2

English

Dear client,

We thank you for choosing one of our products, the result of technological expertise and continued research in pursuit of a superior prod-

uct in terms of safety, reliability and features.

Inthis manual you will find all the information and useful advice necessary to get the most out of your appliance in total safety.

DT2010001-00

IMPORTANT INFORMATION DT2010208-02

REFERENCE STANDARDS DT2010209-00

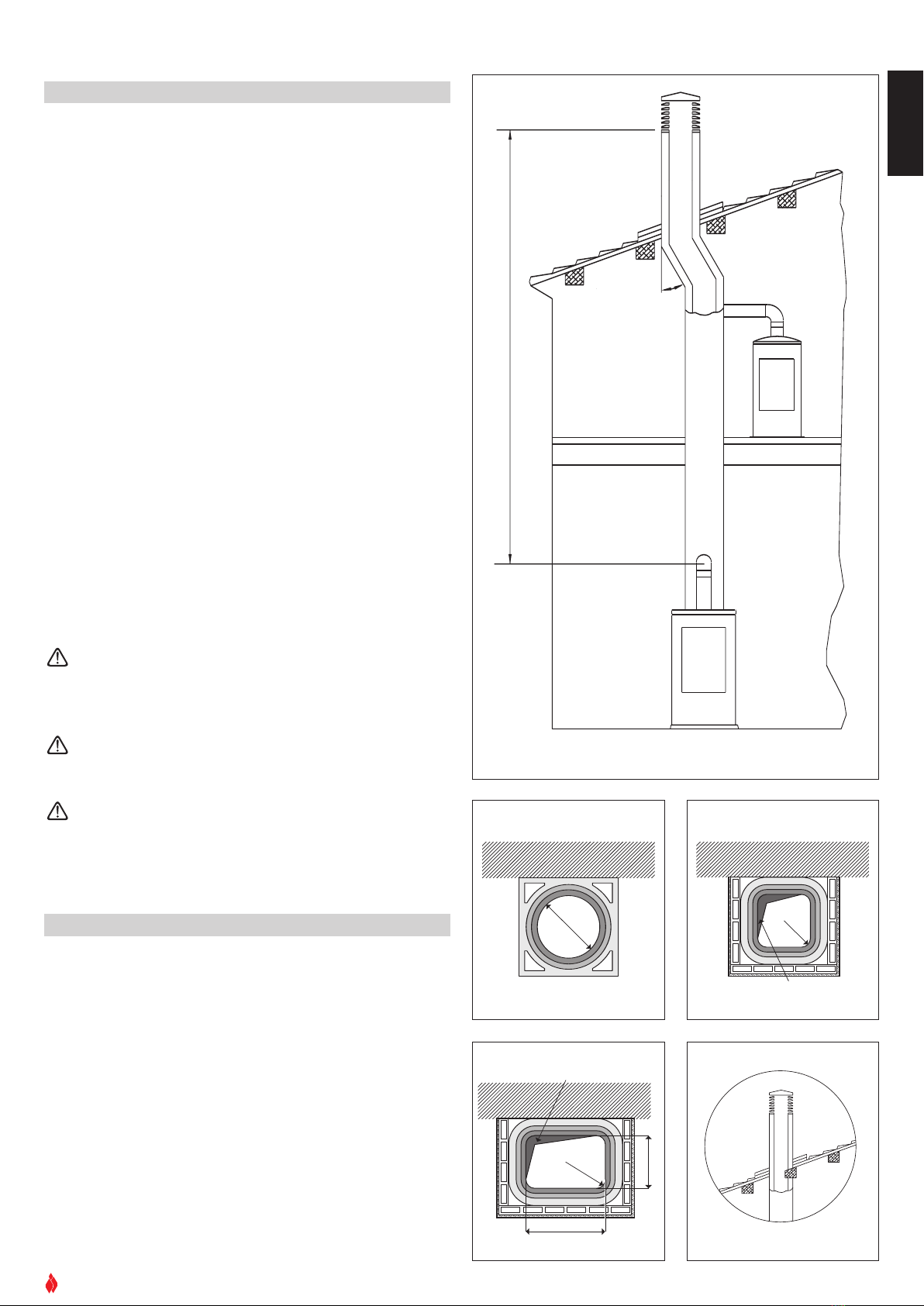

The assembly of the cover should be undertaken by two people (follow the assembly instructions in the attached booklet).

