STRILING ULT25NEU User manual

Operating Manual

7.15.19

ULT25NEU -86˚C Portable

Ultra-Low Temperature Freezer

6000 Poston Rd Athens, Ohio 45701, USA t: 740.274.7900 / 855.274.7900 f: 740.274.7901 www.stirlingultracold.com

2 of 28 Operating Manual: ULT25NEU ULT25NEU-LIT-OM-BX2 | 7.15.19

THIS PAGE INTENTIONALLY LEFT BLANK

3 of 28

Operating Manual: ULT25NEU www.stirlingultracold.com

U LT25NEU Quick Guide

Initial Setup

Port Stopper/Sealant The Port Stopper/Sealant must be in place during operation.

Power Indicator The unit is ON when lit

Power ON Press and hold for two beeps

Power OFF Press and hold for three beeps

LCD Display Displays chamber temperature

Display Setpoint Press/Release to display current setpoint, S ## displayed

Return to Temp Display Press/Release or wait eight seconds

Change Setpoint Press and hold until Set T LED (E) glows, S ## displayed,

then or (D)

Advanced Functions

Change to Preset Press and hold Set (F) until Set T LED (E) glows, S ## displayed,

then select Preset 1, 2 or 3 (J)

Postpone Over Temp Alarm

When Over Temp LED (I) glows, press Preset 3 (J) until time shows

(1.0 h) (If Over Temp LED is not glowing, then Preset 3 acts as a

Temp Preset)

Return to Temp Display Wait eight seconds, press Preset 3 to return to temperature display

See Error Code Again If Error LED (H) is glowing, press Preset 2 (J) briefly

(If Error LED is not glowing, then Preset 2 becomes Temp Preset)

Lock Panel Press and hold Preset 1 AND 2 AND 3 (J) until Locked LED (G) turns

on (~five seconds)

Unlock Panel Press and hold Preset 1 AND 2 AND 3 (J) until Locked LED (G) turns

off (~five seconds)

LCD Display Codes P ## – Preset Temp, ## h – Alarm Silenced, E ## – Error Code

(see operating manual)

B

B

C

F

F

Notice:

When unit is first turned on, red Over Temp LED (I) will be on until

temperature is within 10ºof setpoint.

Panel cannot be locked until temperature is within 10ºof setpoint.

A

DB

C

AGHI

J

E

F

!

F

4 of 28 Operating Manual: ULT25NEU ULT25NEU-LIT-OM-BX2 | 7.15.19

THIS PAGE INTENTIONALLY LEFT BLANK

5 of 28

Operating Manual: ULT25NEU www.stirlingultracold.com

The ULT25NEU (Ultra-Low Temperature, 25 liter volume) incorporates next generation

free-piston Stirling engine technology. Free-piston Stirling engine technology differs from

conventional compressor-based refrigeration in that it provides high efficiency, deep-tem-

perature cooling in a lightweight package allowing true portable operation.

ULT25NEU

-86˚CPortable Ultra-Low Temperature Freezer

Table of Contents:

1. SAFETY PRECAUTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

1.1 Injury Prevention . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.2 Damage Prevention . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.3 Transportation Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.4 Flammable Refrigerant Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2. UNPACKING AND SETUP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89

3. FEATURES OF THE ULT25NEU FREEZER. . . . . . . . . . . . . . . . . . . 10-13

3.1 Pictorial Tour, Freezer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-11

3.2 Pictorial Tour, Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.3 Power Cords. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.4 Intended Uses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4. OPERATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-17

4.1 How to Turn the Freezer On/Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.2 Changing the Set Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-15

4.3 Using Preset Temperatures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.4 Over-Temperature Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.5 Error Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.6 Locking the Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.7 How to Switch Between Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5. ERROR CODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6. MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.1 Caring for Your Freezer Gasket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.2 Air Intake Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.3 Storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.4 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

7. TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

8. CALIBRATION GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2021

9. SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22-23

9.1 Freezer Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

9.2 Freezer Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

9.3 Pull-Down and Warm-Up Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

10. WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24-25

6 of 28 Operating Manual: ULT25NEU ULT25NEU-LIT-OM-BX2 | 7.15.19

1. Safety Precautions

To prevent personal injury, injury to others, or damage to property,

read these safety precautions carefully before use.

