 652131

Australia

(08) 618 8443 9625

Help Lines &AirSense Technology has taken every care to ensure that Stratos is as simple to install as

possible, but in case of difficulty please contact our Help Line to ensure trouble free

installation.

About the author

The author has been involved for many years with the design of various successful fire

detectionproducts.Formanyyearshewasalso Electronic Engineering Manager ofthe

Company that first imported High Sensitivity aspirating Smoke Detection products to

Europe from Australia. He was subsequently involved in making this earlier generation

system suitable for application in the European fire market and developing differing

variants of this system. Since February ’93, Kit Girling has been responsible for leading

the design team that has developed the Stratos-HSSD®system.

World Patents Pending ©AirSense Technology Ltd. 1999

ISSUE 2.4

Page 4

TECHNICAL.MANUAL

Many principles have been used to detect fire and are still in use, although some are

only used in special applications. The following comments describe some of the more

commonly used principles:

All fires give off heat, and sensing the temperature of the air at a given point in a given

zone can indicate the presence of a fire occurring in it. The method is simply to sense

if the temperature rises above a pre-determined trigger level and give a warning. If the

trigger temperature is low, relatively early warning can be given. Unfortunately an

unwanted alarm could be generated by heating systems being switched on or a heat

wave occurring, taking it above the trigger temperature. If the trigger temperature is

high, the fire may be well alight before warning is given. Such a system is unlikely to

be ideal in many applications.

In order to improve on this situation, the ‘Rate of Rise’ temperature detector is more

often used. These sensors do not measure the actual temperature, but the rate at

whichit increases. In this detector, the background temperature islargelyignored, but

if the rate at which the temperature rises is greater than a given amount, it is assumed

that this is due to a fire. Unfortunately, for general use, the unwanted alarm conditions

still occur even if not so readily as with the simple heat detector; also the fire must be

well alight to generate the rates of rise of temperature required to trigger them.

Heat detectors must either be strategically placed with respect to potential fire sources

or have a very high placement density in order to be effective. The heat of the fire must

also be transmitted to them rapidly.

Carbon products are given off in the form of smoke and gasses when a fire occurs. If

a small sample of air is ionised by means of a radioactive substance, then the ions will

allow a small electrical current to flow between two electrodes placed in the sample.

If the combustion products mix with the air in the sample then they will inhibit the

movement of the ions that then as a result de-ionises, and the electrical current will

decrease. This is the operating principle of the Ionisation detector. A low concentra-

tion in the air of the products of combustion is required to effect a detectable change

in the current, and this can make the detector quite sensitive. Unfortunately the

current is also effected by draughts in the air and to a lesser degree by humidity,

atmospheric pressure and temperature. Although these unwanted effects can be

Background

Ionisation Detectors

Heat Detectors

World Patents Pending ©AirSense Technology Ltd. 1999

ISSUE 2.4 Page 5

TECHNICAL.MANUAL

minimised, the combination of them, and the very small nature of the ionisation

current (10 - 50 picoamps), limit the sensitivity and usefulness of ionisation detectors.

It should also be noted that the use of radioactive elements is generally frowned upon

by today’s society because of the difficulty in safely disposing of them. The main

advantage of this type of detector is its simplicity of manufacture and low cost.

General Optical Detectors

The standard used for measuring the concentration of smoke in air is the amount of

attenuation it will cause in the intensity of a light beam shining through it, usually

expressed as ‘percent obscuration per metre’. When the smoke is invisible, such as that

which can effect an ionisation detector, then a correlation is derived between the

different types of smoke, visible and invisible. The measurement units for optical

detection systems always end up as ‘percent attenuation per unit length’ because they

can be translated into an accurate laboratory measurements.

The different principles of Optical detection are described below.

Asimplified adaptation of thelaboratorymeter described above immediatelybecomes

interesting as a smoke detector. The laboratory instrument itself is costly to manufac-

ture, and is impractical as a commercial smoke detector due to calibration problems

in an industrial situation. In order to make it commercially viable, the specification

must be changed so that dust build-up etc. does not cause unwanted alarms. A large

attenuation of the beam is required (typically 30 - 50%) and consequently it needs to

cover large areas. The attenuation in light is achieved by several means, but a

commonly used method is to shine a collimated light beam through many metres to

a reflector from which the light is reflected toward a light sensor near the beam source.

Smoke occurring in the beam will attenuate its intensity, and this reduction in intensity

will be used to trigger an alarm. Such a system is also good at detecting mist, steam

or dust, also anything that may physically interrupt or reduce the beam intensity. Dirt

build-up on lenses and reflectors have been known to cause serious problems, as have

normal movement in buildings caused by temperature changes and wind.

Beam Detectors

World Patents Pending ©AirSense Technology Ltd. 1999

ISSUE 2.4

Page 6

TECHNICAL.MANUAL

Another type of optical detector is immediately suggested by the beam detector, when

one considers what happens to the light in the beam that is not returned to the sensor.

Very little of this light will be ‘absorbed’ (e.g. translated to another energy form). Most

of it will be scattered out of the light beam, and hence not returned to the sensor. The

suggestion is, that if the scattered light itself is sensed, its intensity would be a direct

measure of the scattering medium or smoke. This principle is used very successfully in

many detectors although it is more expensive to realise than an ionisation type detector,

but gives a more reliable and potentially more sensitive detector.

A second type of optical light scattering detector uses a tightly focused laser beam to

produce pulses of light which are scattered from individual particles in an air stream

passing through the point of focus of the laser. This is the ‘particle counter’ detector,

which was originally designed for monitoring the quality of Clean Rooms (microelec-

tronics and pharmaceutical manufacture and research). For smoke detection it is only

viable when used in an aspirating system.

Light Scattering

Detectors

Most fires will generate light of one sort or another, infrared light being the most

prominent. Extremely sensitive infrared cameras are available, which could be used in

an alarm system. Such cameras are not used due to their high cost and the problem of

identifying the position of a fire but they could provide a means of identifying very small

temperature rises. The source of heat must be visible to the detector, either directly or

by reflection. This is not the case though with most other types of detector. A simplified

version that did not produce an image could be acceptable for fire detection although

it would not pinpoint the source of the heat in the same way that a camera would.

