i

CHAPTER 1 SAFETY RULES …………………………………………………………………… 1-1

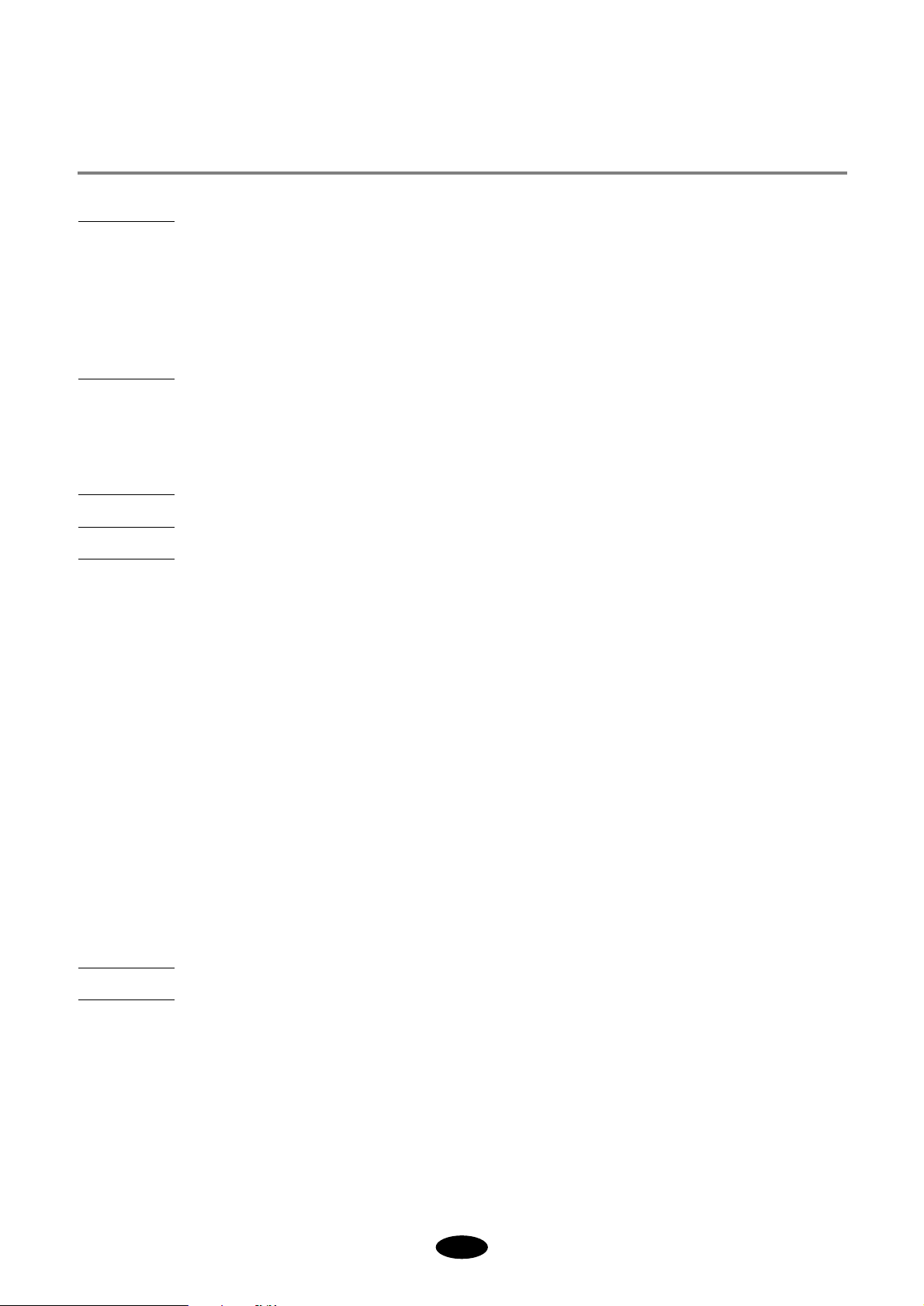

1-1) MACHINE DELIVERY ……………………………………………………………… 1-1

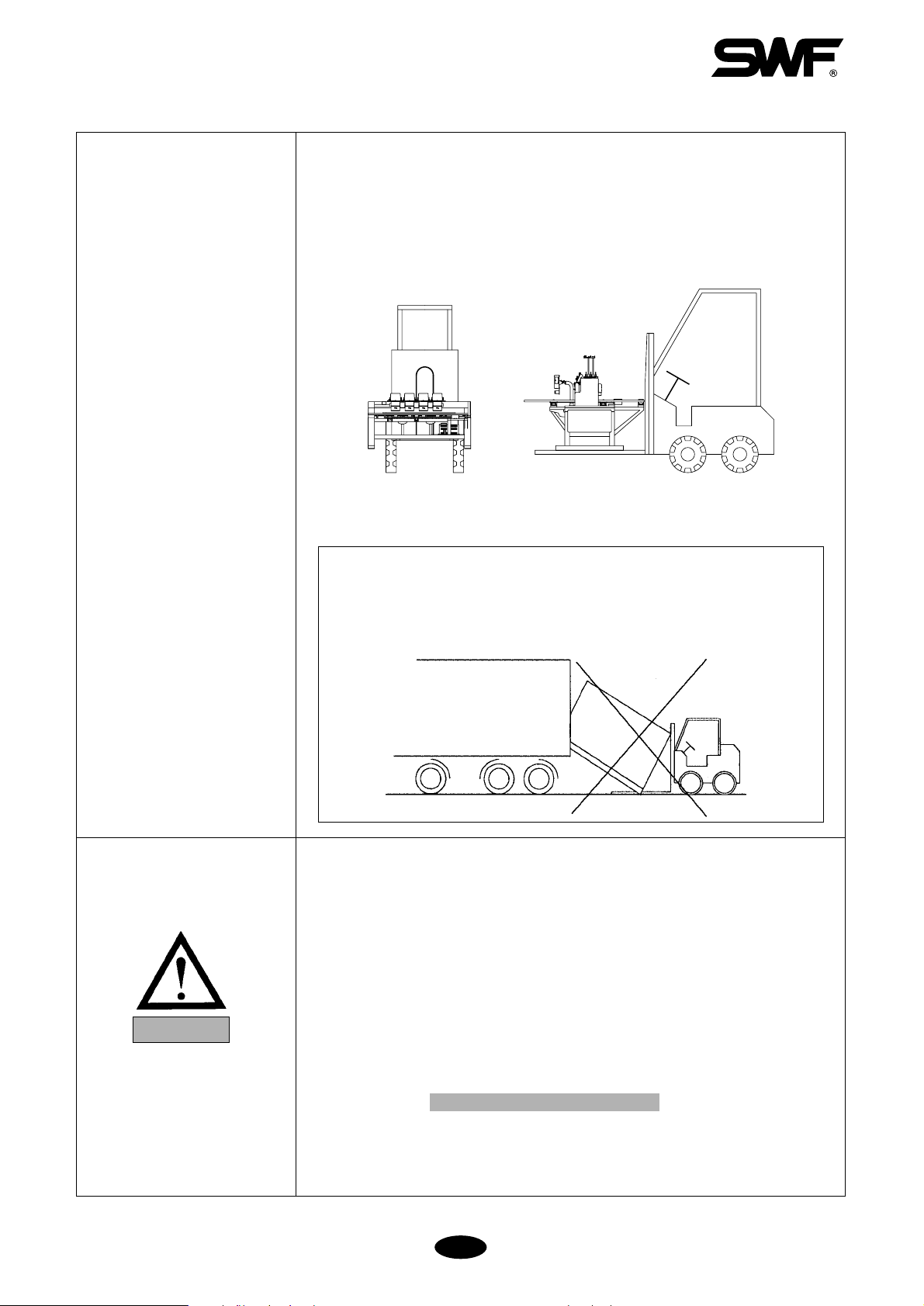

1-2) MACHINE INSTALLATION ………………………………………………………… 1-2

1-3) MACHINE OPERATION …………………………………………………………… 1-3

1-4) REPAIR ……………………………………………………………………………… 1-3

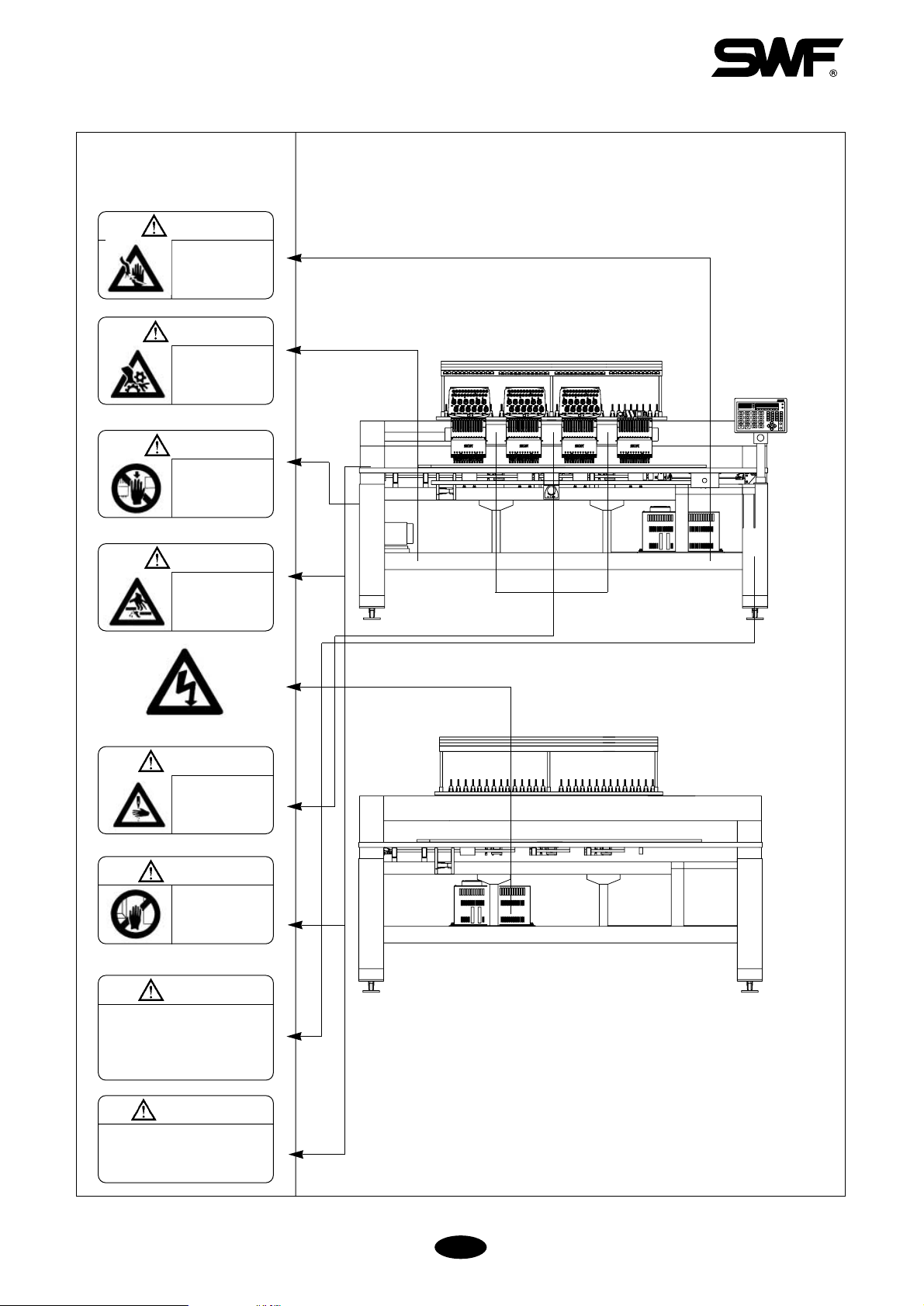

1-5) PLACEMENT OF WARNING STICKERS ………………………………………… 1-4

1-6) CONTENTS OF WARNING STICKERS …………………………………………… 1-5

CHAPTER 2 INSTALLATION AND MACHINE ASSEMBLY ………………………………… 2-1

2-1) ENVIRONMENT …………………………………………………………………… 2-1

2-2) ELECTRICITY………………………………………………………………………… 2-2