1.1 – Injury Prevention

• Do not cut, change or modify the power cable.*

• When removing the plug, hold onto the plug and not the cord.

• An ultra-low temperature freezer is qualitatively different than a home freezer.

At -86ºC frostbite can occur instantly.

• The user should establish and follow a protocol for safe ultra-low temperature

operating procedures. This should include (but not limited to):

— Never handle samples or freezer accessories with bare hands.

— Do not use gloves which become brittle at ultra-low temperatures.

— Nitrile and latex gloves are inadequate.

• Permeable gloves are dangerous because ultra-low temperature materials can

contact skin and cause damage.

— Be especially careful that materials at ultra-low temperature are not spilled

onto skin or clothing.

— Use only sample containers that have been approved or tested for ultra-low

temperature use.

— Some plastics shatter at ultra-low temperatures. Avoid splinter hazards.

— Biological and chemical hazards are still hazardous at ultra-low temperature.

Always wear proper protective equipment and follow appropriate isolation protocols.

— Many types of labels will fall off and/or break at ultra-low temperature. Some types

of ink which stick to glass and/or plastic at room temperature lose adhesion at

ultra-low temperature.

• In addition to the ultra-low temperature hazards above, there are also physical

hazards to consider:

— Be cautious when closing the lid to avoid a pinching hazard.

—Be careful when loading the box with heavy items.

— Always use the handles to carry the freezer.

1.2 – Damage Prevention

• Do not disassemble, modify or repair. There are no user serviceable parts inside

the freezer unit.*

• Do not immerse in water or pour water on the unit.*

• Do not put ice or liquid water directly in the freezer box, always use suitable

containers.

• Do not use glass containers when the contents might freeze and break.

• Do not store flammable items such as gasoline, thinner or solvents in the freezer.

The freezer is NOT rated as an explosion-proof freezer.

• Do not use hard and/or sharp objects, such as knives, screwdrivers, etc. to remove any

7 of 28

Operating Manual: ULT25NEU www.stirlingultracold.com

frost or ice which has accumulated on the inside of the freezer. The inside panels are

heat exchangers and can be damaged.

• Do not block the air intake or air discharge vents.

• Do not drop, throw or abuse the freezer.*

• Do not operate under extreme environmental conditions, such as in a car trunk,

in very high humidity environments, in rain or other severe weather.*

• Do not use solvents to clean the control panel or the outside or inside of the freezer.

1.3 – Transportation Care

• Only ship via ground transportation to ensure proper unit function (especially import-

ant for domestic addresses).

• Use only factory-provided packaging. If unavailable, contact the manufacturer for

replacement packaging materials.

• Do not place unit on sides or turn upside down.

1.4 – Flammable Refrigerant Use

ULT25NEU uses 10-12 grams of R-170 (Ethane) in a hermetically sealed thermosiphon

tubing. It requires caution in use and repair.

A. Danger – Risk of Fire or Explosion. Flammable Refrigerant Used. Do Not Drill

or Puncture Inner Liner.

B. Danger – Risk of Fire or Explosion. Flammable Refrigerant Used. To be Repaired

Only by Trained Service Personnel. Component Parts Shall Be Replaced With Like

Components. Do Not Puncture Refrigerant Tubing.

C. Caution – Risk of Fire or Explosion. Flammable Refrigerant Used. Consult

Repair Manual/Owner’s Guide Before Attempting to Service this Product.

All Safety Precautions Must be Followed.

D. Caution – Risk of Fire or Explosion. Dispose of Properly in Accordance

with Federal or Local Regulations. Flammable Refrigerant Used.

E. Caution – Risk of Fire or Explosion Due to Puncture of Refrigerant Tubing;

Follow Handling Instructions Carefully. Flammable Refrigerant Used.

*Warning: Unauthorized modication to the cabinet, controls or free-piston Stirling engine is prohibited

and will void all warranty provisions.

