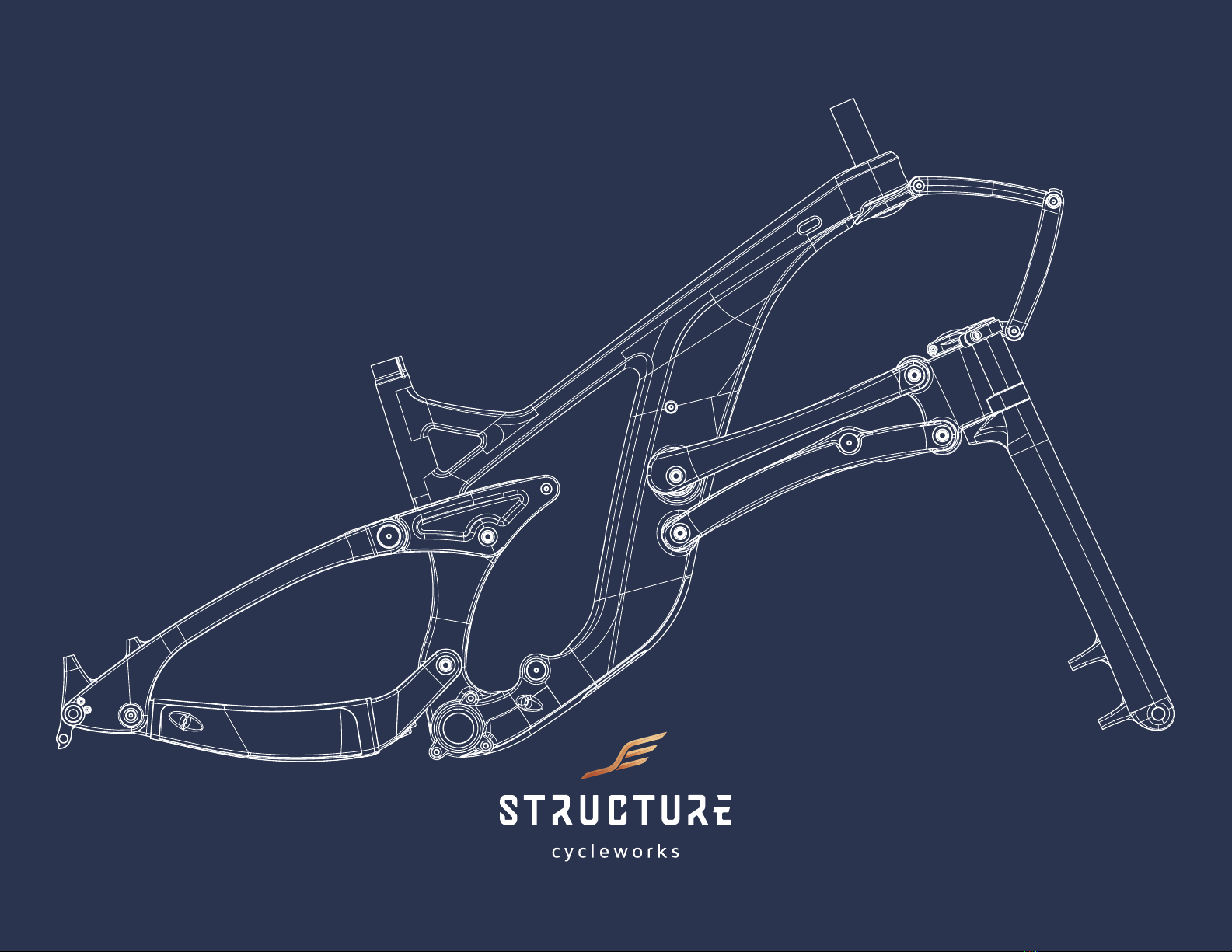

Structure Cycleworks SCW1 User manual

OWNERS MANUAL

Welcome

Congratulations on your purchase of a new Structure Cycleworks

SCW1, welcome to our family. Undoubtedly you are eager to throw

a leg over and blast down your favorite trails, but before you do so

take the time necessary to properly build and test your bike before

aiming it down those paths.

Here we have a walk-through of how to unpack and assemble the

full linkage chassis to ride ready condition. If you feel that you are

not up to the task or are missing important tools (torque wrenches,

hose cutters, etc.) be sure to bring it to your favorite local bicycle

shop to have one of their professionals do it for you. No judgment –

pro riders rarely wrench on their own rigs.

WITHOUT TELESCOPING FORK (WTF) LINKAGE SUSPENSION

Structure’s linkage front suspension is designed to be similar to

rear linkage suspension. It uses the same 17mm colleted axles as the

rear suspension at all main pivots and the same 6903 30mm sealed

cartridge bearings, which can be found at most bicycle shops.

The front and rear shock absorbers are identical in design. However,

the front shock includes three volume spacers in the positive

air chamber and requires approximately 65% of the air pressure

required for the rear shock (due to the greater load placed on rear

suspension). Follow the shock absorber manufacturer’s instructions

for shock service intervals, service instructions, and setup.

2

Table of Contents

Safety.................................................................................................. 4

-Components....................................................................................... 5

Overview

-Torque Specications ......................................................................... 6

-Spare Parts ........................................................................................ 8

-Specications ................................................................................... 10

-General Service and Care................................................................ 11

Assembly

-Unboxing and Basic Assembly......................................................... 12

-Suspension Shock Set-up Chart ...................................................... 13

-Internal Cable/Hose Routing .......................................................14-16

Maintenance

-Colleted Axles Removal And Installation.......................................... 19

-Bearing Replacement....................................................................... 19

-Brake Dive Reduction Eccentric Position......................................... 20

-Spherical Bearing Replacement....................................................... 21

Maintenance

-Schedule .......................................................................................... 22

-Warranty........................................................................................... 23

3

Safety

• WARNING

Keep this manual handy for reference.

It is strongly recommended that you follow Structure Cycleworks’ and

component manufacturers’ instructions where indicated in this manual,

as many tasks should only be performed by a bicycle repair technician.

