Studio 54 Alexander 5T User manual

ALEXANDER 5T - 10T - 15T

Ed.12/2011 1

Made in Italy

ALEXANDER 5T - 10T - 15T

Ed.12/2011 2

Via Gian Lorenzo Bernini 147, Z.I. Paviola 3

35010 S. Giorgio in Bosco (Pd) Italy

TEL. 049 9450466 FAX. 049 9451044

ALEXANDER 5T - 10T - 15T

Ed.12/2011 3

1. General Information

We recommend you to read carefully the owner’s instructions, remembering that it

is an integral part of this equipment, and it must be kept with care.

In case of loss or damaging of the present manual, don’t hesitate to request

another copy of it, specifying the model and the date of purchase of the product.

The blast chiller/freezer has been designed and built exclusively to blast

chilling/freezing of temperature for food.

THE PRODUCING COMPANY DECLINES ANY RESPONSIBILITY FOR

DAMAGES RESULTING FROM

•ILLEGITIMATE USE

•USING OF NOT ORIGINAL SPARE PARTS

•NON-AUTHORIZED MODIFICATIONS ON THE PRODUCT

•FAILURE TO COMPLY WITH THIS MANUAL INSTRUCTIONS

ELEMENTARY SAFETY MEASURES

•Unplug before making any kind of intervention on the electrical parts: the

contact can cause the death.

•Don’t use the appliance with damp or wet hands or feet.

•Unplug before cleaning the appliance.

•Don’t insert any screwdriver, kitchen utensil, etc. among the moving

components or the protections.

2. Preliminary checks

At the receiving of the product, please verify immediately the packaging integrity

checking if there is any transport damaging.

Open the packaging and make sure that there are all the accessories.

If there have been transport damages, inform immediately the driver; within three

days such reservations must be confirmed by recorded delivery letter addressed

to the forwarder sending a copy of it directly to the producing company or its

reseller.

Every claim must be notified within 8 days from the receiving of the goods.

ALEXANDER 5T - 10T - 15T

Ed.12/2011 4

3. Warranty terms

The product is covered by a 12 months warranty starting from the date of the

purchase, except for the electrical components. The spare parts will be eventually

supplied under warranty ex works San Giorgio in Bosco (PD).

Before the delivery of spare parts under warranty, there must be the returning of

the damaged goods.

The warranty certificate must be filled and sent to the producer within 8 days from

the installation.

4. Installation

The main characteristics, as dimensions, absorption, etc., are specified on the

European Community silver label.

The appliance must use an electric socket equipped with an automatic cut-out,

respecting the safety regulations. Make also sure that voltage and power line are

suitable to the motor absorption.

4.1 POSITIONING

The installer must verify the presence of fire prevention regulations, and place the

appliance in full obedience of the industrial injuries legislation and the current

regulations.

The appliance works with an air condenser, so it is necessary to pay attention to

the placing of it, keeping free the side of the incoming of the cooling air.

Besides, it is also necessary to keep it at least at 20 cm from wall or other

appliances nearby the air exit, so as to obtain the best performances.

To refrain from placing the appliance in closed or poorly aired spaces, from

exposing it directly to sun-beams, and from the heat sources.

4.2 AMBIENT

Generally, the refrigerators with air condensing units work with a maximum

ambient temperature of 32°C. The declared performances are not guaranteed

where there are higher temperatures.

The producing company guarantees an IP43 degree of protection (in accordance

with CEI 70-1 EN 60529 and IEC529 laws). The installer will estimate if different

ambient conditions require other kind of protection degrees.

ALEXANDER 5T - 10T - 15T

Ed.12/2011 5

NOTE

Correct installation:

- Verify the electrical connections

- Verify the absorption at working appliance

- Switch on the fridge and let it to reach the desired temperature before putting

inside the food

If the appliance has been transported in a non-appropriate way (i.g. non-vertical

position or laying on the back), wait at least 4 hour before switching it on.

The end user must be informed on the right use of the appliance.

4.3 CORRECT DISPOSAL

Subject: Legislative Decree n. 151 dtd 25/07/2005 (ROHS – RAEE)

Correct disposal of this product (waste electrical and electronic equipment)

(Applicable in the European Union and other European countries with separate

collection systems)

IT08020000000717

This marking shown on the product or its literature, indicates that it should not be

disposed with other household wastes at the end of its working life.

To prevent possible harm to the environment or human health from uncontrolled

waste disposal, please separate this from other types of wastes and recycle it

responsibly to promote the sustainable reuse of material resources.

Household users should contact either the retailer where they purchased this

product, or their local government office, for details of where and how they can

take this item for details of where and how they can take this item for

environmentally safe recycling.

Business users should contact their supplier and check the terms and conditions

of the purchase contract. This product should not be mixed with other commercial

wastes for disposal.

Some economic sanctions to the defaulting user are provided for wrong wasting of

the products with RAEE mark.

