Sturtevant Richmont Global 400 User manual

Global 400 User Manual

!

v1.1!revision!1!

2 February 2016 Manual Part Number 857412

Global 400 User Manual 2 of 85 v1.1 revision 1

2 February 2016

Table of Contents

Quick Start ...................................................................................................................................... 4!

Chapter 1: Overview ....................................................................................................................... 9!

Warnings ................................................................................................................................... 10!

Cautions .................................................................................................................................... 10!

Unit Overview........................................................................................................................... 11!

Compatible Tools...................................................................................................................... 11!

Chapter 2: Using the unit .............................................................................................................. 12!

Concepts.................................................................................................................................... 13!

Run Screen ................................................................................................................................ 14!

History....................................................................................................................................... 17!

Unit Status................................................................................................................................. 18!

Rundown Graph ........................................................................................................................ 19!

Network Status.......................................................................................................................... 19!

Tool Status ................................................................................................................................ 20!

I/O State .................................................................................................................................... 21!

Chapter 3: Configuring the unit .................................................................................................... 22!

Introduction............................................................................................................................... 23!

Saving Configuration Changes ................................................................................................. 23!

Entering letters .......................................................................................................................... 23!

Main Menu................................................................................................................................ 24!

Tools ......................................................................................................................................... 25!

Parameters................................................................................................................................. 28!

Groups....................................................................................................................................... 33!

Jobs ........................................................................................................................................... 35!

Network Setup .......................................................................................................................... 37!

Unit Setup ................................................................................................................................. 38!

Enter new Password.................................................................................................................. 42!

Reset Defaults ........................................................................................................................... 43!

Channel Change ........................................................................................................................ 44!

Events........................................................................................................................................ 45!

Global 400 User Manual 3 of 85 v1.1 revision 1

2 February 2016

Chapter 4: Serial communications ................................................................................................ 46!

Introduction............................................................................................................................... 47!

Barcode ..................................................................................................................................... 47!

Serial Printer ............................................................................................................................. 50!

Chapter 5: Atlas Copco Open Protocol......................................................................................... 52!

Introduction............................................................................................................................... 53!

Using Groups with Atlas Copco Open Protocol ....................................................................... 53!

Configuration Options .............................................................................................................. 53!

Supported Commands............................................................................................................... 56!

Unsupported Commands........................................................................................................... 57!

Chapter 6: ToolsNet...................................................................................................................... 59!

Introduction............................................................................................................................... 60!

Configuration Options .............................................................................................................. 60!

Chapter 7: EtherNet/IPTM.............................................................................................................. 62!

Vendor-Specific Objects........................................................................................................... 63!

Assembly Object Connection Points ........................................................................................ 71!

Backwards Compatibility Assembly Object Connection Points .............................................. 74!

Chapter 8: Data Management ....................................................................................................... 79!

Download data to USB ............................................................................................................. 80!

Upload USB file to device ........................................................................................................ 81!

Chapter 9: Firmware Updates ....................................................................................................... 82!

Chapter 10: Product Specifications............................................................................................... 84!

Dimensions ............................................................................................................................... 85!

Radio Information..................................................................................................................... 85!

Global 400 User Manual 4 of 85 v1.1 revision 1

Quick Start 2 February 2016

Quick Start

Global 400 User Manual 5 of 85 v1.1 revision 1

Quick Start 2 February 2016

This quick start will guide you through the process of configuring the unit for first time use.

Plug the provided power cable into the unit and 100-240

VAC power and turn on the power switch. The beeper

should sound a series of quick beeps and the display should

show the loading progress.

Once the loading is completed, the unit should go to the

Run screen. If the unit stays on the loading screen with an

error, please contact support.