1. Safety Precautions

8 of 28 Operating Manual: ULT25NEU ULT25NEU-LIT-OM-BX2 | 7.15.19

A. To use the AC Power Supply:

i. During setup, identify the service power and plug

configuration available and then locate the

appropriate line cord for the service type you will

be using.

ii. If the appropriate line cord is not currently installed,

simply unplug the line cord from the unit and then

plug the appropriate line cord in its place.

iii. Plug the other end of the line cord into the power

source and then attempt to power on the unit.

B. To use the DC Power Cord in a motor vehicle:

i. Make sure the freezer remains level. Exceeding an

angle of 12 degrees may cause loss of cooling.

ii. Plug the DC Power Cord into a 12V outlet that is

rated at 20 amps.

NOTE: Not for use with 24 volt automotive systems.

20 A DC REQUIREMENT: Consult your automotive

specialist if your vehicle lacks 20 A rated 12V outlets.

iii. Plug the opposite end into the freezer. Slide the

male line cord adapter into the female connection

port, lining up the two plastic bungs on the male

adapter with the cutouts in the female port of the

freezer. Press the male adapter firmly into the

connection port and turn clockwise until an audible

“click” indicates full connection.

2. Unpacking and Set-Up

1. Remove the freezer and all accessories from the box. Carefully inspect

the freezer and all accessories for any shipping damage.

2. Check the packing list to verify that the shipment is complete.

3. Ensure the access port stopper or sealant is in place.

4. Place the freezer on a level surface.

5. Make sure that the air inlets and outlets are not blocked.

6. Connect to a power source. While the freezer can be used with either the AC

Power Cord for lab, home or office use, or the DC Power Cord for mobile use, it is

recommended that the initial pull-down to Setpoint be completed via AC power.

Power Cord Available

Separately.

Power Cord Available

Separately.

9 of 28

Operating Manual: ULT25NEU www.stirlingultracold.com

7. Notes on operation in a vehicle.

A. The freezer will operate on vehicle battery power for a limited time before

the battery is drained and the motor vehicle cannot be started. This time will

vary from vehicle to vehicle but is generally only a few hours.

B. The vehicle engine should be running to prevent accidental total discharge

of the battery.

C. The power to 12V outlets in some vehicles may be interrupted during

engine starting. This will cause a sudden stop of the cooling unit which may

produce a sound that is different than when turning off the freezer by using

the On/Off button. This is normal and will not damage the cooling engine.

The cooling engine will restart automatically once power resumes.

D. 20 A DC REQUIREMENT: Please note that 20 A DC service is required for

proper functioning of the freezer in a motor vehicle. Some vehicles may not

be equipped with 20 A DC service. Consult your automotive specialist to

verify the level of DC service installed in your vehicle.

E. Do not operate the freezer in an unattended vehicle. This may lead to

overheating if left in the sun and subsequent damage to stored contents.

8. Disconnecting from power.

A. Turn off the freezer (Press and hold On/Off button for three beeps).

i. The LCD display will show the word“OFF”while the unit turns off.

ii. Unplug the freezer after the word “OFF”disappears and the

display goes dark.

iii. If you unplug the freezer while it is on, you will hear a sudden noise

as the free-piston Stirling engine shuts off. Power outages will also

cause the same noise. This noise (described as a “bonk”) is not

indicative of damage.

2. Unpacking and Set-up

10 of 28 Operating Manual: ULT25NEU ULT25NEU-LIT-OM-BX2 | 7.15.19

3. Features of the ULT25NEU Freezer

3.1 – Pictorial Tour, Freezer

The Stirling Ultracold ULT25NEU free-piston Stirling engine ultra-low

temperature freezer has the following features:

1. A freezer chamber which is protected by two lids

— Inner lid has a tight fitting foam lid.

2. Control Panel

— Described in more detail on page 12.

3. Lid Latch

— For positive closure.

4. Access Port

— For thermocouple wires, etc.

5. Cleanable Filter

— Helps protect the heat rejection fins from dust.

6. AC Power Connection

— Polarized to avoid error.

7. DC Power Connection

8. Temperature Probe Clip (optional)

— For holding the temperature probe in place

for calibration and monitoring.