ALEXANDER 5T - 10T - 15T

Ed.12/2011 6

5. OWNER’S INTERFACE

THE WORKING AND THE SETTING OF THE DIGITAL CONTROL DEVICE ARE

EXPLAINED IN THE ENCLOSED INSTRUCTION MANUAL FOR THE DIGITAL

CONTROL DEVICE EVCO EVC80S10P7XXX01

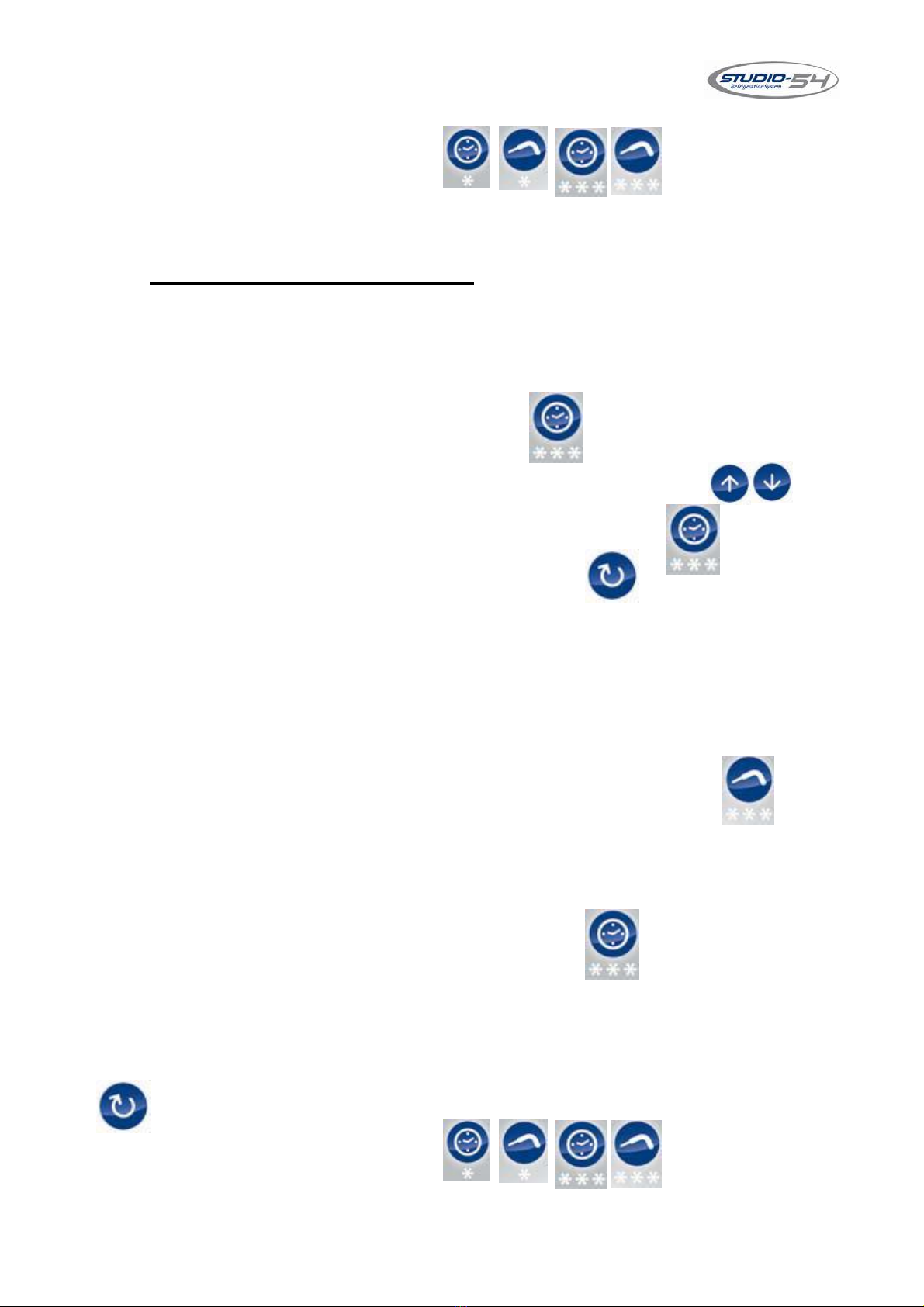

6. KEYS

SYMBOL NAME

START Key

TIME BLAST CHILLING Key

TEMPERATURE BLAST

CHILLING Key

TIME BLAST FREEZING Key

TEMPERATURE BLAST

FREEZING Key

DEFROSTING Key

INCREASE Key

DECREASE Key

ALEXANDER 5T - 10T - 15T

Ed.12/2011 7

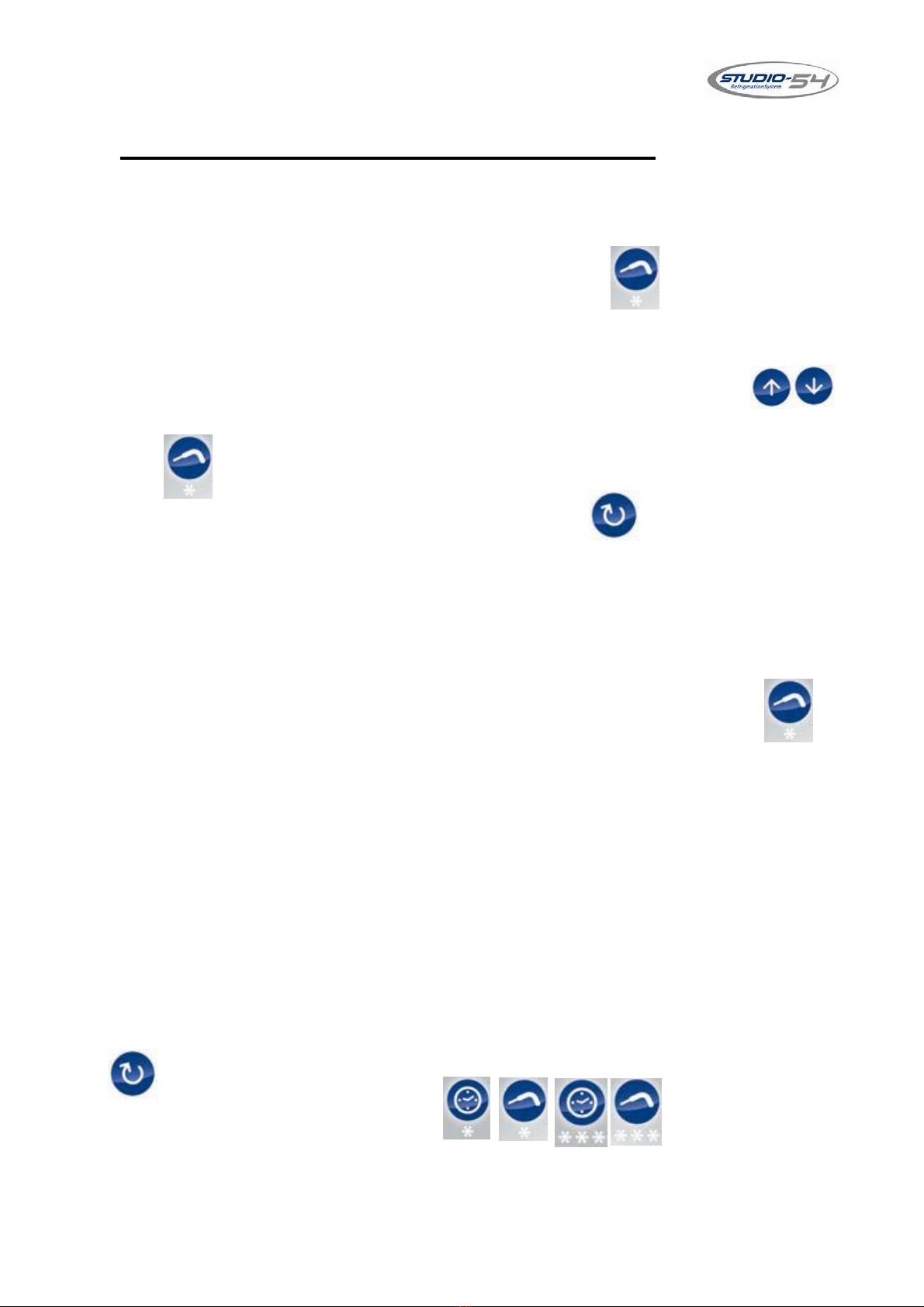

6.1 Icons

7. INSTRUCTION FOR THE STARTING OF THE BLAST

CHILLING AND SHOCK FREEZING CYCLES

Here follow the setting instructions for the starting of the most common functions

of the appliance.

