This SUN-POWER XP Auto gate Operator has undergone rigorous factory load testing and has been

passed as ready for site installation.

Please ensure that you read ALL of these instructions, plus any other instructions supplied, then

simply follow Instructions step by step.

Take your time - Read the Manual –Get it right –Enjoy the benefits

IMORTANT NOTE [Warning]: Do NOT alter any pre-wiring of circuit board [except motor polarity* when

necessary]. Altering Pre-wiring [except motor polarity*] will compromise your warranty

* ALL power [240v/Solar/battery] must be disconnected before attempting to change motor polarity

XP Series Swing Gate Operators are suitable for and guaranteed, when they are correctly hinged and

operate smoothly and evenly*.

* XP Series Gate operators will drive a variety of Gate Styles, Sizes & Weights. Suitability is dependent on

the quality of hinging and the force required, at One Metre from the hinge center-point, to open and close

the gate. 15 Kg is the maximum for gates opening IN [PULL] and 7.5 Kg for gates opening OUT [PUSH]

240V Power, Solar Panel or Battery must not be connected until appropriate [see item 6 page 6] or if you do

not understand any of the instructions, or have any doubts, then please Fax 02 6280 7592 or Email your

queries sungate@bigpond.net.au or ring us on 02 6280 4655 re your concerns before you apply power to

the unit or you may void your warranty

DO NOT connect the RED Spade Terminal to the Battery until you are ready to set the Limit Switches. The

RED Spade Terminal is supplied, disabled* from the Battery. [* i.e. Not connected to the Battery]

The last item to be connected is the SOLAR PANEL, do this after ALL other settings and adjustments have

been made.

Important: [Battery change - Circuit board posts - Motor polarity change ]

Before moving the circuit board for any reason [or changing motor polarity], including when changing the

Battery, you must ensure that ALL Power from any 240v/ Battery/ Solar Panel is disconnected to avoid

damage to the circuit board. The Circuit board is supplied mounted on top of 4 nylon ‘posts’ please ensure

these ‘posts’ remain in place and circuit board is correctly located on top of these posts.

Ensure that there are NO loose wire strands when disconnecting and connecting any wires.

Do not expose control board or any electronic circuitry to Rain/Moisture etc .

Surface insecticide spray/ant sand/moth balls must not be applied onto any electronic circuitry.

All cabling must not be run in conjunction with any high voltage cables or electric fencing –if in doubt, seek advice

from a qualified Electrician in Your State or Territory.

Installation:

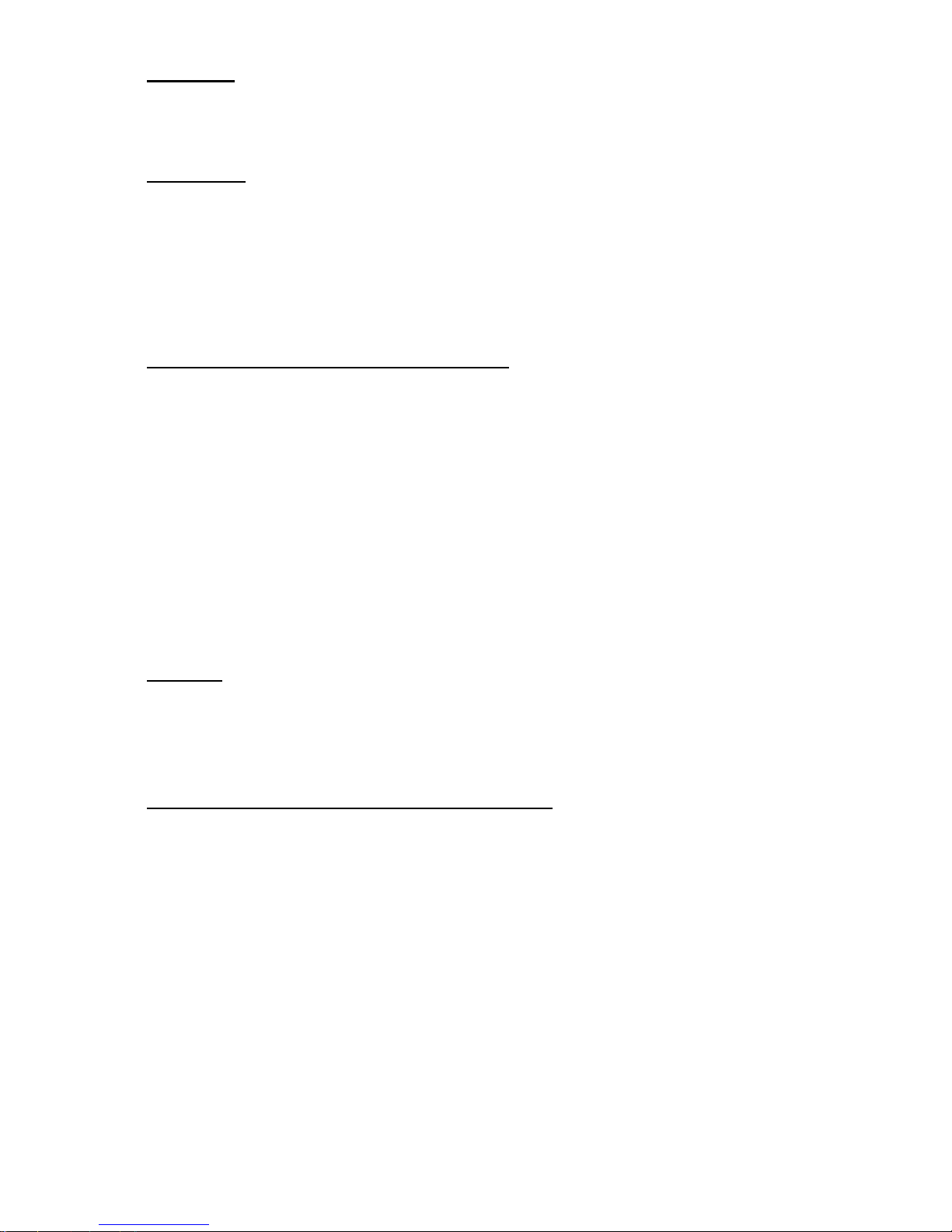

Standard Installation. [PULL]

A “Standard Installation” is one where gate[s] open in - ie; swinging INWARD toward the Motor Housing.

Generally the gate hinge should be no more than 200mm* from the rear of the Pier/Post/Pillar, ask us for

advice if this distance is greater.

Side room of 350mm is normally required to accommodate the swing of the arms. Refer to Pages 7/8/9 if

there is restricted side room [See fig 1] some pictures of restricted side-room installation are in the

“image gallery at “www.sungateaustralia.net

2.