Adhere to all torque and sizing specications. Over-tightening can

damage threads or cause parts to fail. Using the wrong size part can

cause part failure and may cause a crash, which can result in serious

injury or death.

More than most machines, a mountain bike is subject to wear and

high stresses. Various materials and components react to wear and

stress in different ways and may suddenly fail and cause a crash,

which can result in serious injury or death. Any form of scratch, crack,

unusual noise, dent, ber delamination, or change in colouring can

indicate that a component should be inspected by dealer service

personnel and/or replaced before riding.

In the event of an impact or crash, damage to carbon ber

components or frame may be invisible. Consult your dealer service

department immediately for inspection.

Your bicycle requires regular maintenance, frequent inspection, and

timely replacement of parts to address any issues.

Excessive vibration or noise from the wheels, pivots, or frame

indicates a serious problem. Stop riding immediately and consult

your dealer.

Do not expose your bicycle to temperatures of 65°C (150°F)

or higher. High temperatures can damage carbon ber resin or

frame joints.

Do not attempt to repair damaged carbon ber components. Contact

Structure Cycleworks customer service for crash replacement if

necessary. Repairing a carbon ber frame component can compromise

safety and will void the warranty.

Do not place your hands near a moving wheel or drive train

components. A spinning wheel can catch your hand between the

spokes and frame and crush, pinch, or lacerate your hand. Areas

where the chain contacts sprockets can pinch and cause injury, and

sprocket teeth and brake rotors have sharp edges that can cut.

Wear appropriate PPE (personal protective equipment) when cutting,

drilling, using chemicals, or performing other tasks than may expose

you to harm while working on a bicycle.

4

Components

We outline the basics of installation for each the components

included on a complete bike purchase. If you nd these

instructions hard to follow or need a more step-by-step guide go

to the manufacturers website and download the PDF or follow

the online instructions or video.

Full instructions on all components available on the following

websites:

dvosuspension.com

oneupcomponents.com

magura.com

sram.com

• WARNING

Please follow component manufacturer’s installation, torque, and

adjustment instructions for each component. Failure to do so

may result in component malfunction, injury, or death.

5

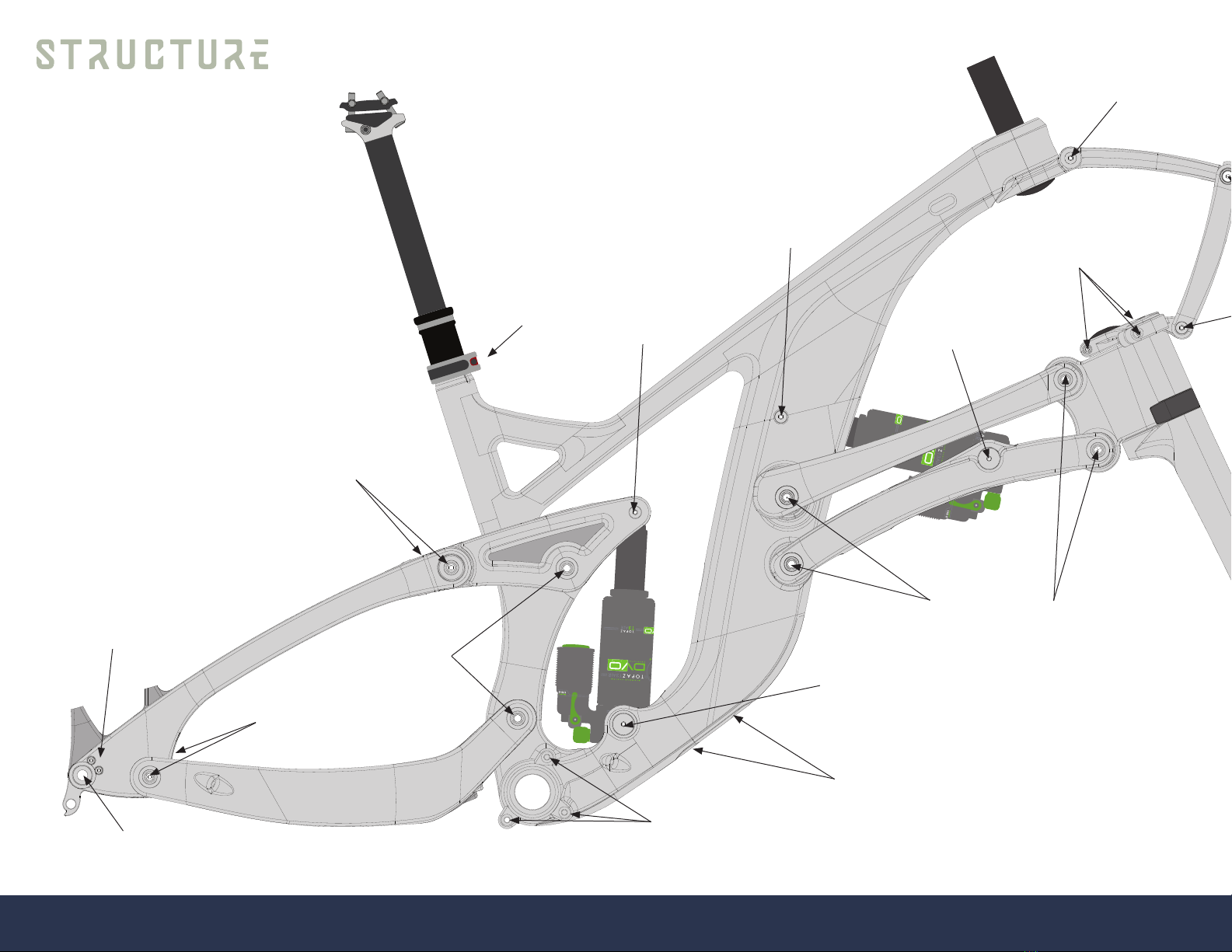

Seat Clamp Bolt

4 Nm Shock Bolt

6 Nm

Shock Bolt

6 Nm

Derailleur Hanger Bolts

3 Nm

Through Axle Bolt

10 Nm

Horst Link Bolts

4 Nm

Collet Retention

8mm Bolts

7 Nm

Seatstay to Rocker Bolts

10 Nm

ISCG Bolts

5 Nm

Battery Cover Bolts

1 Nm

Trunnion Bolts

10-11 Nm

Upper Steering Plate Bolt

6 Nm

Triple Clamp Bolts

5 Nm

Trunnion Bolts

10-11 Nm

Colleted Axle Bolts

Hand tight then 3 Nm

Torque Spec.

