STS 808 User manual

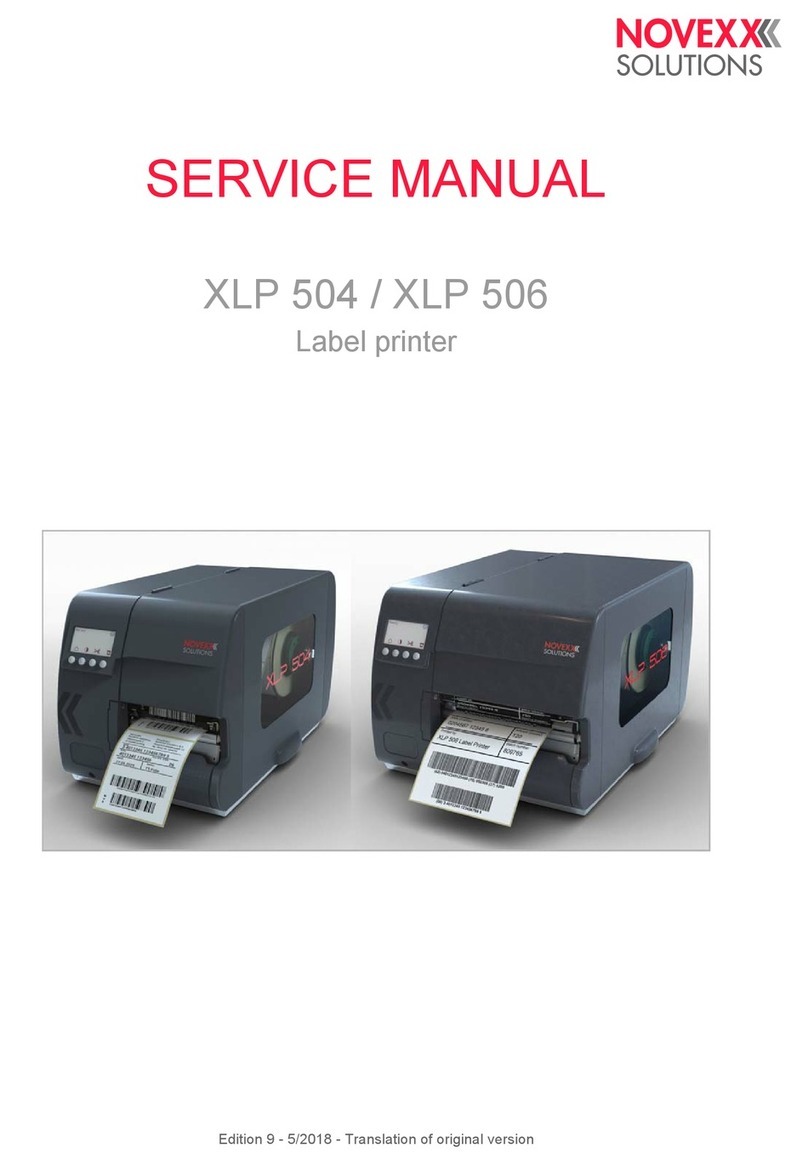

Labeling machine for spreading labels

on cylindrical surfaces

LABEL APPLICATOR

STS 808

Operating manual

/original instruction/

STS 808

LABEL APPLICATOR

MC

V.4.02

phone: (+359) 66 801 536 fax: (+359) 801 547

[email protected] www.stselectronics.eu

- 2 - STS808

Content

Pictograms used........................................................................................... page 3

1. Introduction...................................................................................................... page 3

Proper use.................................................................................................... page 4

Equipment .................................................................................................. page 5

Scope of delivery ........................................................................................ page 5

Technical data ............................................................................................ page 5

Noise information. ...................................................................................... page 5

2. General safety instructions for handling electrical appliances.

Safe work ................................................................................................... page 7

Specific safety instructions. ........................................................................ page 7

3. Operating instructions.

Mounting ..................................................................................................... p age 8

Preparing for work ...................................................................................... page 8