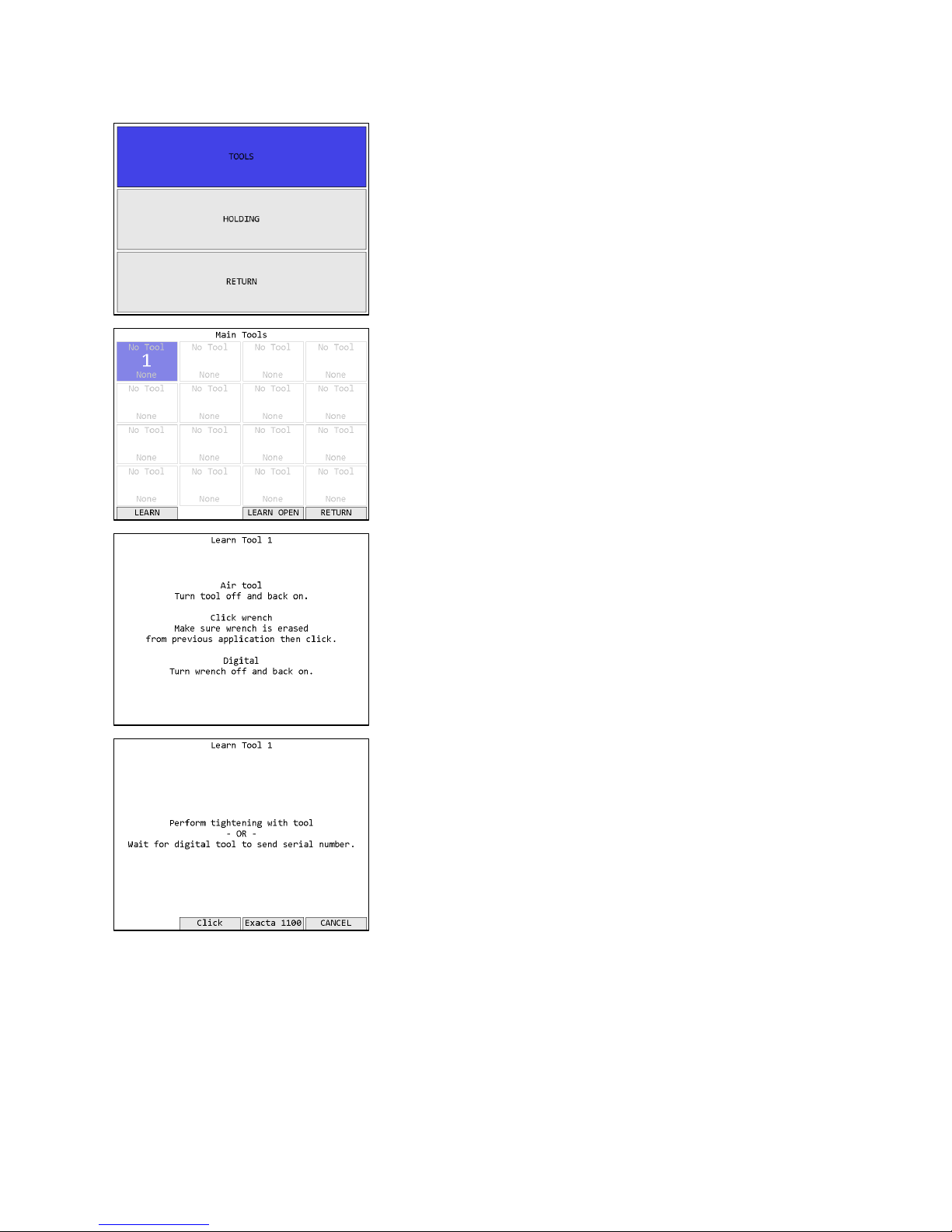

To use a tool with the Global 400, you must first “learn” the

tool to the Global 400. To do so, press the button below

MENU.

Enter the password (0104 by default) using the numeric

keypad and pressing ENT when completed.

In the menu, press the right arrow to select TOOLS and

press ENT.

Global 400 User Manual 6 of 85 v1.1 revision 1

Quick Start 2 February 2016

In the tools menu, press ENT to go to the main tools page.

If the tool you are going to learn to the Global 400 has

previously been used with another unit, make sure the tool

has been “forgotten” from that unit before continuing. Press

the button beneath LEARN to begin the learn process.

Follow the directions on screen to learn the tool.

Once the tool has found the unit, you may need to perform

an additional step for the unit to know which type of tool

was just learned. Holding tools, air tools, and newer click

tools can be distinguished by the unit, but digital tools and

older click tools will be require some additional

information. The digital tools will automatically transmit

their serial number in a few seconds. However, if you are

learning an older click tool, you will need to perform a

tightening (good or bad) with the wrench, or push the

appropriate button on screen.

