Stronghold SELECT Series User manual

StrongHold clamping system

StrongHold

SELECT

Series

StrongHold Standard

Series

MRO

Interchange

Reduced

Maintenance

Costs

Proven

Application

Performance

Robust

Products

DE-STA-CO Subject to technical modifications without notice 15.1

StrongHold Clamping SystemTM

15_StrongHold. xp:15_DES_StrongHold-1-14.indd 1/2/08 9:02 AM Page 15.1

15.2 Subject to technical modifications without notice DE-STA-CO

Product group – stronghold clamping system

Model no. Page

70250

70260

15.18

090-011-113

090-012-221

090-012-224

090-013-332

090-013-334

090-021-111

090-021-114

090-022-222

090-022-225

090-023-333

090-023-335

15.19

010-011-113

010-012-221

010-012-224

010-013-332

010-013-334

010-021-111

010-021-114

010-022-222

010-022-225

010-023-333

010-023-335

15.20

010-210-400

010-210-501

010-210-702

010-211-002

010-211-004

010-211-502

010-211-504

010-212-004

15.21

030-1-S-475

030-1-D-475

15.23

030-1-S-1100

030-1-D-1100

15.24

Model no. Page

030-1-S-2400

030-1-D-2400

15.25

030-1-S-4000

030-1-D-4000

15.26

031-S-475

031-L-475

031-S-1100

031-L-1100

031-S-2400

031-L-2400

031-S-4000

031-L-4000

15.27

052-Series 15.29

051-Series 15.29

70626 15.30

020-011-011DE

020-012-021DE

020-013-031DE

15.31

039-101-000DE

039-104-000DE

039-108-000DE

039-109-000DE

15.33

StrongHold Clamping SystemTM

15_StrongHold. xp:15_DES_StrongHold-1-14.indd 1/2/08 9:02 AM Page 15.2

DE-STA-CO Subject to technical modifications without notice 15.3

Product group – stronghold clamping system

Model no. Page

70150 15.34

100178DE

100178-230DE

15.35

100186DE

100186-230DE

15.36

100179DE

100179-230DE

15.37

100888DE

100888-230DE

15.38

100279DE 15.39

100920DE

100190DE

15.40

037-100-122 15.41

Model no. Page

500173DE

500174DE

15.42

70912

70913

15.43

StrongHold Clamping SystemTM

15_StrongHold. xp:15_DES_StrongHold-1-14.indd 1/2/08 9:03 AM Page 15.3

15.4 Subject to technical modifications without notice DE-STA-CO

Building safe workholding systems

Safety means paying attention to the smallest details. A hastily

assembled workholding system can result in a hazardous operator

environment. Hydraulic workholding is not a generic technique where

most anything will work, nor is there one right or best answer for all

situations. Each application is different and can be approached in

many different ways. ecause of this versatility, there is no rule-of-

thumb to follow to guarantee safety. A careful balance of knowledge,

fixture design and common sense are key to avoiding injuries.

Plan your fixture installation with operator safety in mind. y nature,

most clamping devices have pinch points. Many times the fixture can

be designed to shield the operator from a pinching hazard. Often the

placement of the clamping device in the fixture can minimize the gap

between the clamp and the workpiece, thus reducing or eliminating

the pinch point. Perhaps the clamping control valve or switch can be

located such that the operator

cannot reach the fixture

and the control at the same

time. Dual palm buttons on

electrically-actuated systems

serve the same purpose.

Do not require the operator

to hold the workpiece in position during the clamping operation. Make

sure that the workpiece is self-supporting and self-locating so that

operator hands are out of danger when the hydraulic system is

actuated. Often a simple spring plunger is all that is necessary.

The lowest pressure rating of any

component in the clamping system

sets the maximum pressure rating

for the entire system.

Most hydraulic workholding

components are rated at 5,000

PSI maximum. However, some components are rated at less than 5,000

PSI. The maximum pressure is listed on each product page of this

catalog. Never exceed this rating.

Just having a clamp that is rated

at 5,000 PSI is not enough. Every

hose, fitting, valve, adapter and

tube exposed to pressure must be

rated at or above the maximum

hydraulic system pressure. Most

“hardware store” fittings are intended only for low pressure

plumbing. Never use ater pipe fittings or copper tubing and brass

fittings for hydraulic service.

Use proper tools when

bending tubing, and maintain

proper minimum bend radii for

hoses and tubing. If a hose or

tube is ever kinked, replace it.

Don’t risk a rupture. Fluid

escaping under high pressure is dangerous. The resulting loss in

pressure could release the workpiece from the fixture and cause

serious injury and equipment damage by being ejected from the

machine or breaking tooling.

Tubing and hoses do flex when

pressurized. Allow for that

movement by supporting the

fluid lines away from surfaces

which could abrade the surface

and eventually cause damage.

Avoid straight lengths of hose and tubing. A bend will allow for this

deflection without putting too much stress on the line.

Even if proper hydraulic tubing

and fittings are specified, be

sure to protect them from

abuse. Components damaged

from abrasion or accidental

dropping of a workpiece will no

longer have the strength and

safety of the original design.

Use proper mounting hardware

when installing workholding

clamps and other components.

Always use the largest bolt

available to fit in the mounting

hole. In many cases, the

recommended cap screw or thread is specified on the product page

of this catalog. Sometimes the mounting hardware is included with

the component. Always use supplied hardware.

Safety means

paying attention

to the

smallest details.

StrongHold Clamping SystemTM

15_StrongHold. xp:15_DES_StrongHold-1-14.indd 1/2/08 9:03 AM Page 15.4

DE-STA-CO Subject to technical modifications without notice 15.5

StrongHold Clamping SystemTM

Power workholding systems

Application A

Multiple double-acting actuators can be operated

simultaneously when powered by a pump.

Application B

Two pairs of single-acting actuators are independently

operated by remote mounted control valves and

powered by one pump. Check valves prevent return

line pressure fluctuations from affecting released

clamps. Pressure port “P” check valves are built into

the control valve.