A flaming fire will produce a flickering ultraviolet light, and an ultraviolet sensor can be

used to detect it while also discriminating against other sources of ultraviolet, arc

welding for example, by means of the flicker rate. When materials burn they produce

light of different colours depending upon the elements that constitute the material.

These colours are produced in certain proportions and sensors can be made selectively

responsive to these colours by means of colour filters. By sensing the colours of light in

the required proportions an alarm can be triggered. The response time of such a

detector can be extremely rapid.

Light sensing fire detectors tend to have specialised uses, furthermore, although the

Light Sensing

Detectors

World Patents Pending ©AirSense Technology Ltd. 1999

ISSUE 2.4 Page 7

TECHNICAL.MANUAL

response time to fire may be rapid enough to detect flame within a few milliseconds,

most fire situations will progress through a relatively long smouldering period, and

generally light sensing detectors are either not sensitive to this stage or are inefficient

at detecting it.

There are many variations on these principles, they are also used with varying degrees

of technical expertise in order to suit different markets and applications. In general the

sensitivity and reliability of a detector, of whatever principle, can be improved with an

increase in cost. The large majority of detector designs are ‘point’ type, for either

consumer or commercial use, where, due to the highly competitive nature of the

market, costs have to be kept to the minimum. In the great majority of cases, detectors

are operated from a remote control unit, and one control unit will usually have many

detectors connected to it. The control unit provides the power necessary for them to

operate and itself operates fire sounders, automatic signalling to a remote centre (e.g.,

the Fire Brigade), fire extinguishing systems, etc. It normally indicates the signals it is

receiving from the detectors by means of lamps but the use of special PC programmes

to display more comprehensive information, is becoming more common.

This is the name given to the type of detector normally found in most buildings

distributed on the ceilings. A point detector depends upon normal air currents and

convection to carry the smoke, products of combustion or heat to it. For this reason,

the volume covered by the detector is limited. Where large volumes need to be covered,

more detectors are used and in very large volumes a great many detectors may be

required to provide complete coverage. There needs to be more than one tier of

detectors for very high volumes.

In the earlier days of such detection, all these detectors were wired in parallel on a single

pair of wires from a control panel. The wires provided electrical power to the detector

and also carried the alarm signal. The cost of the wires makes a significant contribution

to the total cost of the installation. Since the system must continue running during a

mains power failure, back-up batteries are required to take over at such times. The

capacity of the batteries will depend upon how much power each detector needs to run

it. In order to keep the size and cost of batteries low, point detectors are designed to

draw very low currents.

Point Detectors

World Patents Pending ©AirSense Technology Ltd. 1999

ISSUE 2.4

Page 8

TECHNICAL.MANUAL

Any detector on the pair of wires which signals an alarm is signalled back to the control

panel. This type of control panel is unable to say which of the many detectors had

operated, so the signalling is only ‘zonal’. Later developments use an addressable system

whereby the detector is given an coded unique identification which forms part of the

signal back to the control panel. The control panel can identify which of the detectors

(or other alarm device) on a given pair of wires is signalling. The detector can also signal

back more information than a simple alarm state, for instance; it can signal back that it

has a fault or pre-alarm condition. This has the effect of allowing the ‘pinpointing’ of

which detector has given the alarm and it also allows rapid identification of certain faults

in a detector.

Since a large number of detectors is often needed in a point detection system, the cost

of each unit must be kept within tolerable limits. In order to do this the design is kept

reasonably simple and the performance is consequently comparatively modest com-

pared to that possible with modern technology. In addition to this, National Standards

always demand a limit to maximum sensitivity of these devices in an effort to reduce

unwanted alarms. Point detectors are usually set to give an alarm at a smoke density

corresponding to between 2% and 4% obscuration per metre. Although they are

capable of signalling a fault condition, they will not signal the occurrence of every

possible type of fault.

Although these detectors often provide quite adequate protection, the probability of

them giving an unwanted alarm could, in some cases, be lessened by a more costly

design, and the sensitivity could be increased if cost were no object. Their general

performance reliability, although good, may not be as high as that required by a person

wishing to protect a very valuable property, and a higher sensitivity would certainly give

an earlier warning. Where very valuable property is to be protected by point detectors,

or where certain fire extinguishing systems are to be automatically released, two

different types of point detector are commonly used in a ‘coincidence’ (or ‘double

knock’) configuration. This configuration requires an alarm to be indicated by both of

the detectors before it is accepted. Since two detectors of the same principle would be

equally susceptible to the same source of unwanted alarm, usually they are of different

operating principles, e.g. a heat detector and an ionisation detector. The probability

that such a configuration will give an unwanted alarm is very much less than with a single

detector. Normallydetectorsare specially selected to suit the hazards in the volume they

World Patents Pending ©AirSense Technology Ltd. 1999

ISSUE 2.4 Page 9

TECHNICAL.MANUAL

are protecting; to give a rapid and sensitive alarm. The price paid for this degree of

certainty is the time delay required for both detectors to trigger an alarm and the

effective sensitivity are reduced to that of the least suitable detector of the pair.

Where a large volume is to be covered or an area is to be covered at a high sensitivity;

instead of using many low cost, inherently low sensitivity point detectors, an Aspirating

system may be used. Such a system consists of a single, more sensitive and highly

developed detector and an air sampling system to cover the required volume. The air

sampling system consists of a length or lengths of pipe with strategically placed

sampling holes along its length. An air impeller is used to draw air along the pipe from

the sampling holes and through the detector measuring chamber. The transit time for

air to travel from the sampling holes to the detector head can be significant, so there

must be significant advantages to this system to offset this delay. The detector is

designed to be stable, reliable and highly sensitive (approximately 10 to 200 times the

sensitivity of a point detector). Such additional sensitivity allows the detection of smoke

at a very much earlier stage in the development of a fire, and as a consequence, this may

reduce damage levels considerably. This saving of time more than offsets the delay due

to the transit time.