2-3) LEVELING THE MACHINE ………………………………………………………… 2-3

2-4) ASSEMBLY OF PERIPHERAL DEVICES

CHAPTER 3 PARTS OF THE MACHINE ………………………………………………………… 3-1

CHAPTER 4 FUNCTIONS AND FEATURES …………………………………………………… 4-1

CHAPTER 5 FUNCTIONS FOR BASIC MACHINE OPERATION ……………………………… 5-1

5-1) NAMES AND FUNCTIONS OF PARTS IN OPERATION BOX ………………… 5-1

5-2) EMERGENCY POWER AND START/STOP/BAR SWITCH ……………………… 5-4

5-3) EMERGENCY STOP ………………………………………………………………… 5-6

5-4) LAMP ON THREAD TENSION ADJUSTMENT BOARD ………………………… 5-7

5-5) NEEDLE STOP CLUTCH (JUMP) ………………………………………………… 5-8

5-6) UPPER THREADING AND TENSION ADJUSTMENT …………………………… 5-9

5-7) LOWER (BOBBIN) THREADING AND TENSION ADJUSTMENT ……………… 5-12

5-8) BOBBIN WINDER …………………………………………………………………… 5-13

5-9) FLOPPY DISKS ……………………………………………………………………… 5-16

5-10) IN AND OUT OF DESIGNS ……………………………………………………… 5-18

5-10-1) FLOPPY …………………………………………………………………… 5-18

5-10-2) TAPE ……………………………………………………………………… 5-18

5-10-3) EMBROIDERY OUTPUT ………………………………………………… 5-18

5-11) RETURN TO PREVIOUS LOCATION IN UNEXPECTED BLACKOUTS ……… 5-18

5-12) NEEDLE- HOOK TIMING CONTROL …………………………………………… 5-19

5-13) ASSEMBLY AND FUNCTIONS OF THREAD DETECTOR …………………… 5-24

5-13-1) FUNCTIONS OF THREAD DETECTOR ………………………………… 5-24

5-13-2) DISASSEMBLING THREAD DETECTOR ……………………………… 5-24

CHAPTER 6 BASIC MACHINE OPERATION …………………………………………………… 6-1

CHAPTER 7 NAVIGATING THE CONTROL PANEL …………………………………………… 7-1

7-1) INSTALLING THE OPERATING SYSTEM ……………………………………… 7-1

7-2) MAIN INDICATION SCREEN ……………………………………………………… 7-7

7-3) THE FUNCTION MENU …………………………………………………………… 7-9

7-3-1) OUTLINE OF FUNCTION MENU ………………………………………… 7-9

7-3-2) FUNCTION MENU DIAGRAM …………………………………………… 7-10

7-4) USE OF FUNCTION MENU ………………………………………………………… 7-11

7-4-1) IN AND OUT OF DESIGNS ……………………………………………… 7-11

7-4-2) BASIC SET-UP FUNCTIONS ……………………………………………… 7-22

7-4-3) SUB WORK ………………………………………………………………… 7-27

7-4-4) REPETITION WORK ……………………………………………………… 7-32

TABLE OF CONTENTS