6

Through Axle Bolt

10 Nm

Spherical Bearing Bolt

12 Nm

Lower Steering Plate Bolt

6 Nm

Steering Linkage to Side

Bearings Bolts

6 Nm

Other Torque Spec.

Headset preload 5mm Hex 3 Nm

Seat rail clamp bolts 5mm Hex 8 Nm

Remote bar clamp 3mm Hex 1 Nm

Remote cable clamp 3mm Hex 3 Nm

Remote body to clamp 4mm Hex 3 Nm

Stem top bar bolts 4mm Hex Until no gap

Stem bottom bar bolts 4mm Hex 6 Nm

Stem steerer bolts 5mm Hex 9 Nm

Grips 3mm Hex 2 Nm

Brakes:

Bar clamp top bolt T25 Until no gap

Bar clamp bottom bolt T25 4 Nm

Calipers T25 6 Nm

Rotor bolts T25 4 Nm

Banjo bolt loosen 30˚ max T25 30˚

Banjo bolt tighten T25 3 Nm

Sleeve nut 8mm wrench 4 Nm

Drive train:

Cassette Lock ring tool Hand thread then 40 Nm

Shifter mount T25 or 4mm Hex 2 Nm

Rear derailleur 5mm Hex 11 Nm

Derailleur cable T25 or 4mm Hex 4.5 Nm

Bottom bracket Cups 12 notch tool 50 Nm

Crank set 8mm Hex 54 Nm

BB preload on crank 2mm Hex Until ends touch

Pedals Pedal specic tool 54 Nm or mfg. spec.

