Table of Contents

1.0

Machine Operating Program

.................................................................................................................................. 1-1

1.1 Machine Setting Report ................................................................................................................................1-1

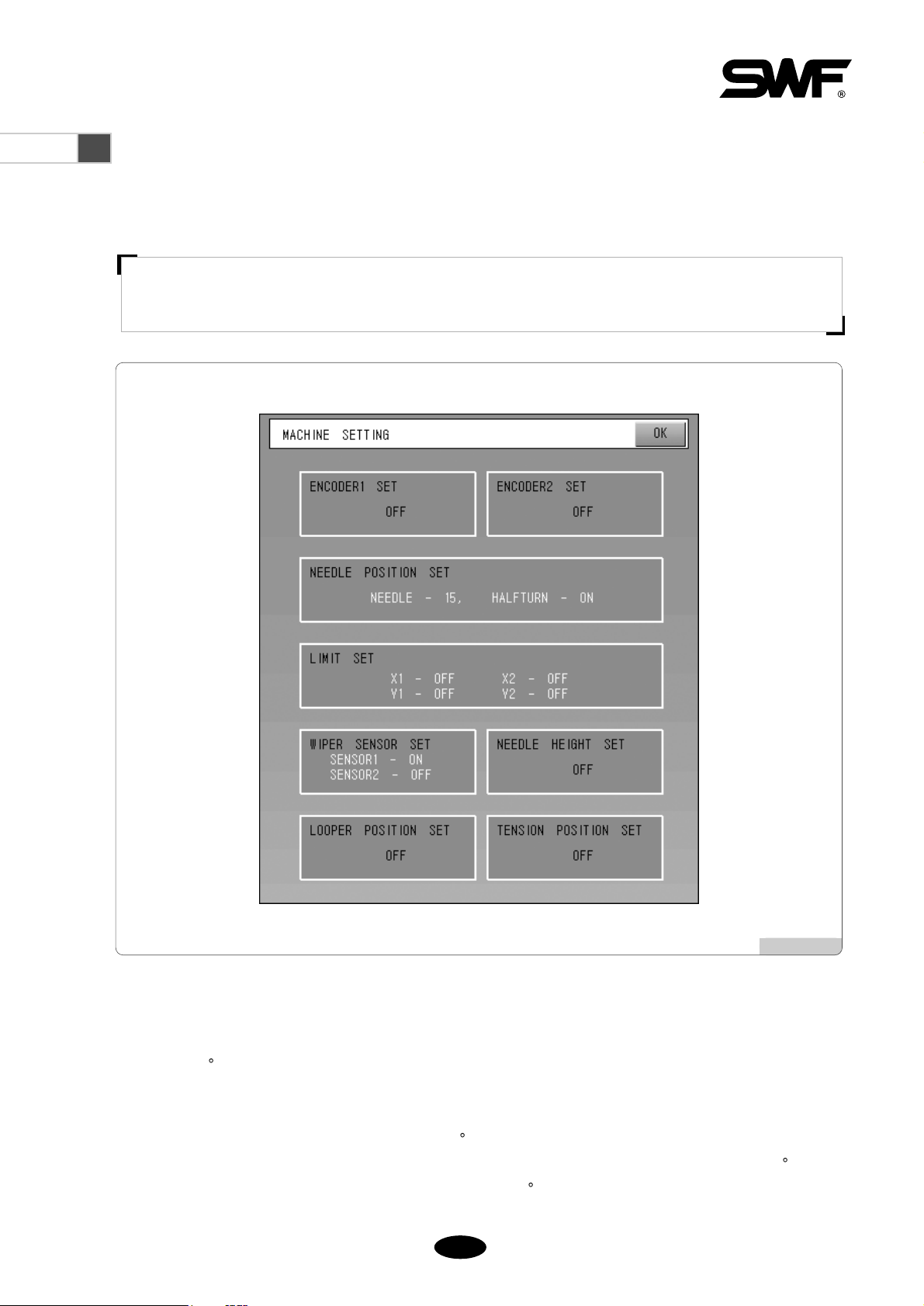

1.2 Machine Setting .............................................................................................................................................. 1-2

2.0

Function Buttons

........................................................................................................................................................ 2-1