Aspirating smoke detectors are susceptible to considerable dilution of smoke in the air

sample, and it is important that this effect is understood. For example, if it is assumed

that a detector chamber has a typical sensitivity of 0.1%/metre obscuration, and it is

drawing its sample through ten holes in the length of pipe, and that each sampling hole

contributes equally to the volume through the detector measuring chamber, then if

smoke only effects one of the sampling holes, then, due to dilution from the other 9

holes, the actual detector responsiveness will only be equivalent to a 1% detector. If

however, say 5 of the 10 holes are effected by smoke, the apparent sensitivity will be

0.5%/metre. The more widespread the distribution of smoke among the sampling

holes, then the higher will be the density of smoke appearing in the chamber, and the

apparent sensitivity will be greater. Sampling pipe design should take this effect into

consideration.

The action of pulling air into the air sampling system gives a better smoke collection

method than the naturally occurring air convection relied upon by point detectors, and

the sampling pipe systems frequently allow the sampling holes to be strategically better

High Sensititivity

Aspirating Systems

(a.k.a. Air Sampling

Systems)

World Patents Pending ©AirSense Technology Ltd. 1999

ISSUE 2.4

Page 10

TECHNICAL.MANUAL

placed, for example in an air extraction system or within smoke strata which may be

anticipated.

.

A high sensitivity aspirating detector can cover the same volume as many point

detectors, but with added advantages. Economically speaking this allows more money

for the cost of the detector, which, in turn allows it to be designed to be considerably

more sensitive, but with the added advantages of being considerably more stable. The

removal of stringent economic factors also allow a higher degree of repeatability in

performance with a similar reliability to a great quantity of point detectors.

The added advantages of an aspirating system make it the natural choice where very

reliable performance is required. The ability to use a very sensitive system is an

advantage for protecting very clean environments such as computer rooms or micro-

electronics or pharmaceutical manufacturing clean rooms. The air sampling inlets can

be very nearly invisible which makes them ideal for use in historic buildings, where point

smoke detectors would detract from the appeal of the building. Other important

applications are found where their specific properties include; museums, art galleries,

warehouses,telephoneexchanges, penal establishments, dusty or dirty areas, unusually

hot or cold areas, areas with high levels of radio energy, atrium buildings, etc.,

The detectors used in successful aspirating systems in recent times, have nearly all been

designed to work on the optical, light scattering principle. There is still one produced

in the UK that uses an Ionisation chamber and another is available from USA that uses

a variant of the Optical principle called a Wilson Cloud Chamber.

The improvements in sensitivity make the optical detector capable of detecting invisible

quantities of smoke. One of the advantages of their very high sensitivity is that indication

occurs so early that it is of a potential rather than an actual fire. This allows corrective

action to be taken long before an extinguishing action is needed, or indeed, could be

effective. This fact alone translates into savings in the cost of extinguishing agents and

the possible damage its discharge could incur. Also, some of the most common

extinguishing agents are Halons (halogenated hydrocarbons). The manufacture of

these materials is being curtailed because of its damaging effect on the Earth’s ozone

layer.

World Patents Pending ©AirSense Technology Ltd. 1999

ISSUE 2.4 Page 11

TECHNICAL.MANUAL

Thus the air sampling system can overcome most of the disadvantages of other

detection methods, but tend to be economically designed to the limit of the market.

(i.e. The design maximises the possible performance advantages on the assumption

that the customer will pay more for them.)

There are many aspirating systems available around the globe, although there are only

three generally available High Sensitivity aspirating Detection systems in common

usage. It is known that there are a few products under development at this time which

may become available in this rapidly expanding market sector. In definition of the term

High Sensitivity, this is taken to mean that the system is capable of detecting the

electronic fire simulations described in the appendix of BS 6266 1992. All three

detectors have essentially similar levels of sensitivity, with no single product having any

great advantage over the other in this aspect. Interestingly, all three detectors use the

Light Scattering principle of operation, but each in a different manner; One uses a

Xenon flash bulb as its light source, whilst two take advantage of the very reliable

semiconductor laser (in this application, Mean Time Between Failure can be in excess

of 1000 years). Of the two laser based products, one is a particle counter, whilst the

other is responsive to the Mass of airborne material over a wide size range rather than

the number (count) of particles.

A potential problem with High Sensitivity Smoke Detectors is the possibility of alarm

signals being given by dust particles. This problem is dealt with in various ways

depending upon the actual system and its detection principle, but it is usually at least

partly dealt by an air filter of some description on the assumption that dust particles are

physically larger than smoke particles. The two laser based systems also use dust

discrimination to enhance this effect, although both do so in differing manners. It is also

useful to understand that there is an unfortunate effect whereby the more a filter

becomes clogged with dust, the smaller the particles are which it will remove out of the

air-stream. This is can be a very serious shortcoming, because air will still flow easily

through the filter when the size of particle being stopped is the size of smoke particles.

Specific types of

Aspirating Systems.

World Patents Pending ©AirSense Technology Ltd. 1999

ISSUE 2.4

Page 12

TECHNICAL.MANUAL

Particle counting works on the principle of counting the number of particles in a given

volume of air sampled. In order to do this, the rate of air-flow through the chamber must

be maintained within limits, or the effect of increased counting due to increasing the

air-flow must be allowed for.

The method used is to focus a laser beam into a very small volume in the air-stream and

measure the light scattered by a particle entering this volume. This will give a light

scatter pulse of a duration and size proportional to the size of particle. By its very nature

it is an absolute measuring instrument, i.e. its reading is the number of particles per unit

volume; it is not relative to anything. At first sight this appears to be a point in its favour,

and for measuring the impurity of air in a clean room it certainly is. It should be taken

into consideration though that the smoke level that is indicative of fire is not absolute,

it may be any level depending upon the normal amount of smoke present. The increase

in the count rate above normal is an indication of unusually large numbers of particles

being present. The size of the particle being counted is not a prime factor in the count,

since either a very large particle, or a very small particle will increase the count by one

unit.