Application C

Similar to Application C, one pair of single-acting

actuators and one pair of double-acting actuators

are independently controlled by 100969DE

directional control valves. When using more than

one directional valve in one circuit, “P” port check

valves 500174DE are required to prevent loss of

clamping pressure in one circuit while actuating

another. “T” port check valves 500173DE should be

used in single-acting circuits where return line

pressure fluctuations may affect released clamps.

15_StrongHold. xp:15_DES_StrongHold-1-14.indd 1/2/08 9:03 AM Page 15.5

15.6 Subject to technical modifications without notice DE-STA-CO

StrongHold Clamping SystemTM

Power workholding systems

Application F

Similar to Application , (on page 15.8) the three actuators

are operated by a remote mounted control valve. This type

of valve allows the pump to be located away from the

workstation. The valve can be manually operated or, as

shown, an electrically operated remote control valve is

used. This valve can be used to give the operator push-

button convenience or fully automated control by the

machine tool.

Application E

Two single-acting actuators operate simultaneously,

controlled by a remote manual valve. A sequence valve

insures that the workpiece is clamped before the work

support is locked.

Application D

Rotating unions are used to connect pressure and

return lines on applications where fixture rotation

does not allow fixed plumbing. Here, three single-

acting actuators are independently operated by

three remote mounted control valves. Each valve is

connected to the rotating union which, in turn, is

connected to a single pump.

Application

Similar to Application F (above), a double-acting

swing clamp is actuated before sequencing a

work support. When released, the work support

drains back through the sequence valve’s

internal check valve.

15_StrongHold. xp:15_DES_StrongHold-1-14.indd 1/2/08 9:03 AM Page 15.6

DE-STA-CO Subject to technical modifications without notice 15.7

StrongHold Clamping SystemTM

Application J

For pallets using double-acting actuators,

DE-STA-CO’s double-acting pallet valve

system uses a pilot-operated check valve

to maintain pressure on the pallet. The

three position directional valve mounts at

the operator’s workstation instead of the

pallet. Any of DE-STA-CO’s standard,

constant pressure pumps operate the

system. An accumulator makes up for

temperature change and minor leakage.

Application I

DE-STA-CO’s Manual Pallet Valve is the

simplest way to disconnect the power source

from a pressurized pallet. For use only with

single-acting actuators, it provides an

automatic, leak free shut-off. An accumulator

makes up for temperature changes and

minor leakage. uilt-in filtration protects this

valve from contamination.

Application H

Like Application C (on page 2), two single-acting systems

are independently operated by remote mounted control

valves. Here the pressure reducing valve allows each

system to have its own maximum pressure. The cylinder

on the left operates at the pressure of the power source.

The cylinder on the right can be set at a lower pressure by

adjusting the pressure reducing valve.

Power workholding systems

15_StrongHold. xp:15_DES_StrongHold-1-14.indd 1/2/08 9:03 AM Page 15.7

Planning

The most important and cost effective part of the fixture design process

is planning. All facets of the project should be considered, and all

questions answered before fixture design begins.

How many operations are required?

What machine will be used?

What is the expected cycle time?

How many parts will be run? How often?

How fast must the workpiece be changed?

The answers to questions like these will help determine the relative

cost/benefit of the clamping system chosen for the fixture.

The following information will help prove that a hydraulic power

clamping system can be a cost effective fixturing alternative.

Hydraulic Force

A basic principle of hydraulics states that pressure applied to a confined

fluid is transmitted equally in all directions. This principle allows the

transmission of pressure through tubes and hoses to remotely located

actuators where that pressure is converted to usable force.

The simplicity of hydraulic power clamping can be summed up in one

small equation:

FORCE = Pressure X Area

In the cylinder above, the fluid pressurized at 2,000 PSI is acting on the

3 sq. in. piston. As the formula says, 2,000 PSI times 3 sq. in. yields a

force of 6,000 lbs.

This same concept applies to all hydraulic actuators.

Plumbing Options

The method used to route the pressure to the actuators on the fixture

should be determined early in the planning stage. The plumbing is an

essential part of the fixture and should never be left as an afterthought.

There are two basic plumbing methods: conventional and

manifold mount.

Conventionally mounted components have threaded ports which accept

fittings for tubing and hoses. Many different types of fittings are

available, giving you several options for customizing your design. Since

most of these components are commonly available, conventional

mounting will typically be the lower cost option.

Conventional

Mounting

The threaded ports are usually one of two designs, NPT tapered pipe

threads or SAE O-Ring boss.

NPT Tapered Pipe Threads depend on the interference of the mating

thread forms. This thread form has been in use for general plumbing

applications for many years. Consequently there is a wide selection of

fittings available for even the most unique applications. However, the

thread form is the same whether the application is a household water

supply or a high pressure hydraulic workholding system. It is important

to specify only fittings that are rated for the maximum pressure to be

seen in your application. Plastic, copper and iron pipe fittings are not

acceptable alternatives.

Straight Thread, O-Ring Boss Ports per SAE J514 are common in both

industrial and mobile hydraulic systems. ecause this system of ports

and fittings depends on a simple, replaceable O-ring for sealing instead

of the interference of perfectly formed threads, the chance for leakage

is greatly reduced.

Systems can be disassembled and reassembled numerous times with

no additional make-up required. Fittings will always be in the exact

same place and elbows will always point in the right direction. There is

never the need to over or under-tighten elbows to properly align them

in your system.

Pipe sealants and teflon tapes that can contaminate your system are

not required. The torque needed to properly tighten these fittings is

less, too.

All of DE-STA-CO’s newest products have the SAE ports. In addition, we

have made many of our other products available with SAE ports. Where

available, this is noted on the product description page.

15.8 Subject to technical modifications without notice DE-STA-CO

StrongHold Clamping SystemTM

System design information

Pressurized fluid =

2,000 pounds per square inch (PSI)

Piston area =

3 square inches (Sq. In.)