Turn on ....................................................................................................... page 9

Defining “Offset Stop” ................................................................................. page 9

Working with the menu and changing parameters ..................................... page 9

Labeling ...................................................................................................... page 9

Adjusting of the dysplay .............................................................................. page 9

Appendix 1 - Setting up the label sensor ....................................................page 10

Appendix 2 - Determination of parameter value - Offset stop .................... page 11

Appendix 3 - Determination of parameter value - Offset Stop 1 ................ page 12

- Determination of parameter value - Offset stop 2 ................ page 13

Appendix 4 - Working with the menu and setting parameters .................... p age 14

Appendix 5 - Adjusting the brightness and the contrast of the display......... page 17

Appendix 6 - Determination of parameter value - distance between labels... page 18

4. Maintenance and cleaning ............................................................................ page 19

5. Service ........................................................................................................... page 19

6. Warranty

General terms ............................................................................................. page 20

Warranty conditions ................................................................................... page 20

7. Transportation ............................................................................................... page 20

8. Disposal ......................................................................................................... page 20

9. EC Declaration of Conformity ..................................................................... page 21

10. Producer. ........................................................................................................ page 24

V.4.02

phone: (+359) 66 801 536 fax: (+359) 801 547

[email protected] www.stselectronics.eu

In the present Operation Manual have been used the following pictograms.

- 3 -

Read the Operation Manual!

Before starting the machine for the first time, get acquainted with the

functions of the machine and be informed about the correct operation with

electrical appliances. In this connection, read the following operating

instructions. Follow the instructions in the manual. When handing over the

machine to third parties, hand over and all the documentation.

Follow safety warnings and instructions!

Protect yourself from electric shock. Danger to life!

Keep the children away from the machine!

Risk of life from electric shock when a power cord or plug is damaged!

Dispose the packaging and the appliance in accordance with

environmental regulations!

!

1. Introduction

phone: (+359) 66 801 536 fax: (+359) 801 547

[email protected] www.stselectronics.eu

STS808V.4.02

Proper usage

The machine is designed to spread one or two self-adhesive labels (front side and

back side ones) on cylindrical vessels of different diameter and length, with smooth walls.

Labels should be on one roll, / in case of front and back labels - arranged consequently in

series / on the conveyor.

Place the container horizontally on the machine shafts, between the detents. The

process starts. The machine glues the label as it rotates the vessel. After stopping the

rotation, the label is glued and the container is removed from the machine manually. The

process is visualized on the manufacturer's website -http: //stsmachines.eu.

Any other use is considered unlawful and generates significant risks of accident. The

manufacturer accepts no responsibility for faults and damages caused by use contrary to the

indicated instructions.

The electrical protection of the machine is accomplished by protective sheath of the

current-carrying parts and by zeroing of the metal housing. This requires the use of a straight

electrical outlet (socket). Overcurrent protection is provided by fuses built into the machine.

Their replacement should by performed qualified personnel.

Attention !

Do not place any larger or smaller vessels on the machine than those

specified in the technical data! Do not use damaged vessels or vessels

which have irregularly shapes. There is a danger of being injured.

Do not dispose onto the shafts full vessels which are not sealed

good!There is a danger of electric shock!

Do not use labels with size beyond those specified in the specifications!

Feed with labels, maintain and clean the machine only when the power

is off!

Do not cover the ventilation openings of the machine!

Be careful not to spill liquid on the machine!

Do not insert objects into the openings of the machine! There is a danger

of electric shock!

Do not place your hand or fingers on the shafts of the machine! There is a danger of

injury!

Attention !

In case of electric shock! Injury immediately disconnect the electrical

supply through pulling the plug out of the socket!

Get medical attention immediately

- 4 -

!

!

phone: (+359) 66 801 536 fax: (+359) 801 547

[email protected] www.stselectronics.eu

STS808V.4.02

Equipment /Figure 1.1, Figure 1.2/.

