Strobel VEB100-3 User manual

For the professional user

Für den professionellen Anwender

Mechanikeranleitung

Class:

Klasse:

Model:

Ausführung:

Dated:

Stand:

VEB100-3

2

Spezialmaschinen GmbH

Mechanic‘s Instructions

Im Zeichen der Qualität

ou nd the Strobel trademark on every Strobel

machine leaving our works. And with good reason.

This symbol is a guarantee of the high quality of

our products. Quality which creates trust – trust

in our technology, our service and, not least of all,

in our good name.

ie nden die Strobel-Schutzmarke auf jeder

Strobel-Maschine, die unser Werk verlässt.

Und das aus gutem Grund. Denn dieses Zeichen

garantiert Ihnen die hohe Qualität unserer

Produkte. Qualität, die Vertrauen schafft – in unsere

Technik, unseren Service und nicht zuletzt in unseren

guten Namen.

S

Y

The sign of quality

trobel clients know that they can expect a particularly

high standard of performance from our company and our

machines. Now you have settled for one of our products.

For us this is a source of encouragement and of obligation

to Justify your trust.

If you wish to prot from the performance and efciency of

your Strobel machine as long as possible, exact handling

and thorough care is necessary. For this reason we kindly

request that you read the operating instructions closely.

It provides all the information you need for trouble free

operation.

And if you do happen to need a spare part the enclosed

spare parts list gives a complete overview. It is clearly

classied according to components so that you can nd the

required part quickly and easily. In order to avoid errors we

request you to quote machine class, machine number and

part number completely on your spare part order.

We wish you lots of success in your work with your new

Strobel machine.

S

A decision with future

Spezialmaschinen GmbH

1 MA_VEB100-3_A2_181015_en

Mechanic’s instructions

STROBEL Class VEB100-3

Table of contents

1General notes on safety ............................................................................................5

2General notes............................................................................................................7

2.1 Operating instructions.....................................................................................7

2.2 Class designations, machine number and initial basis for descriptions ..........7

2.3 Applications of the machine............................................................................7

2.4 Technical data of machine..............................................................................8

2.5 Abridged version of adjustment manual..........................................................9

3Notes on repair and adjustments.............................................................................10

3.1 Needle plate assembly..................................................................................10

3.1.1 Removing the needle plate (Fig. 1)..................................................10

3.1.2 Installing the needle plate (Fig. 1)....................................................12

3.1.3 Adjusting the needle plate (Fig. 2)....................................................12

3.1.4 Replacing the needle slide plate (Fig. 3)..........................................12

3.1.5 Adjusting the cloth retainer (Fig. 4) ..................................................13

3.2 Needle lever..................................................................................................14

3.2.1 Assembly..........................................................................................14

3.2.2 Adjusting the needle stroke (Fig. 6, Fig. 7 and Fig. 9)......................15

3.3 Loop stroke...................................................................................................17

3.3.1 Adjusting the loop stroke..................................................................17

3.4 Looper...........................................................................................................18

3.4.1 Removal and installation of the looper shaft.....................................18

3.4.2 Looper deflection (Fig. 8) .................................................................18

3.4.3 Adjusting the looper (Fig. 9).............................................................19

3.5 Feed dogs.....................................................................................................20

3.5.1 Adjusting the feed dog (Fig. 10).......................................................20

3.5.2 Adjusting the bottom belt feed..........................................................21

3.5.2.1 Belt tension .....................................................................21

3.5.2.2 Presser plate pressure (Fig. 11)......................................21

3.5.2.3 Belt feed lifting (Fig. 11) ..................................................21

3.5.2.4 Belt exchange (Fig. 12)...................................................22

3.6 Plunger .........................................................................................................23

3.6.1 Plunger exchange (Fig. 13)..............................................................23

3.6.2 Plunger adjustment (Fig. 13)............................................................23

3.6.3 Adjusting the material support arm...................................................24

3.6.4 Setting the pre-tension of the spring in spring-loaded plungers .......24

2 MA_VEB100-3_A2_181015_en

3.7 Pneumatic lifting ...........................................................................................25

3.7.1 Setting the lifting...............................................................................25

3.8 Thread trimmer (Fig. 15)...............................................................................26

3.8.1 Removing and remounting of the thread trimmer drive (Fig. 15)......27

3.8.2 Adjustment.......................................................................................27

3.8.3 Replacing the knife (Fig. 15 und Fig. 16) .........................................28

3.8.4 Cutting position (Fig. 16)..................................................................28

3.9 Motor.............................................................................................................28

3.10 Motor.............................................................................................................28