FORCE =

6,000 lbs.

15_StrongHold. xp:15_DES_StrongHold-1-14.indd 1/2/08 9:03 AM Page 15.8

Manifold

Mounting

Manifold mounted components eliminate the need for external fittings,

tubing, and hoses because the fluid passages are machined directly

into the fixture. Securing the workholding component to the fixture

automatically makes the hydraulic connection.

Manifold Mounting:

Provides no-tool hydraulic connections

Saves valuable fixture space

Eliminates tubes, hoses or fittings that disrupt coolant

flow and collect chips

Simplifies post-machining fixture cleaning

Reduces assembly and maintenance time

Improves performance

Means fewer hydraulic connections resulting in fewer

potential leak points

Results in a cleaner, more professional-looking fixture

Plumbing Sizing

When designing and assembling your hydraulic system, keep in mind

that your choices of size and length of plumbing lines can significantly

change the performance of your fixture. The back-pressure created by

fittings, tubing and hoses can slow the operation of your system, especially

single-acting systems. Larger diameter plumbing runs with a minimum

number of bends and fittings will reduce this back pressure.

When sizing hydraulic lines, make sure you look at the inside diameter:

1⁄4" hose is not the same as 1⁄4" tubing. Hose is specified by its inside

diameter. Hydraulic tubing is usually specified by the outside diameter.

As example, 1⁄4" O.D., .035" wall tubing has an inside diameter of

.180", a flow carrying capacity of only 50% of that of the hose.

Single-acting clamps can develop only a limited amount of pressure to

force hydraulic fluid out of the clamp and allow it to retract. When the

return fluid from multiple clamps must share the same hydraulic line,

back pressure can easily become excessive and slow the

clamp’s retraction.

When connecting multiple clamps, you can use either a “daisy chain”

or “home run” configuration. In a daisy chain, you use a tee at each

clamp and run tubing from the first clamp to the second and then to the

third and then the fourth, etc. When using a home run configuration,

you begin at a manifold and run hydraulic lines all the way from the

manifold to each clamp.

The daisy chain method uses less tubing so it might appear that this

would minimize back pressure. However, in the daisy chain the fluid

from all of the clamps must pass through a single hydraulic line. In the

home run, while there may be longer runs, each line only has to

accommodate flow from one clamp.

The viscosity of the hydraulic fluid used will also affect back pressure.

Viscosity is affected by temperature. Contact the factory to discuss

applications running below room temperature. We recommend using

only DE-STA-CO fluids. Other fluids may have different viscosities or

other characteristics that can adversely affect system operation.

Single-acting vs. Double-acting

Another decision to be made early in the planning stage is whether to

use single-acting or double-acting components.

Single-acting components are typically actuated using hydraulic

pressure. When released, the pressure is removed and the actuator is

returned by a spring which forces the hydraulic fluid back into the

pump reservoir. This type of system is usually the most cost effective

because each actuator needs only one pressure source connection for

operation. Single-acting actuators should be vented to clean

atmosphere whenever appropriate. Remember to double the plumbing

for double-acting systems. This does, however, use more valuable

fixture space and adds to the cost.

Nevertheless, there are good reasons to use double-acting systems.

The larger and/or more complex the circuit design, the greater the

potential for return restrictions which will slow the return of the

single-acting actuators. Double-acting actuators are ideal for

applications which require both pushing and pulling or returning

clamps with heavy, custom designed attachments. They work well for

powering linkages which require fast actuation in both directions.

Double-acting clamps are often used in automated systems where

coordinating the action of the clamp with that of the rest of the system

requires fast, positive, predictable cycle times. y installing pressure

switches in both the pressure and return lines, the status of the clamp

can constantly be monitored.

DE-STA-CO Subject to technical modifications without notice 15.9

StrongHold Clamping SystemTM

System design information

Single-acting Double-acting

15_StrongHold. xp:15_DES_StrongHold-1-14.indd 1/2/08 9:03 AM Page 15.9

15.10 Subject to technical modifications without notice DE-STA-CO

StrongHold Clamping SystemTM

Automation

Hydraulic power clamping provides varying degrees of automation.

During the planning stage, the method of actuating the fixture must be

considered. The simplest systems use manually operated valves where

the operator turns a handle to clamp and unclamp the fixture. In totally

automated systems, the machine tool itself can be programmed to

control the clamping and unclamping functions through the use of

electric solenoid valves.

Positioning vs. Clamping

Hydraulic actuators are typically used on a fixture to perform one of two

functions: positioning or clamping. The primary purpose of a positioning

actuator is to push the workpiece against the solid positioning stops

built into the fixture. Clamping actuators hold the workpiece in position

during machining.

With a properly designed fixture, all the operator needs to do is to place

the workpiece into the fixture. The positioning actuators (typically

cylinders) will move and correctly orient the workpiece against the

stops, and hold it there while the clamps are sequenced, thus securing

the part to resist machining forces. While clamps are always needed

to hold the part, positioning actuators are sometimes optional

depending on the workpiece, fixture design, and the level of

operator involvement.

3-2-1 Locating Principle

One of the most basic concepts of workholding is referred to as the

3-2-1 Locating Principle. To repeatedly locate (or reference) a workpiece,

it must be oriented and positioned in three planes: X, Y and Z.

Thinking of a typical fixture where the workpiece is loaded and gravity

holds it in place during clamping, start with the Z axis. Knowing that

three points define a plane, it follows that any rigid object in the fixture

is technically being supported at only three points regardless of shape.

With the part supported in this manner, the workpiece is prevented from

moving in the Z direction, but is still free to rotate or slide in the X and

Y directions. To prevent rotation and position the workpiece in the Y

direction, two stops are used. With the part contacting three stops in the

Z axis, and two stops in the Y axis, the only direction the part can move

is in the X direction. A single stop is all that is needed to prevent this

motion. Always use three locators as the primary Z locators, two

secondary Y locators and one tertiary X locator; thus, the name 3-2-1

principle. In rigid parts, these are the only solid stops required to locate

the part. Any more are a duplication and can affect repeatability from

one part to the next.