Global 400 User Manual 7 of 85 v1.1 revision 1

Quick Start 2 February 2016

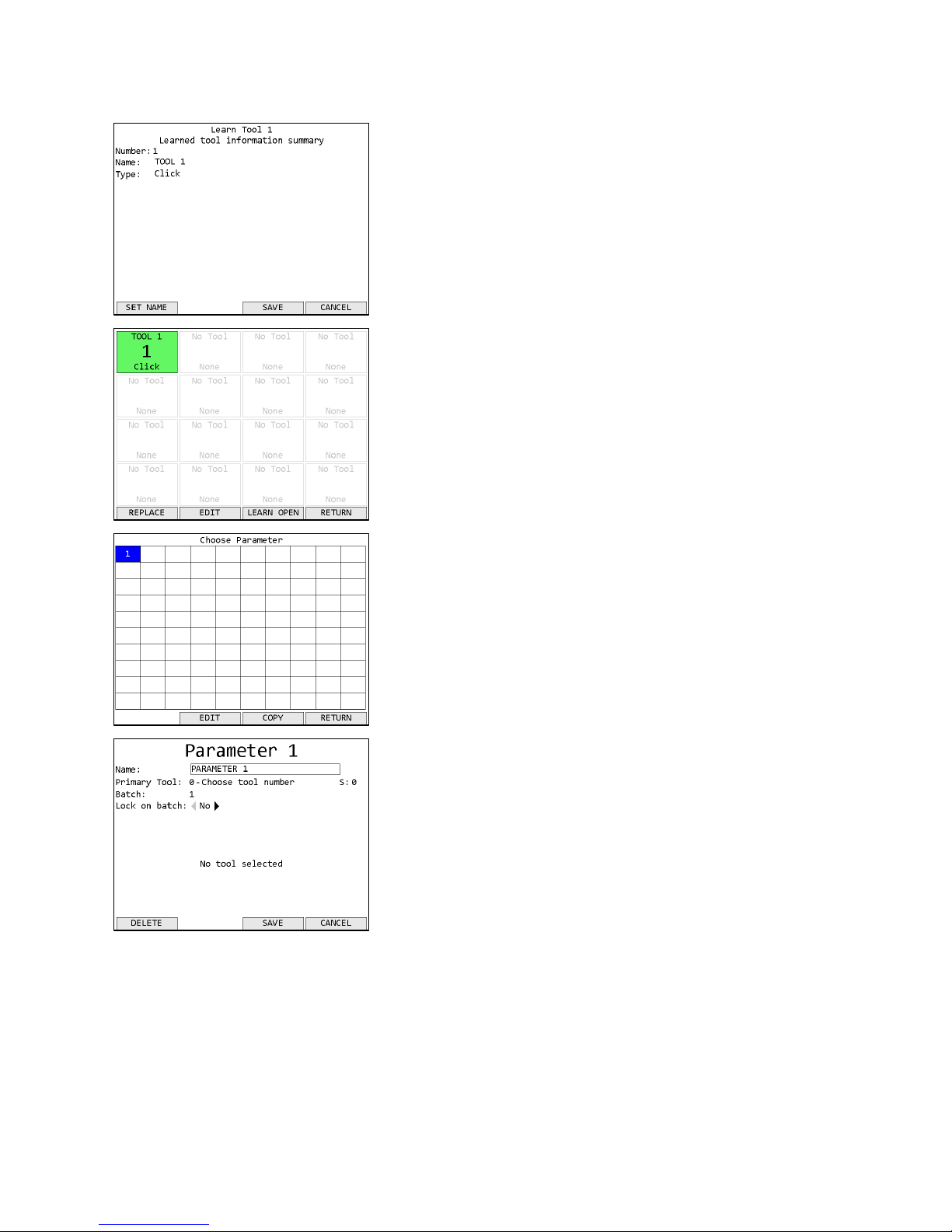

Once the tool learn is completed, the unit will show a

summary of the new tool information. Press SAVE to store

the tool information and continue.

The unit will return to the Tools screen with the just learned

tool now with a tool name of “TOOL 1” instead of “No

Tool”. If the just learned tool is a digital tool, the default

name will be the tool serial number.

Before you can run the tool, you must first assign it to a

parameter. Return to the menu by pressing ESC twice.

Then press ENT to go to the Choose Parameter screen.

Press the button below EDIT to go to the Parameter Edit

screen.

Press the down arrow to move the cursor to the Primary

Tool row, followed by 1 to assign the tool to the parameter.

Press ENT or the button below SAVE to save the changes

and return to the Choose Parameter screen.

Global 400 User Manual 8 of 85 v1.1 revision 1

Quick Start 2 February 2016

Parameter 1 should now be shown in black instead of white

to indicate that it was set up successfully. Press the button

below SELECT to select Parameter 1.

You will be returned to the Run screen, now with Parameter

1 selected. You can now perform tightenings with Tool 1

that will be monitored, stored, and reported by the qualifier.

Global 400 User Manual 9 of 85 v1.1 revision 1

Chapter 1: Overview 2 February 2016Chapter 1: Overview 2 February 2016

Chapter 1: Overview

Global 400 User Manual 10 of 85 v1.1 revision 1

Chapter 1: Overview 2 February 2016

Warnings

Do not disassemble the unit for repair or modifications. There is a high

electrical voltage inside the unit that could cause electric shock.

Do not allow any type of liquid to come into contact with any part of the

unit.

Insert all fittings fully into their mating receptacles. Failure to do so could

result in injury.

Do not fold, bend or apply excessive force to any cable or fitting.

Cautions

Please use caution when handling this or any other electrical appliance.

•This unit accepts an AC input voltage from 100-240 VAC. Trying to operate this unit with a

voltage outside that range may cause damage to the unit.

•Avoid placing or storing this unit in a location where it may become wet or dust covered.

•Do not place or mount this unit in an unstable area.

•Dropping this unit may result in personal injury or damage to the unit.

