Electrical

doto:

6.Use the

battery

assembly

workstation

convenient

for

operating

range and

expand

the welding method.

Soldering iron part:

Temperatur:

150C-450t

Power:50W

7.Installation

and

adjustment

of

welding

needle

DFix

the copper head

by

the

wrench.

Put

the welding needle

into

the

copper hold,and

tightening

by

the

hex

wrench.

Pay

attetion

to

the

balance

between

the

two

welding

needle.

The

two

welding

needle

cannot

knocking

together

when

adjust

welding

Output voltage:20VDC

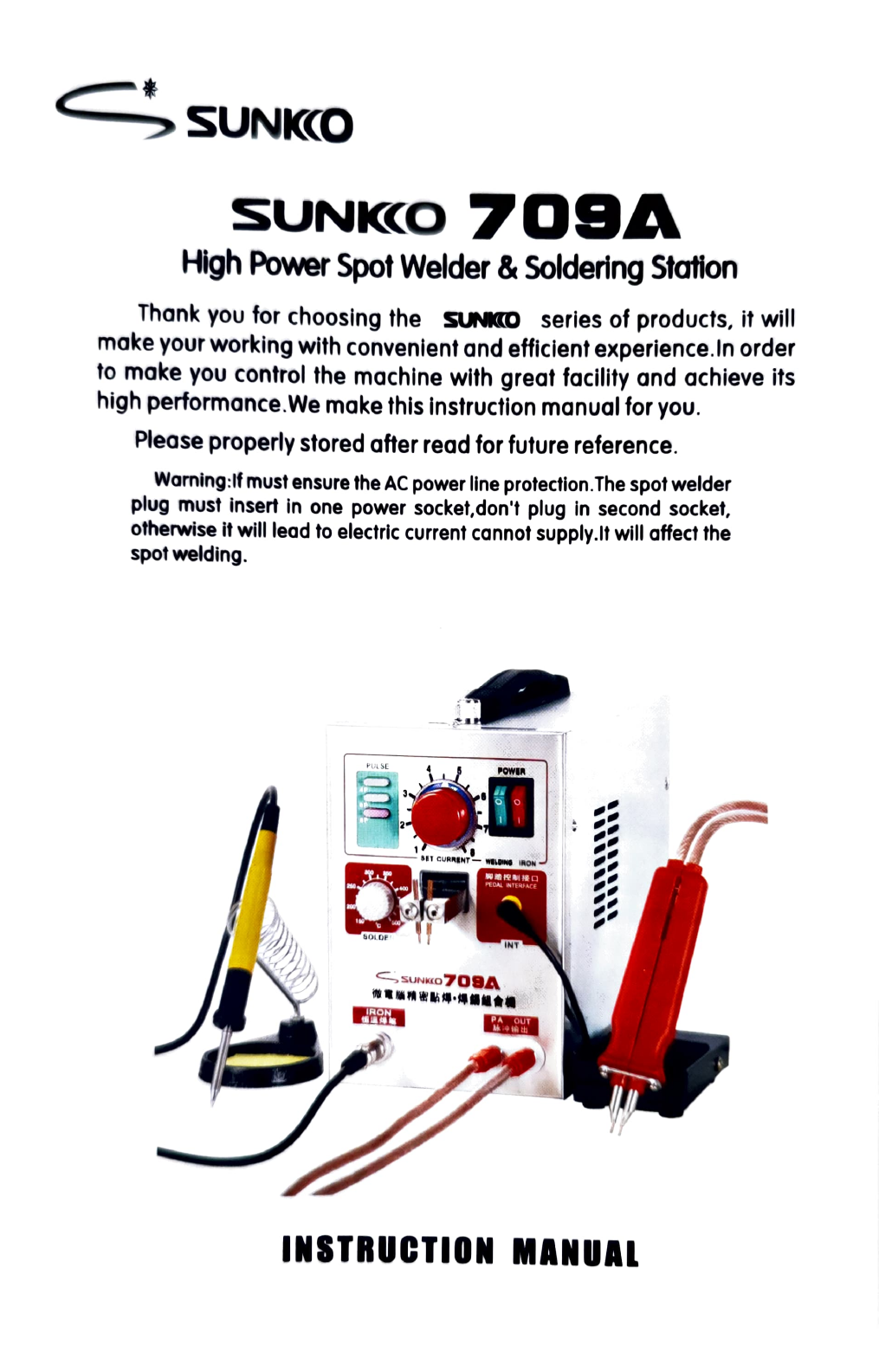

Spot-welder

part:

Supply

voltage:

AC

11ov/220V

10%

Power:

3.2

KW

(Instantaneous)

Current:

800

A

needle.

