3 4

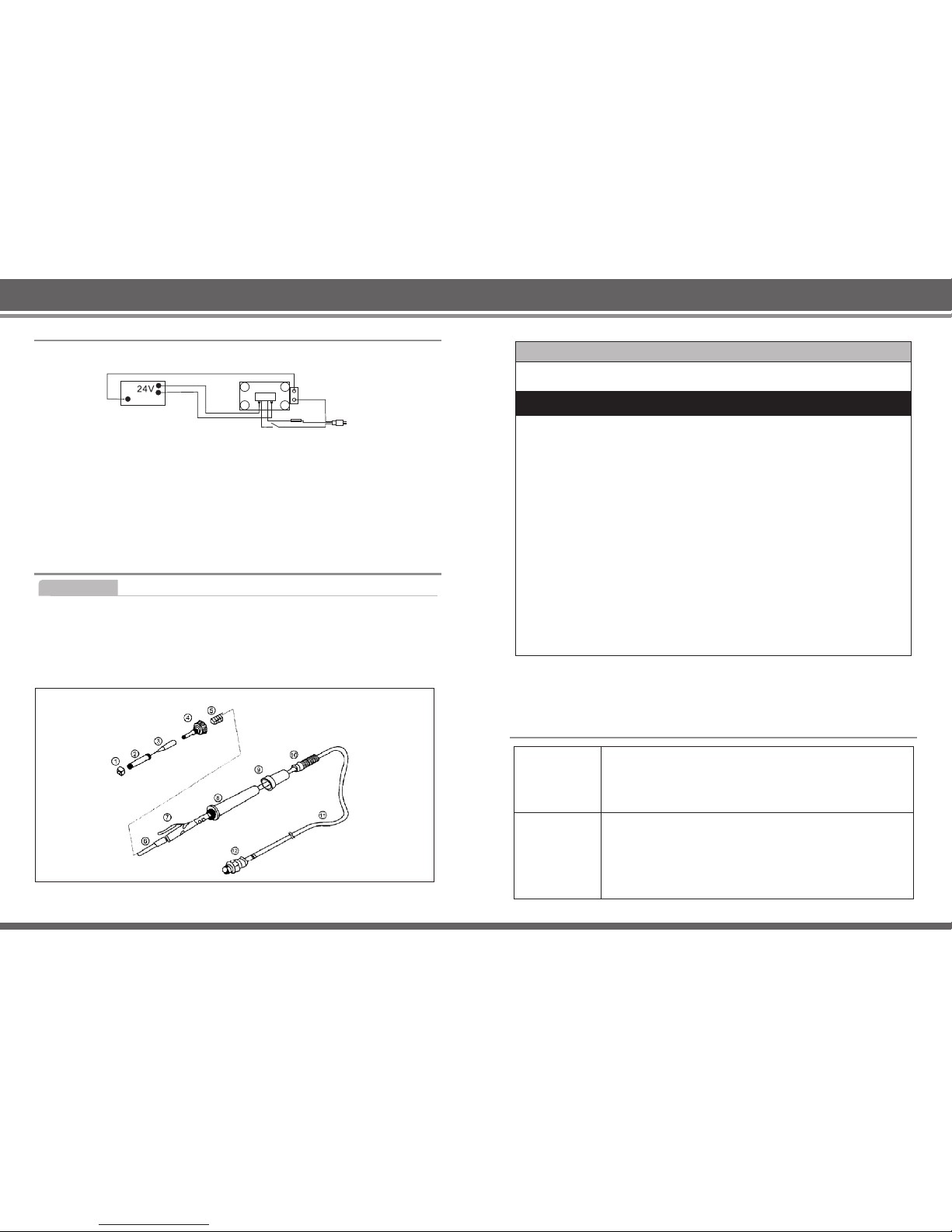

三、电路图

接地

印刷电路板

隔离变压器

3芯电线

四、烙铁发热芯和烙铁头的更换

1、旋出螺母1,再将钢管2取出,这时就可以取下烙铁头进行更换了。

2、如需更换烙铁发热芯可继续旋出螺纹头4,拔出烙铁发热芯6和线路板7,要注意弹

簧5的连接线。

3、将烙铁发热芯从线路板上焊下,更换新的发热芯,装好即可。注意烙铁发热芯引线

的连接顺序。

烙铁部件更换 图1

接地弹簧

螺纹头

烙铁头

钢管

螺母

发热芯

线路板

手柄壳

硅胶套

线尾

航空座

手柄线

图1

Warning!!!

Use the machine, the following basic measures should abide, avoid electric

shock or cause injury or damage caused by fires.

1. To ensure personal safety, after the machine completed work, please turn

off the main power switch, and unplug the power cord if long time no use.

2. You must use the original approval or recommendation of the parts, other-

wise it will lead to serious consequences.

3. Machine failure must be by professionals or the company designated per-

sonnel for repair.

4. This product is grounded three - wire plug, must be inserted within the

three - hole grounded outlet, do not change the plugs or use ungrounded

three adapter made it bad grounded.

5. Hot air gun or soldering station is open, its temperature are likely to reach

400 . Do not use it near flammable gas, objects. Tube and the heat emi-°C

tted very hot, can burn the body, do not touch the hot pipe and direct injec-

tion to heat the human body.

6. Before hot air gun turned on, please ensure it is in safety environment, do

not leave the jobs site.

7. When the hot air gun opening do not install nozzle, the heat pipe and the

nozzle must be cooling. Then installed the other nozzle.

8. After use, the machine need to cool down when packing.

9. Do not use a soldering iron to weld outside the work; Do not iron percussi-

on table to clear the residual flux, this could seriously damage the iron.

10. The machine welding will take smoke, please do proper ventilation.

I. Tip Maintenance And Use

Tip temperature

High soldering temperature can degrade the tip. Use the

lowest possible soldering temperature. The excellent

thermal recovery characteristics ensure efficient and effec-

tive soldering even at low temperatures. This also protects

the solder de items from thermal damage.

Cleaning

Clean the tip regularly with a cleaning sponge. As oxides and

carbides from the solder and flux can form impurities on the

tip. These impurities can result in defective joints or reduce

the tips heat conductivity. When using the soldering iron

continuously, be sure to loosen the tip and remove all oxides

at least once a week. This helps prevent seizure and

reduction of the tip temperature.