9

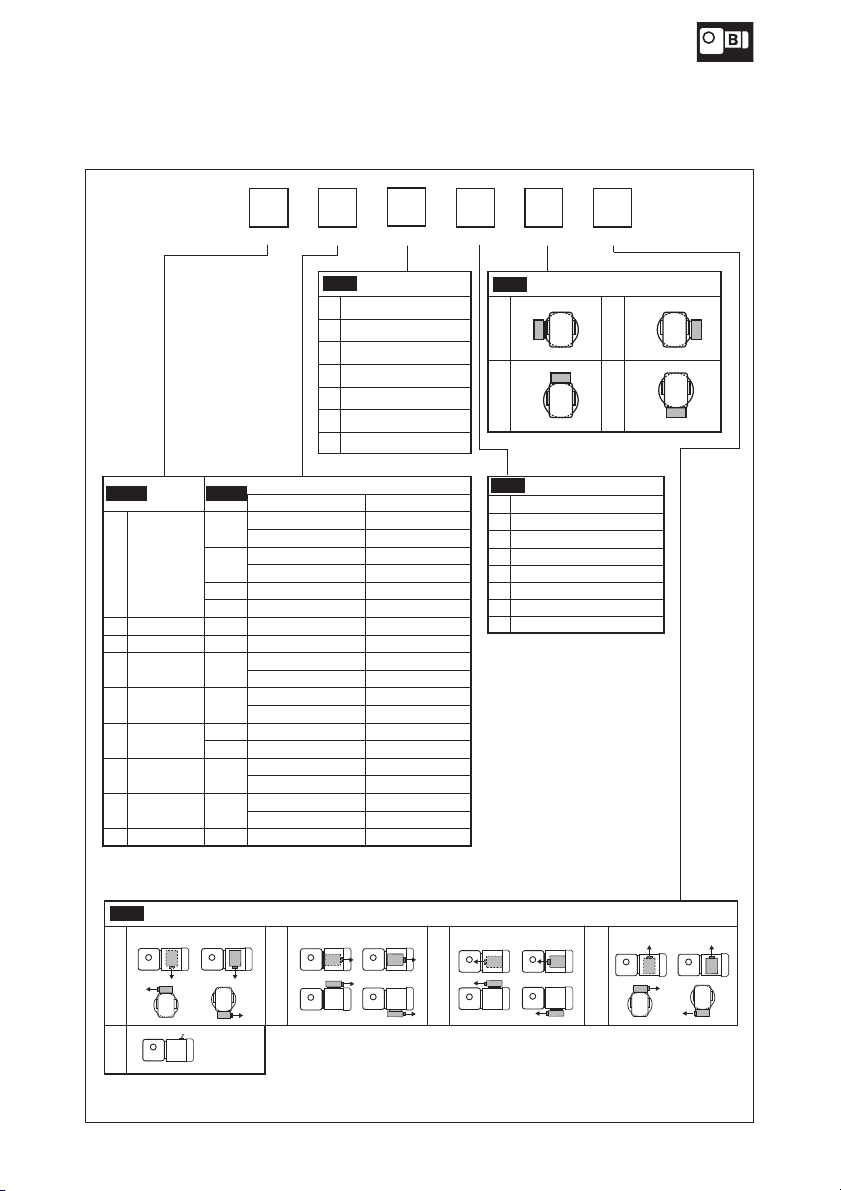

4–3) Flange mounting (RNFM series), Foot mounting (RNHM series)

Use bolt shown under Table 2. and refer to 5. coupling with other machines. (P14-18)