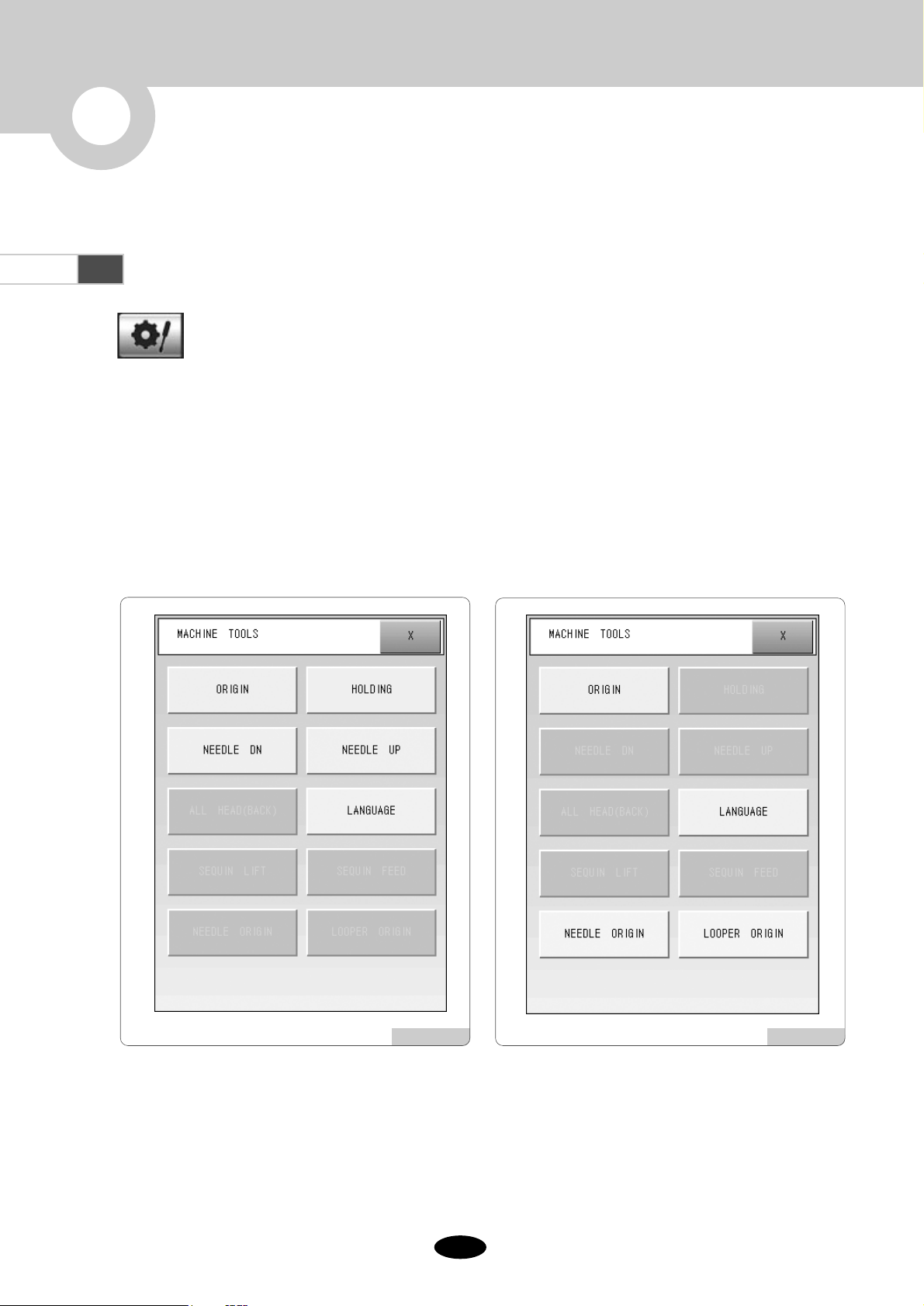

2.1.0 Tool Box .......................................................................................................................................................... 2-1

2.1.1 Origin ............................................................................................................................................... 2-2

2.1.2 Holding .............................................................................................................................................. 2-2

2.1.3 Needle DN / Needle UP ................................................................................................................... 2-2

2.1.4 Language ........................................................................................................................................... 2-2

2.1.5. Needle Origin .................................................................................................................................... 2-2

2.1.6 Looper Origin .................................................................................................................................... 2-2

2.1.7 All Head(Back) ................................................................................................................................. 2-2

2.1.8 Sequin Lift / Sequin Feed ................................................................................................................. 2-2

2.2 Needle Bar (color) Change............................................................................................................................... 2-3

3.0

Setting

............................................................................................................................................................................ 3-1

3.1 Needle (Color) Setting ..................................................................................................................................... 3-1

3.2 Chenille Setting ................................................................................................................................................ 3-5

4.0

Troubleshooting

.......................................................................................................................................................... 4-1

4.1 Error Message and Corrective Measures .................................................................................................... 4-1

4.2 Control Board Switch Setting ...................................................................................................................... 4-2

4.3 Bootloader of Thread Sensing Board ............................................................................................................. 4-7

4.4 System Block Diagram .................................................................................................................................... 4-10