1. Supporting shaft. 10. Control panel.

2. Driving shaft. 11. Start button.

3. Stopers (detents). 12. Sensor for labels.

4. Pull shaft. 13. Power switch.

5. Pressing shaft. 14. Power supply coupling.

6. Clamping mechanism 15. Driving shaft.

7. Stoper (detent) of label tape roller . 16. Label tape rooller driver.

8. Roll label holder. 17. Coupling external start.

9. Brake of the label tape roller.

Scope of the delivery.

Check immediately after unpacking the machine:-

-1 labeling machine for spreading labels on vessels with cylindrical surfaces Label

aplicator STS808;

- 1 power cable 220V, 3x0,75mm2, 1,8m;

- 1 'Start pedal' with connection cable and coupling M12-4P;

- 1 operation manual.

Technical data.

Supply voltage: 220V AC, 50Hz.

Own consumption: <100VA.

Electrical conection: cable with plug type 'SHUKO'.

Dimensions: 365mmW, 245mmH, 330mmD.

Machine weight: 12kg.

Diameter of the vessel: 25 ... 160mm.

Length of the vessel: 80 ... 240mm. / distance between stops

(detents)/

Diameter of the labels roll: <200mm.

Spool diameter: 50 ... 70mm.

Width of the roll / of the label /: 25 ... 150mm.

Label length: 25 ... 500mm.

Distance between labels on the tape: >2,5mm.

Download speed of the tape: 0.1m/sec.

Noise information.

Noise level determined by analysis A.

Acoustic pressure level <70dB (A).

Noise level <70dB.

- 5 -

phone: (+359) 66 801 536 fax: (+359) 801 547

[email protected] www.stselectronics.eu

STS808V.4.02

STS 808

LABEL APPLICATOR

MC

10

11

Peeling edge

2

1

4

5

7

8

9

3

6

6

15

17

14

13

7

9

16

12

Figure 1.1

Figure 1.2

- 6 -

phone: (+359) 66 801 536 fax: (+359) 801 547

[email protected] www.stselectronics.eu

STS808V.4.02

2. General safety instructions for handling electrical

appliances.

Attention!

The following safety precautions must be observed when using

electrical appliances to protect against electric shock, risk of injury and fire.

Read all of these instructions before using the machine and store them

carefully.

Safe work.

-Keep your workplace in order. Clutter in the work area can lead to

accidents.

- Ensure good lighting in the workplace.

- Do not use the appliance in humid conditions.

- Do not use the appliance in places where there is a risk of fire or explosion.

- Keep bystanders, especially children, away from the appliance when

operating the appliance.

- Do not use the appliance for purposes other than those intended.

- Do not use the cord to pull the plug from the wall socket. Protect the cable

from oil heat and sharp edges.

- Avoid unnatural postures of the body. Take care of a secure posture, keep

balance in every way.

- Carefully maintain your appliances.

- If you do not use the appliance, remove the plug from the socket.

- Do not use the appliance with a damaged power switch.

An electrical appliance that cannot be switched on and ?Carefully maintain

your appliances.

- If you do not use the appliance, remove the plug from the socket.

- Do not use the appliance with a damaged power switch.

An electrical appliance that cannot be switched on and switched off is

dangerous and needs to be repaired

- 7 -

!

-Be careful. Treat your work with caution. Do not use the appliance if you are not

concentrated enough.

- Check the appliance for eventual damages. Check that the moving parts function

flawlessly and are not tightened and that there are no damaged parts. All parts must be

installed flawlessly and meet all conditions to ensure a faultless working condition of the

appliance. Damaged safety components and parts must be repaired reliably by a certified

electrician or replaced, unless otherwise stated in the instructions of the operation manual.

Damaged circuit breakers must be replaced by a workshop.

Specific safety instructions.

The vessels are placed and removed manually. The adhesive procedure is started by

pressing the built-in 'Start' button, or by an external start / 'Start' pedal connected to the

intended coupling /.

- Do not place a vessel while the machine shafts are rotating.

- Do not start the machine with a vessel placed incorrectly.

- Do not remove the vessel from the machine before the shafts rotation is stopped.