9. Remote Alarm Contacts (optional)

10. Key Lock

— Locking lid for

sample integrity.

11. Power Supply Fan

12. Vent

1

3

4

2

8

5

10

9

7

12

11 of 28

Operating Manual: ULT25NEU www.stirlingultracold.com

3. Features

1 4

76

89

Outer Lid:

double gasket

moisture seal.

Inner Lid:

high-density, closed cell,

rigid foam.

Access Port:

1/4” (6.3 mm) standard–

may be enlarged up to

1” (25.4 mm).

DC Power Connection.AC Power Connection.

Remote Alarm Contacts

(optional).

Temperature Probe Clip

(optional).

5

Slide-out Filter:

easy to clean, protects

heat rejection ns.

11

6

Power Cord Available

Separately.

Power Cord Available

Separately.

12 of 28 Operating Manual: ULT25NEU ULT25NEU-LIT-OM-BX2 | 7.15.19

3.2 – Pictorial Tour, Control Panel

A. On/Off Indicator LED

B. On/Off button

— Turns freezer on and off.

C. LCD display

— Alpha/numerical display; default display is chamber temperature.

D. / buttons

— Used to adjust Setpoint Temperature (when the display shows S ##).

E. Set Temp LED

— Temperature can be adjusted when lit.

F. Set Temp button

— This must be pressed to adjust the Set Temperature.

G. Locked LED

— Indicates when the control panel is locked.

H. Error LED

— Indicates when there is an electrical, mechanical

or similar error condition.

I. Over Temp LED

— Indicates when the chamber is over/under

the setpoint.

The audible beeper can be set to delay warning.

J. Temperature Preset buttons

C

AGHI

E

DB JF

13 of 28

Operating Manual: ULT25NEU www.stirlingultracold.com

3.3 – Power Cords

A simple line cord change can allow for multiple power and receptacle types. See

Section 4.7 for directions.

Make sure to use the cord and plug appropriate for your location. Power supply

options include:

• North America. 120VAC 60Hz. NEMA 5-15P plug and 240VAC 60Hz. NEMA 6-15P plug.

• Europe/International. 240V, AC, 50Hz. Standard two-pin plug.

3.4 – Intended Uses

The ULT25NEU freezer provides ultra-low temperature storage for both medical and

non-medical purposes. The ULT25NEU is registered with the FDA as a Class I medical

device (Product Code JRM). The storage of blood or blood products intended for

medical purposes is prohibited.

3. Features

14 of 28 Operating Manual: ULT25NEU ULT25NEU-LIT-OM-BX2 | 7.15.19

4. Operation

Important changes to the freezer settings require sustained button pushes.

This helps prevent accidental changes to the settings during transportation.

Some sequences require a three-second button press and hold while other

sequences require a five-second button press and hold.

For example,

Turning the freezer ON requires a three-second press and hold (two beeps).

Turning the freezer OFF requires a five-second press and hold (three beeps).

The default display is the chamber temperature. Other displays such as Setpoint,

Alarm Postpone, etc., are marked with a letter such as S (Setpoint), h (Alarm

Postpone), etc. These secondary displays revert to the default display after

approximately eight seconds of button inactivity.

4.1 – How to Turn the Freezer On/O

4.1.1 – To Turn the Freezer On

• Press and hold the On/Off button for two beeps (~three seconds).

• The freezer will display a greeting message, and then display the chamber temperature.

4.1.2 – To Turn the Freezer O

• Press and hold the On/Off button for three beeps (~five seconds).

• The freezer will display “OFF”for 10 seconds, and then go dark.

4.2 – Changing the Set Temperature

4.2.1 – To See the Current Set Temperature

• Press the Set Temp button briefly.

• The current set temperature will be displayed with the letter S ##.

— After eight seconds of inactivity the display will revert to the current temperature.

4.2.2 – Change the Setpoint to a New Value

• There are two ways to change the Setpoint.

— Manually adjust the temperature using / .

— Use one of the three adjustable Preset Buttons.

• Adjusting the Setpoint manually.