3.11 Seam Lock....................................................................................................29

3 MA_VEB100-3_A2_181015_en

Appendix

Circuit diagrams

Electric mains, sewing drive - sewing machine lamp:

258.00.35 Mains connection plan cl. general

(AB611A with/without sewing machine lamp gen.)

Connecting the sewing machine:

258.21.63 Electrical connection plan cl. 45, 58, 103, 120, 170, VEB

258.21.75 Electrical connection plan cl. VEB with seam lock

259.00.37 Pneumatic circuit diagram cl. gen. with pneum. lifting

259.10.37 Pneumatic construction circuit diagram cl. gen.

with pneum. Lifting

259.00.66 Pneumatic circuit diagram cl. VEB100-3 with seam lock

259.10.66 Pneumatic construction circuit diagram cl. VEB100-3

with seam lock

Connecting Thread trimmer:

258.21.47 Electrical connection diagram cl. gen. – thread trimmer

We reserve the right to make design changes.

4 MA_VEB100-3_A2_181015_en

5 MA_VEB100-3_A2_181015_en

1 Every person in charge of setting up, operating, servicing and repairing the

machine must first read and understand the operating instructions and

particularly the safety instructions before starting up the machine.

General notes on safety

Failure to comply with the following safety instructions can lead to bodily

injury or damage to the machine.

1. The machine must only be operated by persons familiar with the relevant

operating instructions and who have been instructed accordingly.

2. Before commissioning also read the notes on safety and the operating

instructions of the sewing drive manufacturer.

3. Only use the machine in the intended manner and never without the

provided guards. Always observe the pertinent safety regulations.

4. Switch off the main switch or pull the power plug for threading, changing

the reels, exchanging sewing tools such as needle, gripper, needle plate,

transport devices, possibly cutter and cutting block, for cleaning and when

leaving the workplace as well as for maintenance.

5. General maintenance tasks may be carried out only by properly trained

persons in accordance with the operating instructions.

6. Repair work, retrofitting and maintenance may be carried out only by

technicians or specially trained personnel.

7. When servicing or repairing pneumatic equipment, the machine must be

disconnected from the pneumatic supply. Exceptions are only allowed for

adjustment work and tests of functionality performed by specially trained

technicians.

8. Only specially qualified technicians may work on the electrical equipment.

9. It is forbidden to work on electrically live components! Exemptions are

covered by the EN50110 (DIN VDE0105) regulations.

10. Any retrofitting or alterations to the machine may only be performed under

strict compliance with all pertinent safety regulations.

11. Only use our approved spare parts when servicing and/or repairing the

machine.

12. It is forbidden to operate the sewing head until it is determined that the

entire sewing unit complies with EU provisions.

13. It is essential that you observe and follow these instructions as well as the

generally valid safety regulations.

6 MA_VEB100-3_A2_181015_en

14. Warning instructions given in the operating instructions that pertain to

especially dangerous parts of the machine must be indicated at these

positions using a safety symbol.

Warning instructions given in the operating instructions that pertain to

special injury hazards for operating personnel or technicians must be

indicated at these positions using a safety symbol.

7 MA_VEB100-3_A2_181015_en

2

2.1 General notes

Every person in charge of setting up, operating, servicing and repairing the

machine must first read and understand the operating instructions and

particularly the safety instructions before starting up the machine.

Operating instructions

2.2

The operating side of the machine is the initial basis for left/right descriptions.

The class designation (type) and machine/model numbers are fastened to the

rear of the machine case.

This data is also noted on the front cover page of the operating instructions.

Class designations, machine number and initial basis for

descriptions

2.3 Class VEB100-3 is suitable for attaching waistbands linings on trousers, also for

waistbands with belt loops attached.