8.The

adiustment

of

welding

needle

pressure

There

is

a pressure

regulator

above the

machine,

according

to

the

thickness

of

diferent

workpieces

the pressure between the

welding

needle and

workpiece

can becan be adjusied through the regulator.when

weld

thin

workpiece,

tum

to

anti-clockwise

position

to

reduce

the

pressure,

when

weld

thick

workpiece,

tum

to

clockwise

position

to

increase the pressure. to observe the solder

joint

after

adjust

the welding pressure everytime.to make the solder

joint

fim and

reliable,

in

order

to

achieve the purpose of precise

welding.

Time

of

double pulse:1-10ms (adjustable)

Time of four pulses:

2-20ms

(adjustable)

Time

of

eight pulses:

8-80ms

(adjustable)

Weight:7KG

Size:140X245X200mm

The

thickness

of

welding:

0.05-0.3mm

The

Operation

Method of

Spot

Welding

Setting

up

&Operation

of

the

Iron

1.Frst,disconnect the power

line.Carefully

installation and adjustment ofwelding

needle,fastening screwAdjustment

of

welding needle pressure

2.Plugged-in,press

the

welding

switchthe

red

switch,

The

welding

machine

isin

standby

state

3.Adjust

current

and

pulse,

the

specic

method

as

follows:

.Connectthe cord assembly to the receptacle.

2.Place the soldering

iron

in

the

iron

in

the

iron

holder

3.Plug

the powercord

into

the power

supply.Be

sure

to

ground

the unit.

4.Set the temperature

control

knob

to

the desired temperahure.

When

the soldering

iron

head heating

to

the settemperature,that

is

the

iron

can be welder.

Clockwise adjust the fast setting current knob,the series

is

greater,the electricity

is

greater

21The

customer can press the three option button of trigger pulses

to

adjust

the

welding

pulses.

The

trigger

pulses

is

the total

of

the press pulse-button.fthat

have not press the pulse-button,the defaut pulses

is

2.The

more trigger pulses,

he

welding

strength

is

stronger

at

the

same

welding

current.

3)For

example:f

you

want

to

use

the

welding

copper head

connect

the

batiery

by

0.2

thickness

nickel.normaly.you

can

press

the

pulse

4

pulse

and

adjust

the current to

level

4-5.M

you

use

the

battery

welding

pento

welding

the

0.2

thickness

nickel,at

the

same trigger pulses,that

will

Use

grealer

peak

current.

Tip

Care

and

Use

Tip

Temperature

High

soldering

temperatures

can

degrade

the

tip.Use

the

lowest

possible

soldering

temperature.The

excellent thermal recovery characteristics

ensure

efficient

and

effective

soldering

even

at

low

TEMP.

This

also

protects

the soldered

items

from

thermal

damage.

Cleaning-Clean the

tip

regularly

with a

cleaning

sponge,as

oxides and carbides

from

the solder and

flux

can

form

impurities

on

the

tip.These

impurities

can

result

in

defective

joints

or

reduce the

tip'

s heat

conductivity.When

using

the

soldering

iron

continuously,

be

sure

to

loosen

the

tip

and

remove

all

oxides

at

least

once

a

week.

This

helps

prevent

seizure

and

reduction of the

tip

temperature.

When

Not

in

Use

Never

leave

the

soldering

iron

sitting

at

high

temperature

for

long

periods

of

time,as the

tip's

solder

plating

will

become

covered

with

oxide,which

can

greatly

reduce

the

tip's

heat

conductivity.

After

UseWipe the

tip

clean

and

coat

the

tip

with

fresh

solder.This

helps

prevent

tip

oxidation.

4.Set

the

paramelers/welding

current

and

pulse)

according

to

the

welding

material

thickness.And

push

up

the

welding

material

to

the

spot

welding

electrode.

That

will

completion a

welding.

5.In

precise

spot

welding.that

cannot

use

poke

welding.

must

use

the foot

switch

control

function

in

order

to

ensure

the

quality

of

spot

welding.

When

connect the

pedal

switch,the

spot

welding

function

will

transfer

to

foot

controlled.

4