7

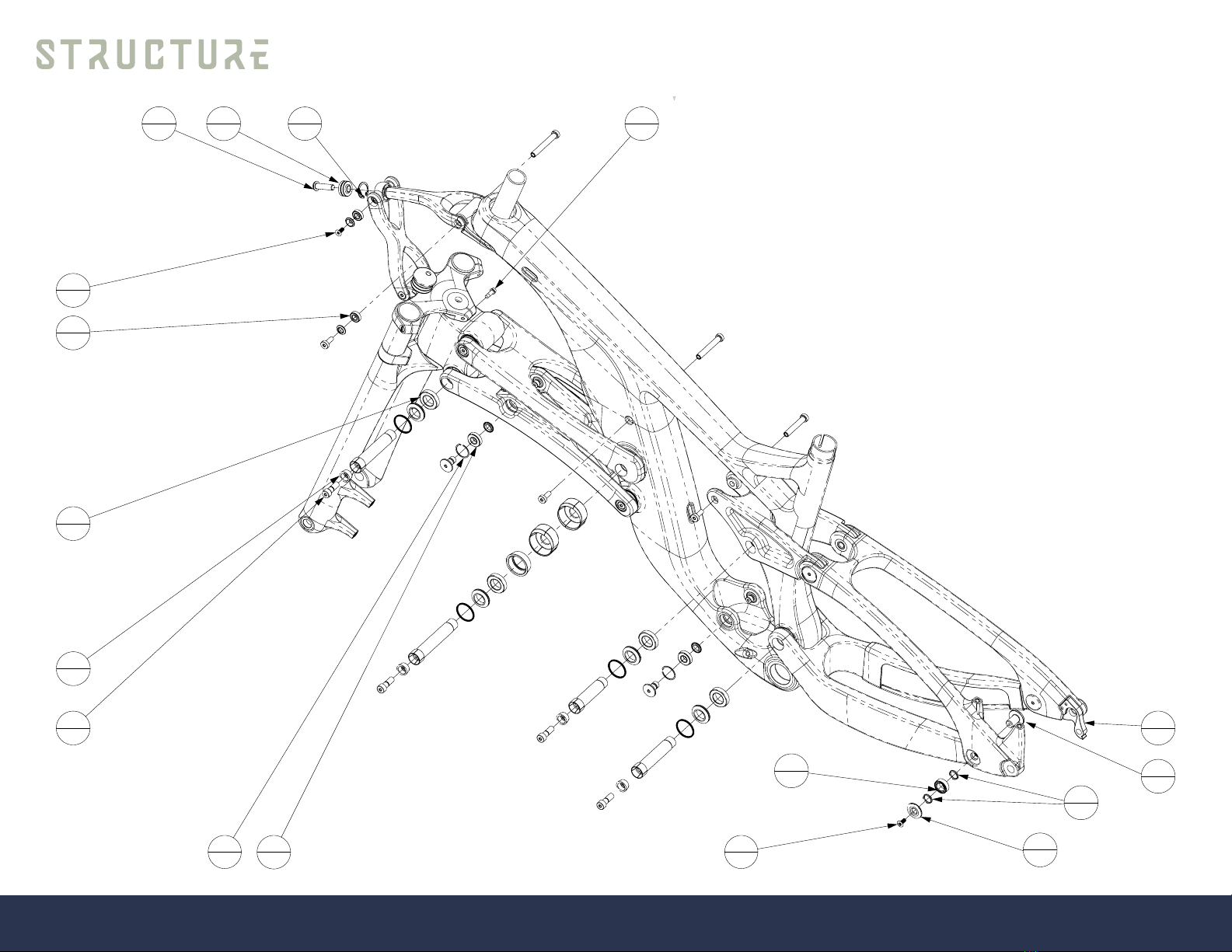

58

1

57

6

51

1

55

1

49

6

50

2

45

2

47

4

46

12

56

3

28

6

29

6

54

4

44

4

57

6

16

2

37

1

Spare Parts

8

Most Common Spare Parts Listing and Number on Bike

#Part Number Description QTY

16 KQS 3791 Pivot bolt, rear triangle 2

28 KQS 2723 Collet washer 6

29 KQS 3785 Bolt Collet M8 6

37 KQS 3550 Rear derailleur hanger 1

44 KQS 3793 Bearing spacer, rear triangle 4

45 KQS 3792 Horst link pivot washer 2

46 6903-2RS Bearing 6903 12

47 6900-2RS Bearing 6902 4

48 3802-2RS Bearing 15x24x7 2

49 688-2RS Bearing 688 6

50 3801-B-2RS-TVH Bearing 3801 2

51 COM-M8T Spherical bearing, 22mm OD x 8mm bore x 12mm wide ball 1

55 98394A440 Internal Retaining Ring, 22mm ID 1

56 BN15857 M5 x 15 Stem Bolt 3

57 BN3803 M5 x 0.8 x 12 Flat Head Cap Screw - T25 Driver 6

58 BN6404 M8 x 1.25 x 30 Button Head Cap Screw 1

59 BN15857 M4 x 0.7 x 12 Socket Head Cap Screw 2

9

Specications

Frame-fork-set Details

Frame/Fork Carbon ber, including fork, linkages and rear triangle

Travel 153mm front / 154mm rear

Wheel size 27.5” (650b)

Tire clearance 2.6” with generous mud clearance

Hardware 17mm colleted aluminum through-axles, machined and engraved 7075 triple clamp

Shocks (2) DVO Topaz / T3AIR custom tuned / 205x65 Trunnion mount

Headsets (2) Cane Creek / 40 series

Axles Boost 15 x 110 mm GW Twist Lever front / 12 x 148 mm stealth rear

Bearings high precision sealed cartridge: 6903 Main pivots / 6902 Trunnion end bearing / 3802 Rocker-seat / 688 Steering link pivots /

22x8x9 Spherical - Teon-coated stainless

Chain line Boost 52 mm (also non-Boost compatible)

Chain ring clearance 34 T Boost / 32 T non-Boost

Front derailleur Single-ring only / chain guide & bash guard compatible

Chain guide mounts ISCG-05

Bottom bracket BSA

Seat post clamp 36.0 mm / Alloy clamp included

Seat post diameter 31.6 mm

Seat post stroke 150mm (G1), 180mm (G2), 210mm (G3)

Cable routing Internal, sleeved / Di2 compatible, wire guides and internal battery mount

Derailleur hanger Replaceable

Brake mounts 203 mm post front / 180 mm post rear

Water bottle mount G1-G3 1 under frame at Di2 battery cover - G3 size has mount in main triangle for 16oz side load bottle

10

General Service and Care

STORING

Store your bicycle where it will not be an obstacle and with protection

from the elements. Do not park your bicycle near electric motors;

ozone from motors can damage rubber and paint. Rain or snow can

cause the metal on your bicycle to corrode. Ultraviolet radiation

from the sun can fade the paint and crack the rubber or plastic on

your bicycle. Before you put away your bicycle for an extended time,

clean and service it and apply frame polish. Hang your bicycle off the

ground with the tires at approximately half the recommended ination

pressure. Before you ride your bicycle again, be sure it operates

correctly.

MAINTENANCE

Bicycle service requires special knowledge and tools and should be

performed by a professional bicycle mechanic. This user manual is to

be used in conjunction with the manuals supplied by the component

manufacturers. If you did not receive the manual provided by the

component manufacturer, download the materials off the Internet

or contact your local dealer. Consult your local dealer to create a

maintenance plan and refer to the Maintenance Schedule on the next

page as a guide for frequent inspection, service, and replacement of

parts.

INCIDENTAL DAMAGE

Do not let your bicycle fall. Do not set your bicycle down with the

frame or derailleur touching the ground. Use care with car racks and

work stands. Clamping devices, such as those found on a work stand

or car carrier, can cause damage to the paint or tubes of bicycle

frames. To hold the bicycle for repairs, clamp the seat post. To hold

the bicycle for transportation on a motor vehicle, clamp the bicycle

by the wheels or fork. If you accidentally apply a bending force to the

fork, do not ride the bicycle until your retailer has inspected the fork

for damage. The nish, or paint, on your bicycle can be damaged by

chemicals (including some sports drinks) or abrasive contact. Dirt can

scratch or remove paint (and even frame material), especially where a

cable rubs or a strap is placed around a tube. Keep the bicycle clean.

Use adhesive padding to prevent rubbing in critical spots.

CLEANING

Clean your bicycle with a soft, moist cloth and bicycle cleaner or a

solution of dish soap and water. Do not use industrial solvents or harsh

chemicals that can damage the paint or moving parts. Do not use

high-pressure water. Every three months, clean and polish the frame

nish. Some nishes do not require polish. If you are not certain,

consult your retailer.

TRANSPORT

When packaging your bicycle for travel, use a hard case or carton

that will protect it from damage. Attach padding to all the frame and

fork tubes, and use a rigid block to protect the fork tips and maintain

structural support of the fork blades. If the bicycle is not packaged

correctly, it could be easily damaged in transit. If you are not sure, ask

your retailer to package your bicycle for you.

11

Assembly

Tools required

1 – T25 Torx tool

1 – T30 Torx tool

1 – ball end hex tool set with 2.5, 3, 4, 5, 6, 8, and

10-millimeter drivers

1 – cassette tool

1 – 24mm socket and ratchet for above

1 – torque wrench, 3-20 Nm range

1 – torque wrench, 20-80 Nm range

1 – brake bleed kit with royal blood (blue mineral oil)

1 – hydraulic hose cutter

1 – cable cutter

Unbox bike frame, fork, and parts bags. Lay out on a soft surface.