•Before performing any maintenance on the unit, make sure to turn it off and remove the

power plugs.

•There are no user serviceable parts inside the main enclosure of the unit.

Global 400 User Manual 11 of 85 v1.1 revision 1

Chapter 1: Overview 2 February 2016

Unit Overview

The Global 400 is equipped with a color LCD display, four function

keys immediately below the LCD, a numeric keypad with decimal

point, navigation keys, and enter and escape buttons. The current

function of the function keys is indicated at the bottom of the LCD

above the button.

The beeper provides an audio indication for any combination of

accepts, rejects, and batch completions. The beeper volume can be

adjusted through the user interface. (See the Unit Setup section in the

next chapter.)

The Global 400 has two RJ-45 Ethernet ports to allow it to be used in a

chain or ring network configuration.

The USB-A connector is used to provide firmware updates via a

standard USB drive.

The RS232 DSUB9 connector can be used with a serial barcode reader

or serial printer.

The 5-pin remote connector connects to other devices that provide I/O

capabilities.

The power plug accepts 100-240 VAC at 50-60 Hz.

Compatible Tools

The Global 400 works with the following models of tools:

•SLTC-FM 2.4 GHz preset clicker-type torque wrenches

•1100-Series Exacta 2 digital torque wrenches

•PST series air tool transducers

•Holding wrenches

Global 400 User Manual 12 of 85 v1.1 revision 1

Chapter 2: Using the unit 2 February 2016

Chapter 2: Using the unit

Global 400 User Manual 13 of 85 v1.1 revision 1

Chapter 2: Using the unit 2 February 2016

Concepts

Tools

The Global 400 can associate with up to 16 Sturtevant Richmont radio torque tools and 8 holding

tools. At most, 4 torque tools and 4 holding tools will be active at a time, depending on the

selected operation. To use a tool with the Global 400, you must first “learn” the tool to the

qualifier. The process to do this is described in the Quick Start.

Tools are not activated directly by the unit. Instead, they are activated when a parameter that

uses the tool is running. A tool may be used by more than one parameter.

The Global 400 can store some information about when calibration or preventative maintenance

should occur. These are set up in the Tool Configuration screen, which is described in the next

chapter.

Parameters

Parameters are the basic unit of operation for the Global 400. A parameter contains a tool to run

and some settings to use with it, such as the batch size and minimum and maximum torques. The

Global 400 supports 100 parameters. Each parameter must be associated with one of the learned

tools before it can be run.

A parameter may additionally have a holding tool assigned.

Groups

Groups are multiple parameters that must all run together and can run simultaneously in any

order. The Global 400 supports 100 groups with up to 4 parameters each. A group cannot

contain more than one parameter that uses a given tool, as it would not be able to determine

which parameter a result should be assigned to. Additionally, a group may only contain

parameters with the same type of primary tools. When defining a group, you may override the

batch count for parameters in the group while the group is running. This does not change the

batch size defined in the parameter. When running a group, all parameters must complete a full

batch before any parameter can begin running a second batch.

Jobs

Jobs are the top level of operation in the Global 400, made up of multiple parameters or groups

that must all run together in a sequence. The Global 400 supports 100 jobs with up to 30 steps

each. Unlike groups, a job may have multiple parameters that use the same tool or even the same

parameter or group multiple times and may use parameters with different types of primary tools.

As with groups, you may override the batch count for parameter steps in the job. You cannot

change the batch sizes for groups when run in a job.

Global 400 User Manual 14 of 85 v1.1 revision 1

Chapter 2: Using the unit 2 February 2016

Run Screen

The run screen shows which parameters the unit is currently running. Depending on the number

of active parameters, the run screen will be in one of several modes.

