Outdoor Grill (OG) Series

Installation Information

2-2

#814144 - Revision B - October, 2011

GENERAL INSTALLATION INFORMATION

This section of the manual covers some of the installa-

tion issues that a service technician may need to know

when servicing a Wolf Outdoor Grill. If additional instal-

lation information is needed after reviewing this section

of the manual, refer to the complete Installation Guide

or contact Wolf Appliance Customer Service.

Regulations

The installation of a Wolf OG appliance must conform

with local codes or, in the absence of local codes, either

the National Fuel Gas Code, ANZIZ223.1/NFPA54, or

CAN/CGA-B149.1, Natural Gas Installation Code or

CAN/CGA-B149.2, Propane Installation Code.

The utilization of an external electrical source requires

that when installed, a Wolf OG outdoor cooking gas

appliance must be electrically grounded in accordance

with the local codes or, in the absence of local codes,

with the National Electrical Code, ANSI/NFPA70, or the

Canadian Electrical Code, CSAC22.1. Keep any elec-

trical supply cord, or the rotisserie motor cord and the

gas supply hose away from any heated surfaces.

A Wolf OG appliance must be installed in accordance

with National Electrical Codes, as well as all state,

municipal and local codes. The correct voltage, fre-

quency and amperage must be supplied to the appli-

ance from a dedicated, grounded circuit which is pro-

tected by a properly sized circuit breaker or time delay

fuse. The proper voltage, frequency, and amperage rat-

ings are listed on the product rating plate.

Important Instructions to the Owner

• Installation and service must be performed by a

qualified installer, service agency or the gas supplier.

• Warranty service must be performed by a Wolf

authorized service center.

• Do not store or use gasoline or other flammable liq-

uids or vapors in the vicinity of this or any other

appliance. An LP gas cylinder not connected for use

shall not be stored in the vicinity of this or any other

appliance.

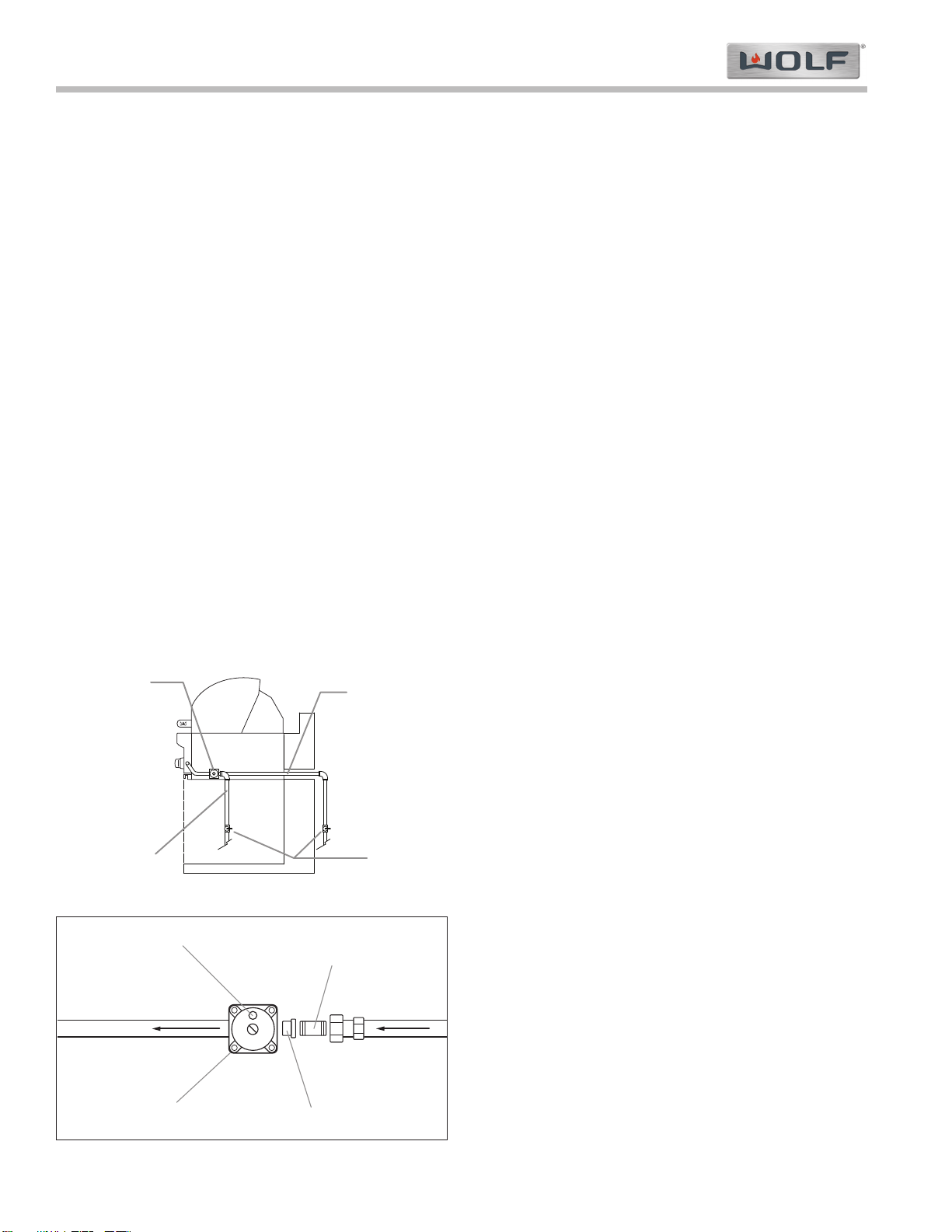

• In Massachusetts: All gas products must be installed

using a “Massachusetts” licensed plumber or gasfit-

ter. A “T” handle type manual gas valve must be

installed in the gas supply line to this appliance. This

applies to permanently installed natural gas and

propane installations. This does not apply to propane

portable installations using a 20-lb tank.