Applications of the machine

The range of applications of the different machines can be extended by

exchanging the variable sewing tools, i.e. those other fabric qualities than the

ones mentioned above can be sewn as well.

Variable sewing tools please see point 7 in operating instruction.

8 MA_VEB100-3_A2_181015_en

2.4 Recommended rated speed: 2200 min-1

Technical data of machine

Machine pulley diameter dw 80 mm

Min. motor power 550 W

V-belt profile 10 x 6 mm

Toothed belt pulley/machine Z=38

Toothed belt profile HTD 5M-9

Stitch length-upper feed 5 - 8 mm

(depend on fabric)

Kind of stitch: single thread chain stitch blind stitch

Stitch type 103

Needle system GROZ-BECKERT 1669 EEO

Needle size 90

Thread polyester continuous filament

Thread size 120/2

Pneumatic connection 6 bar

Average air consumption depending on the equipement

Required space 0.5 m x 1.1 m

Noise:

Average noise level at a speed of

n = 2200 min-1: LpAm 71 dB (A)

Noise test according to DIN 45635-48-1 KL3

9 MA_VEB100-3_A2_181015_en

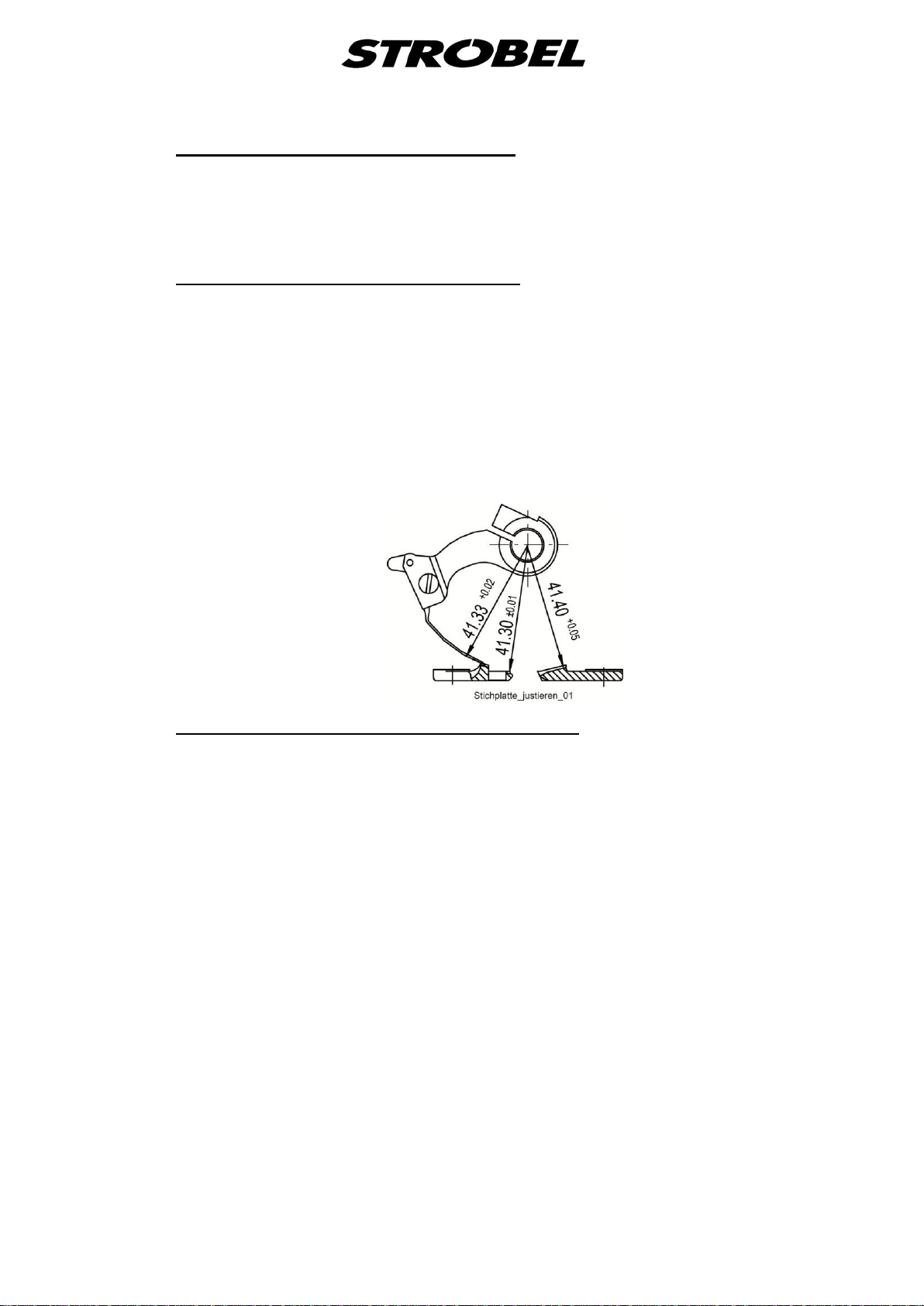

2.5 Theoretic needle radius: 41.3 mm

Abridged version of adjustment manual

Left needle guide: 41.33 +0.02 mm

Needle glide plate: 41.30 ±0.01 mm

Right needle guide: 41.40 +0.05 mm

Needle stroke, needle eye to looper finger: 1.5 +0.5 mm

Ball pin to needle shaft: 4 ±0.5 mm