Failure to keep the above instructions may result in injuries or damages.

phone: (+359) 66 801 536 fax: (+359) 801 547

[email protected] www.stselectronics.eu

STS808V.4.02

3. Operating instructions

Attention !

Every operator working wth the labeling machine (with the Label

aplicator) should become acquainted carefully with the present operating

manual.

Mounting.

The machine should be placed on a flat, horizontal surface larger than its

base. Should provide space around the machine for maintenance servicing and handling.

From the kit supplied with it, a power cord is conected to the supply socket and alsow a 'start

pedal' is connected to an external start cuplung.

Preparation for work.

The orientation of the vessel (left - right) is selected, depending on the direction of the

printed labels. The height of the clamping mechanism and the position of the support shaft

are adjusted according to the diameter of the vessel. Adjust the detents (the stopers) so that

the container is in the middle of the work area.

The label tape roll is affixed to the label roller stand so that the labels face the

adhesive zone. The position of the roll is fixed by the two magnetic stoperes (detents). The

brake is positioned in the middle of the roll.

The pressure shaft is 'unlocked' by moving it forward. The label roll is loaded

according to the attached scheme – Figure 3.1. The sensor is positioned so that the label roll

fully covers the sensor area (narrow gap). Sensor setting up

Scheme of label movement

Pulling shaft

Pressing shaft

Peeling edge

Path of the label Driving shaft Supporting shaft

SensorDrive shaftDrivers

Clamping mechanism

Figure 3.1

- 8 -

!

phone: (+359) 66 801 536 fax: (+359) 801 547

[email protected] www.stselectronics.eu

STS808V.4.02

is caried out according to Appendix 1. The beginning of the label (front - for two labels) is

positioned next to the peeling edge. The pressure shaft is 'locked'. Label tape drivers are

positioned and fixed to the edges without squeezing it.

Turn on.

After the machine is switched on, an advertisment logo is visualised on the display and

the software version after that is switched to operating mode.

Determination of parameter value 'Offset stop'.

The sensor which is reading the end of the label is located at distance 100mm before

the peeling edge and its position cannot be changed. This requires the input of the 'Offset-

stop' parameter / for single-label mode / and 'Offset-stop 1' and 'Offset-stop 2' / for two-label

mode /. This parameter determines the proper positioning of the subsequent label to the

peelinge edge. The values depend on the length of the labels and the distance between

them. For convenience, the measurement of the labels, the distance between them and the

calculation of the offset are done before mounting the label roller on the machine.

In the case of single-label gluing, the parameter value is determined according to

Appendix 2.

In the case of two labels gluing, the parameter values are determined according to

Appendix 3. If the front label is less than 100mm and the back (rear) label is larger than

100mm, it must be started by spreading and gluing the longer label or by spreading and

gluing the back (rear) one.

Working with the menu and changing parameters.

Menu access is password protected, which is fixed and cannot be changed. Through

the menu can select the language, operating mode / one or two labels /.

For the one label mode shall be set : 'Offset stop' and additional adhesive movemnt

time.

For the two labels mode shall be set: the gap between labels on the the tape, the

distance between the labels affixed to the vessel, 'Offset-stop 1', 'Offset-stop 2' and the

movement time for the adhesive. Access and operation with the menu is carried out

according to Appendix 4.

Labeling.

First starting shall be done without a vessel for control. The new label / front - for two

labels mode/, should be just to the peeling edge. Offset-stop adjustments are made if

necessary.

The adhesive procedure is started by pressing the built-in 'Start' button, or by an

external start / 'Start' pedal connected to the intended coupling /. Performance is indicated on

the display. At the completion of the spreading and affixing (gluing) procedure, the label

counter increases. During the working regime any time the key is pressed for more than 3

seconds, the counter is reset.

Adjusting the display.

The brightness and the contrast of the display can be adjusted if needed. Menu

access and operation are described in Appendix 5.