Locate shocks and depressurize by depressing Schrader valve. Remove

retention o-ring at the piston end of the main air canister. Holding the

top of the shock, twist and push the outer canister cover down. Insert

3 volume spacers into the positive air chamber of the front shock and

3 volume spacers into the positive air chamber of the rear shock, per

DVO’s instructions. Without pinching the o-ring that separates positive

and negative air chambers, carefully slide the cover back into position

until fully seated and replace o-ring.

The SCW1 is delivered with three volume spacers in the positive air

chamber of the front shock and three in the rear shock. This allows for

plush, responsive small-bump compliance in early in the travel, with

strong resistance to bottom-out. If you determine that you would like

to change the number of volume spacers in your DVO shocks, please

follow DVO’s instructions found on their website.

Please refer to the accompanying graph as a chart to setting shock

pressures as a starting point according to riding style. ¢

Locate shock fasteners and bearing washers, place washers (with

smaller taper toward the trunnion(upper eyelet) bearing’s inner race)

against bearing, then hold them in place by putting the trunnion bolt

through the bearing from the outside, just far enough to hold the

washer.

NOTE: For rear shock only, it is best to have trunnion end fully

installed and tightened before fastening small end. Align the shock

with chamber down and wiggle the trunnion end between both

spacer washers until one of the bolts engages threads in the shock

body. Start threading one side and then the other side an ensure both

trunnion end bolts are engaging threads smoothly. Torque to 10-

11Nm. Repeat for the other shock.

For shock small end(lower eyelet), use DVO 8mm x 30mm tment kit,

installed according to DVO instructions. Work the shock’s small end

into position, then install 8mm female bolt from the drive side with a

small amount of assembly grease on the outside surface. Install male

bolt with medium thread locker. While holding male bolt with T30

Torx driver, from the drive side of the bike apply 6 Nm of torque to

the female bolt only.

Locate fork, steering linkage, headsets and stem. Install the bumpers

onto the fork making sure the ats align (moisture will help slide

them on). Set aside crown races (unnecessary). Install lower headset

bearings at both upper and lower steering heads, using a plastic dead-

blow hammer (if necessary) to gently seat the bearings. Place fork

12

into lower steering head and install top headset bearing and split race

on top of fork steerer tube (for fork only, set aside top cap, as it will

not be used).

On the steering linkage, loosen all three cinch bolts on the triple

clamp and carefully slide the triple clamp over the three tops of the

fork. Install headset top cap and bolt and tighten until bearings are

engaged but not overly tight (4 Nm). Fold and/or rotate linkage to

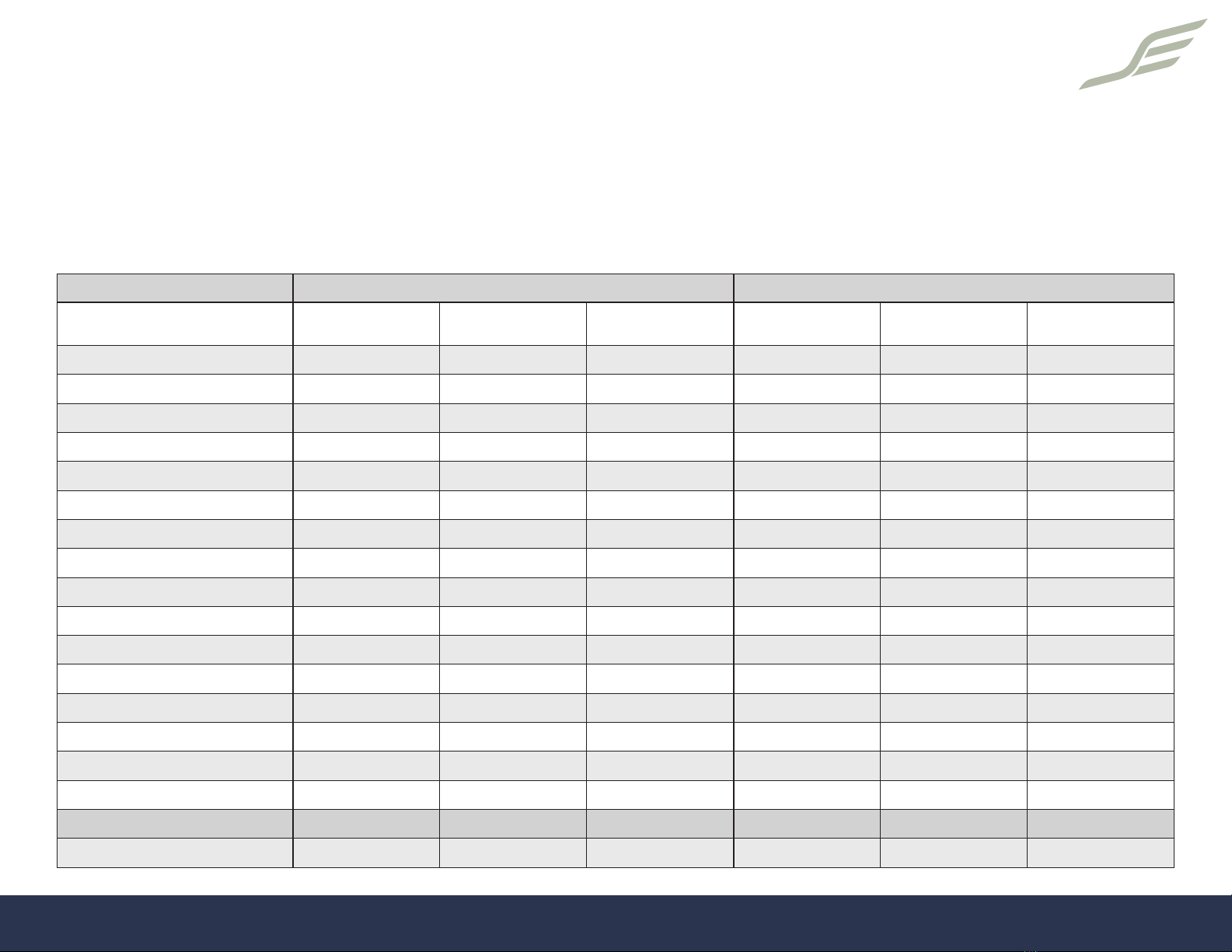

Rider Weight, With Gear Rear Shock Front Shock

(lbs) Plush

(3 vol. spacers) Aggressive

(2 vol. spacer) Bike Park Jump (2

vol. spacers) Plush

(3 vol. spacers) Aggressive

(3 vol. spacers) Bike Park Jump (3

vol. spacers)

