I

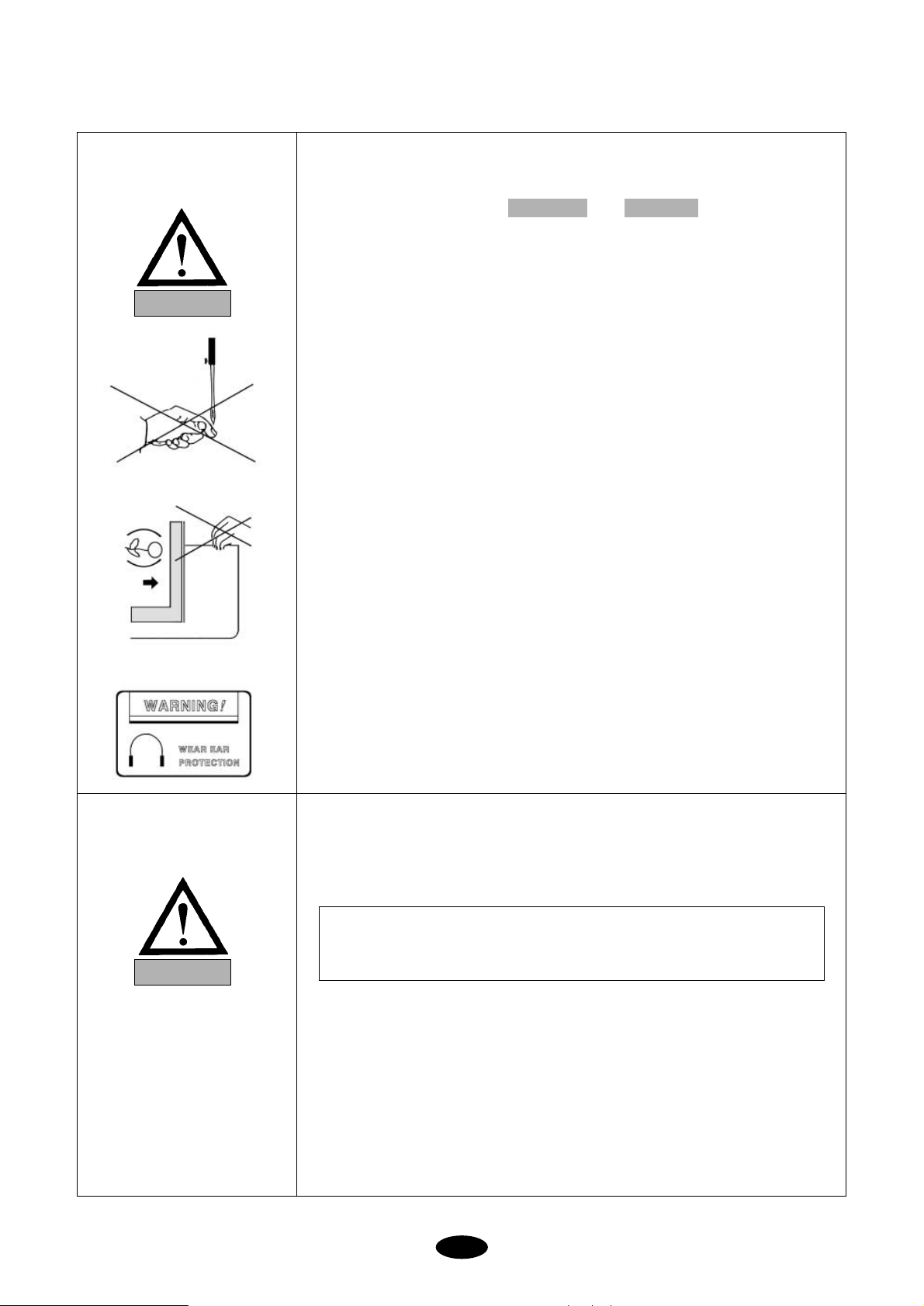

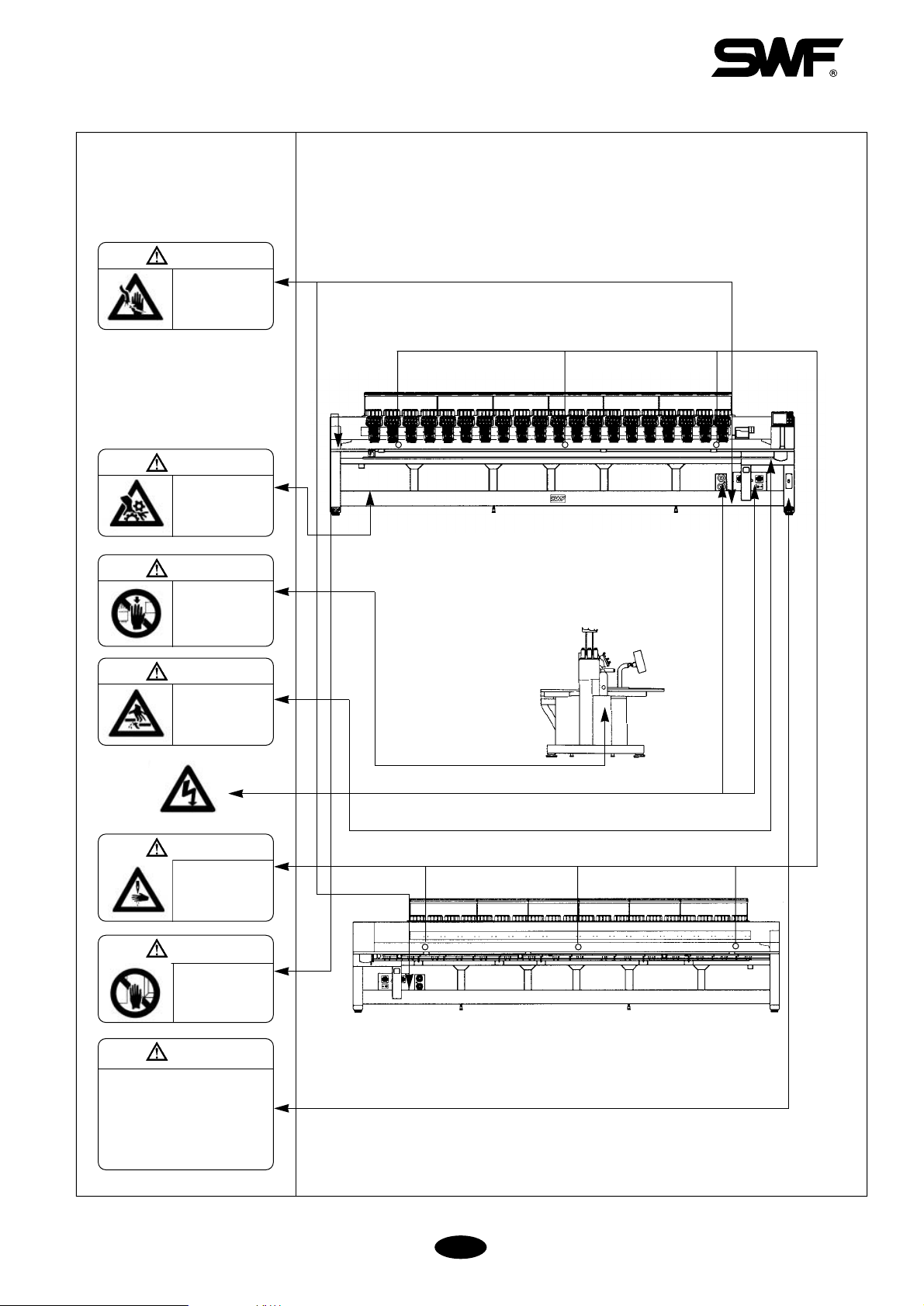

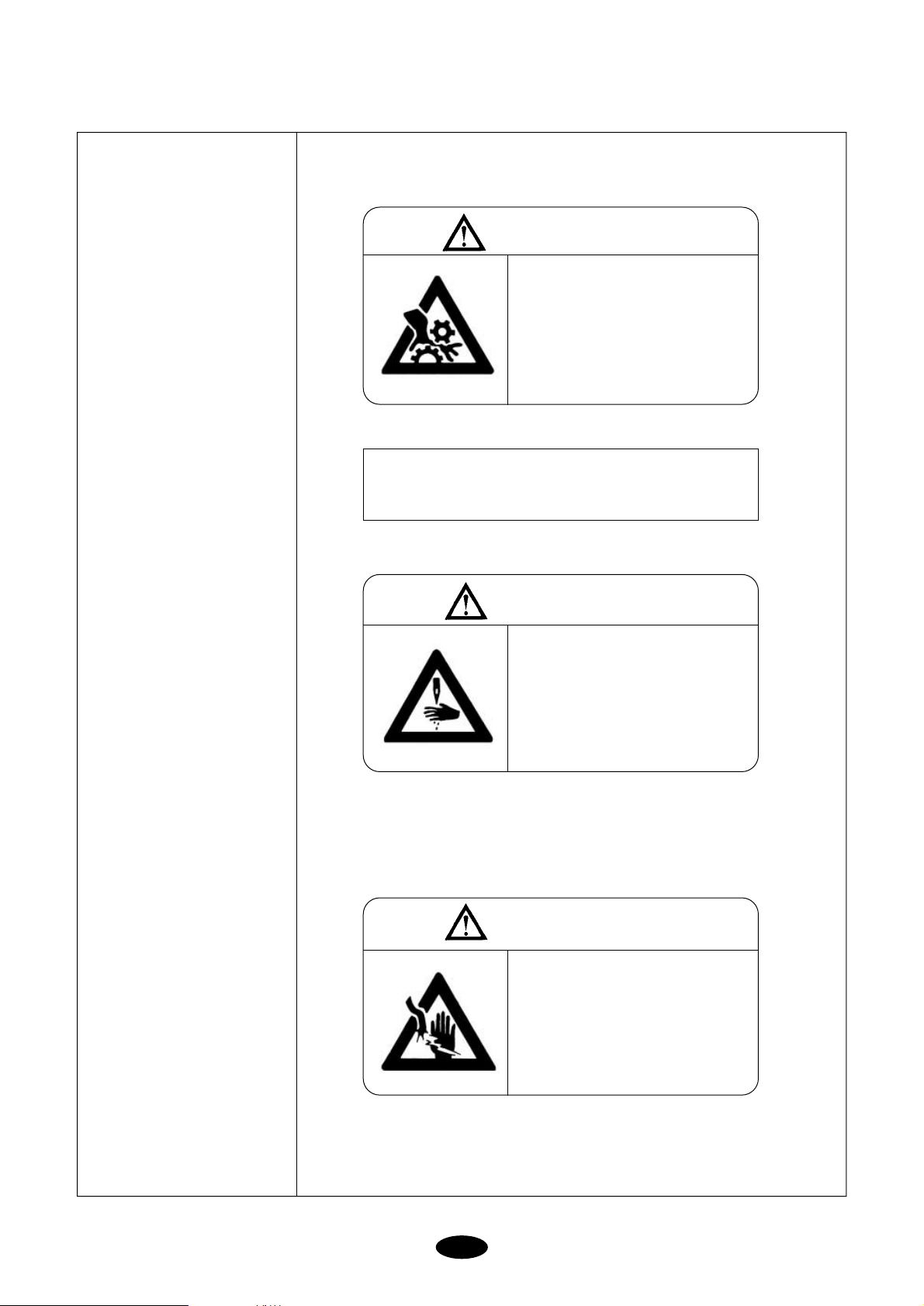

CHAPTER 1 SAFETY RULES ................................................................................................................................. 1-1

CHAPTER 2 MACHINE INSTALLATION AND ASSEMBLY ....................................................................... 2-1

2-1) INSTALLATION ENVIRONMENT .................................................................................... 2-1

2-2) ELECTRICITY INSTALLATION ........................................................................................ 2-1

2-3) LEVELING THE MACHINE ................................................................................................ 2-2

2-4) PERIPHERALS ASSEMBLY ............................................................................................... 2-4

CHAPTER 3 NAMES OF MACHINE PARTS ...................................................................................................... 3-1

CHAPTER 4 FEATURES AND SPECIFICATIONS ........................................................................................... 4-1

CHAPTER 5 FUNCTIONS FOR BASIC MACHINE OPERATION .............................................................. 5-1

5-1) NAMES AND FUNCTIONS OF PARTS IN OPERATION BOX ....................................... 5-1

5-2) EMERGENCY POWER AND START/STOP BUTTONS .................................................. 5-3

5-3) BAR SWITCH ....................................................................................................................... 5-4