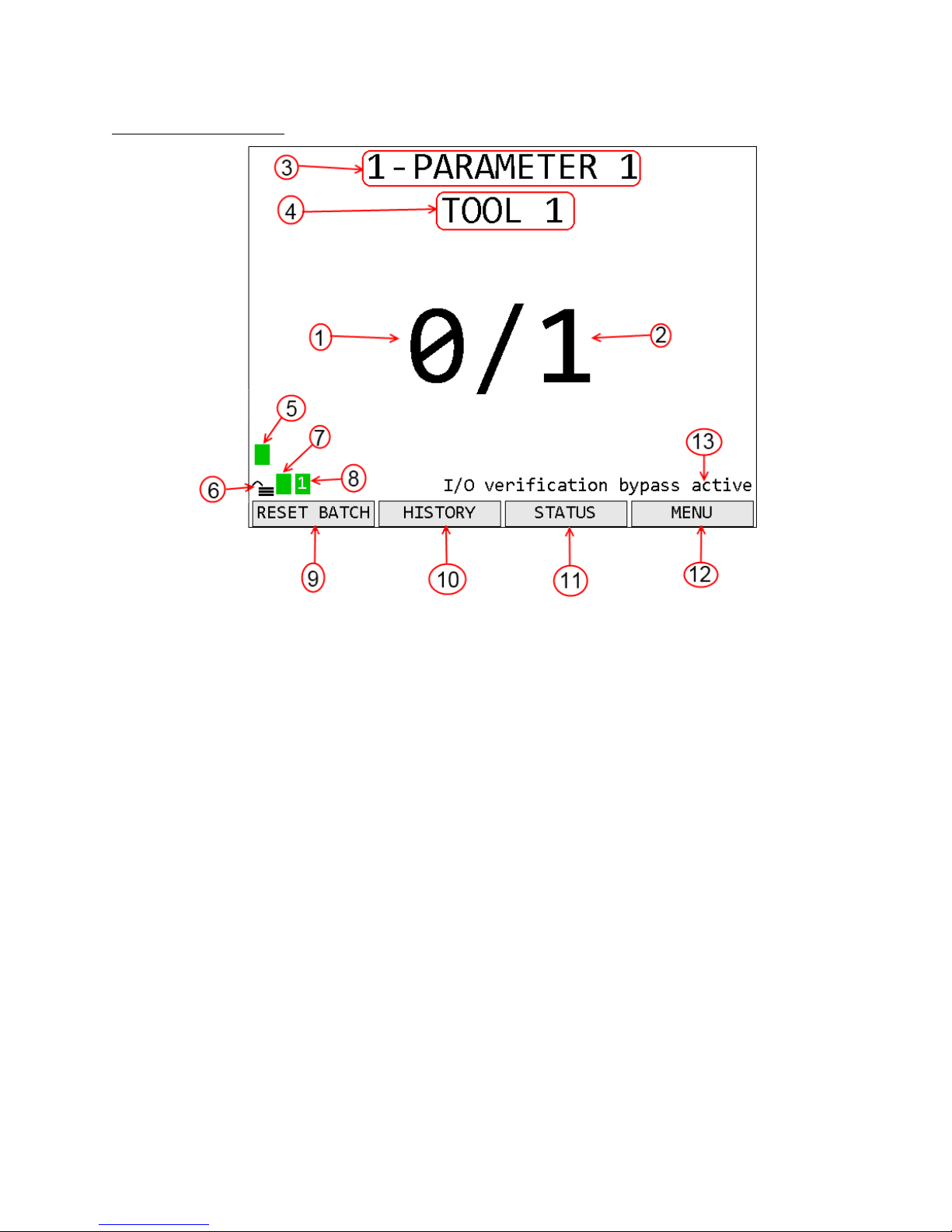

Figure 1: No active parameter

Figure 2: Suspended

Figure 3: 1 active parameter

Figure 4: 2-4 active parameters

Tightening Notifications

Every time a tightening is received from a running tool, the background of the area of the screen

showing the current parameter and batch count for the tool will be shaded with a color indicating

the status of the tightening.

•Red – A rejected tightening occurred.

•Green – An accepted tightening occurred that did not complete a batch.

•Blue – An accepted tightening occurred that completed a batch. If the qualifier NOKs setting

is set to Count, this further indicates that no rejected tightenings were counted towards this

batch.

•Yellow – An accepted or rejected tightening occurred that completed a batch. This color will

only occur when the qualifier NOKs setting is set to Count and one or more rejected

tightenings were counted towards the current batch.

Global 400 User Manual 15 of 85 v1.1 revision 1

Chapter 2: Using the unit 2 February 2016

1 Active Parameter

1. Count – The number of tightenings completed in the current batch

2. Batch – The number of tightenings required for the current batch

3. Parameter Name – Name of the currently running parameter. When running a job, this is the

job name and the parameter name is shown below the tool name.

4. Tool Name – Name of the tool for the currently running parameter

5. Tool Status Indicator – Shows the status of the tool for the parameter

6. Unit lock – Indicates if the unit is locked and requires a password to access menu functions

7. Unit Radio Status – Shows the status of the unit radio

8. Network Status – Shows the status of the Ethernet and current number of connections.

9. Function key 1 – Shows the current function of function key 1.

10. Function key 2 – Shows the current function of function key 2.

11. Function key 3 – Shows the current function of function key 3.

12. Function key 4 – Shows the current function of function key 4.

13. Notifications – Shows notifications of unit status beyond radio and network statuses

Global 400 User Manual 16 of 85 v1.1 revision 1

Chapter 2: Using the unit 2 February 2016

2-4 Active Parameters

1. Count – The number of tightenings completed in the current batch of the parameter.

Repeated for each active parameter.

2. Batch – The number of tightenings required for the current batch of the parameter. Repeated

for each active parameter.