- 9 -

phone: (+359) 66 801 536 fax: (+359) 801 547

[email protected] www.stselectronics.eu

STS808V.4.02

Appendix 1 - Ajustment of the label sensor.

The sensor is positioned in such a way that the label and

the support base must completely cover the sensor area (narrow

gap) when moving. In the case of irregularly shaped labels, cut-

off parts must not pass through the sensor area. The sensor and

the label tape roller must be at rest during adjustment!

1. The label tape roller is positioned on the gap between

the labels - Figure 3.2 taking into account the markers on the

front face panel.

2. Press and hold key for more than 3 seconds -

LED 'T' /yellow/ illuminates - sensor is in setting mode. When the

key is released, the LED starts blinking - automatic sensor

training begins. The signal level indicated by the bar graph 'L' is

increasing. Waiting for LED 'T' to go out.

3. The label tape roller is positioned on a label - Fig.3.3.

4.The key is pressed. 'T' LED lights up. When the

button is released, the LED starts to blink. With the 'T' LED off,

the automatic tuning is complete.

If the gap signal level is insufficient / after step 2 / or there

is insufficient gap between the gap-label signals / after step 4 /,

the bargraph starts to blink - indicating an error.

Exit from this state is caried by new / correct / training or

by turning off the power

TEACH

TEACH

Figure 3.2

STS Electroncs

STS Electroncs

STS Electroncs

STS Electroncs

L

O

T

S

TEACH

+

ULTRASONIC

LABEL SENSOR

STS Electroncs

STS Electroncs

STS Electroncs

STS Electroncs

L

O

T

S

TEACH

+

ULTRASONIC

LABEL SENSOR

STS Electroncs

Figure 3.3

- 10 -

phone: (+359) 66 801 536 fax: (+359) 801 547

[email protected] www.stselectronics.eu

STS808V.4.02

Appendix 2

Determination of parameter value Offset stop.

Determines the right positioning of the begining end of the following (subsequent

label) to the peeling edge.

There are some possible variants and they are shown on Figure 3.4

L = 100mm - distance between the label

sensor and the peeling edge.

1. The lenght of the used label is biger

than L. The parameter value of Offset is

100 [mm].

2. The length of the label used and the

half of the gap are equal to L.The

parameter value of Offset is 100 [mm].

3. The length of the label used is less

than L. The Offset value shall be

determined by subtracting the length of

the label and the half of the gap from

100 [mm].

4. The length of the label used is several

times less than L.The Offset value is

determined by subtracting from 100

[mm] the sum of all lengths of the fitted

labels and gaps between them, and

adding the half of the gap.

Note: Measured offset results are a

good start. Several adjustments may be

needed to better position the start of the

label.

Label

Label

LabelLabel

Label Label Label Label

Label

Label

1.

2

3.

> 100mm

Offset stop = 100mm

Offset stop = 100mm

= 100mm

Offset stop

Offset stop

100mm

<< 100mm

< 100mm

100mm

L0

.

4.

Figure 3.4.

- 11 -

phone: (+359) 66 801 536 fax: (+359) 801 547

[email protected] www.stselectronics.eu

STS808V.4.02

L0

2

3

Offset stop 1 = 100mm

= 100mm

Offset stop 1

Offset stop 1

100mm

<< 100mm

< 100mm

100mm

Label

back

Label

back

Label

back

Label

front

Label

front

Label

front

1

> 100mm

Offset stop 1 = 100mm

Label

back

Label

front

4

Appendix 3

Determination the parameter value of Offset stop 1

Offset stop 1 determines the correct positioning of the begining end of following

(subsequent) back label against to the peeling edge. Measerment shall be done from the

begining end of back label.

There are several possible variants and are shown in Figure 3.5

L = 100mm - distance between the label

sensor and the peeling edge.

1. The lenght of the used back label is

bigger than L. The parameter value of

Offset is 100 [mm

2. The length of the back label used and

the half of the gap are equal to L.The

parameter value of Off set is 100 [mm].

3. The length of the back label used is

less than L. The offset value shall be

determined by subtracting from 100

[mm] the length of the label and the half

of the gap.