Plans and diagrams are supplied as examples at the manufacturer’s discretion; in the pursuit of a policy of continuous development and innova-

tion the manufacturer may, without prior warning, make any modifications deemed appropriate.

This document is the property of Gruppo Piazzetta S.p.A.; it may not be divulged in part or in whole to third parties without written permission from

Gruppo Piazzetta S.p.A. Gruppo Piazzetta S.p.A. reserves all its statutory rights.

•This manual has been prepared by the manufacturer and constitutes an integral part

of the product, and must accompany it throughout its life. In the event of sale or relo-

cation of the product make sure this booklet accompanies it, since the information

contained in it is addressed to the purchaser and to anyone involved in the installa-

tion, use and maintenance of the product.

• Read the instructions and the technical information contained in this manual care-

fully, before proceeding with installation, use or any repairs.

• The observance of the instructions and technical information in this manual guaran-

tees the safety of the user and the product, a more efficient operation and an

increased lifespan.

• The product’s installation and use should conform to the manufacturer’s instructions

and to local bylaws.

• However, when carrying out any operation we recommend that you follow carefully

the instructions contained in this manual, and that you keep it at your disposal.

• Installation, electrical connection, checks, maintenance and repairs are operations

which must be carried out exclusively by qualified and authorised personal with spe-

cialised knowledge of the product.

•Before installing the product read all instruction booklets relating to installation of the

cladding, the ventilation kit and any other accessories.

•Be verycareful when moving anyceramic components.

•Check thatthe floor where the product is to be installed is exactly level.

• To help correct potential unevenness and irregularities a sheet of adhesive fibreglass

accompanies the product.

• Do not block the electrical socket; it should be close to the unit but accessible.

•Connect the pellet stove to the electricity supply only after it has been connected by

an expert to the flue system.

• The plug at the end of the power supply cable must be easily accessible after instal-

lation.

• Use only regulation wood pellets (refer to section entitled “Technical charateristics

and specifications” ).

•Never use liquid fuels to light the stove or to relight the embers.