Slot ball pin: approx. 15°

Looper stroke: 18 +0.5 mm

Pressures:

Feed plate: left 12 N

right 12 N

Cloth support arm: 140 N (meas. at presser shaft)

Plunger limit stop: 6 N

Feed length: approx. 5 - 8 mm

Lifting between needle plate

and feed plates: approx. 13 mm

Lifting between needle

and plunger: approx. 10 mm

Loop stroke: 2.8 +0.3 mm

Number of spot tacks 2 – 4 stitches

10 MA_VEB100-3_A2_181015_en

3

Notes on repair and adjustments

CAUTION! Injury hazard!

Read the safety and operating instructions before

performing maintenance and/or repair work. Failure to

comply with them can lead to severe bodily injury.

3.1

Needle plate assembly

CAUTION! Injury hazard!

Switch off the machine electrically!

Needle plates are adjusted at the factory and can be easily exchanged in their

entirety. When replacing needle guide(s), the adjusting dimensions must be

rechecked using a dial gauge. After removing the needle lever, the dial gauge is

inserted into the needle shaft and, by turning the handwheel, touches the

surface of the needle guide.

3.1.1 1. Switch off machine electrically, cloth support arm is lifted.

Removing the needle plate (Fig. 1)

2. Remove needle and needle lever.

3. Remove the thread trimmer's drive unit as described under “3.8.1

Removing and remounting of the thread trimmer drive (Fig. 15)” or pull the

plug only.