4. The length of the back and front

labels is several times less than L.The

offset value is determined by subtracting

from 100 [mm] the sum of all lengths of

the fitted labels and gaps between them

/alternating back and front/ , and adding

the half of the gap.

Note: Measured offset results are a

good start. Several adjustments may be

needed to better position the start of the

label.

Figure 3.5

- 12 -

phone: (+359) 66 801 536 fax: (+359) 801 547

[email protected] www.stselectronics.eu

STS808V.4.02

Determination of the parameter value - Offset stop 2.

Offset stop 2 determines the right (the correct) position of the begining of the following

(subsequent) front label to the peeling edge. Measerment shall be done from the beginnig of

the front label.

There are some possible variants and they are shown in Figure 3.6.

1

2

3

> 100mm

Offset stop 2 = 100mm

Offset stop 2 = 100mm

= 100mm

Offset stop 2

Offset stop 2

100mm

<< 100mm

< 100mm

100mm

Label

front

Label

back

Label

back

Label

back

Label

front

Label

front

Label

front

Label

back

Label

front

4

L0

Figure 3.6

L = 100mm - the distance between the

label sensor and peeling edge

1. The lenght of the used front label is

bigger than L. The parameter value of

Offset is 100 [mm].

2. The length of the front label used and

the half of the gap are equal to L.The

parameter value of Offset is 100 [mm].

3. The length of the front label used is

less than L. The offset value shall be

determined by subtracting from 100

[mm] the length of the label and the half

of the gap.

4. The length of the back and front

labels is several times less than L.The

offset value is determined by subtracting

from 100 [mm] the sum of all lengths of

the fitted labels and the gaps between

them /alternating back and front/ , and

adding the half of the gap.

Note: Measured offset results are a

good start. Several adjustments may be

needed to better position the start of the

label

- 13 -

phone: (+359) 66 801 536 fax: (+359) 801 547

[email protected] www.stselectronics.eu

STS808V.4.02

Access to the parameter change menu is password protected.

Pressing and holding the key for longer than 3 seconds displays a

password window - Figure 3.8. It is canceled by pressing the key,

and access to the input menu by pressing the key - Figure 3.9. The

password is entered by pressing the key and thus the displayed

digit changes cyclically

Going to the next digit is done by pressing the key. Pressing the

key returns to the default password input position.

The password for this machine is 8083 - fixed and cannot be

changed by the user. If the password is incorrectly entered, an error window

is displayed - Figure 3.10. By pressing the key goes to a new input -

Figure 3.8. Cancelation of new input shall be done by pressing the

key and it goes into working mode - Figure 3.7.

Properly entered password gives access to change the parameters.

The first window that appears is the language selection - Figure 3.11. By

pressing the key , the language is cyclically changed - Figure 3.12.

Confirmation of the desired selection is done by pressing key. Go to

the next parameter input - Select mode / 1, 2 labels / - Figure 3.13.

Pressing the key cycles through the mode / ONE LABEL /

TWO LABELS /. Confirmation of the desired selection is done by pressing

the key.

Selecting 'ONE LABEL' mode.

When selecting the 'ONE LABEL' mode, and confirming it, it

proceeds to entering the next parameter - Offset stop - Figure 3.14. Its

value determines the proper positioning of the begining of a subsequent

label to the peeling edge. Its determination depends on the length of the

label and is given in Appendix 2.

The input is made by changing the specified number trough pressing

the key. Go to the next digit shall be done by pressing the

key. The process is cyclical.

Appendix 4 -

Working with the menu and changing parameters.

MODE 1 LABEL

------------------------------

WAIT START

000

NUMBER LABELS

Figure 3.7

PASSWORD

------------------------------

* * * *

PASSWORD

------------------------------

* * * 0

PASSWORD

------------------------------

ERROR!