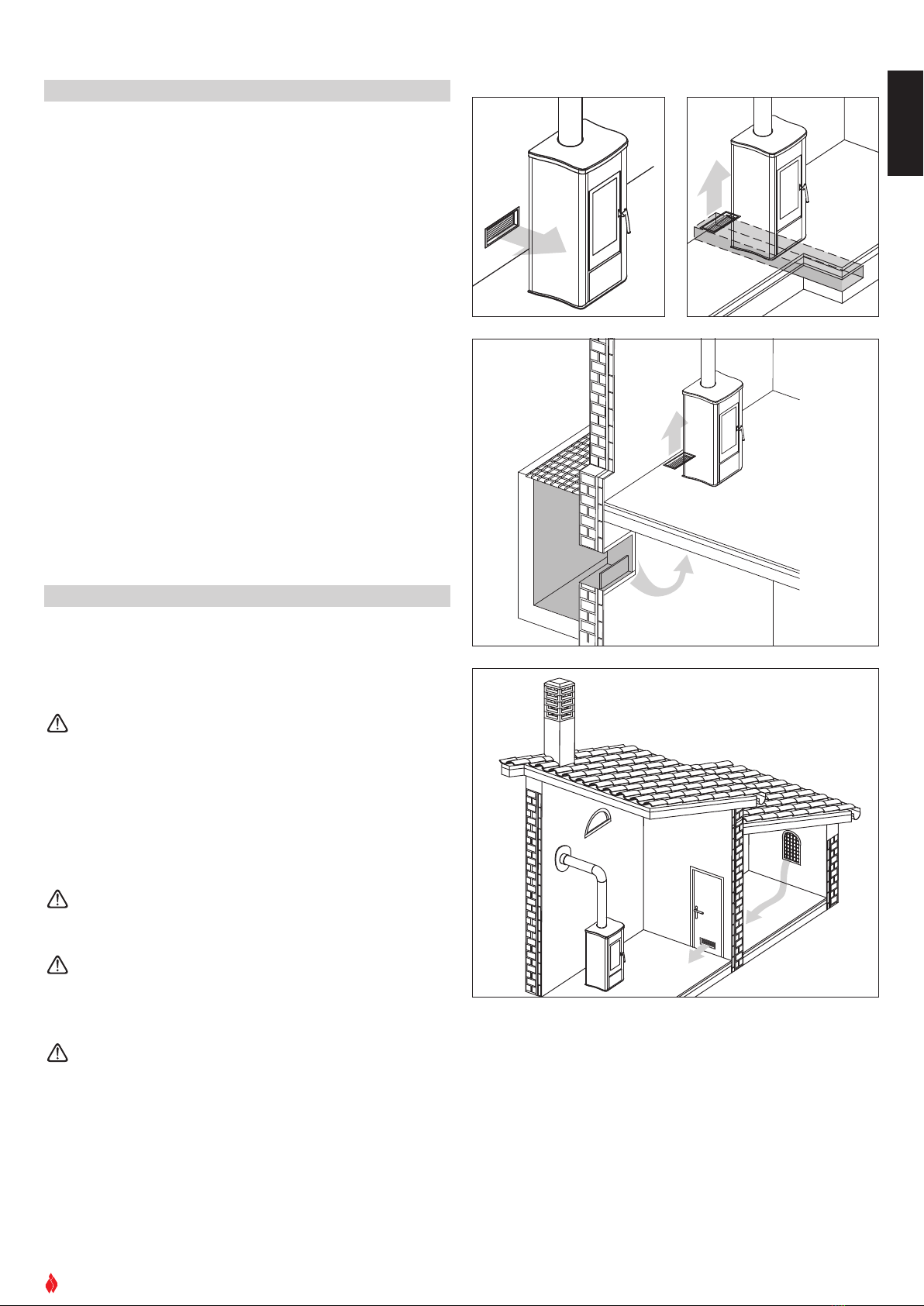

• Ensure that the area where the stove is installed is properly ventilated while the stove

is lit.

• In the event of technical faults the fuel supply will be interrupted. Restart the stove

only after having eliminated the cause of the fault.