3. Group Name – Name of the currently running group.

4. Parameter Name – Name of the parameter. Repeated for each active parameter.

5. Tool Name – Name of the tool for the parameter. Repeated for each active parameter

6. Tool Status Indicator – Shows the status of the tool for the parameter. Repeated for each

parameter

7. Unit lock – Indicates if the unit is locked and requires a password to access menu functions

8. Unit Radio Status – Shows the status of the unit radio

9. Network Status – Shows the status of the Ethernet and current number of connections.

10. Function key 1 – Shows the current function of function key 1.

11. Function key 2 – Shows the current function of function key 2.

12. Function key 3 – Shows the current function of function key 3.

13. Function key 4 – Shows the current function of function key 4.

14. Inactive parameter – When not all the parameter slots on a screen are needed to show all the

active parameters, the rest of the slots will be grayed out.

Tool Radio Status Codes

The radio status indicator for each active parameter shows the status of the tool radio for the

parameter. When the tool is ready to run, the indicator should be green with no number. If the

tool is not ready to run or a warning or error condition occurs, the indicator will change to yellow

for a warning or red for an error and display a code to indicate the radio condition. The possible

codes are:

Global 400 User Manual 17 of 85 v1.1 revision 1

Chapter 2: Using the unit 2 February 2016

Code

Color

Meaning

1

Red

Tool has not communicated with the unit since power-up

2

Yellow

Enabling or disabling tool

2

Red

Tool programming failed

3

Yellow

Tool is disabled

4

Yellow

The battery is low. It should be changed when possible to avoid interruptions in service.

Only click and holding tools provide battery level information.

4

Red

The battery is very low. Interruptions in service may occur until the battery is replaced.

5

Yellow

Radio signal strength is below recommended level for best performance

5

Red

Radio signal strength is below recommended minimum level for use

6

Yellow

Tool requires calibration

7

Yellow

Tool requires preventative maintenance

Unit Radio Status Indicator

The unit radio status indicator shows the status of the radio in the unit. In normal use, the

indicator should be green with no number. If the radio is not working correctly, the indicator

will be red with an error code.

Network Status Indicator

The network status indicator shows the status of the Ethernet ports on the unit. When the

Ethernet is used, the indicator will be green and show the number of currently active network

connections. If no Ethernet cable is plugged into either port, the indicator will be yellow. If the

network initialization fails, the indicator will be red and show an error code. The Network Status

screen shows more detailed information.

History

Figure 5: History screen

Function keys

1. No function

2. PREVIOUS – Go to the previous page of more recent tightenings. When on the first page,

this key will be blank.

3. NEXT [ENT] – Go to the next page of older tightenings. When on the last page, this key

will be blank.

4. RETURN [ESC] – Returns to the Run Screen.

Global 400 User Manual 18 of 85 v1.1 revision 1

Chapter 2: Using the unit 2 February 2016

The History screen shows some information about the tightenings stored in unit memory. More

information about the tightenings is not shown but is available via the network protocols. This

screen shows

•Time – The time the tightening occurred. The date is indicated at the top of the table and

each time it changes in a white row.

•T# – The tool number that produced the tightening

•Param – The number and name of the parameter that produced the tightening

•Count – The current batch count and batch size for the tightening

•Torque – The torque of the tightening. This value is only provided for digital tools. The unit

of torque will be whatever the unit of the parameter that produced the tightening was at the

time.

•Id – The tightening id number. This screen shows only the last 4 digits of the id number;

additional digits may be present in the network commands.

Unit Status

Figure 6: Unit Status screen

Function keys

1. GRAPH – When a single air tool is running, goes to the Rundown Graph screen. For other

tool types or when a group is running, this key has no function.

2. NETWORK – Go to the Network Status screen.

3. TOOL – Go to the Tool Status screen.

4. I/O – Go to the I/O State screen

The Unit Status screen shows some basic information about the current unit configuration that

may be useful for diagnostics purposes. Press ESC to return to the Run Screen

The average signal strength is for all tools learned to the unit and should be from 0 to -70 dBm.

If the signal strength is weaker, the unit may have frequent slow or failed communication. To

improve the signal strength, try bringing the unit and tools closer together, changing the XBEE

channel, or reducing sources of interference from the environment.

Last barcode shows the command number of the last barcode scanned (see Chapter 4: Serial

communications) or an error if the last attempt barcode could not be processed. VIN and ID 2-4

show what will be included with tightenings in the associated result data fields.

Global 400 User Manual 19 of 85 v1.1 revision 1

Chapter 2: Using the unit 2 February 2016

Rundown Graph

Figure 7: Rundown Graph screen

Function keys

1. EDIT – Go to the Parameter Edit screen for the running parameter. This will require the

password to be entered.

2. No function

3. REFRESH – Refresh the graph with the data for the most recent run of the tool.

4. RETURN [ESC] – Returns to the Unit Status Screen.

The Rundown Graph screen retrieves and shows the last rundown from an air tool. The rundown

will be overlaid with yellow horizontal lines for each of the three thresholds and vertical lines

showing the timers, purple for Timer Min and Timer Max, blue for Timer Clutch. Additionally,

the total time for the rundown is shown at the right end of the horizontal axis.