ИЗБОР НА ЕЗИК

------------------------------

> БЪЛГАРСКИ

АНГЛИЙСКИ

Figure 3.8

Figure 3.9

Figure 3.10

Figure 3.11

SELECT LANGUAGE

------------------------------

>ENGLISH

BULGARIAN

Figure 3.12

SELECT MODE

------------------------------

> ONE LABEL

TWO LABELS

Figure 3.13

- 14 -

phone: (+359) 66 801 536 fax: (+359) 801 547

[email protected] www.stselectronics.eu

STS808V.4.02

M

C

C

M

C

M

M

OFFSET STOP

------------------------------

017

^

------------------------------

[001 ... 999 mm]

Figure 3.14

TIME MOVE MOTOR

------------------------------

02.00

^

------------------------------

[00.00 ... 60.00 s]

Figure 3.15

CM

MODE SELECT

------------------------------

ONE LABEL

>TWO LABELS

Figure 3.16

DISTANCE LABELS

------------------------------

01.17

^

------------------------------

[00.90 ... 30.00 cm]

Figure 3.18

OFFSET STOP 1

------------------------------

017

^

------------------------------

[001 ... 999 mm]

Figure 3.19

OFFSET STOP 2

------------------------------

017

^

------------------------------

[001 ... 999 mm]

Figure 3.20

LABELS GAP

------------------------------

03

^

------------------------------

[ хх (mm) ]

Figure 3.17

C

M

C

M

CM

CM

- 15 -

phone: (+359) 66 801 536 fax: (+359) 801 547

[email protected] www.stselectronics.eu

STS808V.4.02

By pressing the key, the reading is reset. By pressing the

key, the set offset is confirmed and proceeds to setting the next parameter -

movement time - Figure.3.15. The value determines the time of rotation of

the vessel in order to adhere the label. It is set by the user at his discretion.

The input is made by changing the specified number by pressing the

key. The next digit is passed by pressing the key . The process is

cyclical. By pressing the key, the reading is reset. By pressing the

key the set time is confirmed and switched to operating mode - Figure 3.7.

Selecting 'TWO LABELS' mode.

When selecting the 'TWO LABELS' mode, please see Figure 3.16,

and confirming it, the next parameter shall be entered - the gap between the

labels - Figure 3.17.

The entry is made by changing the specified number by pressing the

key . The next digit is passed by pressing the key. The

process is cyclical. By pressing the key the reading is canceled. By

pressing the key, the given gap is confirmed and proceeds to the

next parameter - label spacing (distance between front and back label) -

Figure 3.18.

The value determines the correct location of the front / back label. It

is determined by the circumference of the vessel and the total length of the

two labels - referred to in Appendix 6.

The input is made by changing the specified number trough pressing

the key. To move to the next digit, press the key. The

process is cyclical. By pressing key the reading is reset. By pressing

key, the set distance is confirmed and the next parameter is set -

Offset stop 1 Figure3.19. Its value determines the proper positioning of the

beginning of the front label to the peeling edge. Its determination depends

on the length of the two labels (front, back), and is given in Appendix 3.

The input is made by changing the specified number by pressing the

key. To move to the next digit, press the key. The process is

cyclical. By pressing key the reading is reset. By pressing

key, the set Offset stop 1 is confirmed and proceeds to the next parameter -

Offset stop 2 - Figure 3.20. Its value determines the proper positioning of

the beginning of the back label to the peeling edge. Its determination

depends on the length of the two labels (front, back), and is given in

Appendix 3.

The input is made by changing the specified number trough pressing

the key Going to the next one

CM

TIME MOVE MOTOR

------------------------------

02.00

^

------------------------------

[00.00 ... 60.00 s]

Figue 3.21

C

M

- 16 -

phone: (+359) 66 801 536 fax: (+359) 801 547

[email protected] www.stselectronics.eu

STS808V.4.02

digit shall be done by pressing the key. The process is cyclical. By

pressing key the reading is reset. By pressing key, the set

Offset stop 2 is confirmed and proceeds to the setting of the next parameter

- movement time - Figue 3.21. The value determines the time of rotation of

the vessel in order to adhere the label properly.