— Because of the importance of the Setpoint Temperature, changing the Setpoint

requires a“two-button procedure”. This means:

Method A - press/hold the Set Temp button while simultaneously pressing.

/ — OR

Method B - press/hold the Set Temp button until the Set Temp LED glows and

then press / .

(Methods A and B achieve the same effect. The user can use whichever method

they prefer.)

15 of 28

Operating Manual: ULT25NEU www.stirlingultracold.com

• To change the Setpoint by Method A

— Press and hold the Set Temp button and then push the / buttons (do not

release the Set Temp button).

– The Setpoint temperature will appear with the prefix S in the

LCD display.

– When the / buttons are first pushed the Setpoint will change by

1ºC at first.

– If the / buttons are held for five seconds the step size will

increase/decrease by 5ºC.

– If the / buttons are briefly released (less than a half second)

while continuing to hold down the Set Temp button the increment/

decrement size will return to 1ºC.

– Release all buttons once the desired Setpoint is achieved. The display

will return to chamber temperature after about eight seconds.

• To change the Setpoint by Method B

— Press and hold the Set Temp button until the Set Temp LED glows.

– The Setpoint temperature will appear with the letter S in the first

LCD display.

— The / buttons can be used to change the Setpoint.

– When the / buttons are pushed the Setpoint will change

by 1ºC at first.

– If the / buttons are held for five seconds the step size will

increase to 5ºC.

– Briefly release (a half second) the / buttons while continuing

to hold down the Set Temp button the increment/decrement size will

return to 1ºC.

– Release the / buttons once the desired Setpoint is achieved.

— Press the Set Temp button briefly (less than one second) to turn off the

Set Temp LED. The display will return to chamber temperature.

4. Operation

16 of 28 Operating Manual: ULT25NEU ULT25NEU-LIT-OM-BX2 | 7.15.19

4.3 – Using Preset Temperatures

• The Temperature Presets — 1, 2 and 3 can be used to quickly change the Setpoint to

frequently used values. When shipped the Presets are set to -86ºC, -40ºC, and -20ºC.

• To choose one of the preset temperatures:

—Press and hold the Set Temp button until the Set Temp LED glows.

—Push one of the Temperature Preset buttons briefly.

—The new Set Temperature will be shown in the LCD display.

—If this is the desired Set Temperature, the user can either:

– Briefly press the Set Temp button to turn off the Set Temp LED.

— OR

– Wait for approximately eight seconds when the freezer control panel

will return to normal operation.

4.4 – Over-Temperature Alarm

• If the freezer compartment temperature is 10ºC warmer or colder than the Setpoint

for five seconds then it will go into temperature alarm mode.

—The Over Temp LED will turn on (this is used for under temperature alarms as well).

—The freezer will make a double beep every 10 seconds.

—Situations which can affect the freezer’s ability to maintain a steady state

or cooling rate include:

– The lid is ajar

– The air vents are blocked

– Addition of a large relatively warm mass

– Power supply problems

– Mechanical and/or electrical problems

4.4.1 – How to Silence the Audible Temperature Alarm

• The Over Temp LED will always be lit when the freezer’s temperature is over or under

the set temperature by more than 10ºC.

4.4.2 – To Postpone an Alarm

• When the audible alarm is sounding it can be postponed.

• Press the Temperature Preset - 3 button (located directly beneath the Over Temp LED)

and the audible alarm will be turned off for 1 hour.

17 of 28

Operating Manual: ULT25NEU www.stirlingultracold.com

4.5 – Error Conditions

• Certain conditions will cause an Error Code to be displayed on the LCD display, and

the Error LED will be lit.

—The error code will be of the form E ##, where ## is the error code. See Section 5

for possible error codes.

—The error code will be displayed for about five seconds and then the display

will show the chamber temperature. The Error LED will stay on.

—The error code can be recalled by briefly pressing the Temperature Preset - 2 button,

located directly under the Error LED. This will recall the error code for approximately

10 seconds.

—If the Temperature Preset - 2 button is pressed and held for five seconds (three

beeps) this will clear both the LCD display and the Error LED. However, if the error

condition persists the error cycle will start over again.