N.B. FOR A BETTER WORKING OF THE APPLIANCE, REMEMBER TO

MAKE AN AUTOMATIC DEFROSTING AFTER 2/3 CONSECUTIVE BLAST

CHILLING/FREEZING CYCLES.

SUCH OPERATION CAN BE MADE KEEPING THE DOOR OPEN AND

PRESSING THE DEFROSTING KEY . THAT SUCCESSION OF

CONTROLS MAKES THE APPLIANCE GO INTO THE AUTOMATIC

DEFROSTING FUNCTION.

ATTENTION: We recommend you to insert the food probe 2 – 3 cm max

inside the product.

SYMBOL NAME

BLAST CHILLING icon

It flashes during the blast chilling cycle, it is switched on

during the successive preservation.

SHOCK FREEZING icon

It flashes during the shock freezing cycle, it is switched on

during the successive preservation.

PRESERVATION icon

It is switched on or it flashes during a preservation cycle.

TEMPERATURE icon

It is switched on during a temperature cycle.

TIME icon

It is switched on during a time cycle.

OFF icon

It is switched on when the digital control device is in off, it is

off with all the other functions.

FAHRENHEIT icon

It is switched on in red or green, depending by the colour of

the display, if it is displayed a temperature, and if the unit of

measurement is the Fahrenheit degree.

CELSIUS icon

It is switched on in red or green, depending by the colour of

the display, if it is displayed a temperature, and if the unit of

measurement is the Celsius degree.

ALEXANDER 5T - 10T - 15T

Ed.12/2011 8

7.1 SOFT TEMPERATURE BLAST CHILLING

Procedure to use the SOFT temperature blast chilling function:

1. Insert the probe in the food

2. Press the TEMPERATURE BLAST CHILLING key until when it

appears the word SOFT. After 3 seconds the displays shows the set point of

temperature of the cell during the blast chilling function (-5°C) in red light.

Such value can be changed pressing the increase and decrease

keys, and must be confirmed with the TEMPERATURE BLAST CHILLING

key .

3. Start the working cycle pressing the START key

4. The blast chilling cycle ends when the probe temperature goes to +3°C.

5. Now it automatically starts the preservation phase.

During the temperature blast-chilling phase it is always possible to visualize the

probe temperature pressing the TEMPERATURE BLAST CHILLING key

In that way, on the display will appear for 5 seconds the probe temperature in

green light.

Moreover, it is always possible to visualize the passed time from the beginning of

the cycle pressing the TIME BLAST CHILLING key .

In that way, on the display it will appear for 5 seconds the passed time from the

beginning of the cycle in green light.

When it is time to remove the food from the blast chiller/freezer press the START

key .

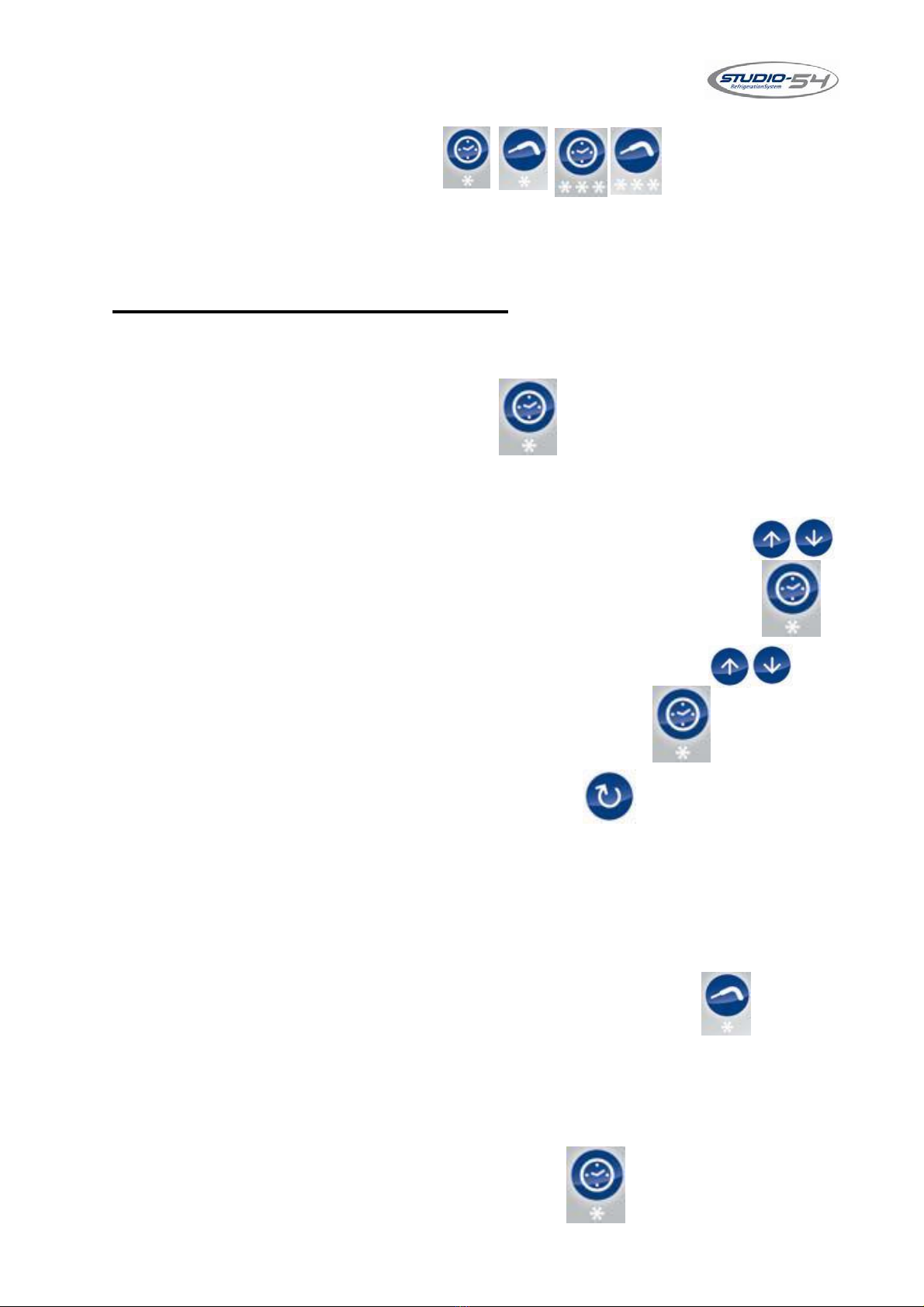

Pressing for 3 seconds one of the keys the digital control

device goes in standby and the machine is ready for a new cycle.