5-4) LAMP ON THREAD TENSION ADJUSTMENT BOARD ................................................ 5-6

5-5) NEEDLE STOP CLUTCH ..................................................................................................... 5-7

5-6) LAMP ON COLOR CHANGE BOX .................................................................................... 5-8

5-7) UPPER THREADING AND TENSION ADJUSTMENT .................................................... 5-9

5-8) LOWER (BOBBIN) THREADING AND TENSION ADJUSTMENT .............................. 5-12

5-9) BOBBIN WINDER .............................................................................................................. 5-13

5-10) FLOPPY DISKS ................................................................................................................ 5-16

5-11) IN AND OUT OF DESIGNS ............................................................................................. 5-17

5-12) RETURN TO PREVIOUS LOCATION IN UNEXPECTED BLACKOUTS .................. 5-17

5-13) NEEDLE- HOOK TIMING CONTROL ........................................................................... 5-18

5-14) ASSEMBLY AND FUNCTIONS OF THREAD DETECTOR ........................................ 5-23

CHAPTER 6 BASIC MACHINE OPERATION .................................................................................................... 6-1

CHAPTER 7 OPERATION BOX .............................................................................................................................. 7-1

CHAPTER 8 ERROR MESSAGES AND CORRECTION ................................................................................ 8-1

8-1) MAIN SHAFT MOTOR ........................................................................................................ 8-1

8-2) X, Y PULSE MOTORS ......................................................................................................... 8-1

8-3) COLOR CHANGE ................................................................................................................. 8-1

8-4) ENCODER ............................................................................................................................. 8-2

8-5) FLOPPY DRIVE & COMMUNICATION ............................................................................ 8-2

8-6) MEMORY .............................................................................................................................. 8-3

8-7) TAPE READER & TRANSMISSION .................................................................................. 8-3

CHAPTER 9 CONTROL BOX .................................................................................................................................. 9-1

9-1) MAIN CONTROL BOX ........................................................................................................ 9-1

9-2) MAIN SHAFT MOTOR DRIVE ........................................................................................... 9-3

9-3) X, Y MOTOR DRIVE ........................................................................................................... 9-4

TABLE OF CONTENTS