ADJUSTMENT INSTRUCTIONS (continued)

3. Ignite the xenon bulb and check the current. Allow (30) seconds for the current to stabilize and

provide an accurate reading. If the current is

not

within the desired range, extinguish the bulb. It will

be necessary to increase or decrease the DC output.

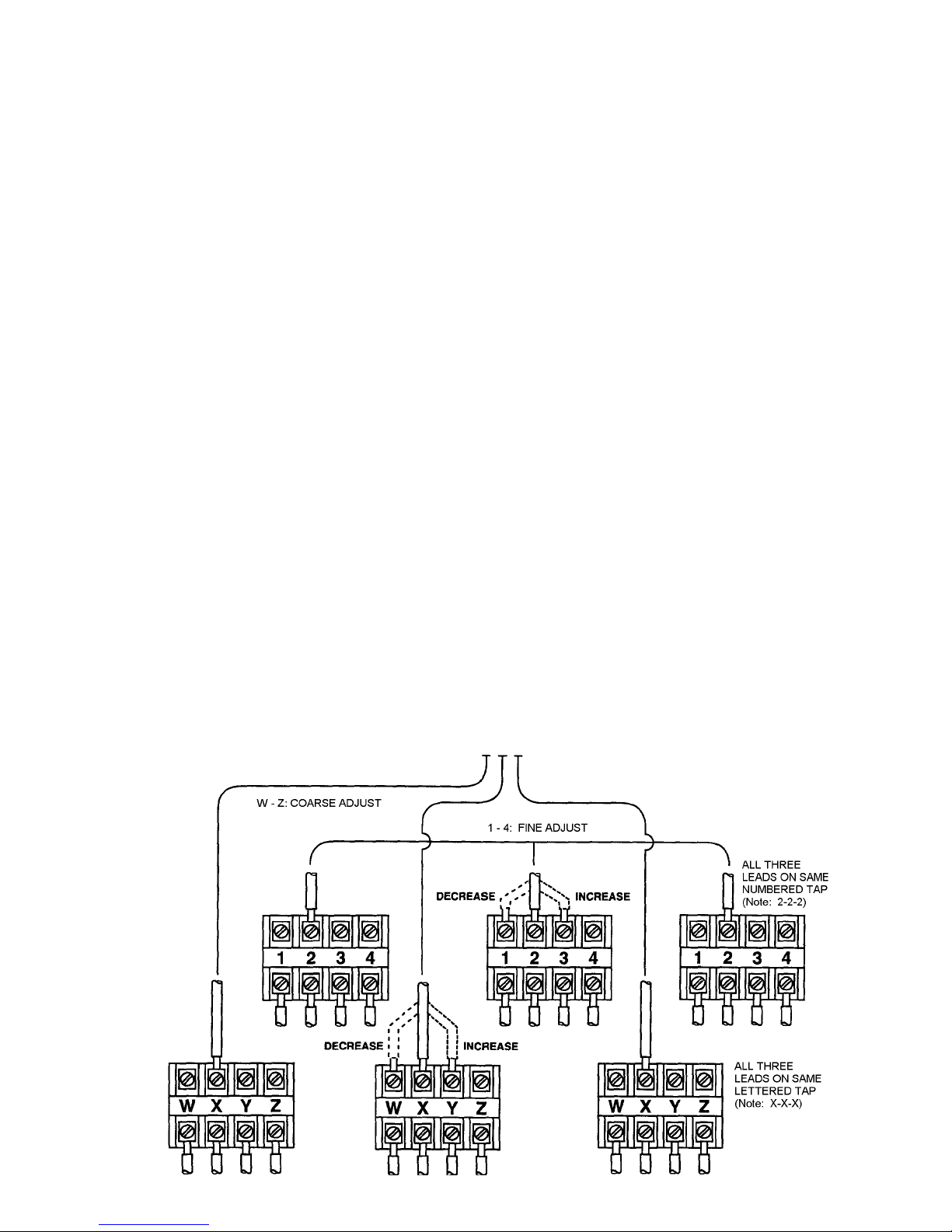

4. Fine adjustment

of the DC current is made to the

NUMBERED

taps found on the upper three terminal

blocks (TB4, TB5, TB6). Fine taps are numbered 1-2-3-4, with “1”providing the lowest output, increas-