ALEXANDER 5T - 10T - 15T

Ed.12/2011 9

7.2 HARD TEMPERATURE BLAST CHILLING

Procedure to use the HARD temperature blast chilling function:

1. Insert the probe in the food

2. Press the TEMPERATURE BLAST CHILLING key until when it

appears the word HARD. After 3 seconds the displays shows the set point

of temperature of the cell during the blast chilling function (-5°C) in red light.

Such value can be changed pressing the increase and decrease

keys, and must be confirmed with the TEMPERATURE BLAST CHILLING

key .

3. Start the working cycle pressing the START key

4. The blast chilling cycle ends when the probe temperature goes to +3°C.

5. Now it automatically starts the preservation phase.

During the temperature blast-chilling phase it is always possible to visualize the

probe temperature pressing the TEMPERATURE BLAST CHILLING key

In that way, on the display will appear for 5 seconds the probe temperature in

green light.

Moreover, it is always possible to visualize the passed time from the beginning of

the cycle pressing the TIME BLAST CHILLING key .

In that way, on the display it will appear for 5 seconds the passed time from the

beginning of the cycle in green light.

When it is time to remove the food from the blast chiller/freezer press the START

key .

Pressing for 3 seconds one of the keys the digital control

device goes in standby and the machine is ready for a new cycle.

ALEXANDER 5T - 10T - 15T

Ed.12/2011 10

7.3 SOFT TIME BLAST CHILLING

Procedure to use the SOFT time blast chilling function:

1. Insert the probe in the food

2. Press the TIME BLAST CHILLING key until when it appears the word

SOFT. After 3 seconds the displays shows the set point of temperature of

the cell during the blast chilling function (-5°C) in red light.

Such value can be changed pressing the increase and decrease

keys, and must be confirmed with the TIME BLAST CHILLING key .

3. Set the desired working time with the increase and decrease

keys and confirm with the TIME BLAST CHILLING key .

4. Start the working cycle pressing the START key

5. The blast chilling cycle ends when the set time as during of chilling phase

has passed.

6. Now it automatically starts the preservation phase.

During the time blast-chilling phase it is always possible to visualize the probe

temperature pressing the TEMPERATURE BLAST CHILLING key

In that way, on the display will appear for 5 seconds the probe temperature in

green light.

Moreover, it is always possible to visualize the passed time from the beginning of

the cycle pressing the TIME BLAST CHILLING key .

In that way, on the display it will appear for 5 seconds the passed time from the

beginning of the cycle in green light.

When it is time to remove the food from the blast chiller/freezer press the START

key .

ALEXANDER 5T - 10T - 15T

Ed.12/2011 11

Pressing for 3 seconds one of the keys the digital control

device goes in standby and the machine is ready for a new cycle.

7.4 HARD TIME BLAST CHILLING

Procedure to use the HARD time blast chilling function:

1. Insert the probe in the food

2. Press the TIME BLAST CHILLING key until when it appears the word

SOFT. After 3 seconds the displays shows the set point of temperature of

the cell during the blast chilling function (-5°C) in red light.

Such value can be changed pressing the increase and decrease

keys, and must be confirmed with the TIME BLAST CHILLING key .

3. Set the desired working time with the increase and decrease

keys and confirm with the TIME BLAST CHILLING key .

4. Start the working cycle pressing the START key

5. The blast chilling cycle ends when the set time as during of chilling phase

has passed.

6. Now it automatically starts the preservation phase.

During the time blast-chilling phase it is always possible to visualize the probe

temperature pressing the TEMPERATURE BLAST CHILLING key

In that way, on the display will appear for 5 seconds the probe temperature in

green light.

Moreover, it is always possible to visualize the passed time from the beginning of

the cycle pressing the TIME BLAST CHILLING key .

ALEXANDER 5T - 10T - 15T

Ed.12/2011 12

In that way, on the display it will appear for 5 seconds the passed time from the

beginning of the cycle in green light.

When it is time to remove the food from the blast chiller/freezer press the START

key .

Pressing for 3 seconds one of the keys the digital control

device goes in standby and the machine is ready for a new cycle.