It is assumed that dust particles are larger than smoke particles, and the particle counter

can give a signal indicative of particle size and the system may be set to ignore those

above a certain size. In relatively clean environments this may entirely obviate the need

for a filter. Unfortunately, the size of a fire can only be accurately measured either by the

weight or volume (mass) of smoke particles emitted and not the number of particles.

A particle counter will reach saturation when the rate at which it is required to count

particles is beyond its capability. This can be near the normal amount of smoke present

which includes dust particles when they are present.

These systems look for the amount of light scattered by a stream of air through an

optical chamber. With perfectly clean air there is a very small amount of scatter.

As the volume of particles below a given size increases, the amount of light scatter

increases. Measuring the amount of scatter thereby gives a measure of the volume

of impurity in the air. This has a direct relationship to the size of the source fire.

The ultimate limit to the sensitivity of such a detector is set by the amount of

electrical noise being generated by the sensor, the light source and their associ-

ated circuitry. This is because the system must be able to differentiate between the

Particle counters

Light scatter

(mass detection)

systems.

World Patents Pending ©AirSense Technology Ltd. 1999

ISSUE 2.4 Page 13

TECHNICAL.MANUAL

true signal given by smoke, and the noise signals with sufficient reliability to

prevent an alarm being triggered by the electrical noise. The amount of light

scattered by a given volume of particles is highly dependent upon the wavelength

of the light, with the amount of scatter increasing rapidly with a decrease in

wavelength. The direction of scatter is determined by the relationship between the

wavelength of the light and the particle size and shape. This is particularly the

case with large particles. It is however of great importance to note that all shapes

and sizes of particle give a large amount of scatter in the forward direction, that is,

scatter that diverts light only a few degrees from its original path. Detectors that

rely primarily on small angle scatter will be sensitive to a wide range of particle

sizes, almost irrespective of the wavelength of light.

One type of aspirating detector, developed in the late 1960’s (although reaching the

market in the ‘70’s) uses a Xenon flash bulb as the light source. This gives a very wide

spectrum of light output extending into very short wavelengths, well below the visible

spectrum. The intensity of scattered light at these wavelengths is high but is only of use

when a light sensor is used which is sensitive to them. The best response of normal

silicon light sensors, as is used in this detector though, only covers the visible spectrum

and the light at longer wavelengths. The advantage promised by the broad spectral

light output is lost.

Other, more recently developed types use semiconductor lasers giving 5 to 100 mW.

of light power. The types used are monochromatic coherent light sources at the red

end of the visible light spectrum. The coherent wave front of a laser beam allows

excellent manipulation of it by lenses. This does not, at first sight, appear to be a

promising light source, but, as pointed out below, can be entirely satisfactory.

Lightemitting diodes can give similar light powers to a semiconductor laser and are also

nearly monochromatic. They are very much cheaper than lasers, however they do not

provide a coherent light source and are usually only (able to be) used in point detectors.

An unfortunate characteristic of Xenon flash tubes is a deterioration of light output over

time. Very expensive tubes can be obtained where this effect is reduced to a minimum,

but they are neither commercially viable or used in this application. This deterioration

Light sources

World Patents Pending ©AirSense Technology Ltd. 1999

ISSUE 2.4

Page 14

TECHNICAL.MANUAL

provides a very difficult problem to overcome where a detector is intended to behave

as an absolute measuring instrument. Due to the deterioration in light output, the

signal will deteriorate to a commensurate degree, requiring the detector to be

frequently re calibrated. The high electrical noise generated by a Xenon tube will offset

the large signals it generates, and the promise of high sensitivity is not fully realisable.

The light from a Xenon flash tube is impossible to focus into a tight beam and it is not

possible to detect much light scattered at small angles from a wide angled beam.

However, complex (dust accumulating) iris systems in the light sensors viewing path

can allow a reasonable signal to be obtained from light scattered at larger angles. The

Xenon flash tube has a high energy requirement for its drive, which is a disadvantage

when intrinsically safe systems are required, or when a system runs from its stand-by

battery source. As a consequence, although at first sight the Xenon lamp looks ideal as

a light source, it has problems that effectively rule it out as a technically viable one with

the advent of semiconductor lasers. Although future developments could conceivably

change this situation, it is difficult to envisage that the effort required would be practical

or cost effective when the alternative of a laser exists.

The semiconductor laser is at present the subject of many semiconductor manufactur-

ers development programmes because of its application in printers, compact disc

players photo- copiers and fibre optic systems. These are expanding markets and auger

well for future improvements in cost and performance. Using a laser as the light source

in a smoke detection chamber has immediate advantages and disadvantages when

comparedwith a Xenon flash tube. The maindisadvantage is that it gives light atasingle

wavelength and this is at the long wavelength end of the visible spectrum, where the

amount of scatter signal is low. However, the single wavelength, coherent light source

that it provides, can be focused to a very tight beam allowing light scattered at very

small angles to be sensed without complex iris arrangements. This may be seen to more

than offset the disadvantage of the low intensity of scatter at these wavelengths, since

the intensity of scatter at small angles is consistently comparatively high, regardless of

particle size. Practical signals can be obtained, as with the Xenon flash tube, for particles

down to large molecule (gas) size. The semiconductor laser gives a consistent intensity

of light output with time and, when it is correctly driven, has an extraordinary length

of life. These advantages score heavily in a competition against the Xenon flash tube.

World Patents Pending ©AirSense Technology Ltd. 1999

ISSUE 2.4 Page 15

TECHNICAL.MANUAL

Absolute Scaling The output of the smoke detector in the conventional aspirating smoke detector system

is assumed to be (essentially) zero for a clean air sample and a fixed known level for a

given amount of smoke pollution. It is, in effect, a meter giving an absolute measure-

ment of ‘smoke-like’ pollution. The full scale reading may be set to a minimum of 0.05%

obscurationpermetre which makes it very sensitive. A usual full scale reading is between

0.1 - 0.2% obscuration per metre. The zero of the scale corresponds to zero pollution.

There are only a few applications where the air is totally free of pollution. There is

normally a constantly varying amount of background pollution. With the ‘Absolute’’

type of detector the alarm levels must be individually set to trigger at the desired level.