4.6 – Locking the Control Panel

To Lock the Freezer Control Panel

• Press and hold the Temperature Preset 1, 2 and 3 buttons until the freezer beeps three

times.

—The Locked LED will light up.

—The control panel cannot be locked if there is an over temperature or other error

condition.

To Unlock the Freezer Control Panel

• Press and hold the Temperature Preset 1, 2 and 3 buttons until the freezer beeps three

times.

—The Locked indicator LED will turn off.

—The freezer will still indicate over-temperature alarms or error conditions

while it is locked. The user has to unlock the control panel to address those

alarms/conditions.

4.7 – How to Switch Between Power Supplies

• See Section 3.3 for possible power sources for the ULT25NEU.

• To change from one power supply to another:

—Turn OFF the freezer (Press and hold the On/Off button).

—Wait for the free-piston Stirling engine to slow and stop (15 seconds).

—Unplug the freezer from the current power source and plug into the new,

approved power source. Reference Section 2, Part B for instructions on use of

a DC Power cable.

—The freezer can be restarted immediately, no wait time necessary.

—Turn ON the freezer by pressing and holding the On/Off button.

4. Operation

18 of 28 Operating Manual: ULT25NEU ULT25NEU-LIT-OM-BX2 | 7.15.19

5. Error Codes

These are displayed in the LCD display as E ##.

10

The free-piston Stirling engine is not maintaining a working temperature. This

could arise from blocked filters, blocked air passages, unusually hot ambient

temperatures (for example >45ºC), or a fan failure. Check air passages and clear

any blockages for good air circulation. Remove from hot environments (car

interiors, etc.).

40 A component which monitors free-piston Stirling engine performance has failed.

The free-piston Stirling engine cannot regulate itself. Please return for repair.

6. Maintenance

6.1 – Caring for Your

Freezer Gasket

The temperature differential between

ambient and the ultra-low interior can attract

moisture near the gasket. For best results

always wipe away moisture during openings

to prevent ice accumulation. Do not use sharp

instruments to scrape ice from the surface.

6.2 – Air Intake Filter

Clean accumulated dust and dirt on the

air intake filter every month. Pull the filter

cover to the left as shown. Please note that it

cannot be completely removed. Gently clean

the filter with a vacuum cleaner. If there are

stubborn residues use a soft brush to work

them loose.

6.3 – Storage

1. Turn off the power and allow the freezer to come to room temperature.

2. Dry the inside of the freezer compartment and clean any spills.

3. Disinfect with suitable sterilizing agent if the freezer has been used for biohazards.

6.4 – Cleaning

The exterior surfaces of the freezer can be cleaned as needed by using a soft

cloth and mild detergent. Do not use solvent or harsh abrasive cleansers or pads.

19 of 28

Operating Manual: ULT25NEU www.stirlingultracold.com

7. Troubleshooting

Problem Possible Cause Solution

Freezer does

not power on

Power is not getting

to the freezer from

the AC input

Check the connections to the power supply

Assure that the wall plug is firmly seated

Power is not getting

to the freezer from

the DC input

Reseat the connections to the DC power cord

Assure that the DC input has live power

Remove any dirt or debris inside the DC socket or

on the plug

Replace any blown automobile fuses

Freezer does

not achieve

desired

temperature

Inadequate

air circulation

Clean air filter screen

Remove air flow obstructions

Inadequate power

Assure that the wall plug is firmly seated

Remove any dirt or debris inside the automotive

DC socket or on the plug

Operate freezer only when automobile is running

Improper

environment

Remove freezer from direct sunlight, hot room, etc.

Check that freezer is level. Tilts of more than 12

degrees in some directions will degrade performance.