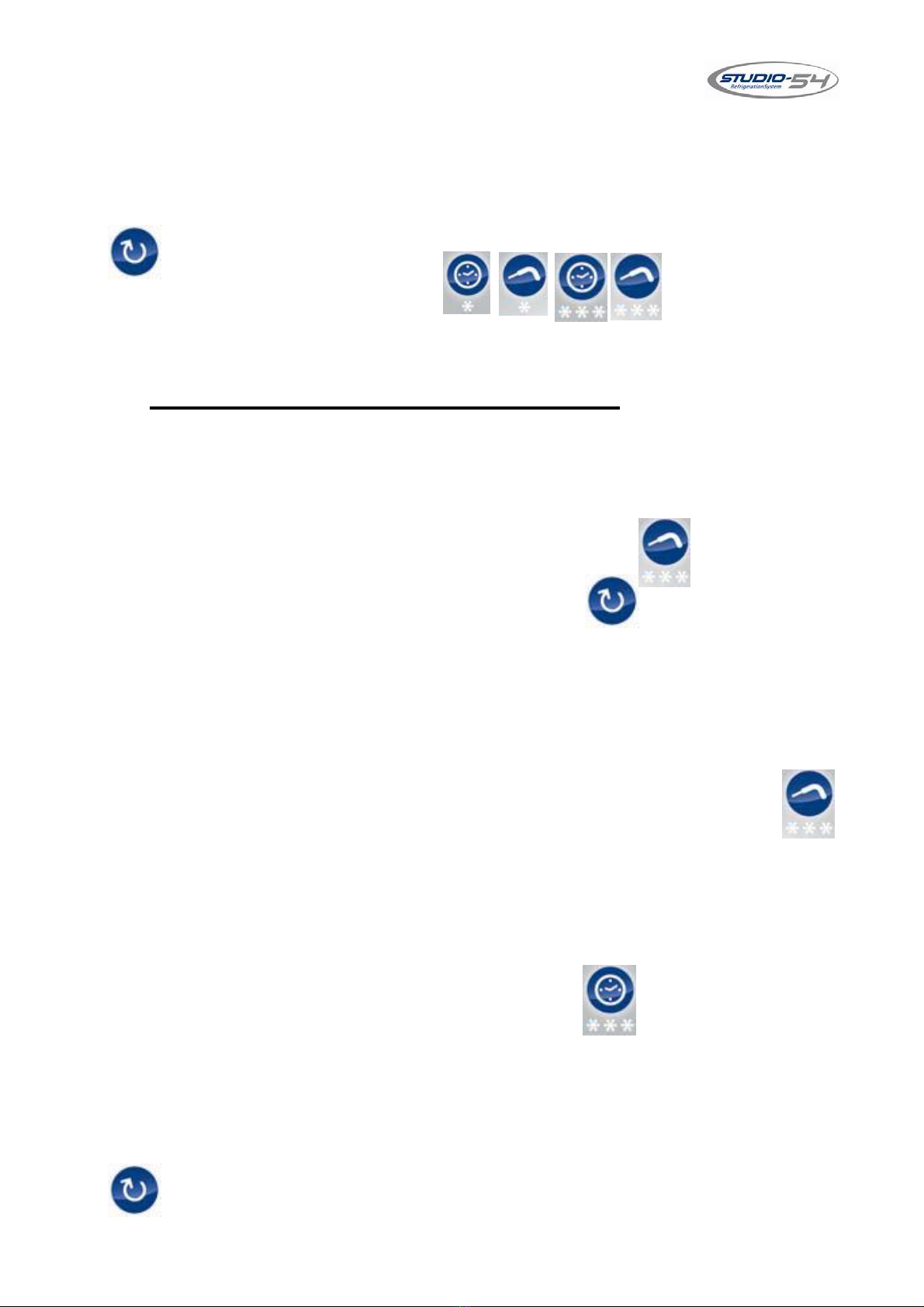

7.5 TEMPERATURE SHOCK FREEZING

Procedure to use the temperature shock freezing function:

1. Insert the probe in the food

2. Press the TEMPERATURE SHOCK FREEZING key

3. Start the working cycle pressing the START key

4. The blast chilling cycle ends when the probe temperature goes to -18°C.

5. It automatically starts the preservation phase.

During the temperature blast freezing phase it is always possible to visualize the

probe temperature pressing the TEMPERATURE SHOCK FREEZING key .

In that way, the probe temperature will appear in green light for 5 seconds on the

display.

Moreover, it is always possible to visualize the passed time from the beginning of

the cycle pressing the TIME SHOCK FREEZING key .

In that way, on the display will appear in green lighting for 5 seconds the passed

time from the beginning of the cycle.

When it is time to remove the food from the blast chiller/freezer press the START

key .

ALEXANDER 5T - 10T - 15T

Ed.12/2011 13

Pressing for 3 seconds one of the keys the digital control

device goes in standby and the machine is ready for a new cycle.

7.6 TIME SHOCK FREEZING

Procedure to use the time shock freezing function:

1. Insert the probe in the food

2. Press the TIME SHOCK FREEZING key

3. Set the desired working time with the increase and decrease

keys and confirm with the TIME SHOCK FREEZING key .

4. Start the working cycle pressing the START key

5. The shock freezing cycle ends when the set time as during of chilling phase

has passed.

6. Now it automatically starts the preservation phase.

During the time blast-chilling phase it is always possible to visualize the probe

temperature pressing the TEMPERATURE SHOCK FREEZING key

In that way, on the display will appear for 5 seconds the probe temperature in

green light.

Moreover, it is always possible to visualize the passed time from the beginning of

the cycle pressing the TIME SHOCK FREEZING key .

In that way, on the display it will appear for 5 seconds the passed time from the

beginning of the cycle in green light.

When it is time to remove the food from the blast chiller/freezer press the START

key .

Pressing for 3 seconds one of the keys the digital control

device goes in standby and the machine is ready for a new cycle.

ALEXANDER 5T - 10T - 15T

Ed.12/2011 14

8. USE ADVICES

N.B. ATTENTION: THE BLAST CHILLER/FREEZER MUST NOT BE USED

AS A NORMAL REFRIGERATING APPLIANCE.

N.B. DO NOT INSERT FOOD WITH HIGHER TEMPERATURE THAN 70°C:

THE ELECTRICAL CONTROL DEVICE WILL INDICATE AN ERROR.

It is advisable, to have the best performances from the appliance, to chill the

chamber making a whole working cycle (chilling or freezing) at least until the

achieving of the preservation temperature, before putting inside the product.

Moreover, to avoid damages to the appliance:

•Do not leave the hot product inside the appliance without starting a cycle.

•Start immediately the suitable working cycle only just after having put inside

the product to treat.

•Avoid covering the inside holders (also with isolating films): the best

performances and times are with the maximum quantity of exposed surface.

•Do not overload the appliance:

5T chilling 16 kg – freezing 12 kg;

10T chilling 38 kg – freezing 25 kg;

15T chilling 60 kg – freezing 45 kg;

•In order to allow a better air circulation, leave a sufficient space between the

inserted holders.

•Place the inserted holder on the supplied grates and not directly on the

bottom part.

N.B. REMEMBER PERIODICALLY TO CHECK THE DEFROSTING WATER

PAN PUT ON THE BOTTOM OF THE APPLIANCE, AND TO EMPTY IT.

8.1 FEAURES OF THE PRODUCT TO TREAT

Considering that the referring timings of the cycles start from +70°C

(chilling cycle from +70°C to +3°C; freezing cycle from +70°C to -18°C :

•Do not leave the food for long time in ambient temperature: the higher is the

humidity lost from the product, the lower will be the preserved softness.

•Insert the product at a higher temperature than +70°C.

ALEXANDER 5T - 10T - 15T

Ed.12/2011 15

N.B. PULL OUT THE PROBE FROM THE TREATED FOOD TAKING IT UP

BY THE RIGID PART OF IT AND NOT PULLING IT BY THE CABLE. THE

WRONG ACTION CAN CAUSE ITS BREAKING, AND ITS SUBSTITUTION

WILL NOT BE DONE UNDER WARRANTY.

9. ROUTINE MAINTENANCE

In order to make ad adequate maintenance of the appliance, the user, the

maintenance man or the non-specialized staff must firstly keep in mind the

elementary safety rules quoted on paragraph n. 1 GENERAL INFORMATION.

Then, it is also compulsory to not remove the safety devices and the protections

during the routine maintenance.

OTHERWISE, THE PRODUCING COMPANY DECLINES ANY

RESPONSIBILITY FOR DAMAGES OR ACCIDENTS RESULTING FROM THE

FAILURE TO COMPLY WITH THE ABOVE-STATED OBLIGATION.

Considered the previous rules, the cleaning of the cooled storage must be done

daily, in order to guarantee the best quality and the perfect sanitariness of the

treated products. Use water and non-abrasive cleansing agents. Wash and rinse

using a cloth or a sponge.

N.B. NO SHARP OR ABRASIVE INSTRUMENTS, NO SOLVENTS OR

DILUENTS

For a better air circulation, keep clean also the condensing unit (part 10) removing

from its wings dust etc. To reach the condensing unit, you must pull out the plug

from the electrical socket, and unscrew the front panel (part 14) paying attention

on not putting in excessive traction the electrical connections. Use a vacuum

cleaner in order of not having a dispersion of dust. Do not scrape with sharp or

abrasive instruments.