Network Status

Figure 8: Network Status screen

The network status screen shows the current Ethernet status

of the unit. The MAC address is assigned by the factory

and cannot be changed. The IP address, subnet mask, and

gateway may be edited from the Network Setup - General

screen or assigned via DHCP.

The Ethernet 1 and 2 lines indicate if a physical cable

connection is detected on the corresponding Ethernet ports

of the unit. If no connection on a port is detected, the unit

will show “Not connected”. If a connection is detected, the

baud rate and duplex of the connection will be listed.

Global 400 User Manual 20 of 85 v1.1 revision 1

Chapter 2: Using the unit 2 February 2016

Tool Status

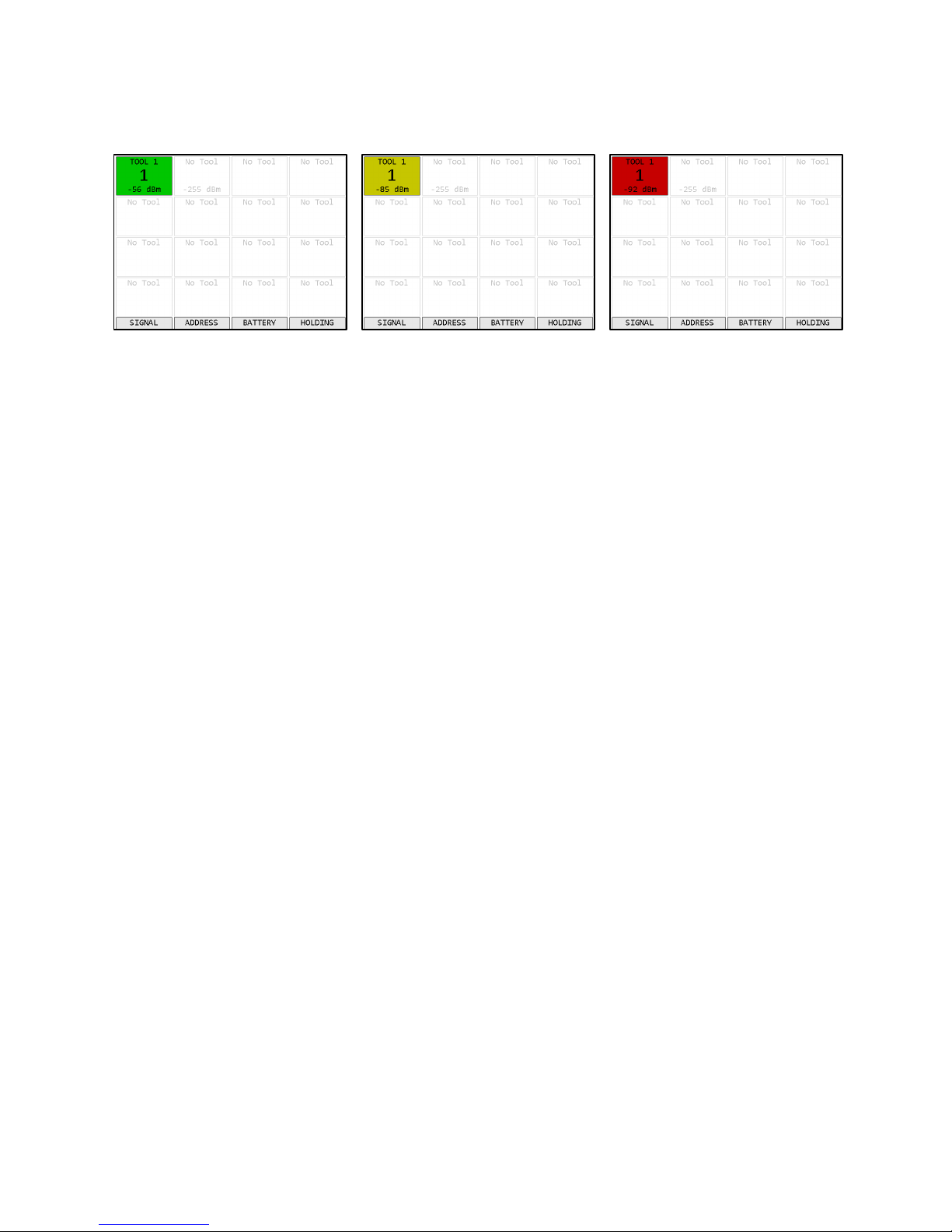

Figure 9: Tool Status - Good Signal

Figure 10: Tool Status – Low Signal

Figure 11: Tool Status - Bad Signal

Function keys

1. SIGNAL – Show the signal strength of each tool.

2. ADDRESS – Show the address of each tool

3. BATTERY – Shows the battery level of each tool, if available. Not all tools report battery

level.