Freezer cools

slowly

Overloading

of freezer Remove some items from freezer

Lid is not

completely closed

Check for ice buildup, remove if necessary,

and properly close lid

Lid is open and

closed too often Minimize opening and closing of lid

Inadequate

air circulation Clean filter and unblock air vents

12V plug

becomes

unusually hot

Dirt or corrosion in

the DC socket Clean the socket

5-7. Errors, Maintenance and Troubleshooting

20 of 28 Operating Manual: ULT25NEU ULT25NEU-LIT-OM-BX2 | 7.15.19

8. Calibration Guide

Calibrating the RTD with an Independent Temperature Indicator

The ULT25NEU’s Resistance Temperature Device (RTD) is factory calibrated to display

both setpoint and operating temperature from a single internal RTD. In the event that

you must recalibrate the unit to match the reading of an independent temperature

recording device or stand-alone electronic thermometer, please follow this process.

1. Tools Required

• Flashlight or work light

• Long handled (6-7”), plastic, Phillip’s or flathead screwdriver

(Do not use a metal screwdriver as this may short circuit the circuit board in the event of a slip.)

• Independent Thermocouple and a NIST traceable temperature measuring device with

sufficient lead wire to pass through the 1/8" access port and affix to the vertical liner

channel

• Tape

2. Procedure

1. Place a thermocouple inside the cabinet via access port (1) and insert plug/

port sealant.

— Note: Display temperature is calibrated using a NIST traceable

thermocouple located in the center of the cabinet (4.4” from back, 6.6”

from left side, 6.7”from bottom).

2. Turn unit on.

3. Set temperature to -80ºC.

4. Wait until the display reads -80ºC.

— For best results wait an additional hour to ensure uniform cabinet

temperature.

5. Connect a NIST traceable temperature measuring device (2) to the

thermocouple located inside the cabinet.

6. Slide open filter door located on the side of the cabinet (3).

7. Using an extra-long screwdriver (4) locate the potentiometer through filter

opening (5).

8. Turn the adjustment screw until the display temperature is the same as the

hand-held instrument. ¼ Turn = 3 DEGREES

9. Turn the screw to change the temperature indicated on the display

(clockwise for warmer and counter-clockwise for colder).

10. After making an adjustment, WAIT 15 SECONDS for the unit’s indicated

temperature to register the adjustment. Repeat adjustment if necessary.