Resisting Forces – Stops vs. Clamps

When designing the solid stops for a fixture, it is usually best to locate

them so that they directly resist the machining forces.

If the cutting tool forces are resisted by solid stops, the workholding

clamps need only hold the part in position and can typically be much

smaller, saving money and valuable fixture space.

System design information

15_StrongHold. xp:15_DES_StrongHold-1-14.indd 1/2/08 9:03 AM Page 15.10

DE-STA-CO Subject to technical modifications without notice 15.11

StrongHold Clamping SystemTM

Torque vs. Tension

A user’s first introduction to hydraulic power workholding is often

the replacement of the nut on a typical strap clamp with a center

hole cylinder.

If the torque of the nut is known, the resulting tension on the bolt or

stud can be easily approximated.

For example, a 1⁄2-13 UNC nut is torqued to 300-in. lbs. The resulting

approximate tension would be:

The most accurate way to determine that the hydraulic power clamping

system is exactly duplicating the mechanical system is to place the

center hole cylinder over the stud or bolt and replace the nut loosely

over the cylinder. Use the hydraulic system to partially extend the

cylinder until it contacts the nut. Use a torque wrench to torque the nut

to its original value while monitoring the system pressure gauge. When

the nut is properly torqued, the gauge will indicate the exact system

pressure setting for this application.

Operating Pressures

Most DE-STA-CO workholding components are rated at 5,000 PSI.

When designing, it is a good rule of thumb to choose components for

your fixture that will give you the forces you need at a pressure of about

3,000 PSI. This gives you plenty of latitude to adjust the system

pressure both up and down when fine tuning the fixture on the machine

tool. Operating at lower pressures, while sometimes necessary, does

not make the most efficient use of these components. Higher pressures

allow the use of smaller components, saving cost and fixture space.

Design Stroke Length

Clamps and cylinders should never be designed into a fixture at their

rated full stroke. Always use something less than full stroke to make

sure that all tolerances and variations in the workpiece, workholding

device and fixture can be accepted, insuring that the workpiece is

properly clamped.

Volume Calculations

The total volume required to actuate a circuit should be checked to

make sure that the power source chosen has enough usable fluid

capacity. The fluid volume required to fully actuate each clamp and

cylinder is listed in the charts on each product page throughout the

catalog. y totaling this value for each component, you know the

maximum fluid volume that could possibly be used in this fixture. Even

the smallest DE-STA-CO pumps have enough fluid volume for most

applications.

Since the fixture is designed to use less than the full stroke of the

actuators, the actual fluid volume will be less. If it becomes necessary

to get an exact figure, it can be easily calculated using the

following formula:

Effective Area (sq. in.) X Stroke (in.)

= Fluid Capacity (cu. in.)

The effective area of the actuators (from product chart) multiplied by

the stroke used (not total stroke) will result in the fluid volume.

For example, if a cylinder has an effective area of 2 square inches, and

an actual stroke of 3 inches, its fluid volume will be 2 x 3 or 6 cubic

inches. (For easy reference, 231 cubic inches = 1 gallon.)

System Care and Maintenance

The single most important factor in determining the life of a properly

designed system is the effort taken to keep the fluid clean.

System Flushing

During assembly, make sure all fluid-carrying components are flushed

with clean solvent and blown dry. Hydraulic tubing is particularly

notorious for the amount of contaminants found inside. If not removed,

this debris will quickly damage seals and score precision-fit metal

parts. The contamination will also clog passages in pumps and

control valves.

After fixture assembly, the entire system should be flushed to remove

any contamination created during assembly. Use only hydraulic fluid for

this procedure. Solvents may become trapped in the system,

contaminating the fluid.

Once the fluid in the system is clean, be sure to keep it that way by

changing the fluid on a regular basis and making sure that extreme

care is taken whenever the system is disconnected or disassembled so

that new contaminants are not introduced.

Torque (In. Lbs.)

Nominal thd. size (In.) X .12 = Tension (Lbs.)

From this:

To this:

= 5,000 lbs. Tension

300

.5 x .12

System design information

15_StrongHold. xp:15_DES_StrongHold-1-14.indd 1/2/08 9:03 AM Page 15.11

15.12 Subject to technical modifications without notice DE-STA-CO

StrongHold Clamping SystemTM

System Bleeding

Air trapped in the hydraulic system is the most common cause of erratic

operation and slow return times. The most common way to bleed a

system is to pressurize the circuit and carefully loosen a fitting just

enough to let fluid escape. The trapped air will usually be flushed out

with the fluid. With conventionally mounted components, the fittings

required for connection provide ideal bleeding locations. Since manifold

mounting eliminates external fittings and lines, the fixture

designer/builder no longer gets bleeding points by default and must

now consciously plan for system bleeding.

As workholding hydraulic systems become more sophisticated, compact

and automated, proper bleeding becomes increasingly important. Air

trapped in the system is most often revealed by the slow retraction of

single-acting (spring return) components. To understand why, picture

the following example:

Single-acting actuators – return springs develop 15 PSI

Flow required to clamp – 1 cu. in.

System pressure – 3,000 PSI

Return time for this application is dictated by the time it takes to force

1 cu. in. of fluid through all of the return line restrictions at 15 PSI.

Take the same example with 1 cu. in. of air (at atmospheric pressure)

trapped anywhere in the system:

When pressurized, this “bubble” compresses and becomes

200 times smaller or .005 cu. in. This means that .995 cuin,

of oil must be pumped into the system just to compress the

bubble. Now when the clamps are released, 1.995 cu. in. of

fluid must leave the system – nearly double that of the same

system without air.

Calculating Machining Forces

To help you choose the right cylinders, clamps, and work supports, it is

important to know how much clamping or supporting force

is necessary.