The correct level is one that will be reached by as low an amount of pollution as is

possible without being reached by the normally occurring background variations.

Alarms triggered by the normal background amounts of pollution will be unwanted

alarms which, as previously explained, must be avoided. The background levels will vary

according to the time of day and the particular activities in the protected area. The

requirement then, is to find what are the appropriate levels to set the pre-alarm and

alarmtriggers points. In order to do thisthe detector output is used in thefollowingway:

Smoke is sampled during the normal usage of the system for a period of 10 to 14 days,

and a chart recording of the levels against time is generated. This chart is assumed to

represent reasonably the future variations that will occur. The chart is examined for high

smoke levels during both the day and the night periods, and the pre-alarm and alarm

levels for day and night usage are both set to be higher than these respective peak levels.

The importance of avoiding unwanted alarms is so great that the trigger levels are

routinely set, as a matter of judgement on the part of the installer, to be well above the

peak levels, in case the chart recording is not truly representative of the future readings.

The aim of the exercise is to set the trigger levels at a point where the probability of an

unwanted alarm is very small and where there is still a high probability of detecting

unusually large signals.

There are a number of problems with the absolute scaling system;

nThe background level does not always vary as it did during the first two weeks after

installation.

Absolute v. relative scaling

World Patents Pending ©AirSense Technology Ltd. 1999

ISSUE 2.4

Page 16

TECHNICAL.MANUAL

nThe peaks indicated on the chart recorder may correspond to levels that should have

triggered an alarm.

nThe two weeks required for setting it up are inconvenient and are hence frequently

omitted or reduced, and the alarm trigger levels set at a ‘safe’ level (i.e., ‘safe’ from

unwanted alarms where the system is comparatively insensitive).

As with all very sensitive equipment, variations in the detector zero point and sensitivity

will occur, and these variations must be taken into account in the installer’s judgement,

when setting the trigger levels. An arbitrary element is contained in this procedure, and

it is unlikely that two different installers will set the same trigger levels.

An alternative method of setting the detector scaling is to determine that zero on the

measurement scale will correspond to the mean (average) of the background level of

pollution, and the full scale point set a given amount above the alarm trigger level. The

alarm trigger level with this method is set by performing a continual statistical analysis

of the background pollution and continuously calculating the level at which a given

probability of a signal occurring is acceptably low. Such measurements and calculations

are well within the capability of the modern micro-processor, and all that is required is

a suitable method. Since the zero and full scale points are set relative to the background

pollution levels, this makes the detector inherently more suited to its specific environ-

ment. It also makes the movements of the detector’s output for zero pollution

immaterial since it is constantly defining its own scale. However, since the scale is set

according to a history of constantly changing background environment, the method

of implementation must place a limit on the duration of the history. For example, the

background level readings taken thirty days ago are likely to be considerably less

significant than the readings taken thirty minutes ago. This method is basically an on-

going ‘learning method’, and to be successful it must ‘learn’ logically.There are a

number of minor problems with this method but all of them may be successfully

overcome by using a micro-processor, in fact the micro-processor becomes the centre

of the detector, governing all its procedures and actions.

Relative Scaling

World Patents Pending ©AirSense Technology Ltd. 1999

ISSUE 2.4 Page 17

TECHNICAL.MANUAL

Stratos is a relatively scaled detector designed around a modern microprocessor of the

same family as that used in Personal Computers. The detector chamber is based on the

light scattering principle with a high power semiconductor laser used as the light

source. The detector operates on the forward scattering detection principle and is

responsive to a wide range of particle sizes. Both dust discrimination and filtration

techniques are employed, which makes the system virtually immune to problems

caused by dust pollution. The problems encountered in its design, their solutions and

the general method of implementation, are listed below.

Histograms and Learning

Readings from the detector chamber(s) are obtained by the micro-processor at the

average rate of once per second. A continually updated histogram is generated from

the detector(s) output, in which the histogram classes contain the percentage of

readings taken between different signal levels. The classes cover all possible readings

that may be obtained, and it shows the distribution of signal levels. From the histogram

the Standard Deviation and Mean of the distribution are continually calculated. A

decayingfactoris used in the build up of the histogram. The effect of the decaying factor

is to limit the past time period or historical period that is represented by the histogram,

it also sets the time which the histogram requires to become truly representative of the

distribution. The method for doing this is an AirSense Technology Limited patented

process called ‘ClassiFire’. If the ClassiFire factor is set so that the a fully maintained

histogram always represents a history of the last ten hours, then it will take ten hours

running from the initial set up to build up a representative histogram. Similarly, a factor

used to make the histogram represent a ten minute history will require a ten minute

period from the initial set up to become fully representative. This is called the Learning

Time. Since the ideal should be a seven to eight hour history, this is a problem for initial

installation. The Learning Time is also a problem for a change in use of the protected

area such as a day-to-night or a night-to-day change. Both of these problems are

overcome by maintaining two histograms; one with a seven hour learning time (the

standard histogram) and the other with a fifteen minute learning time (the fast

histogram). On initial power up the alarm is disabled for fifteen minutes while the fast

histogram becomes representative of the signal distribution during this period. The

histogram so obtained is then used as the standard histogram which then has the decay

factor set to cover a multi-hour historical period. Since the historical period is initially

only fifteen minutes, the spread of the distribution will be smaller than if the historical

Stratos-HSSD®

Description

World Patents Pending ©AirSense Technology Ltd. 1999

ISSUE 2.4

Page 18

TECHNICAL.MANUAL

periodhad been several hoursandit will take severalhoursbefore the distribution shows

the true normal spread. The alarm trigger level is set by the spread, in terms of the

standard deviation. In order to compensate for the initial FastLearn, the figure for this

is increased by a factor that is gradually decreased to unity over the initial period. This

gives an artificially slightly high alarm level for the first few hours after installation but

needs only fifteen minutes before the detector becomes operative. As the detector has

to discern between day and night periods, then the detector takes an initiation period

of 24 hours as part of the initial self set up.