100 90 95 100 55 60 65

110 99 105 110 61 66 72

120 108 114 120 66 72 78

130 117 124 130 72 78 85

140 126 133 140 77 84 91

150 135 143 150 83 90 98

160 144 152 160 88 96 104

170 153 162 170 94 102 111

180 162 171 180 99 108 117

190 171 181 190 105 114 124

200 180 190 200 110 120 130

210 189 200 210 116 126 137

220 198 209 220 121 132 143

230 207 219 230 127 138 150

240 216 228 240 132 144 156

250 225 238 250 138 150 163

Compression (min/med/max) min min med min min med

Rebound (clicks from 0) +6 +5 +6 +6 +5 +6

13

correctly orient the links before installing the upper steerer through

the main frame headset. Install top cover, making sure split ring is in

place. Using assorted 5mm and 10mm steerer spacers to set desired

stem height, install the stem on the steerer.

Tighten preload cap to set headset preload, applying no more than

4Nm of torque. Set preload on lower headset in the same manner,

using no more than 4Nm of torque. Once the fork and steering

assembly rotate smoothly – without looseness or play in either steerer

– tighten stem bolts per stem manufacturer’s torque specication;

then add thread locker and tighten triple clamp bolts to 7 Nm. Go over

all of the fasteners in the steering system a second time to conrm

correct torque at each fastener.

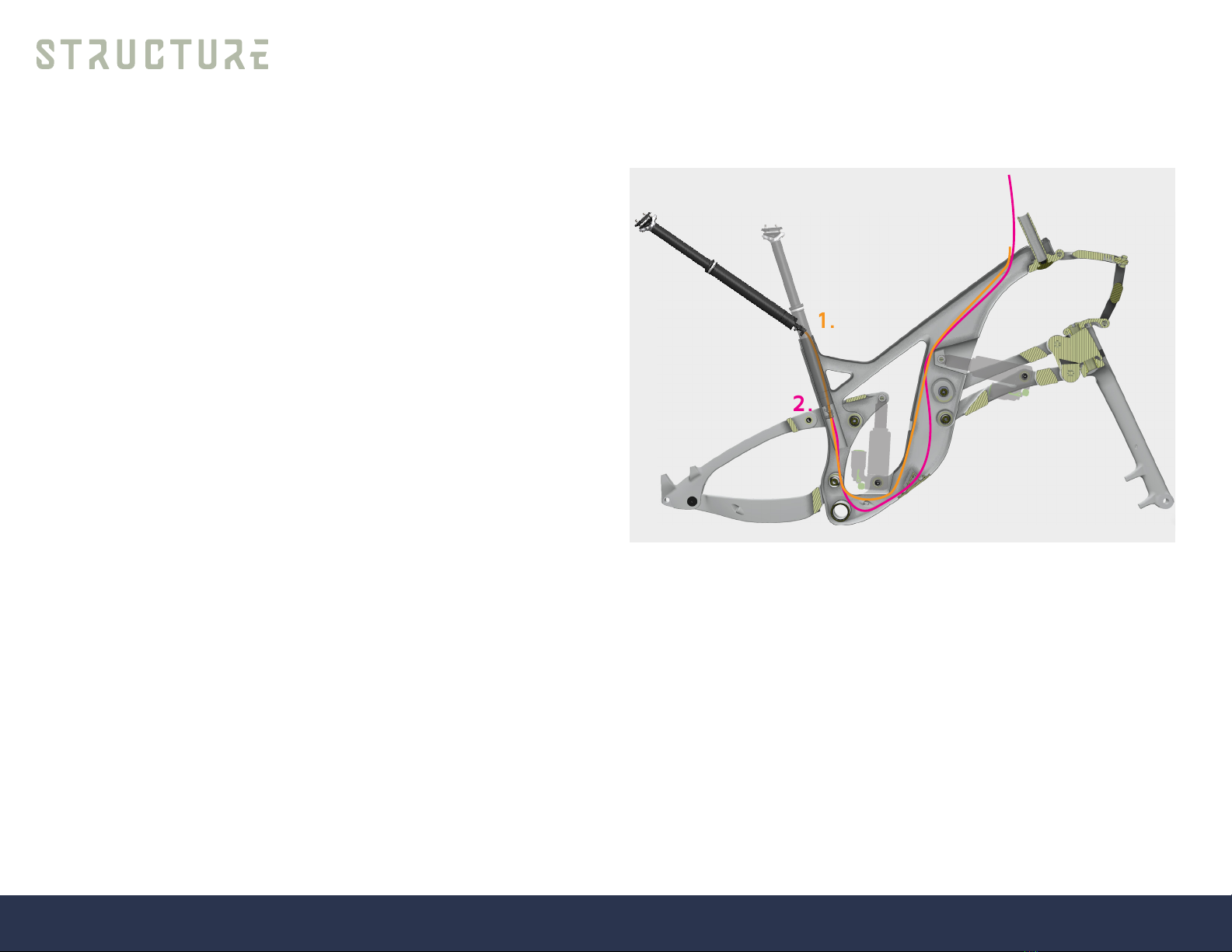

Using a non-marring tool, carefully pry out the two front rubber cable

outlets, starting from a bottom corner. Slowly work the rubber cable

outlet out of the frame.