There are numerous ways to calculate the approximate forces that the

cutting tool places on the workpiece. Please note that the results of

these calculations are estimates and must never replace experience,

common sense, and caution. In addition, these results indicate only the

magnitude of the force, not the direction. Depending on the specific

application, the direction of the force may vary significantly from the

beginning to the end of the cut.

Milling, Turning and Boring

A rough estimate of cutting tool force – if the horsepower required to

make the cut is known – is the result of the following equation:

For example, an operation is expected to take 5 horsepower with a cutting

speed of 150 surface feet per minute.

Where horsepower is not yet known, a value called unit power comes

into play. Unit power is the horsepower required to remove one cubic

inch of material in one minute. (Refer to Table A on Page 10.)

Milling

Example: a 4-flute end mill is used to machine aluminum. The cut is

1⁄2" deep and the feed per tooth is .002". From the table the unit power

value is 0.4. So the cutting force transferred to the workpiece is:

.5 x .002 x 4 x .4 x 125,950 = 202 lbs.

Cutting Force

Note that this calculation assumes a full width cut. Applications using

less than the full cut may reduce the calculated force by the percentage

of the full cut being taken.

Turning and Boring

A similar calculation applies to turning and boring. Note that the cutting

force is usually perpendicular to the cutting tool but since the tool or

workpiece is rotating, the direction of the force relative to the work

piece is constantly changing.

HP x 24,750

Cutting Speed (SFPM)

Cutting Force (lbs.) =

5 x 24,750

150 = 825 lbs. Cutting Force

Depth of Cut (in.)

Feed per Tooth (in.)

Number of Teeth

Unit Power

___X___X___X___ X 125,950 = _____ lbs.

Cutting Force

System design information

15_StrongHold. xp:15_DES_StrongHold-1-14.indd 1/2/08 9:03 AM Page 15.12

DE-STA-CO Subject to technical modifications without notice 15.13

StrongHold Clamping SystemTM

Example: oring a hole in alloy steel heat treated to 37 Rc (unit power

1.7), with a depth of cut of .060", a feed rate of .003" inches per

revolution gives a result of:

.060 x .003 X 1.7 x 396,000 = 121 lbs. Cutting Force

Drilling

The forces involved in drilling can be separated into two distinctly

different categories: thrust and torque. With the number of drill styles

available, the thrust varies tremendously. Torque is somewhat less

variable and can be estimated as shown:

Feed (IPR) x (Drill Dia.)2x Unit Power x 49,500 =

Drilling Torque (In. Lbs.)

For example, drilling a 3⁄4” diameter hole in magnesium (unit power .2)

with a feed rate of .010” per revolution gives a result of:

.010 x .752x .2 x 49,500 = 56 in. lbs.

Friction Coefficient

Now that an estimate of the amount of cutter force being transferred to

the workpiece is available, we must determine how much clamping

force is necessary to resist the cutter force. This depends on the

amount of friction between the workpiece and the fixture, commonly

referred to as the friction coefficient.

Typically, if an object is lying on a surface, the amount of force required

to slide it sideways will be considerably less than the weight of the

object. It follows then that when clamping a workpiece to resist

machining forces, the clamping force will need to be much higher than

the machining force. The following chart shows approximate

friction coefficients:

The estimated clamping force is divided by the appropriate friction

coefficient and then multiplied by a suitable safety factor to get an

estimated total clamping force required.

Example: A steel workpiece on steel rest buttons is being machined

using coolant. The estimated machining force is 300 lbs. From the table

the friction coefficient for steel on steel (lubricated) is .16. After

choosing an appropriate safety factor (usually about 2), the estimated

total clamping force would be:

This total clamping

force may now be

divided by the

number of clamps

holding the

workpiece, which

equals the clamping

force needed for

each clamp.

Depth of Cut (in.)

Feed per Revolution (in.)

Unit Power

____X____X____X 396,000 = _____ lbs.

Cutting Force

Force

Cutting

Tool

Static Friction Coefficients

for Steel on Various Materials

Machining Force (lbs.)

Friction Coefficient x Safety Factor = Total

Clamping

Force (Lbs.)

