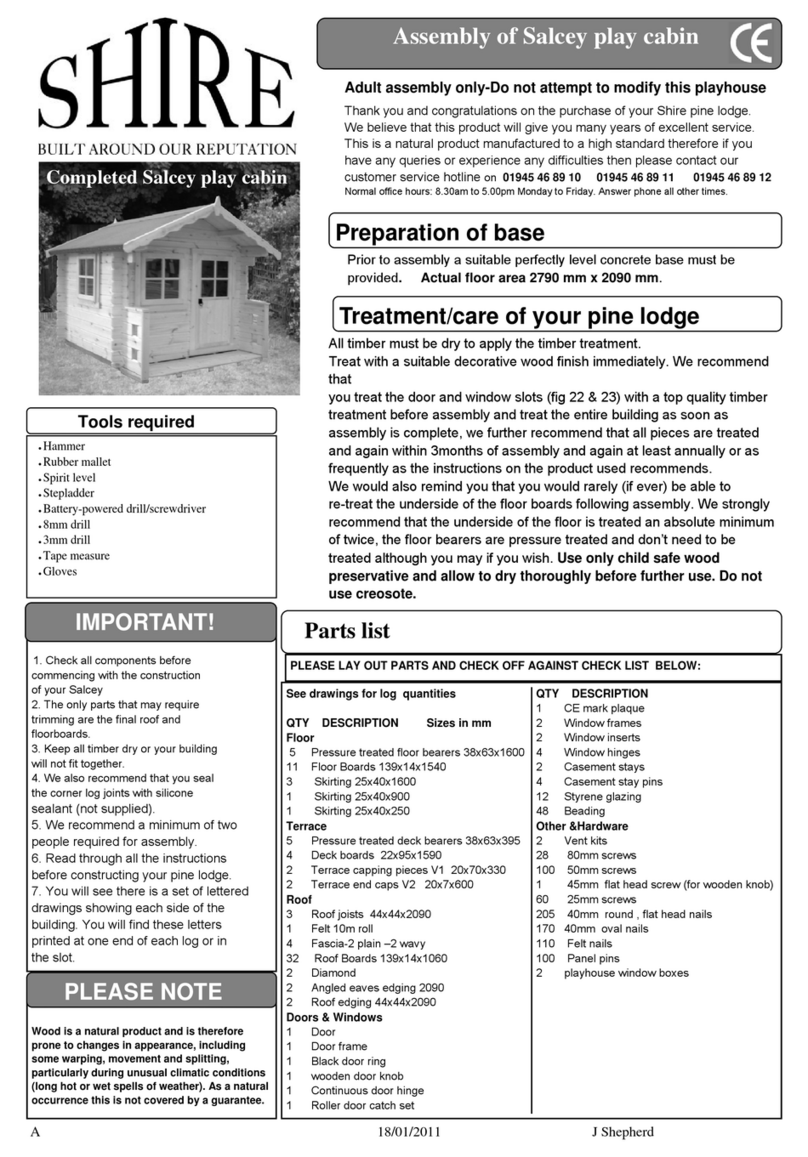

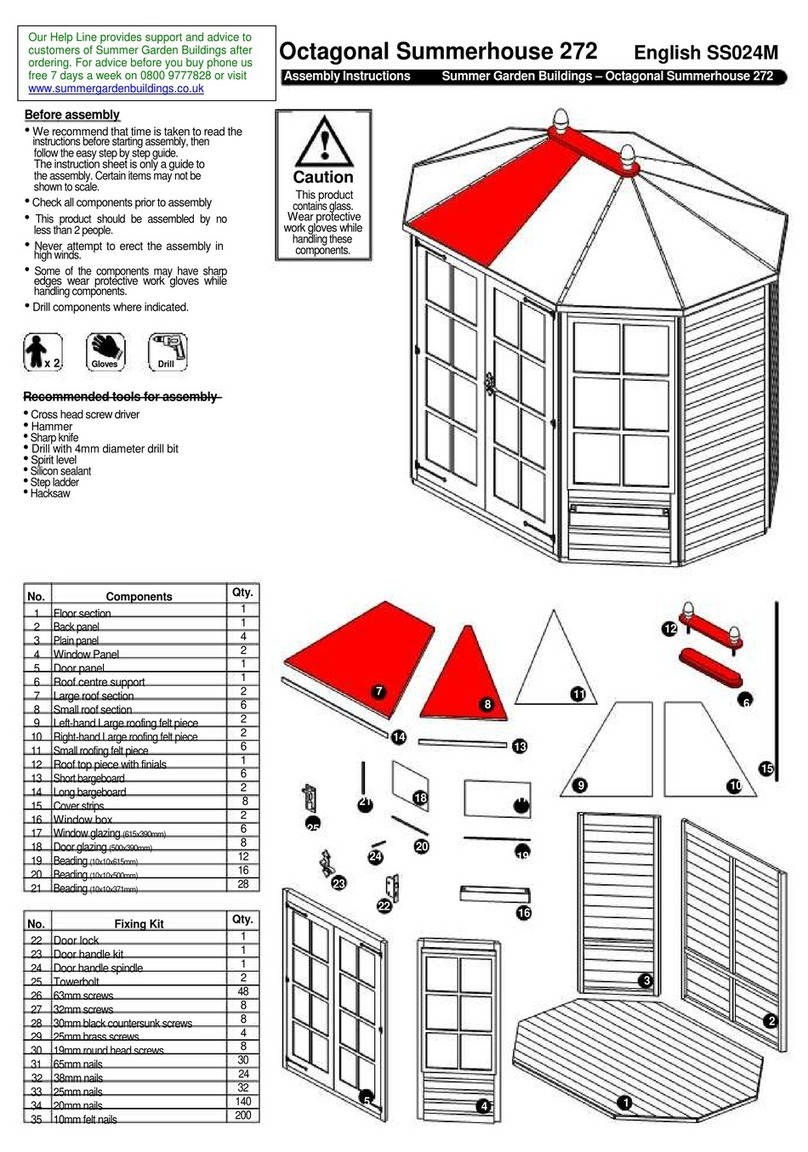

16.Bargeboards andfinials Summer Garden Buildings – Hipped Summerhouse 270

Attach the side bargeboards as shown using 4 x 38mm nails per board long board and 3 x 30mm nails per short board, ensure the top edges and the ends are flush with

the roof line. With the sides in position secure the front and back barge boards using 4 x 38mm nails per board, Ensure their top edges are flush with the roof line and

the ends level with the side bargeboards. The 2 finial centres are about 90mm from the ends of the capping piece. Drill 2 holes for each finial in the capping and secure

the finials using 2 x 63mm screws per finial. Place the capping centrally over the centre of the roof and secure using 4 x 63mm screws. Screw through the capping into the

centreroofblock.

Drill pilot holes for all screws

in thecappingpiece.

3mm

Drill

63mm

38mm

38mm

38mm

38mm

17. Glazing

It is recommendedthat awaterproofsealantis appliedaroundthe

edgeof

38mm

38mm

38mm

the glazing beforefitting.Placewindow panesonthe

Finials centres are90mmin

from each end

38mm

63mm

insideof thewindowframes.Position the

woodenbeadingaround theedge andnailintoposition using 2x25mm

nailsper

beadinglength.

25mm

Window frame

Window pane

Woodenbeading

Important information - retain for future reference

Shiplapbuildingscomereadystainedbutthisisonlyapreparatorytreatment.To VALIDATE the guarantee, the building mustbe properlytreatedwitha recognized

external wood preserver WITHIN 3 MONTHS of assembly and RE-TREATED ANNUALLY thereafter. Adequate provision must be made to ensure ground

contact

isavoidedandairisabletocirculate underneath thebuilding.

Placing the buildingonaconcretepad or slabbaseisacceptableprovidedthat thebuildingisnot allowedtositinpooledwaterduringwetconditions.