Locate seat post collar and place it on the frame with bolt forward

and the reading upright. Locate seat post and lever/cable kit. Apply

assembly grease to the inside of the frame set through the hole in the

bottom bracket shell to facilitate sliding of the cable housing past the

tight radius at the bottom bracket.

Install the cable housing from the top of the seat tube, guiding it past

the front of the chain stay pivot to the hole in the frame’s bottom

bracket shell. With one nger, guide the cable housing forward to feed

it across to the Di2 battery opening in the bottom of the down tube.

Push until it extends out of the battery opening, pulling through until

20mm remains above the seat collar.

Feed end at battery port through one of the smaller foam silencing

tubes and then up into the frame. Aim the cable housing to the space

in the down tube behind the front shock pocket and continue feeding

the housing until it becomes visible at the cable outlets in the top

tube.

Use a spoke or wire with a small hook in the end to grab the housing

and pull it through the non-drive side cable exit, remembering to twist

the loop at the battery opening to straighten the cable housing in the

frame. Install the supplied cable barrel onto the cable.

1.

2.

w

¢

¢

14

Attach cable to seat post actuator, place a ferrule on the seat post end

of the housing and feed the cable into the housing until snug, grab the

cable at the front of the bike pushing the housing back and ease the

seat post into the frame while pulling the cable and housing out the

front.

Tighten the seat post clamp to 4 Nm and then clamp the bike onto

the stand by the seat post. Remove saddle clamps to access Schrader

valve on top of seat post; attach shock pump and pressurize to 275

psi. Replace clamps and attach the seat. Now you may attach the

handlebar to the stem. Locate the brakes, front and rear will have

different length hoses. For the front brake, disconnect the hose at

the lever. Placing the lever on the bar with the open end up, slide the

cover and sleeve bolt back. Using a utility blade or hose cutter, cut

the hose behind the olive and insert a hose plug. Then insert the hose

end into the fork leg until it comes out the top hole and loosely bolt

the caliper to the fork.

Slightly loosen the banjo bolt and rotate the hose to an optimal

position and re-tighten to 3Nm (27 in-lb) Determine the hose length

for the front brake, ensuring that it is not long enough to contact

the upper steering link when the suspension is fully compressed. Cut

the hose and slide on cover, bolt and olive. Grip the hose using two

transport devices and insert barb into hose end. Slide olive and sleeve

nut forward and reconnect the hose to the lever by hand while a

steadily pushing the hose into the lever to assure proper crimping of

the olive. Torque sleeve nut to 4Nm (35 in-lb) Disconnect hose from

rear brake lever, slide cover and sleeve bolt back, cut hose below the

olive, and insert a hose plug. Insert the hose on the non-drive-side

lower stay, feed until it comes out the front outside of the stay, then

feed directly into the main chassis. Guide the hose out the battery

port and loosely attach the caliper to the frame.

Slide the 6mm foam dampening cover onto the extended hose, then

loop back into the frame and guide against the rear of the down

tube until you feel it reach the top tube; slowly feed until it is visible

through the right hand port and use a hook to pull it out and route it

through one of the two drive-side cable guide holes. Slightly loosen

the banjo bolt and rotate the hose to an optimal position and re-

tighten to 3Nm (27 in-lb).

w

¢

¢

¢

¢

¢

15

w

¢

¢

¢

16

Determine the hose length for the rear brake after rotating the

handlebar bumper to bumper. Cut the hose and slide on cover, bolt

and olive. Grip the hose using two transport devices, insert barb into

hose end, slide olive and sleeve nut forward and reconnect the hose

to the lever by hand while pushing hose steadily into the lever, then

torque sleeve nut to 4Nm (35 in-lb)

Drive train - Locate the shifter, derailleur, and shifter housing.

Starting at the drive side port in the chain stay near the derailleur,

slide the shifter housing through to the front of the chain stay, pulling

it until only enough housing is exposed to reach the derailleur, then

guide the forward end into the frame opening adjacent to the upper

ISCG-5 tabs. Find the housing as it reaches the Di2 port and guide

the forward end out of the port. Slice the remaining 5mm silencing

sleeve over the housing and guide the forward end up into the frame

past the rear of the front shock opening until the forward end can be

hooked and pulled out of the drive side cable port.

Attach shifter to the bar with a 5mm hex socket and derailleur to the

hanger and torque to 11 N-m (97 in-lb). Fit a ferrule to the shifter

end of the housing and guide the housing into the shifter. Rotating

bars lock to lock to determine the correct amount of housing to leave

between the cable exit and shifter. Pull excess housing through the

frame and then measure the housing to the derailleur. Retract the

cable forward toward the shifter so it is not cut, then cut the housing

to the correct length. Add a ferrule to the derailleur end of the

housing.

Locate bottom bracket and determine drive and non-drive sides, then

thread in as far as you possible by hand. Using an appropriate bottom

bracket socket, torque to 50Nm (443 in-lb).

Insert drive side crank through bottom bracket and tap with soft

mallet until seated. Attach the non-drive side crank with an 8mm

hex by hand, then use a torque wrench to tighten the crank arm bolt

to 54 Nm (478 in-lb). Remove play from the system by turning the

preload adjuster in the + direction until it stops or makes contact with

the bearing shield. Use a 2 mm hex wrench to tighten the bolt until

the adjuster edges touch. Check the cranks et for play by rocking

the crank arms back and forth. There should be no side-to-side play

present.

Pedals - Install the washer between the crank arm and pedal.

Tighten the pedal shaft to 54 Nm (478 in-lb) unless otherwise

specied by the pedal manufacturer. Note that the non-drive side is

reverse threaded.

Wheels – Tighten the rotor bolts in an alternating sequence until

a torque of 6.2 Nm (55 in-lb) is achieved for each bolt. Install the

cassette onto the driver body until it is fully seated with the splines

engaged, then tighten the cassette with a cassette installation tool.

Torque to 40 Nm (354 in-lb).

Tubeless tire setup - Follow the instructions on the sealant product

you’ve purchased.