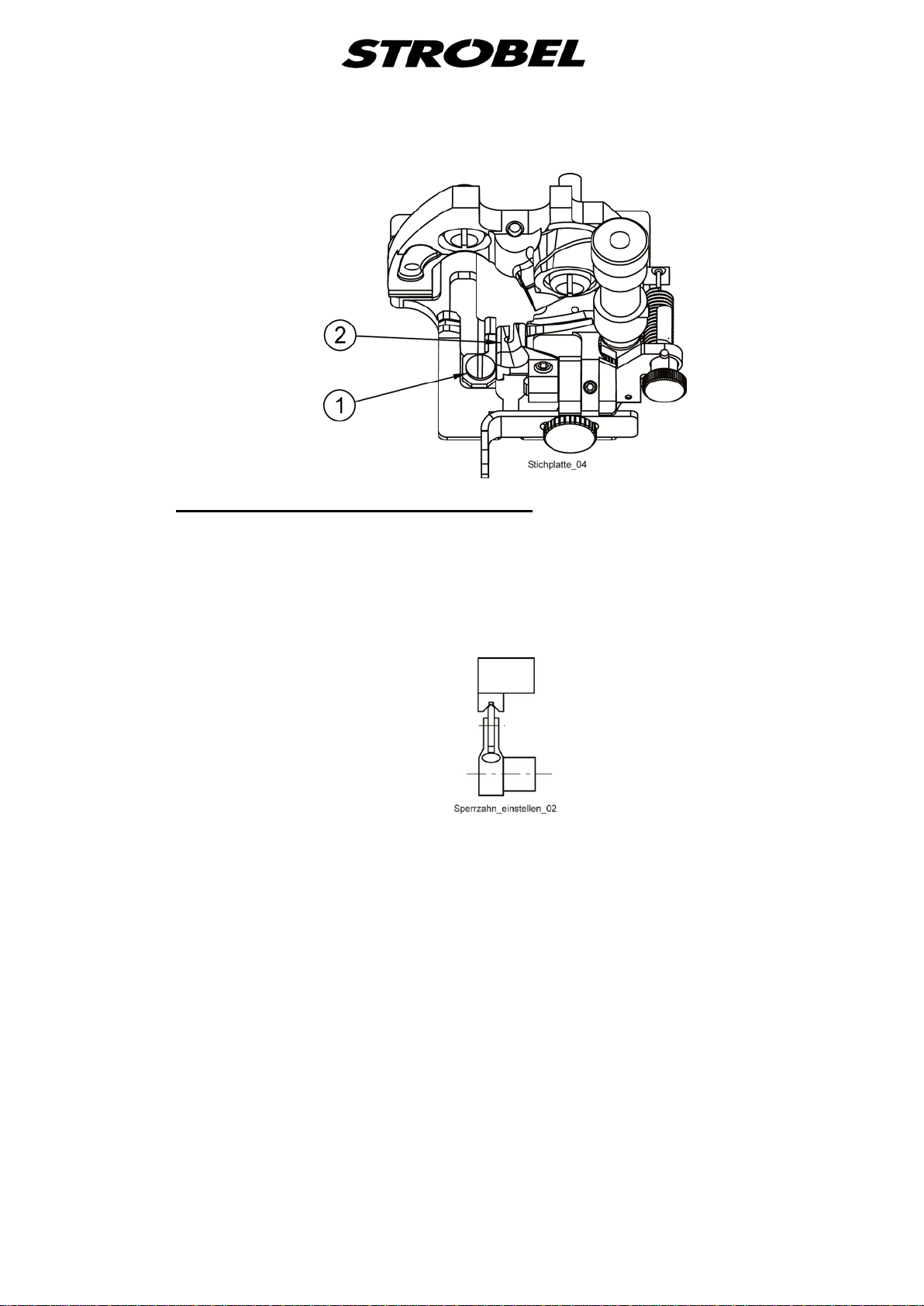

4. Release needle plate fastening screws (1) and (2) and remove the

complete needle plate unit to the front.

11 MA_VEB100-3_A2_181015_en

Fig. 1

12 MA_VEB100-3_A2_181015_en

3.1.2 Remount the needle plate in reversed order but make sure that the needle plate

opening is mounted centrically to the presser foot and that the needle plate is

mounted horizontally. Push the needle plate bow completely upwards until

threaded pin (3) fits closely to the needle shaft bush.

Installing the needle plate (Fig. 1)

3.1.3 At the left needle guide, the theoretical needle radius of 41.3 mm should be

0.03 to 0.05 mm larger. At the needle slide plate, it should be 0.01 mm smaller

to 0.01 mm larger and at the right needle guide it should be 0.06 to 0.08 mm

larger.

Adjusting the needle plate (Fig. 2)

The adjustment must be made using a dial gauge. Deviations lead to

significantly poorer sewing results and may even cause preliminary damage or

wear to the sewing tools.

Fig. 2

3.1.4 The needle slide plate on the central base of the needle plate can be removed

after loosening the screw (1).

Replacing the needle slide plate (Fig. 3)

When assembling, ensure that the needle slide plate lies firmly against the base.

13 MA_VEB100-3_A2_181015_en

Fig. 3

3.1.5 After replacing the needle plate, check whether the cloth retainer

Adjusting the cloth retainer (Fig. 4)

(2) Fig. 3 lies

centrally on the plunger. This is particularly important for roof-shaped

plungers/cloth retainers to ensure that the material is optimally held during

sewing.