It is set by the user at his discretion. The input is made by changing

the specified number by pressing the key. To move to the next digit,

press the key. The process is cyclical. By pressing key the

reading is reset. By pressing key, the set time is confirmed and

switched to Fifure 3.7 operating mode.

When staying in a parameter menu window for more than 60

seconds without activity (pressing any key), the machine enters Fifure 3.7

operating mode. Changes made so far are being recorded.

CONTRAST

------------------------------

>>>>

------------------------------

- CLEAR + UP

Appendix 5 - Ajustment of the brightnes and the contrast of

the display.

MODE 1 LABEL

------------------------------

WAIT START

000

NUMBER LABELS

Figure 3.22

Figure 3.23

BRIGHTNESS

------------------------------

>>>>

------------------------------

- CLEAR + UP

Figure 3.24

C

M

C

M

- 17 -

phone: (+359) 66 801 536 fax: (+359) 801 547

[email protected] www.stselectronics.eu

STS808V.4.02

The menu for changing the display settings is accessed from the

operating mode - Figure 3.22.

Pressing and holding for longer than 3 seconds on the key will

enter the contrast adjustment mode - Figure 3.23. The current level is

represented by a bargraph / >>>> ..... /. Adjustment is done gradually by

pressing key to decrease and key to increase.

By pressing the key, the desired value is stored and switched

to the brightness setting mode - Figure 3.24. The current level is

represented by a bargraph / >>>> ..... /. Adjustment is incremental by

pressing key to decrease and key to increase. The desired

value is memorized by pressing the key, and goes into working mode

- Figure 3.22.

Appendix 6

Determination of the parameter value - Distance beween the

labels

L3 = ( ( D*3,14 - L1 - L2 ) / 2 ) /10 [сm]

L3

L1L2

L3

D

length of

front label

length of

back label

distance between labels

Vessel (container) /bottle, jar/

Front label

Back label

Example:

For a vessel with a diameter of 73 mm, and the length of the labels respectively

front 85 mm and back 55 mm, the distance between the labels is obtained as

follows:

L3 = (( 73*3,14 - 85 - 55) /2 ) /10 [cm]

L3 = 4,461 [cm] .

Input ?value up to the second character: 04,46 [cm].

L1 - length of front label [mm]

L2 - length of back label [mm]

L3 -distance between front and back label [сm]

D - diameter of the vessel /container/ [mm]

- 18 -

phone: (+359) 66 801 536 fax: (+359) 801 547

[email protected] www.stselectronics.eu

STS808V.4.02

!

4. Maintenace and cleaning

Attention! Risk of injury!

Always disconnect the plug from the socket before performing any

work on the machine.

The labeling machine does not require any technical maintenance

within the specified service life.

Clean the machine after finishing the job.

Use a brush or a dry cloth. Do not use solvents to clean the cabinet

and face panel.

Technical alcohol may be used to clean the shafts. No liquids should

enter the machine.

Make sure that the vents are always clear.

5. Service

Attention!

Have the machine serviced by qualified personnel only and only use

original spare parts. This guarantees the safety of the machine.

If the power cord is damaged, replace it with a new one. This ensures

the protection against electric shock and guarantees the safety of the

machine.

- 19 -

!

If detergent gets into your eyes, wash it immediately with water!

If discomfort or vision problems continue, seek medical attention!

In the event of electric shock or injury, disconnect the power supply immediately by

pulling the plug out of the socket!

Get medical attention immediately

phone: (+359) 66 801 536 fax: (+359) 801 547

[email protected] www.stselectronics.eu

STS808V.4.02

Table of contents

Popular Label Maker manuals by other brands

Intermec

Intermec EasyCoder 201II installation instructions

PYD Life

PYD Life CE-AUMP15BL user manual

Citizen

Citizen CBM-253 user manual

DuraLabel

DuraLabel Lobo user guide

Carl Valentin

Carl Valentin Pica II 104/8 operating manual

Brother

Brother PT-9500PC - P-Touch 9500pc B/W Thermal Transfer... Service manual