The fast histogram is constantly maintained as well as the standard histogram, and is

used to compare with it in order to show short term changes or trends. Short term

changes will occur with changes in use of the protected area. The problem with

changes in use is that, with, say, a seven hour learning period, the detector will have

only just learned about one period after a change, when another change occurs and it

begins to learn about that. The detector never has time to settle fully to its current use.

For all practical purposes, changes of use cover only two different levels of use. These

are usually day time and night time, but for the sake of generality may be referred to

as normal time and quiet time.

The problem of maintaining correct alarm trigger levels, in spite of changes in use at

occupied and unoccupied times, is solved by having two standard histograms, one for

the normal time and the other for the quiet time. When the detector is first installed the

approximate times of day for the changes in use are programmed into the micro-

processor. Within a 140 minute period of these set day and night start times (70

minutes either side of the actual time set), the processor looks for a change of use by

comparing the fast histogram with the present standard histogram. When it is satisfied

thatit has detected a change within this 140 minuteperiod,it switches to the alternative

standard histogram and notes the time it occurs. The alternative standard histogram

will contain all the learning from the previous time it was used and consequently needs

no time to re-learn it. The time that was originally programmed for the change to occur

is compared with the time it actually occurred and if there is a difference, the

programmed time is modified to be nearer to the actual time. After some days, the

programmed time will be showing the average of the actual times the changes occur

and will have the ability to capture the next time a change occurs if it is within an hour

of it. This is useful when the clocks change from summer to winter time and activities

change according to the clock.

World Patents Pending ©AirSense Technology Ltd. 1999

ISSUE 2.4 Page 19

TECHNICAL.MANUAL

If the comparison of fast histogram and the current standard histogram shows no

change of use within an hour of the programmed time, then no switch to the

alternative standard histogram is made. This is particularly beneficial if the detector

remains in a quiet period for a day or more, such as for a weekend or holiday period,

when it will remain with the quiet period histogram for the whole period, as, after all,

this type of system is usually used where the optimum in sensitivity is required, and this

feature provides a unique level of sensitivity with this artificial intelligence sensitivity

switching.

An area that requires special care with the light scattering principle, is the exclusion of

abnormal levels of dust from the detector chamber. It is as well to mention that perfect

protection against dust particles is an ideal which is unlikely to ever be fully achieved

although a method of discriminating between dust particles and smoke particles of the

same size is always being sought. It is difficult to obtain, because many dust particles

exist in the same size region as smoke particles. As such, the combination of fully

monitored and compensated (see below) dust particle separation and dust discrimina-

tion used in Stratos provides a very adequate solution.

For reasons of power economy and reliability a low power air impeller is required to

draw air down the sampling pipes. This leads to the problem that the bore of the

sampling pipes must be large in order to obtain the high flow rates required (usually

15 to 25 mm.). High flow rates are required to obtain short transit times between the

sampling holes and the detector head. Even with a well designed system these may

often be as great as 60 seconds for the furthest holes. The result of fast air flow down

large bore pipes is a large volume of air being moved. In order to overcome long term

problems, the air which passes through the detector must be filtered to some degree

to remove the majority of dust particles. The nature of this filter is critical though,

because the matter it filters from the air remains in the filter medium, and as it builds

up will increase the efficiency of the filter. This manifests itself by the filter removing

progressively smaller and smaller particles the more it becomes loaded with dust, until

it is removing the majority of the smoke particles. At this time it will still be passing air

satisfactorily and there will, unless compensated for, be no external indication that it

is blocking smoke until such time as it fails to detect a fire. One indication that occurs

for a relatively scaled detector (Stratos) is that the spread and level of readings will

gradually decrease. Stratos will automatically decrease the scale range to compensate

Dust

Dust

Compensation

World Patents Pending ©AirSense Technology Ltd. 1999

ISSUE 2.4

Page 20

TECHNICAL.MANUAL

for this, but the indication will consist of a marked decrease in the spread of readings.

The essence of the problem is not so much the filtering out of dust, which is a straight

forward design problem, but the life of the filter, and giving a reliable indication that

it is becoming fully loaded. The Stratos detector tackles the problem of dust in four

ways;

nOnly a small part of the total air sample is taken through the detector head. While

a large air flow down the sampling pipes is an advantage, the detector head itself

can measure the pollution density equally well for a small sample as a big sample.

As a consequence, only the small part of the total air sample flowing through the

detector head requires filtering and the filter and detector chamber life is

consequently greatly extended. Additionally the frictional resistance that would

otherwise restrict air flow is greatly reduced.

nProgressive decreases in the variance and mean of readings in the histogram give

a warning that the filter is becoming fully loaded. This progressive reduction in

signal spread causes the detector to compensate, thereby automatically maintain-

ing the sensitivity of the Stratos detector.

nThe flow rate through the detector sampling chamber is relatively fast and an

individual dust particle which does get into the chamber will give just one

abnormally high reading from paired light pulses from the laser. Stratos looks for

such individual, abnormally high readings and ignores them, only accepting a

signal from the lower of the paired pulses. This process is known as Dust

Discrimination.

nThe filter itself is specifically designed to have a very high capacity for holding dust,

which further extends the filter life.

The Stratos scale is represented on the front panel of the Master Stratos detector

by a ten segment bargraph display, with the segments numbered 1 to 10. The

bargraph illuminates continuously from 1 upwards, to the measured amount of

pollution. The alarm trigger level is always pre-set at bargraph level eight. If there