4. HOLDING / TOOLS – Toggles between showing main tools and holding tools.

The Tool Status screen shows the status of the tools learned into the unit. This screen shows the

signal strength of the last packet from the tool but can also show the radio address and battery

level of the tools. Press ESC to return to the Unit Status screen.

For signal strength, a less negative number indicates a better signal (-50 dBm is better than -60

dBM). The screen shows a color based on the quality of the signal.

•Green – The signal from this radio is strong and will work at best performance.

•Yellow – The signal from the radio is weaker than recommended for best performance. The

radio should work but may have slower or occasionally interrupted communication with the

unit.

•Red – The signal from the radio is weaker than recommended for any use. The radio may

successfully transmit some results but will frequently have slow or failed communication

with the unit. If only one tool is red, bring it and unit closer together. If multiple tools are

red, consider using a different radio channel (changed from the Unit Setup screen).

For battery level, the charge remaining is shown. Not all tools report their current battery level.

The screen shows a color based on the level.

•Green – The battery is full and will work at best performance.

•Yellow – The battery is low and should be changed when possible.

•Red – The battery is very low and should be changed. The tool may fail to transmit some

results until the battery is changed.

Table of contents

Other Sturtevant Richmont Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

TSI Incorporated

TSI Incorporated VELOCICALC 5725 Operation and service manual

Agilent Technologies

Agilent Technologies 35670A quick start guide

Dillenger

Dillenger KT-LCD3 user manual

Pfeiffer Vacuum

Pfeiffer Vacuum IKR 251 operating instructions

LaserLiner

LaserLiner MeterMaster Plus quick start guide

Muller Ziegler

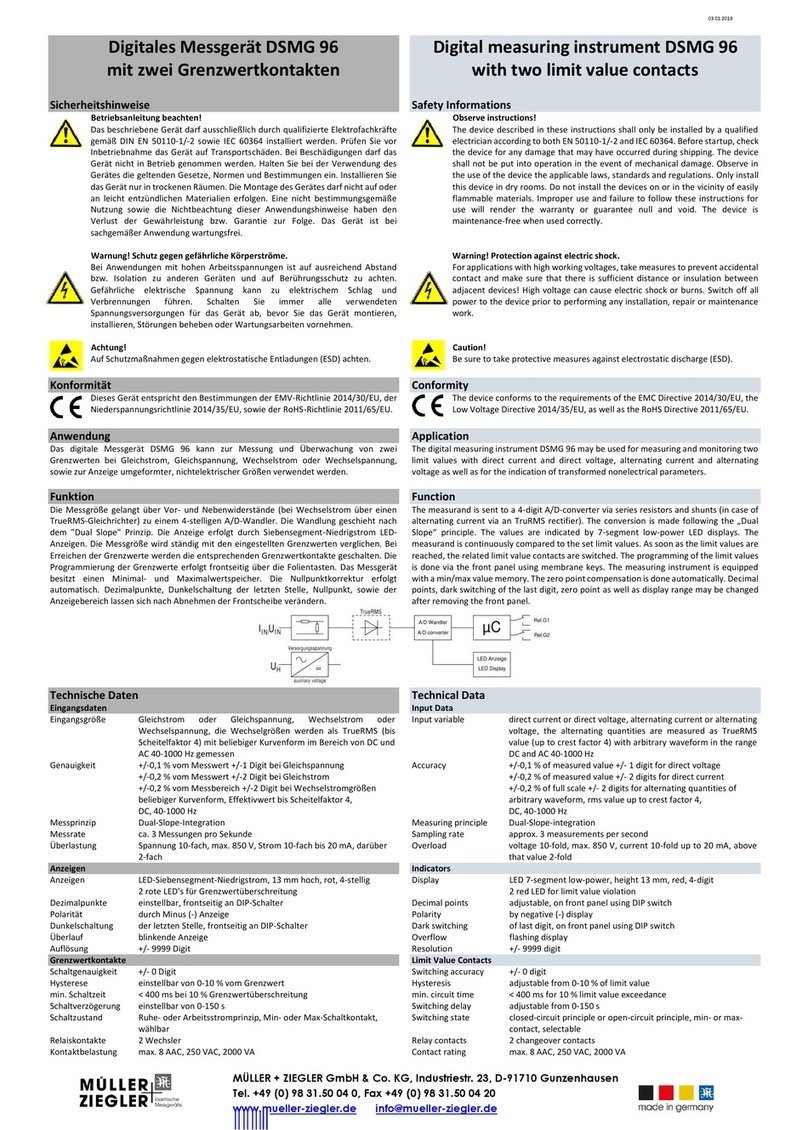

Muller Ziegler DSMG 96 manual