11. Calibration complete.

This manual suits for next models

1

Table of contents

Other STRILING Freezer manuals

Popular Freezer manuals by other brands

Crivit Outdoor

Crivit Outdoor 46862 Operation and safety notes

Delfield

Delfield SSFPT-S Specifications

PROFILO

PROFILO DF6 Series Instructions for use

AEG

AEG SANTO C 7 18 41 I Operating and installation instructions

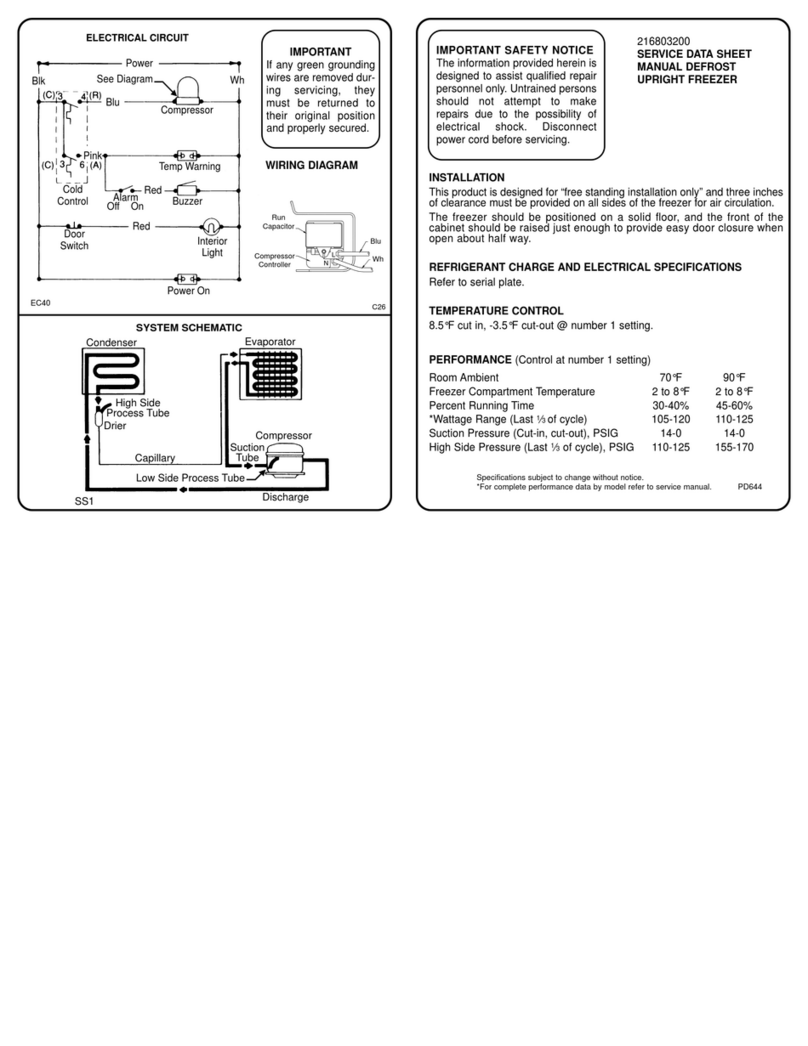

Frigidaire

Frigidaire FFU17C3AW1 Service data sheet

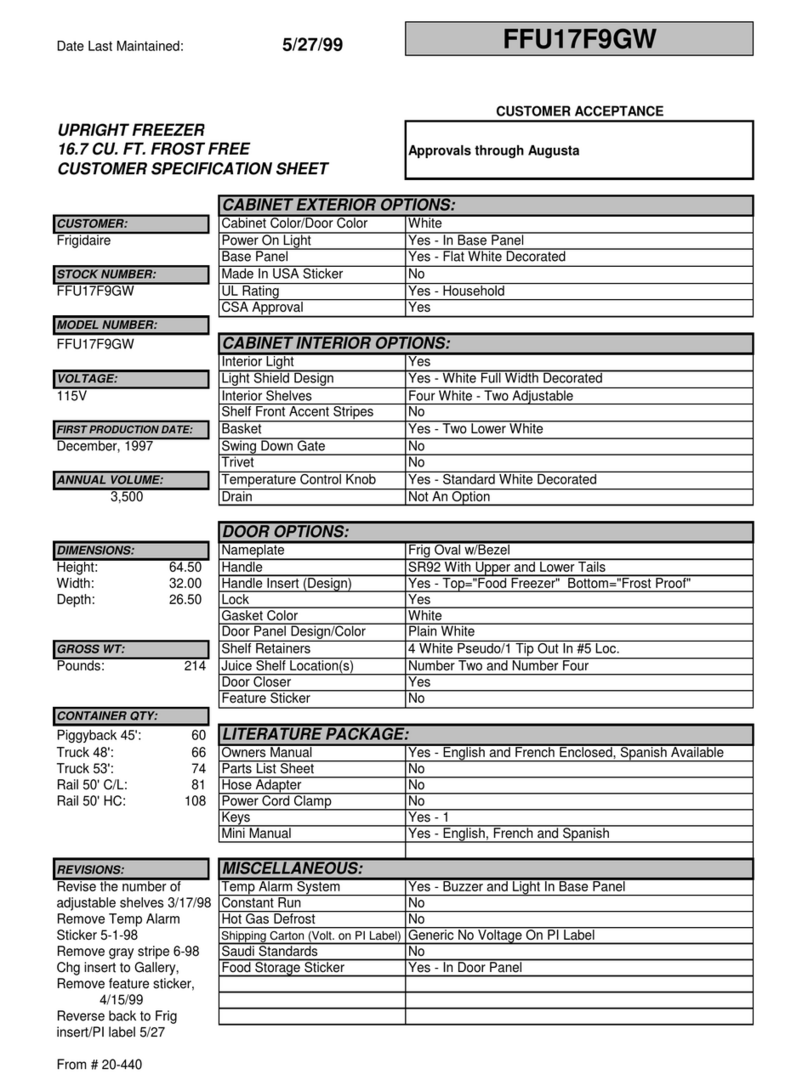

Frigidaire

Frigidaire FFU17F9GW Specification sheet