At the end, reassemble the front panel closing the fixing screws.

The defrosting water goes inside a tank in the bottom of the blast chiller/freezer.

In case of extraordinary maintenance to the refrigerating system, it is possible to

remove the back panel, and also the lateral panel if necessary. Such operations

can be made exclusively by refrigerator or authorised technicians, and only after

having pull out the plug from the electrical socket.

ALEXANDER 5T - 10T - 15T

Ed.12/2011 16

10. ALARMS LIST

Here following we explain you the most frequent alarms of this appliance.

For any further information, we suggest you to read the enclosed owner’s

instructions of the digital control device EVC80S10P7XXX01

CODE PROBLEM SOLUTION

Er 1 Failure chamber probe Check connections an functioning of the

chamber probe

Er 2 Failure product probe Check connections an functioning of the

product probe

Er 3 Failure evaporator

probe (only if enabled)

Check connections an functioning of the

evaporator probe

Er 4 Failure condenser

probe (only if enabled)

Check connections an functioning of the

condenser probe

AL 1 Open door alarm Close the door

AL 2 High pressure alarm Remove the alarm cause, turn off and

switch on the appliance

AL 3

High temperature

condensing alarm (only

if enabled)

Wait the condenser drop in temperature

AL 4 Not inserted pin Check the pin insertion

ALEXANDER 5T - 10T - 15T

Ed.12/2011 17

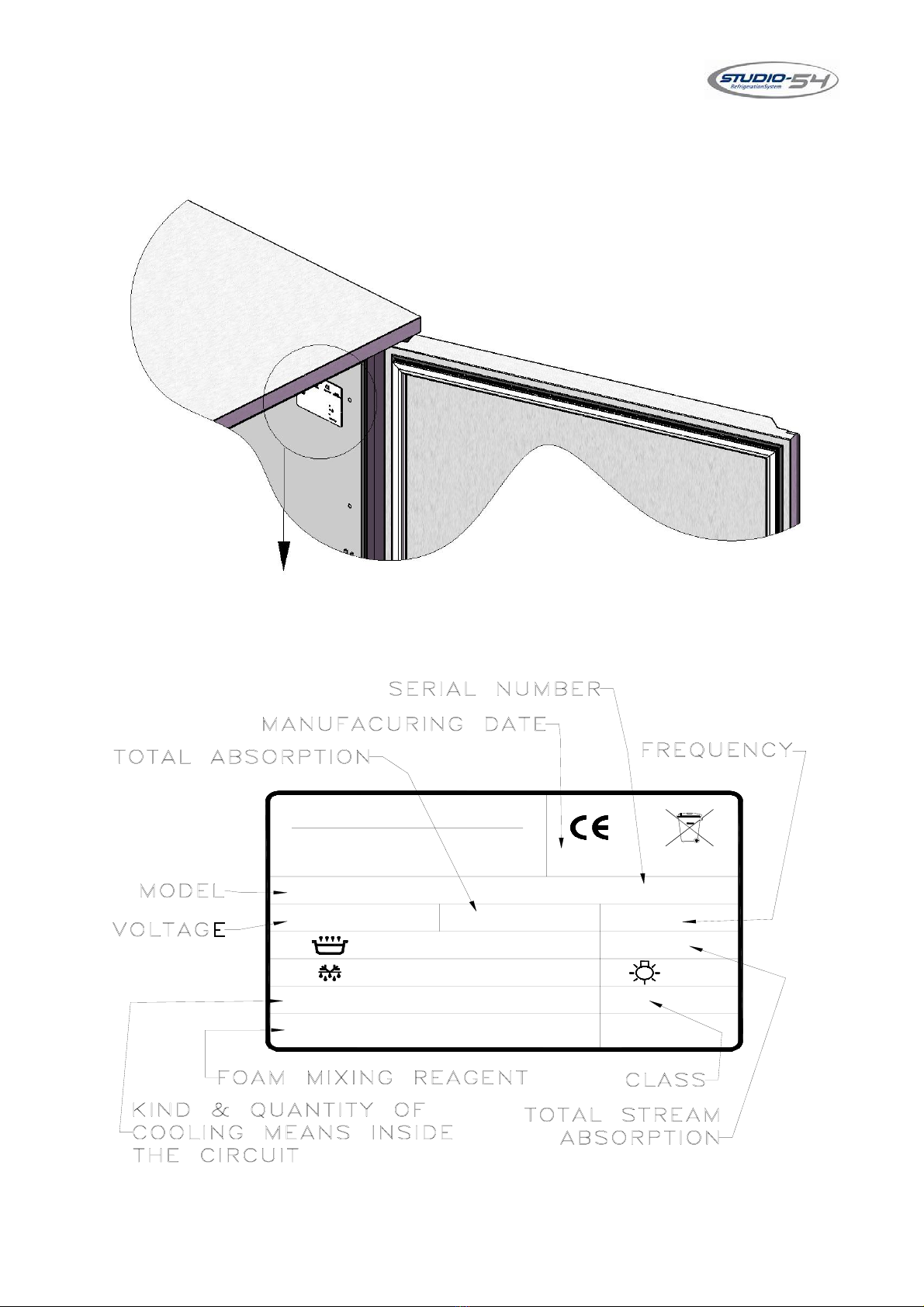

CE PLATE

STUDIO 54 S.r.l

Via Gian Lorenzo Bernini 147

35010 S.Giorgio in Bosco (PD) Italy

Tel. 049-9450466 Fax 049-9451044

01/01/2000 IT08020000000717

MOD. ALEXANDER 10 T

V 400/3N

made in Italy

W /

Nr. 00000001

W 2140 H z 50

A 3,08

Cl. 4

Gas (1) R404A

Gas (2) HSC365/227

Kg (1) 1,900

W /

W /

ALEXANDER 5T - 10T - 15T

Ed.12/2011 18

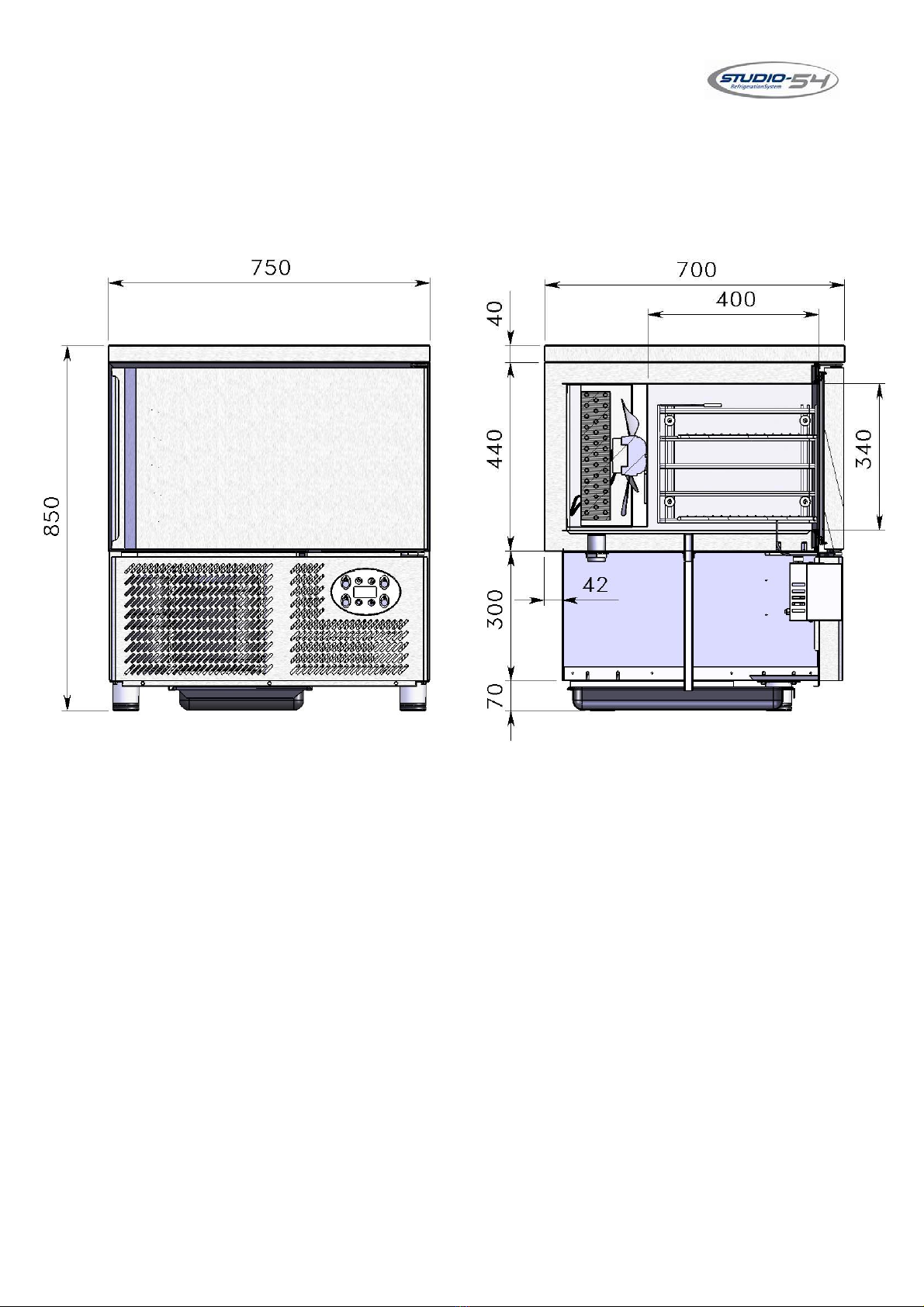

ALEXANDER 5T

ALEXANDER 5T - 10T - 15T

Ed.12/2011 19

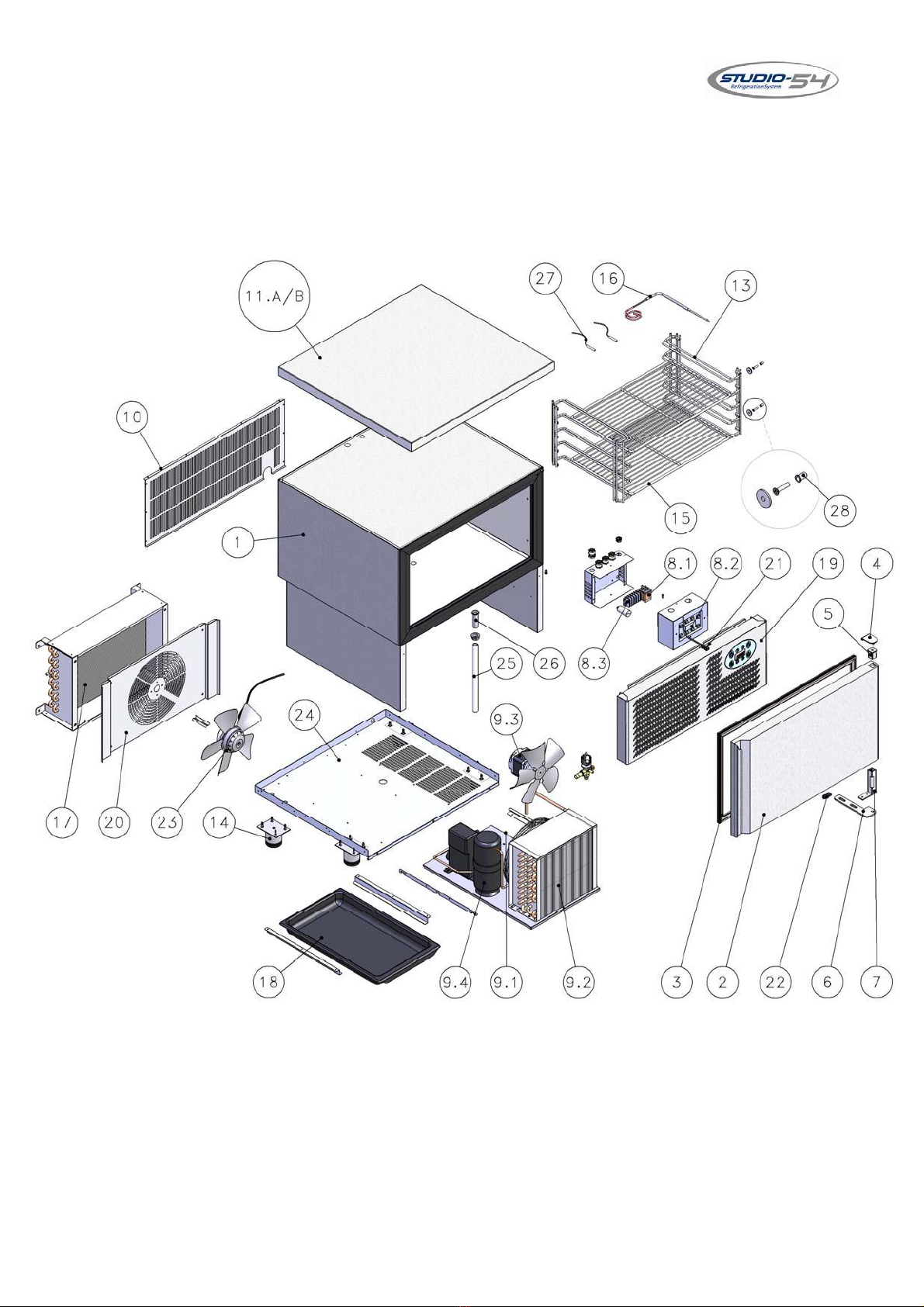

11. ALEXANDER 5T EXPLODED VIEW

ALEXANDER 5T - 10T - 15T

Ed.12/2011 20

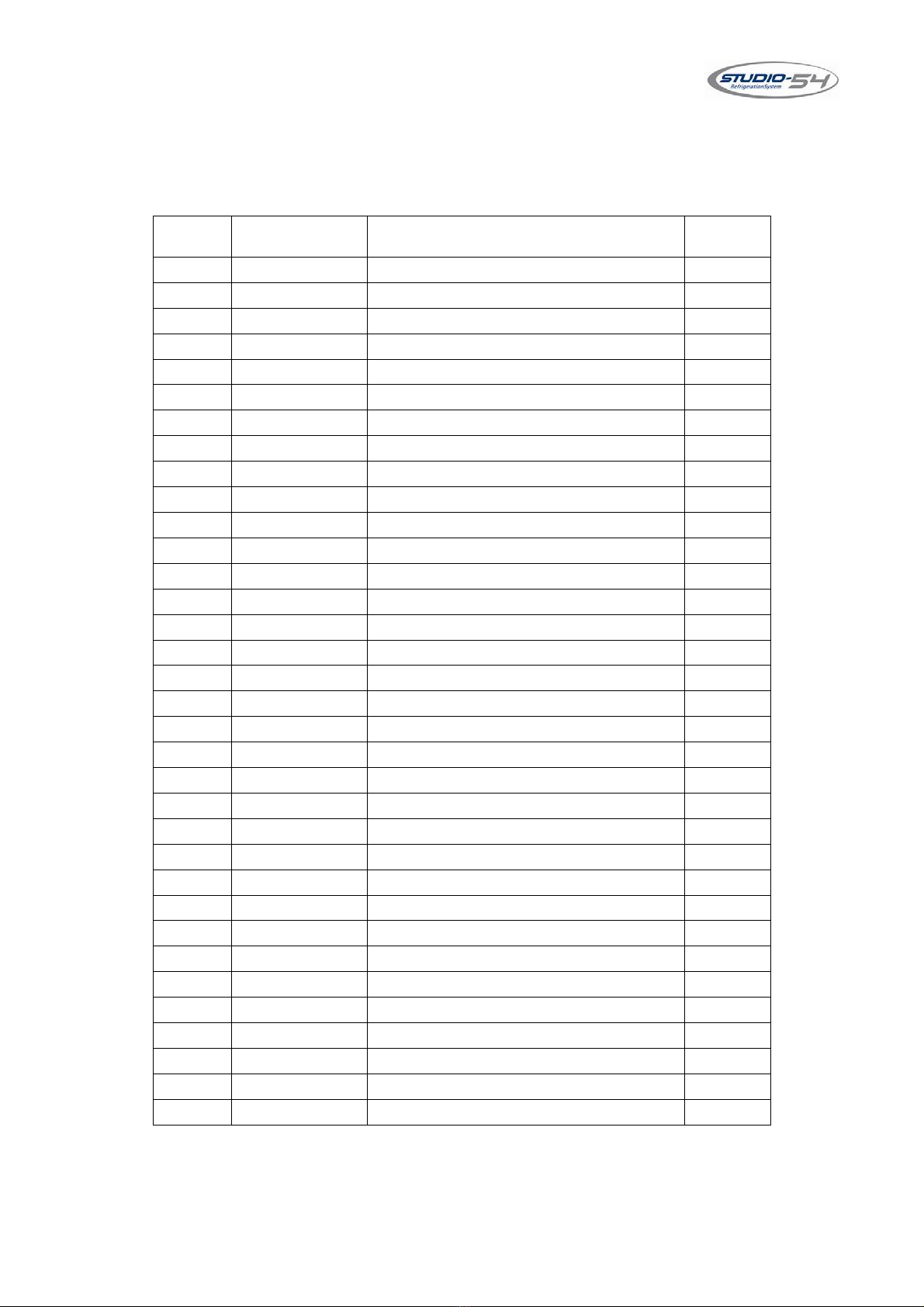

12. SPARE PARTS ALEXANDER 5T LIST

Articolo

num.

NUMERO

PARTE Descrizione Quantità

1 63600370 INSULATED BODY 1

2 63600363 INSULATED DOOR 1

3 64691084 MAGNETIC GASKET 1

4 62500260 SUPERIOR DOOR HINGE 1

5 64700132 BEARING IN PVC 1

6 62500130 INFERIOR DOOR HINGE 1

7 64700128 LOWER TWISTING HINGR 1

8.1 64740150 RELAY 1

8.2 64740178 TEMPERATURE CONTROL DEVICE 1