Fig. 4

14 MA_VEB100-3_A2_181015_en

3.2

3.2.1 Needle lever

Assembly

CAUTION!

Switch off the machine electrically!

Remove screw (10) Fig. 6, move the Thread take-up lever and remove the

needle lever. During installation, please ensure that the needle runs through the

centre of the needle groove and the needle tip is flush with the left needle guide

(Fig. 5).

Fig. 5

15 MA_VEB100-3_A2_181015_en

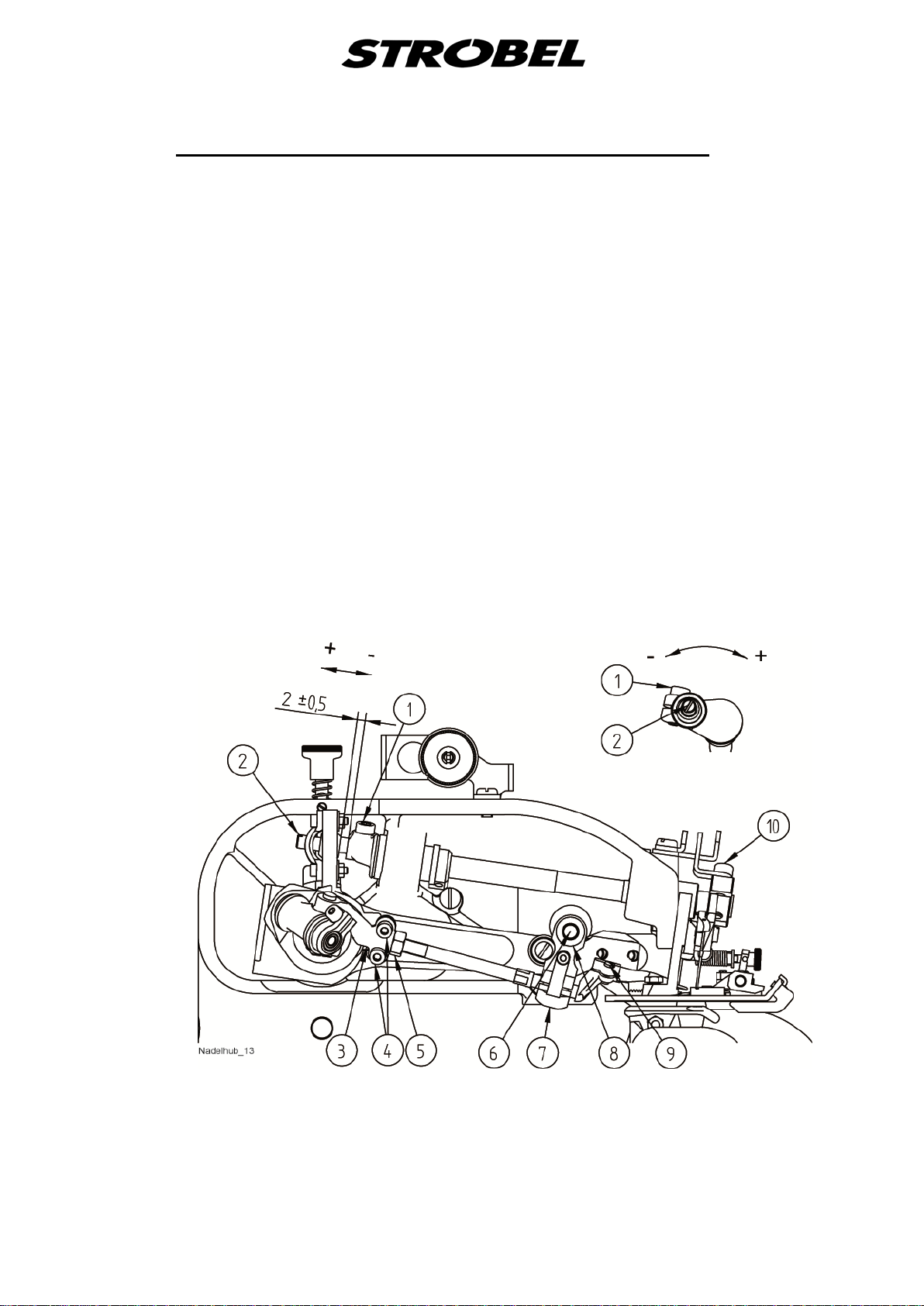

3.2.2 For a loop stroke of 2.3–3.0 mm, the needle stroke must be set to that the left

side of the needle’s eye is approx. 1.0 +0.5 mm away from the large gripping

finger when the tip of the large gripping finger is above the centre of the needle