Install wheels on bike. For the rear wheel, place the rear derailleur

in lock position, place the chain on the smallest cassette cog, and

guide the rotor into the caliper. Insert the axle and with a 5mm hex

key torque to 12.4 Nm (110 in-lb). It is a good idea to get used to the

feel of this torque, as trailside repairs may require removal and re-

installation of the rear wheel.

17

The front wheel uses a QR style through axle. Once wheel is in

position with rotor in caliper, thread the axle until hand tight, then pull

lever outward and align lever arm with fork leg.

Brake centering – Pull and release the lever a couple of times while

helping the caliper center itself. Pull and hold brake lever, then tighten

retaining screws alternately and in stages to torque of 6 Nm (53 in-

lb). Check that wheel spins freely - if necessary, loosen the retaining

screws until caliper can move and repeat the above steps.

With the rear wheel installed - viewing the cassette from the rear of

the bike - adjust the inside adjustment screw on the derailleur (3mm

hex) until the top cog on the derailleur is centered on the outside edge

of the smallest cog on the cassette.

Attach the shift cable to the derailleur, pulling it tight without

deecting the derailleur, and tighten clamp screw to 4.5 Nm (T25 or

4mm hex).

Shift the derailleur to the largest cog using the thumb shifter and

adjust the outside adjustment (3mm hex) screw until the top cog on

the derailleur is centered on the center of the largest cog. Shift back

to the smallest cog and install the chain.

Note: the chain supplied with your bike has been pre-cut to the

correct length. With the rear derailleur still in lock position, feed the

chain from the chain stay over the cassette and into the derailleur –

over the top pulley and under the bottom one. Wrap the chain over

the front chain ring and insert the joiner links onto the ends. Engage

the joiner and lock by holding the wheel and rotating the crank until

the joiner link clicks. Unlock the derailleur by rotating the pulley arm

forward to release, then ease back until the chain is tensioned.

Set up - Test Ride

Now you are ready to throw a leg over and check the setup. Have a

multi tool and with you and roll around near home to adjust handlebar

and control angles, seat height and angle and to check for anything

that might be amiss.

18

Colleted Axle Removal and Installation

Colleted axles are used at all main pivots. To remove an axle, rst

remove the 8mm collet bolt using a T-30 Torx driver. Remove the

tapered collet using an 8mm hex and turn gently by hand until the

collet comes free. The axle itself can then be removed using a 10mm

hex driver.

After removing the axle, swing the suspension arm out of the way

to expose the bearing caps. Remove bearing caps carefully to avoid

damaging the seals. Each of the bearing caps on the main front

and rear linkage bearings includes an x-ring seal. To prevent water

intrusion and creaking due to misalignment of suspension arms with

the bearing cap, it is very important to make sure that the seal on

each bearing cap is fully seated and is not ipped or bulging from its

groove. Carefully and fully seat the seal on each bearing cap before

installing the suspension arm and colleted axle.

To install the axle, ensure that the threads of the axle and suspension

arm are clean and free of contaminants using mild solvent such as

isopropyl alcohol and shop air.

Apply medium strength thread locker to dry threads and tighten the

axle by hand until slight load is placed on the bearings. This is best

felt by hand. It should feel like the axle is just beginning to tighten.

Once slight preload on the bearings is felt, back the axle off and re-

tighten until it feels like the axle is just beginning to tighten and there

is no slack between suspension arms, bearing caps, and bearings. No

additional preload is required. Over-tightening can create noise and

accelerated bearing wear.

Install the axle collet with a smear of grease on the outer surface

to ease future removal. Apply medium strength thread locker to the

threads of the 8mm collet bolt and torque the bolt to 7 Nm.

Bearing Removal and Installation

A bearing puller is recommended for bearing removal. However,

Structure Cycleworks bicycles are designed so that bearings may be

driven out from the opposite side of the frame. If a puller is not used,

to remove a bearing use a plastic dead blow hammer and drive the

bearing out with light, even, alternating taps to opposite sides of the

bearing, taking care to drive the bearing out evenly and avoid damage

to the bearing seat.

To install a bearing, a bearing driver or installation tool is

recommended. Before installing, wipe the bearing seat clean and use

a thin smear of grease on the outer surface of the bearing. While

making sure that the bearing is sitting ush with the outer edge of the

cup, slowly draw the bearing into the cup with the bearing driver until

the bearing is fully seated.

Install the bearing cap, ensuring that the x-ring seal around its

perimeter is fully seated and not twisted or bulging.

• WARNING

If the seal is pinched or bulging, water intrusion, noise, and/or

accelerated bearing wear may occur.

19

Brake Dive Reduction Eccentric Position.

The SCW1 utilizes eccentric bearing housings at the aft end of the

upper front control arm at the down tube. The purpose of the eccentric

housings is to allow selection of one of four dive reduction settings.

Telescoping forks are approximately 30% pro-dive under application

of the front brakes. Structure’s Without Telescoping Fork suspension

system reduces front brake dive by 17% (Plush), 22% (Low), 33%

(High), or 41% (Race), depending on the eccentric housing that is

installed and its orientation up or down.

All SCW1 bikes are delivered to owners with the eccentric in the Plush

(17% dive reduction) setting. To change the amount of front brake

dive reduction, consult the following:

Note that the set of eccentric housings for 17% dive reduction is thin

17% dive reduction position 22% dive reduction position 33% dive reduction position 41% dive reduction position

at the upper edge. This set of eccentrics ips 180° to provide 41% dive

reduction. A separate set of eccentrics (provided to the owner of each

bike) - with a slightly thicker upper edge at 22% than the eccentric for

17% - is used to provide 22% and 33% dive reduction. Make sure to

always use correctly matched pairs of eccentric housings.

When installing the eccentrics, a thin smear of grease is recommended

on the outer surface of the eccentric to ensure ease of removal in the

future.

Ensure that the bearing caps are fully seated and that the x-ring seals

are not twisted or bulging, as improperly seated seals can allow water

penetration to the bearing and may cause excess friction or noise in

the pivot.

20

Table of contents