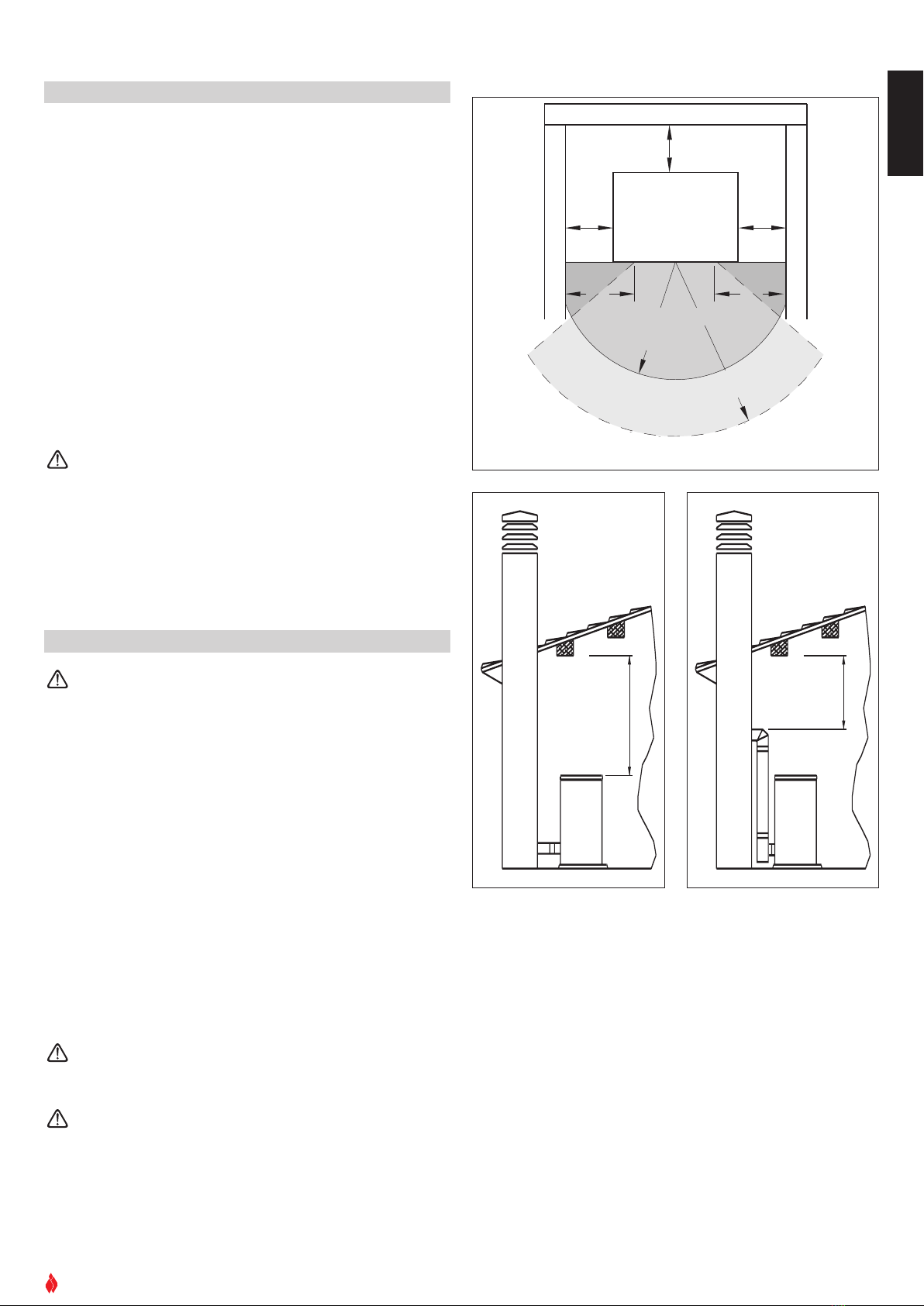

• The wall where the product is to be placed should not be of wood or any other flam-

mable material; furthermore it is important to maintain safety distances (refer to sec-

tion entitled ‘Prevention of domestic fires’ contained in the stove’s manual for use

and maintenance).

• Do not remove the protective grille from the fuel storage tank.

• Any build-up of unused pellets in the burner left over from repeated failed ignitions

must be removed before lighting the stove.

• The operation of the stove can cause surfaces, handles, flue system and glass to

become extremely hot. Touch these parts during operation only with protective cloth-

ing or other specialised equipment.

• Because of the build-up of heat on the glass, take care that those who are unaware

of the workings of the stove do not delay in the installation area.

•Keep children informed of safety measures to be followed when the stove is opera-

tional and atother times.

In the event of difficulties or if you are unable to understand the instruc-

tion manual contact your local Piazzetta dealer.

It is forbidden to place objects which are not heat-resistant on top of the

stove or within the prescribed minimum safety zone.

It is forbidden to open the door while the stove is in operation or to oper-

ate the stove when the glass is broken.

DIN 18894 Solid fuel stoves and fireplaces - Pellet-fired stoves - Requirements, testing and marking

UNI 10344 Heating of buildings. Calculation of energy requirements

UNI 10683 Wood-fired heat generators, Installation requirements

UNI 10847 Single flue systems for liquid and solid fuel generators - Maintenance and control - Guidelines and

procedures

UNI 7129 Gas installations for domestic use fired by mains gas supply

DIN 51731 class HP2 Fuels