were a segment numbered zero, then this is where the measured mean level of

background signal would be indicated. The main purpose of the bargraph is to

Bargraph Scale

Table of contents

Other STRATOS Smoke Alarm manuals

Popular Smoke Alarm manuals by other brands

SilentCall

SilentCall SD4-MC(US) Installation and operation manual

Silent Alert

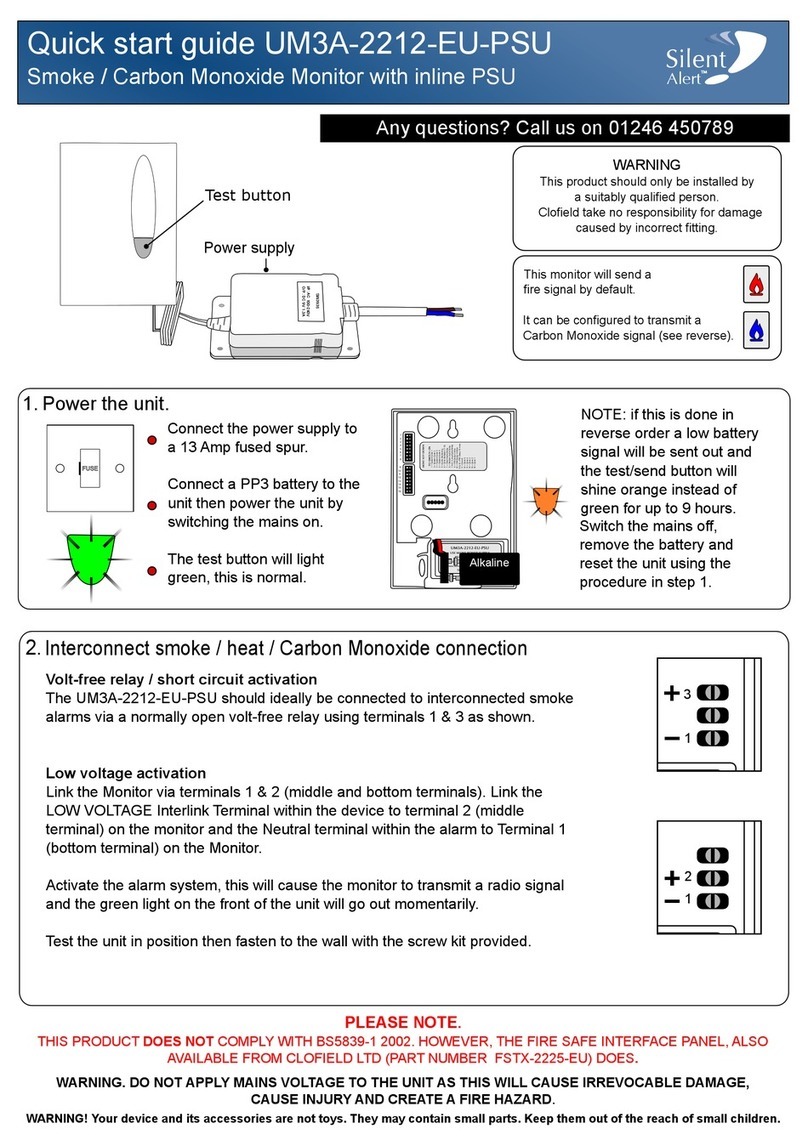

Silent Alert UM3A-2212-EU-PSU quick start guide

System Sensor

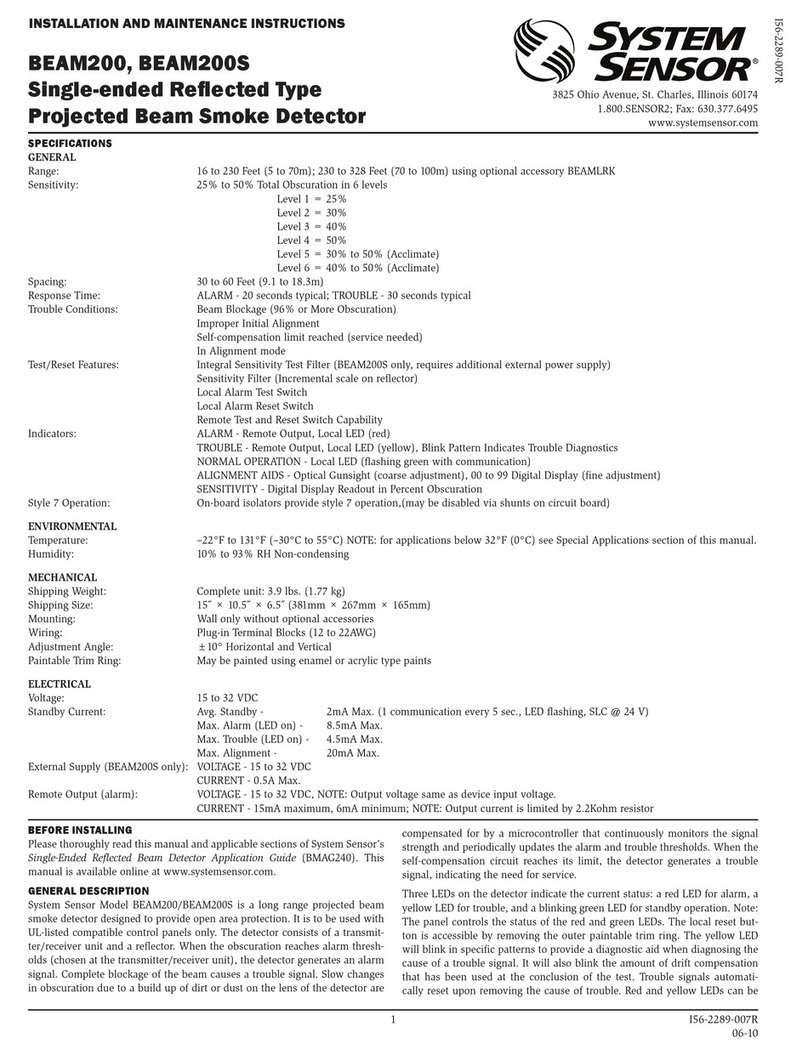

System Sensor BEAM200 Installation and maintenance instructions

Simplex