8.3 64740033 TERMINAL BOX 5 1

9.1 64850320 COMPRESSOR T2180GK 1

9.2 64840105 CONDENSER 1

9.3 64840112 CONDENSER FAN MOTOR 1

9.4 64850323 TANK 1,6 Lt. 1

10 62454024 BACK COVER STEEL 1

11.A 63600245 WORKING TOP 1

11.B 63600253 WORKING TOP WITH SPLASHBACK 1

13 64700112 TRAY HOLDER FRAME 2

14 64700066 FEET H=70 4

15 64700091 GRATE 530x325 1

15 64700092 GRATE 600x400 1

16 64740160 PIN PROBE 1

17 64860166 EVAPORATOR 1

18 64740105 DEFROSTING WATER TANK 1

19 62454054 ELECTRICAL SWITCH PANEL 1

20 62454038 SUPPORT STEEL EVAPORATOR FAN 1

21 64740096 DOOR MICRO-SWITCH 1

22 64740098 DOOR MICRO-SWITCH 1

23 64840101 EVAPORATOR FAN 1

24 62454066 BOTTOM 1

25 64700213 DISCHARGE Ø20x75 1

26 64700159 DISCHARGE Ø20 1

27 64740165 PTC PROBE 2

28 64904053 INSERT M4 L=13mm 8

This manual suits for next models

2

Table of contents

Popular Freezer manuals by other brands

Electrolux

Electrolux ENS6TE19S user manual

Arctiko

Arctiko ULUF P390 Original operating instructions

BOMANN

BOMANN KB 9486 CB instruction manual

K2 Scientific

K2 Scientific K23ULT manual

Linea 2000

Linea 2000 DOMO DO920DV Instruction booklet

Beko

Beko COOL74FDS Installation, operation & food storage instructions