(

Adjusting the needle stroke (Fig. 6, Fig. 7 and Fig. 9)

Fig. 9).

The head cover must be removed for the adjustment. After removing (hex key

size 4) screw (1) shown in Fig. 7, the ball pin (2) shown in Fig. 6can be

adjusted using a slotted screwdriver.

In the horizontal position, insert the ball pin so that the slot of the ø6 bolt stands

vertically beneath the ø7 bolt.

Rotating it clockwise will result in a larger needle stroke while turning it in the

opposite direction will create a smaller needle stroke.

The distance between the ball pin and needle shaft is 2 ±0.5 mm. After

adjusting the needle stroke, the needle lever must be configured as described in

section “3.2.1 Assembly”.

Tighten the screw (1) shown in Fig. 7.

Check the looper and needle movement by turning the main shaft using the

handwheel.

Fig. 6

16 MA_VEB100-3_A2_181015_en

Fig. 7

Other manuals for VEB100-3

2

Table of contents

Other Strobel Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

SCHUNK

SCHUNK ERT 12 Assembly and operating manual

SMC Networks

SMC Networks CS2 Operation manual

ABB

ABB HT587622 Operation manual

Pentair

Pentair Aurora 1080 Series INSTRUCTION, INSTALLATION, MAINTENANCE AND REPAIR MANUAL