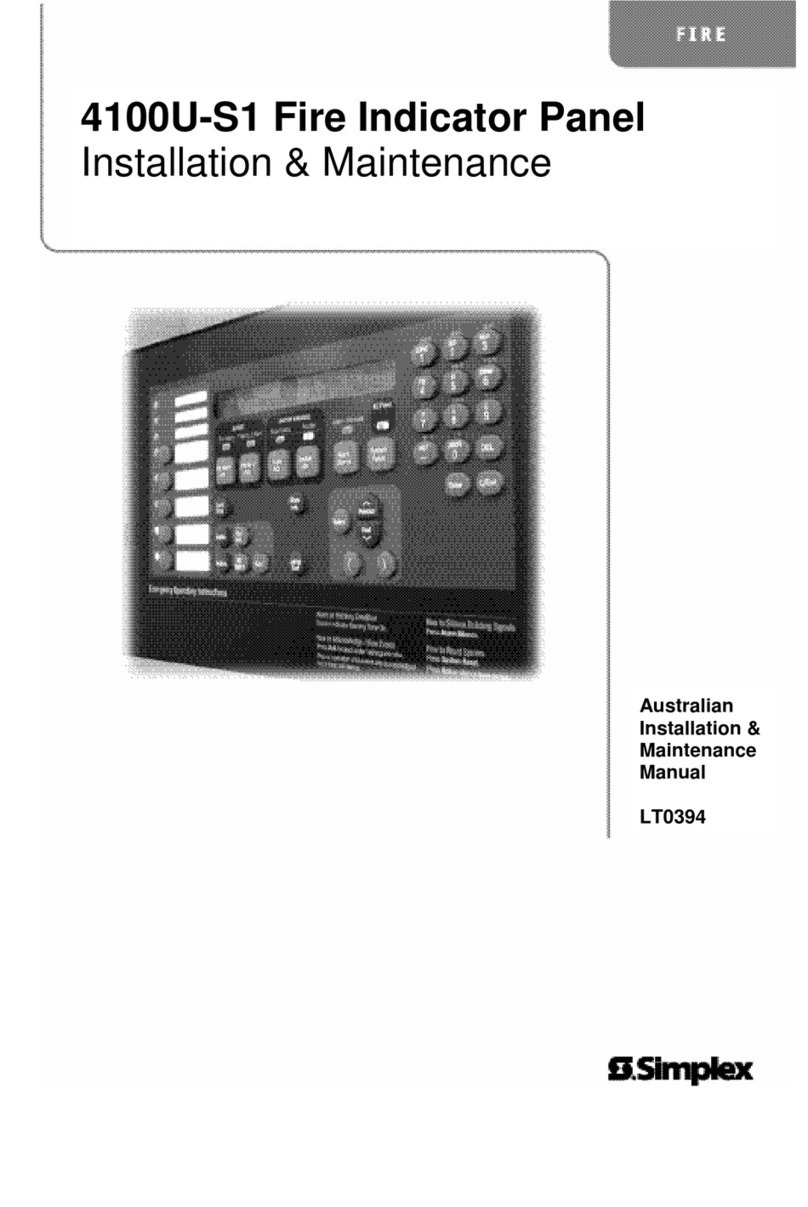

Simplex 4100U-S1 Installation and Maintenance

System Sensor

System Sensor Innovair DH200PL Installation and maintenance instructions

LSC

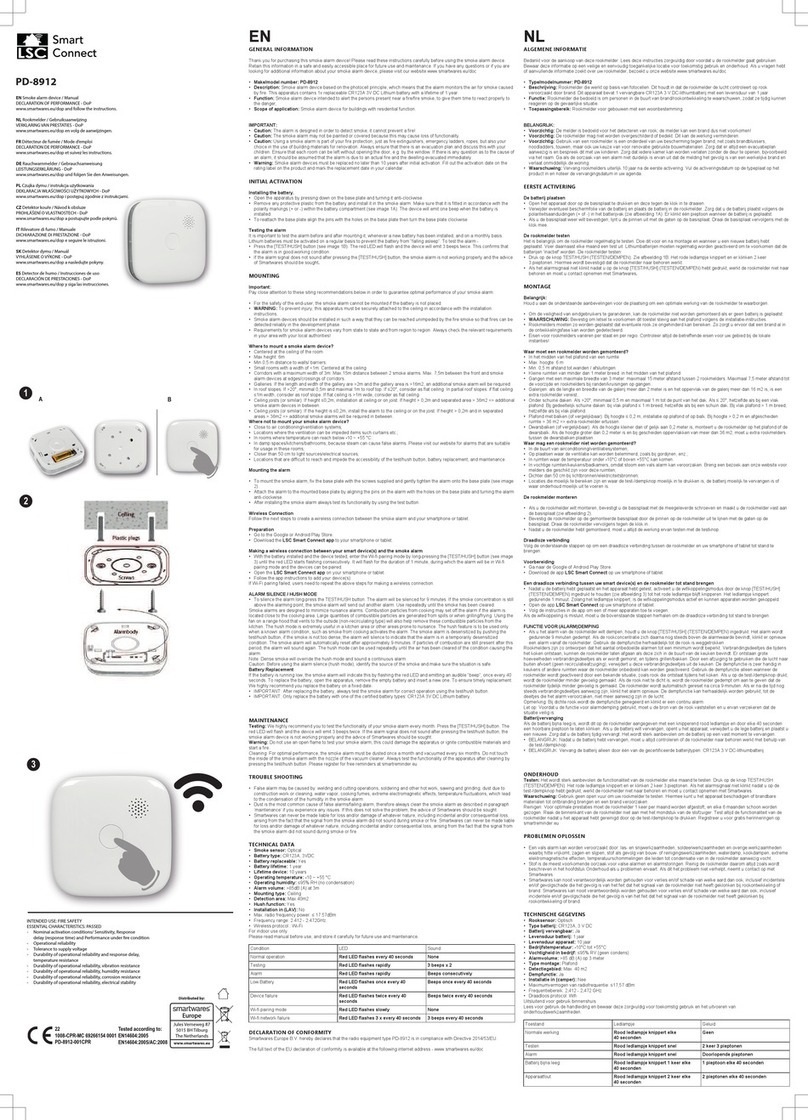

LSC Smart Connect PD-8912 manual

First Alert

First Alert ONELINK SCO501B2 user manual

Kidde

Kidde 0915CA user manual

SONA Electronics

SONA Electronics SM-SN-1 Installation and user guide

Cavius

Cavius 3103-002 user guide

Universal Security Instruments

Universal Security Instruments MDS300 instructions

Brooks

Brooks firetracker FT1020G3 FDCIE Operation manual