LOCATING THE GRILL

NOTE:A Wolf OG appliance is designed and certified

for outdoor use only. A Wolf OG appliance should

never be operated inside a building, garage, recreation

vehicle or any enclosed area.

When choosing an area for a grill, whether a portable or

built-in application, the following should be considered:

•Exposure to wind - a grill should be kept away from

windy areas but in a well ventilated area. The flow

of combustion and ventilation air around the grill can

not be obstructed.

•Proximity to traffic paths - a grill should be kept

clear of traffic paths.

•Length of gas supply line - The gas supply line

should be kept as short as possible to reduce pres-

sure drop.

•Levelness of application - The grill must be level

and flat. The supporting deck and countertop should

also be level and flat.

DO NOT LOCATE GRILL UNDER OVERHEAD COM-

BUSTIBLE SURFACES!

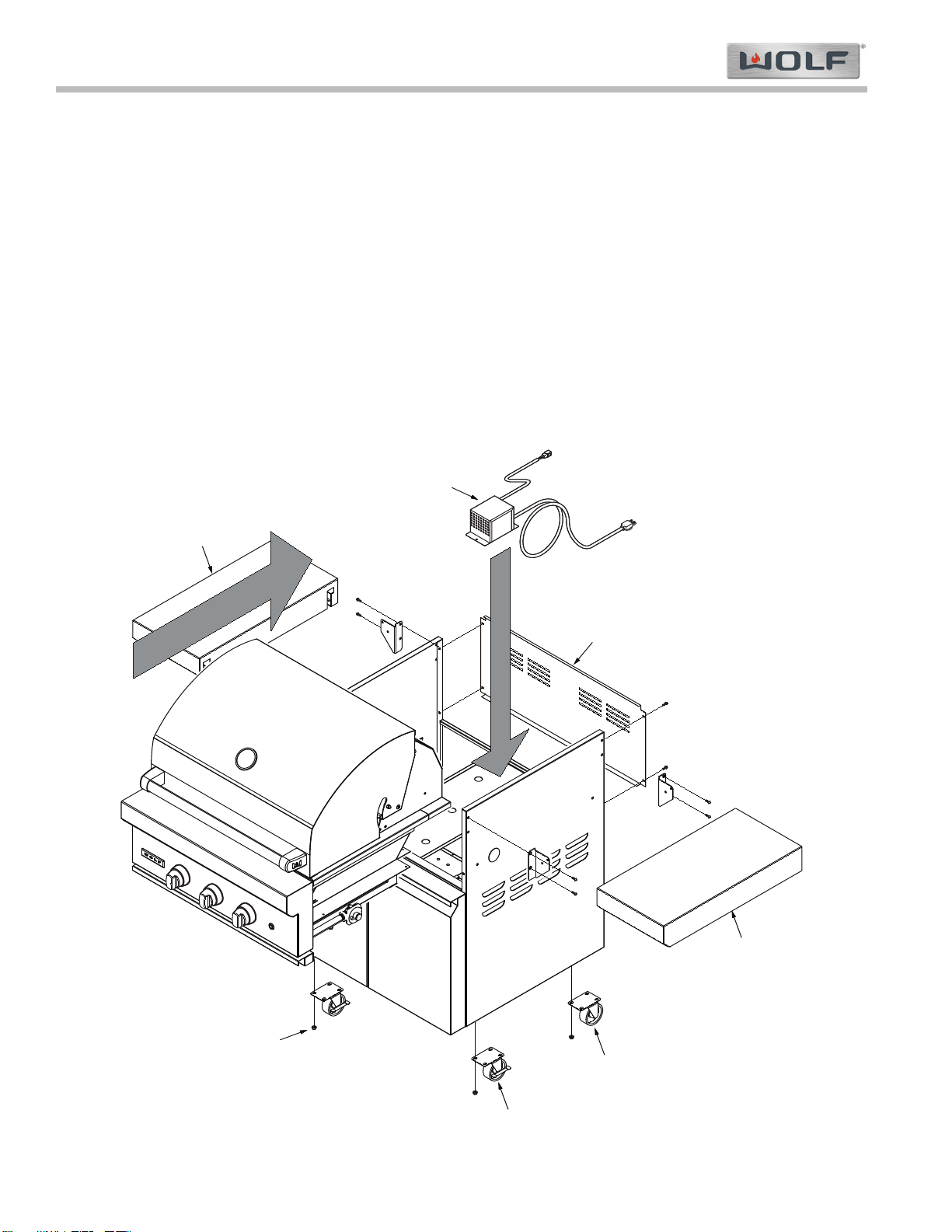

Portable Applications

•Wolf portable grill carts are available to fit most Wolf

outdoor grill models.

• Grill carts are sales accessories, sold separately

from the OG. appliance.

• There is no grill cart available for the OG54 model.