300

.16 x 2 = 3750 lbs. Total Clamping Forces

System design information

TABLE A Unit Power hp/in3/min

Turning Drilling Milling

Material

Hardness

Bhn

HSS &

Carbide

Tools

HSS

Drills

HSS &

Carbide

Tools

STEELS

Plain

Carbon

Alloy Steels

85-200

35-40Rc

40-50Rc

50-55Rc

55-58Rc

1.4

1.7

1.9

2.5

4.2

1.3

1.7

2.1

2.6

3.2

1.4

1.9

2.2

2.6

3.2

CAST IRONS

ray, Ductile

& Malleable

110-190

190-320

0.9

1.7

1.2

2.0

0.8

1.4

STAINLESS

STEELS

135-275

30-45Rc

1.6

1.7

1.4

1.5

1.7

1.9

TITANIUM 250-375 1.5 1.4 1.4

NICKEL

ALLOYS

80-360 2.5 2.2 2.4

ALUMINUM

ALLOYS

30-150

500 kg

0.3 0.2 0.4

MA NESIUM

ALLOYS

40-90

500 kg

0.2 0.2 0.2

COPPER

ALLOYS

10-80Rb

80-100Rb

0.8

1.2

0.6

1.0

0.8

1.2

Material

Friction Coefficient

Clean Lubricated

Brass 0.35 0.19

Bronze – 0.16

Bronze, Aluminum 0.45 –

Bronze, Phosphor 0.35 –

Bronze, Sintered – 0.13

Carbon, Hard 0.14 0.11-0.14

Copper-Lead Alloy 0.22 –

raphite 0.10 0.10

Iron, Cast 0.40 0.21

Steel 0.80 0.16

Tungsten Carbide 0.4-0.6 0.1-0.2

15_StrongHold. xp:15_DES_StrongHold-1-14.indd 1/2/08 9:03 AM Page 15.13

15.14 Subject to technical modifications without notice DE-STA-CO

StrongHold Clamping SystemTM

Design symbols

M

AB

PT

Cylinder Symbols

Power Source Symbols

Work Support Symbols

Clamp Symbols

Control Valve Symbols

Work Support Symbols

Cylinder, Single-acting

Cylinder, Double-acting

Cylinder, Single-acting or Swing/Pull

Clamp,Double-acting

Pull Cylinder, Single-acting, Spring Return

Pull Cylinder, Single-acting

Swing/Pull Clamp, Single-acting

with Flow Restrictor Valve

Swing/Pull Clamp, Double-acting

Swing/Pull Clamp, Single-acting

Work Support, Fluid Advance

Work Support, Spring Advance

Work Support, Air Advance

Electric/Hydraulic Pump

Air/Hydraulic Pump, Reciprocating

Air/Hydraulic Pump,

Reciprocating 2-stage

Screw Pump

Intensifier

Directional Control Valve, Manual 4-Way,

2-Position with Inlet Check Valve

Directional Control Valve, Manual 4-Way,

2-Position with Inlet and Outlet Check Valves

Directional Control Valve, Manual 4-Way,

3-Position Detented

Directional Control Valve, Electric 4-Way,

2-Position with Inlet and Outlet Check Valves

with Manual Override

Directional Control Valve, Manual 4-Way,

2-Position

15_StrongHold. xp:15_DES_StrongHold-1-14.indd 1/2/08 9:03 AM Page 15.14

DE-STA-CO Subject to technical modifications without notice 15.15

StrongHold Clamping SystemTM

Design symbols

Control Valve Symbols Accessory Symbols

Pallet Coupling Symbols

Accessory Symbols

T

P

B

A

Pressure Sequence Valve, Adjustable with

Reverse Free-Flow Check Valve

Pressure Reducing Valve, Adjustable with Reverse

Free-Flow Check Valve w/Over-Pressure Relief Valve

Check Valve, Pilot Operated with Filters

Flow Restrictor, Adjustable with Reverse

Free-Flow Check Valve

Flow Restrictor, Adjustable

Manual Pallet Valve with auge

and Male Coupler

Manual Pallet Valve with Filters,

auge and Coupler

Hydraulic Coupler, Half-Male or Female

Hydraulic Coupler Set, Coupled

Check Valve

Flow Restrictor, Fitted with Reverse

Free-Flow Check Valve with

Filtered Orifice

Hydraulic Coupler Set, Uncoupled

Accumulator, as Charged

Filter

Pressure auge

Rotating Union, Dual Circuit

Rotating Union, Single Circuit

Pressure Switch, Adjustable

Check Valve Sub-Plate

Air Bleed Valve

Ball Valve

15_StrongHold. xp:15_DES_StrongHold-1-14.indd 1/2/08 9:03 AM Page 15.15

15.16 Subject to technical modifications without notice DE-STA-CO

StrongHold Clamping SystemTM

StrongHold

SELECT

15_StrongHold. xp:15_DES_StrongHold-1-14.indd 1/2/08 9:03 AM Page 15.16

DE-STA-CO Subject to technical modifications without notice 15.17

StrongHold Clamping SystemTM

Introducing

Workholding Products from

DE-STA-CO.

The new StrongHold SELECT series brings you hydraulic swing clamps, threaded body cylinders,

block cylinders and accessories.

Immediate advantages include:

MRO Interchange: Flexibility to upgrade and interchange

with other brands, or use in new/duplicate fixture designs

Long-life, decreased maintenance: Advanced seal and

wiper technology that resist contamination and leaks

Corrosion resistance: Treated metal surfaces for better wear

Reduced maintenance costs: High cycle life with less

down time, lower replacement costs

Productivity improvement: Significant set-up time reduction

as operators can clamp entire fixture from one location

Competitive pricing: etter quality components with higher ROI

Our new StrongHold SELECT series is yet another example by DE-STA-CO making the best even

better. Improving upon our existing StrongHold brand, we continue to design products and

expand our product selection that help you, our customers, achieve tangible cost reduction in

your manufacturing process.

We look forward to working with you!

DE-STA-CO is a global leader in the innovation, manufacture, and support of clamping, gripping, transfer and robotic tooling

solutions for orkplace automation needs. The DE-STA-CO family of companies is committed to being a lean resource for its

customers. Our ide range of products and value-added services allo s us to offer you solutions that increase profitability and

efficiency through the use of optimal clamping and automation solutions.

StrongHold SELECT

15_StrongHold. xp:15_DES_StrongHold-1-14.indd 1/2/08 9:03 AM Page 15.17

15.18 Subject to technical modifications without notice DE-STA-CO

StrongHold Clamping SystemTM

Hydraulic Cylinder

H

GD

J

K

M

N

L

B

E

C

F

A

lock Style

Hydraulic

Cylinder

Model no.

Dimensions (In Inches)

A B C D E F H J K L M N

70250

(Single-acting) 2.81 2.50 0.31 1.63 0.56 0.75 1.16 1.00 0.50 1/8 NPT 1/8 NPT 0.25 –

70260

(Double-acting) 3.13 2.88 0.50 2.00 0.25 1.25 1.50 1.25 0.63 1/8 NPT (2) 1/8 NPT (2) 0.25 5/16-18

Model no. Stroke

Force at

3,000 PSI

Extend

Force at

3,000 PSI

Retract

Effective

Area

Clamping

Effective

Area

Unclamping

Oil

Displacement

70250 0.50 1,325 lbs. – 0.44 – 0.221 cu. in.

70260 1.00 1,325 lbs. 763 lbs. 0.44 0.24

Retract 0.25 cu. in. Extend 0.45 cu. in.