ing to “4,”yielding the highest output. A “fine”tap adjustment raises or lowers the current approxi-

mately four amperes. The three fine tap terminal blocks are interconnected by means of a three-

lead jumper wire assembly attached to like-numbered terminals.

•To

increase

the DC output, move the jumper wire assembly to tap the next (3)

higher

numbered termi-

nals, for example, move from terminals “2”to terminals “3.”ALL TAPS MUST BE ON THE SAME NUMBERED

POSITION (1-1-1, 2-2-2, 3-3-3, or 4-4-4). If the DC output is still too low when terminals “4”are intercon-

nected, see the following instructions for adjusting

“coarse”

taps.

•To

decrease

the DC output, move the jumper wire assembly to tap the next (3)

lower

numbered

terminals, for example, move from terminals “3”to terminals “2.”ALL TAPS MUST BE ON THE SAME

NUMBERED POSITION (1-1-1, 2-2-2, 3-3-3, or 4-4-4). If the DC output is still too high when terminals “1”are

interconnected, see the following instructions for adjusting

“coarse”

taps.

5. Coarse adjustment

of the DC current is made to the

LETTERED

taps found on the lower three terminal

blocks (TB1, TB2, TB3). Coarse taps are lettered W-X-Y-Z, with “W”providing the lowest output, in-

creasing to “Z”at the highest output. The coarse tap terminals connect to contactor terminals T1, T2,

and T3. The (3) contactor leads must connect to the same lettered step (W-W-W, etc.). A “coarse”

tap adjustment raises or lowers the current approximately twelve amperes.

•To

increase

the coarse DC output, move each of the contactor leads to tap the next

higher

lettered

terminals, for example, move from terminals “W”to terminals “X.”ALL TAPS MUST BE ON THE SAME

LETTERED POSITION (W-W-W, X-X-X, Y-Y-Y, or Z-Z-Z). Place the fine tap jumper on 1-1-1. Ignite the lamp,

check the output, and increase the fine tap setting as required.

•To

decrease

the coarse DC output, move each of the contactor leads to tap the next

lower

lettered

terminals, for example, move from terminals “Y”to terminals “X.”ALL TAPS MUST BE ON THE SAME

LETTERED POSITION (W-W-W, X-X-X, Y-Y-Y, or Z-Z-Z). Place the fine tap jumper on 1-1-1. Ignite the lamp,

check the output, and increase the fine tap setting as required.

NOTE: Both power supplies should be on the same output setting, i.e.:

Power Supply “A”X-X-X, 3-3-3 (or as required)

Power Supply “B”X-X-X, 3-3-3 (or as required)

6. Set the voltmeter to DC scale and read the arc voltage. The voltage should between 45 and 55 volts

DC. If the actual measured voltage is

not

in this range, consult your bulb supplier immediately.

7. Inspect tap connections to verify that the terminal is clamping the copper conductor, not the

insulation. Make certain all terminal clamping screws are tight.

8. Whenever making a coarse adjustment, again check the output current and make certain the cur-

rent is within the desired range. A fine tap re-adjustment is frequently required after changing coarse

taps.

9. After prolonged operation, the light output of the xenon bulb will decrease. This is a normal factor of

bulb aging, and can be compensated by raising the DC output of the xenon power supplies. If the

bulb was first operated at “nominal”current, the power supply output can gradually be increased

to, but

not in excess of,

the maximum current specified by the bulb manufacturer (220 A.). Increase

the current as instructed above. Decrease the power supply output to its former “nominal”current

level upon the installation of a new replacement bulb.

8