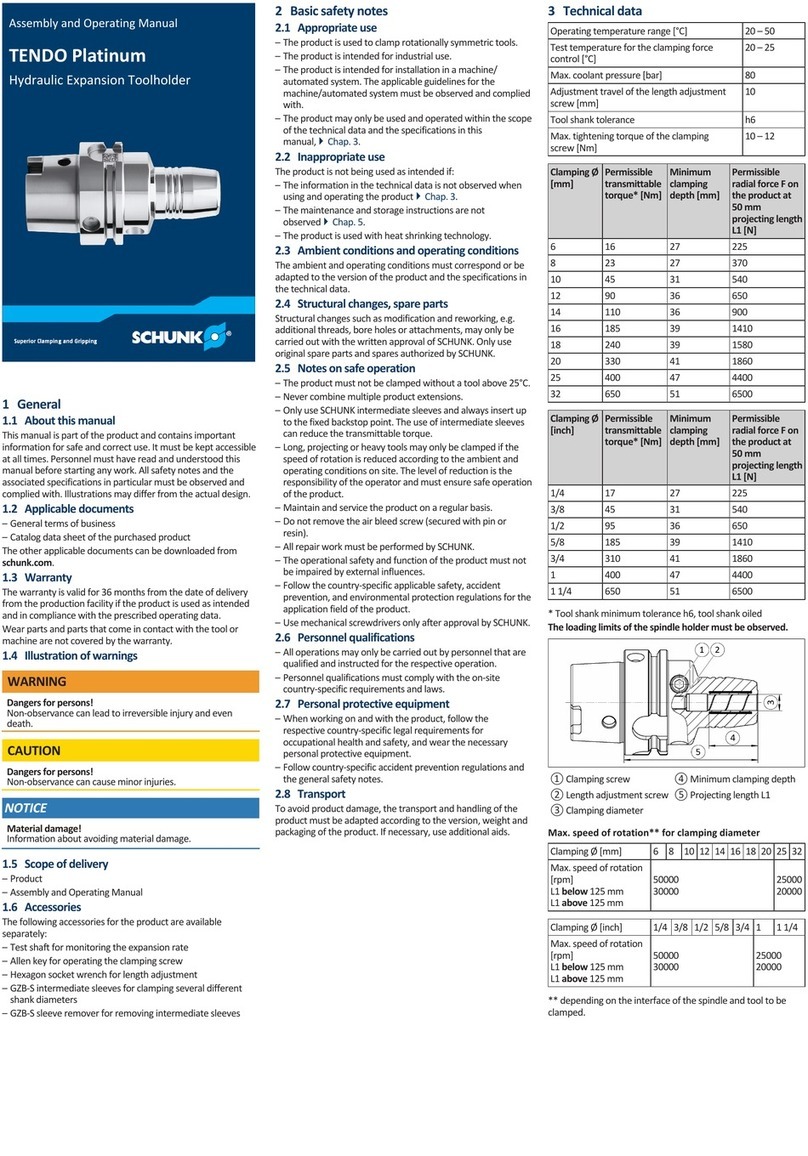

SCHUNK

SCHUNK TENDO Platinum Assembly and operating manual

ABB

ABB HT609828 Operation manual

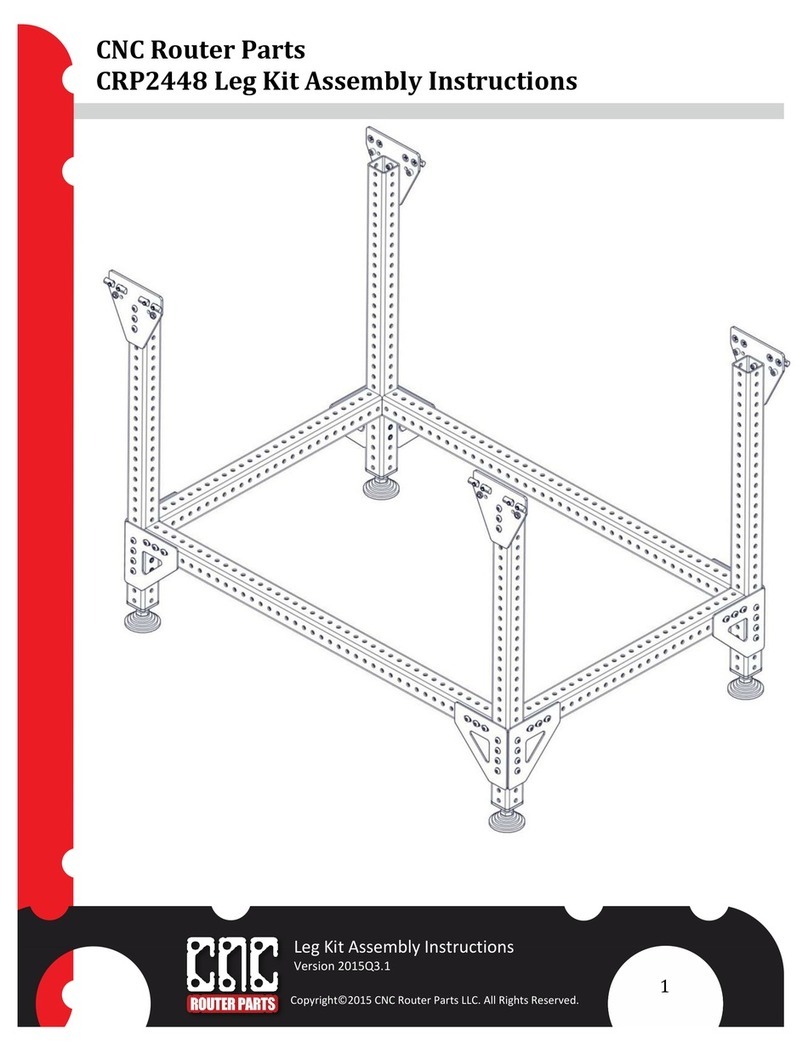

CNC Router Parts

CNC Router Parts CRP2448 Assembly instructions

Honeywell

Honeywell Industrial HERMetic Sampler GTX Chem Operation and service manual

Agil Elektronik

Agil Elektronik eFuse 2-200-10 instruction manual

Hiwin

Hiwin KK Assembly instructions

Hirobo

Hirobo FL-II Assembly

Team

Team SILK FXB630 instruction manual