15_StrongHold. xp:15_DES_StrongHold-1-14.indd 1/2/08 9:03 AM Page 15.18

DE-STA-CO Subject to technical modifications without notice 15.19

StrongHold Clamping SystemTM

StrongHold

SELECT

Block Cylinders

DE-STA-CO’s Single-acting (spring return) and Double-acting lock Cylinders are designed for punching,

pressing, riveting and bending applications. These block cylinders require no special mounting hardware

and can be dual-position mounted (parallel or perpendicular) to piston travel on every model.

Tapped piston-ends allow the use of custom end attachments (double-acting recommended for

attachments or mechanisms), while a vent port featuring a single-acting filter gives the cylinder a

place to “breathe” and helps keep chips and other contaminants from sucking past the wipers

(double-acting unclamp port).

Adjustable force ranging from “negligible” to maximum cylinder capacity is achieved by adjusting the

input pressure. Advanced side-porting is provided for easy plumbing access.

Features:

Variety of strokes to meet specific

design needs

SAE oil ports

No special mounting

hardware required

Operating Pressure –

150 to 5,000 PSI

Single-acting Block Cylinders

Cat no.

Force at

5,000

PSI (lbs.) Bore

ø

(in.)

Rod

ø

(in.)

Stroke

(in.)

Effective

Area

(sq. in.)

Oil

Capacity

(cu. in.)

Push Push Push

090-011-113

090-012-221

090-012-224

090-013-332

090-013-334

2,220

3,900

3,900

8,800

8,800

0.750

1.000

1.000

1.500

1.500

0.437

0.625

0.625

1.000

1.000

0.380

0.270

0.600

0.297

0.447

0.442

0.785

0.785

1.767

1.767

0.168

0.212

0.471

0.525

0.789

Double-acting Block Cylinders

Cat no.

Force at

5,000

PSI (lbs.) Bore

ø

(in.)

Rod

ø

(in.)

Stroke

(in.)

Effective

Area

(sq. in.)

Oil

Capacity

(cu. in.)

Push Pull Push Pull Push Pull

090-021-111

090-021-114

090-022-222

090-022-225

090-023-333

090-023-335

2,220

2,220

3,900

3,900

8,800

8,800

1,400

1,400

2,390

2,390

4,900

4,900

0.750

0.750

1.000

1.000

1.500

1.500

0.437

0.437

0.625

0.625

1.000

1.000

0.630

1.500

0.790

2.000

1.000

2.000

0.442

0.442

0.785

0.785

1.767

1.767

0.292

0.292

0.478

0.478

0.982

0.982

0.279

0.663

0.620

1.570

1.767

3.534

0.184

0.438

0.378

0.956

0.982

1.964

Dimension Chart – Single & Double-acting Block Cylinders

Cat. no.

Single Acting

Cat. no. Double

Acting A (S.ACT.) A (D.ACT.)

Dimensions (In Inches)

B C D E F H I J K L M O P R S T V

–

090-011-113

090-012-221

090-012-224

090-013-332

090-013-334

090-021-111

090-021-114

090-022-222

090-022-225

090-023-333

090-023-335

–

3.698

30031

4.571

3.472

4.622

3.078

4.818

3.551

5.971

4.175

6.175

2.448

3.318

2.761

3.971

3.175

4.175

2.128

2.998

2.441

3.651

2.680

3.680

2.360

2.360

2.559

2.559

3.150

3.150

0.375

0.375

0.500

0.500

0.835

0.835

0.437

0.437

0.625

0.625

1.000

1.000

SAE#4

SAE#4

SAE#4

SAE#4

SAE#4

SAE#4

0

2.058

0

2.558

0

2.620

0.756

0.756

0.788

0.788

0.708

0.708

1.206

1.248

1.378

1.378

1.420

1.440

0.295

0.295

0.295

0.295

0.374

0.374

1.770

1.770

1.969

1.969

2.403

2.403

0.980

0.980

1.181

1.181

1.548

1.548

1/4-20UNC

1/4-20UNC

5/16-24UNF

5/16-24UNF

1/2-13UNC

1/2-13UNC

1.570

1.570

1.772

1.772

2.295

2.295

0.785

0.785

0.886

0.886

1.148

1.148

0.900

1.770

1.181

2.391

1.500

2.500

1.180

1.180

1.280

1.280

1.575

1.575

0.280

0.280

0.350

0.350

0.391

0.391

15_StrongHold. xp:15_DES_StrongHold-1-14.indd 1/2/08 9:03 AM Page 15.19

15.20 Subject to technical modifications without notice DE-STA-CO

StrongHold Clamping SystemTM

StrongHold

SELECT

Threaded Body Cylinders

K

S

T

A

B

D

G

ML

G (S/A Vent Plug)

C

C1

P

DE-STA-CO’s Single-acting (spring return) and Double-acting Threaded Cylinders are extremely

versatile and durable. They can be designed into a variety of high production applications including

workpiece positioning, holding and ejecting applications where space is at a premium.

Double-acting cylinders assure complete powered retraction for CNC controlled operations (where time

is critical) or when using heavy end effectors. Double-acting models are also suited to manufacturing

applications, such as production punching.

Single-acting cylinders should be used with small end effectors

only and where retraction speed is not critical.

Features:

Variety of sizes that support precise

fixture designs

Springs are designed to return the

cylinder and contact points, not

intended to pull mechanisms.

SAE fluid ports are common to all models

Operating Pressure – 150 to 5,000 PSI

Dimension Chart – Single & Double-acting Threaded Cylinders

Cat. no.

Single Acting

Cat. no.

Double Acting A (S.ACT.) A (D.ACT.)