Series Frame Size Size of bolt

RNFM

05#, 07#, 15#, 17#, 190# Hexagon socket head bolt M6

01#, 03# Hexagon socket head bolt M5

20#, 23#, 25#, 270#, 1240# Hexagon socket head bolt M8

30#, 33#, 35#, 370#, 1340#

Hexagon socket head bolt M10

40#, 43#, 45#, 470# Hexagon socket head bolt M10

50#, 53#, 54#, 55#, 56#, 1440# Hexagon socket head bolt M12

1540# Hexagon socket head bolt M16

1630#, 1631#, 1640# Hexagon socket head bolt M20

RNHM

20#, 23#, 25#, 190#, 270# Bolt M8

30#, 33#, 35#, 370#, 1340#

Bolt M10

40#, 43#, 45#, 470#, 1440#

Bolt M12

50#, 53#, 54#, 55#, 1540#

Bolt M16

60#, 63#, 64# Bolt M20

Table 2 Bolt Size

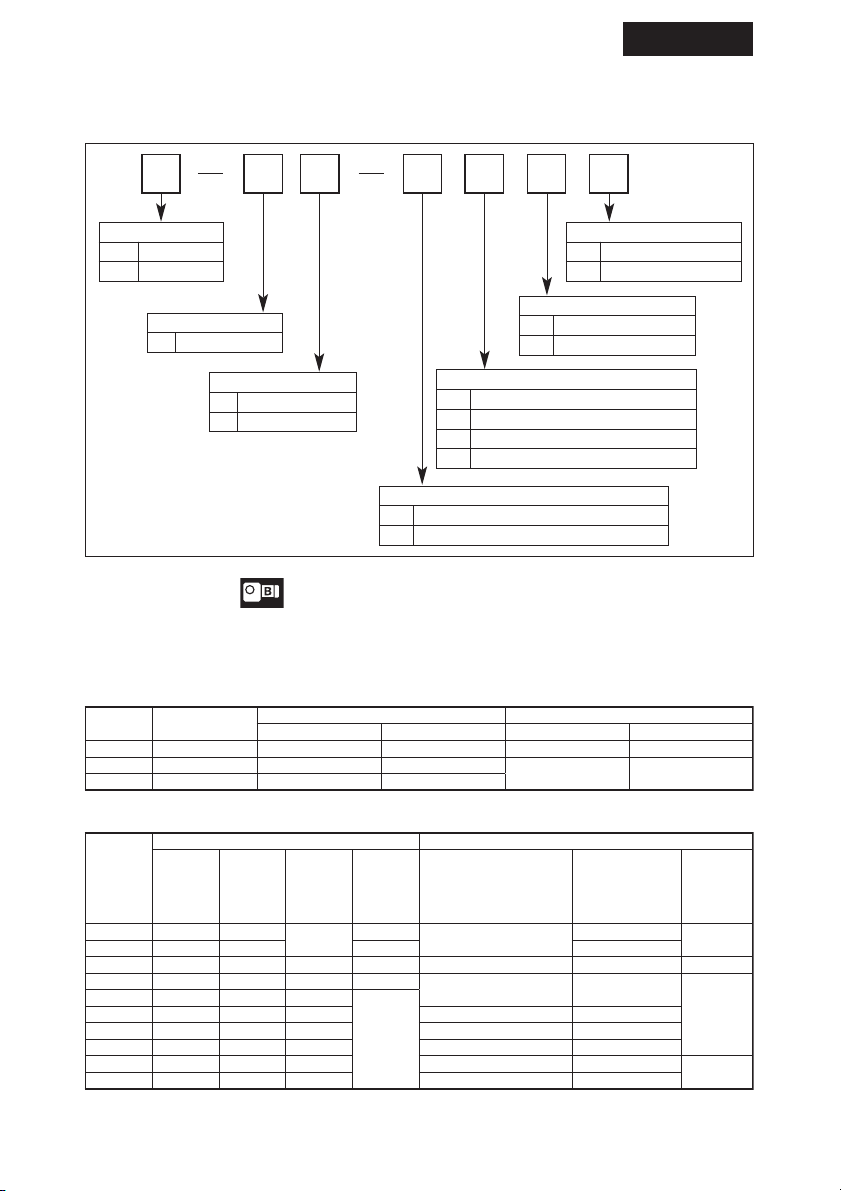

4–4) Hollow shaft (RNYM series)

There are (1) Torque arm mounting and (2) Flange and On-bed mounting for Hollow shaft.

(1) Torque arm mounting

(a-1) How to set the shaft (03#, 07#, 17#, 1010#)

Apply molybdenum disulfide grease to the surface of a driven shaft and the inner

surface of a hollow shaft. Then insert the Drive into the driven shaft.

If the fitting is too tight, lightly knock the end face of a hollow output shaft with a

wooden hammer for smooth insertion. Do avoid knocking the casing. We recommend

making a jig shown Fig 2. Using this jig, you can insert the Drive smoothly.

COMMON

4–2) Installation Angle

There is no restriction on the installation angle.

(For outdoor type gearmotors, standard installation angle is horizontal in the axial direction.

Contact us for other axial directions.)

· Units made to special specifications are necessary for installation under conditions other than

the above.

· Units made according to the outdoor, explosion-proof or other specifications can be used

under the specified conditions without any problem.

· Install units where inspection, maintenance, and other such operations can be easily carried

out.

· Install units on a sufficiently rigid base.

4. Installation