If the building is to sit on soil or grass it MUST be erected on pressure treated wooden 50mm x 50mm or similar bearers (These are not supplied in the kit). We

recommend using pressure treated bearers with all buildings on anytype of base.

Timber Information.

As timber is a natural material, there are certain weather conditions that may affect the materials properties. In times of excessive dry spells the material may lose some of

its internal moisture causing a certain degree of shrinkage on a panel and in periods of excessive rain there will be a certain amount of swelling throughout the wooden

panels. This process can not be avoided. If you have problems with certain boards shrinking in dry spells try to decrease the amount of direct sunlight on the building or the

amountofairpassingover the building. Duringhot spells spray waterdirectly ontothe panels a garden hose.

Ifindoubtofanyaspectregardingthe assembly,useorsafetyof yourbuildingpleasecontactourHelpLine

ROWLINSON GARDENPRODUCTS LIMITED

Green Lane

Wardle Nr.Nantwich

Cheshire

CW5 6BN

Weconstantlyimprovethe quality of ourproducts,

occasionally the components may differ from the

components shown and are only correct at time of

printing. We reserve the right to change the

specification of our products without prior notice.

Summer Garden Buildings does not

guarantee that this is the most recent version of these instructions

or that all data has been accurately reproduced. You are advised to refer to the instructions supplied

with the product before assembly. If for any reason the instructions are not delivered with the product

you are advised to obtain the most recent version before assembly. No guarantee is given regarding

the accuracy of these instructions and no liability will be accepted for any errors or inaccuracies.