Dimensions (In Inches)

B C C1 D D1 E F K L M P S T

–

010-011-113

010-012-221

010-012-224

010-013-332

010-013-334

010-021-111

010-021-114

010-022-222

010-022-225

010-023-333

010-023-335

–

4.064

3.465

5.005

3.917

5.067

3.444

5.184

3.985

6.405

4.620

6.620

2.814

3.684

3.195

4.405

3.620

4.620

2.494

3.364

2.875

4.085

3.125

4.125

0.625

0.625

0.625

0.625

0.690

0.690

1.750-16UN

1.750-16-UN

1.875-16UN

1.875-16UN

2.500-16UN

2.500-16UN

1.564

1.564

1.730

1.730

2.375

2.350

0.437

0.437

0.625

0.625

1.000

1.000

1.375

1.375

1.610

1.610

2.250

2.250

SAE#4

SAE#4

SAE#4

SAE#4

SAE#4

SAE#4

1/4-20UNC

1/4-20UNC

5/16-24UNC

5/16-24UNC

1/2-13UNC

1/2-13UNC

0.422

0.422

0.530

0.530

0.800

0.800

0.390

0.390

0.390

0.390

0.550

0.550

0.200

0.200

0.200

0.200

0.375

0.375

0.375

0.375

0.500

0.500

0.835

0.835

0.500

0.500

0.625

0.625

0.625

0.625

Single-acting Threaded Cylinders

Cat no.

Force at

5,000

PSI (lbs.) Bore

ø

(in.)

Rod

ø

(in.)

Stroke

(in.)

Effective

Area

(sq. in.)

Oil

Capacity

(cu. in.)

Push Push Push

010-011-113

010-012-221

010-012-224

010-013-332

010-013-334

2,220

3,900

3,900

8,800

8,800

0.750

1.000

1.000

1.500

1.500

0.437

0.625

0.625

1.000

1.000

0.380

0.270

0.600

0.297

0.447

0.442

0.785

0.785

1.767

1.767

0.168

0.212

0.471

0.525

0.789

Double-acting Threaded Cylinders

Cat no.

Force at

5,000

PSI (lbs.) Bore

ø

(in.)

Rod

ø

(in.)

Stroke

(in.)

Effective

Area

(sq. in.)

Oil

Capacity

(cu. in.)

Push Pull Push Pull Push Pull

010-021-111

010-021-114

010-022-222

010-022-225

010-023-333

010-023-335

2,220

2,220

3,900

3,900

8,800

8,800

1,400

1,400

2,390

2,390

4,900

4,900

0.750

0.750

1.000

1.000

1.500

1.500

0.437

0.437

0.625

0.625

1.000

1.000

0.630

1.500

0.790

2.000

1.000

2.000

0.442

0.442

0.785

0.785

1.767

1.767

0.292

0.292

0.478

0.478

0.982

0.982

0.279

0.663

0.620

1.570

1.767

3.534

0.184

0.438

0.378

0.956

0.982

1.964

15_StrongHold. xp:15_DES_StrongHold-1-14.indd 1/2/08 9:03 AM Page 15.20

This manual suits for next models

1

Table of contents

Popular Power Tools manuals by other brands

ZURN

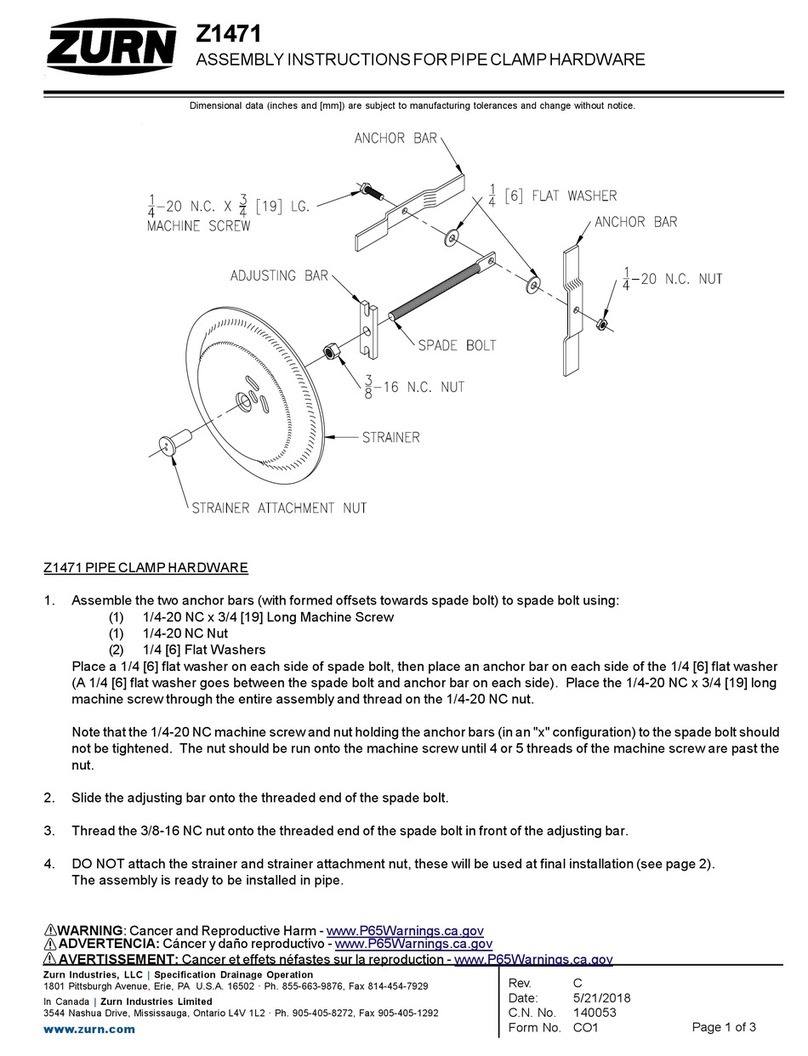

ZURN Z1471 Assembly instructions

BAK Thermoplastic Welding Technology

BAK Thermoplastic Welding Technology RION operating manual

Sealey

Sealey RE97XCKIT instructions

Clarke

Clarke CAT141 Operating & maintenance instructions

Bosch

Bosch Professional GSR 1080-LI Original instructions

Greenlee

Greenlee GATOR EK410L Operation manual