2

HV9910DB3v.3

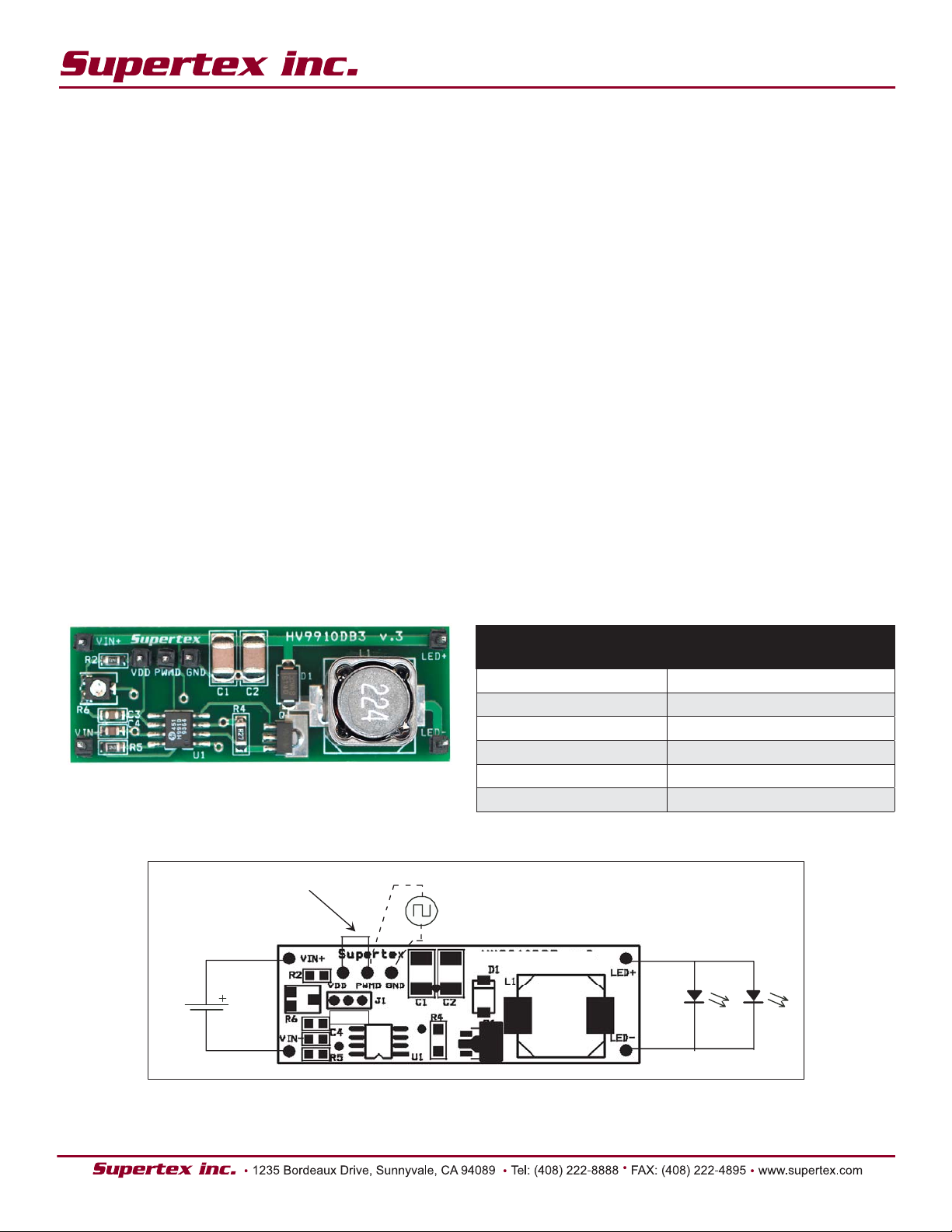

VIN+: Connect the positive terminal of the DC input source

to this pin.

VIN-: Connect the negative terminal of the DC input source

to this pin.

LED+: Connect the Anode of the LED(s) to this pin.

LED-: Connect the Cathode of the LED(s) to this pin.

VDD:This pin is connected to the VDD pin of the HV9910/

HV9910B. The typical voltage on the pin is 7.6V. This voltage

can be used to drive any additional circuitry required. Please

see the datasheet regarding the output current capability at

the VDD pin.

GND: This pin is connected to the Ground connection of the

buck converter.

PWMD: This terminal can be used to either enable/disable

the converter or to apply a PWM dimming signal.

To just enable the converter, connect the PWMD pin to the

VDD pin. Disconnecting the PWMD pin will cause the circuit

to stop.

PWM dimming of the LED light can be achieved by turning

the converter on and off with a low frequency 50Hz to 1000Hz

TTL logic level signal. Changing the Duty Ratio of the signal

changes the effective average current via the LEDs, thus

changing the light emission.

Note: In the case of PWM dimming, the PWMD pin should

not be connected to the VDD pin!

J1: The three pins in J1 are used to set the current level of

the output. The HV9910DB3v.3 has two current levels:

Pin 2 connected to Pin 1: Output Current is 900mA

Pin 2 connected to Pin 3: Output current can be adjusted

using the potentiometer

LED STRING VOLTAGE

In a constant-off time buck converter, the relationship

between the output current ripple ΔI0, the LED string voltage

V0, the inductance value L, and the programmed off time toff

is given by:

From the above equation, it can be seen that for a given value

of Land toff, the output current ripple is directly proportional

to the output voltage. A plot of the current ripple vs. the

output voltage is given below:

In cases where the current ripple is too high (as a percentage

of the average LED current), it may be necessary to add

a small ceramic capacitor between the output terminals to

reduce the LED current ripple.

Testing the HV9910DB3v.3

Connect the LED string to the output terminals. Check the

polarity of the LED connection, anode end of the string

should be connected to the positive output, cathode should

be connected to the negative output. Connect the DC input

to the input terminals (check the polarity). Short the PWMD

pin to VDD. Apply a DC voltage at the input terminals and the

LED string should start to glow.

An ammeter can be connected in series with the LED(s) to

measure the output current. The current level can then be

changed by adjusting the trimming potentiometer.

Open LED test:

After the initial test of functionality, the demo board can be

tested at open LED string. The test is non-destructive and

not time restricted. Disconnect one end of the LEDs and

power up the demo. There will be no light emission and the

AC current withdrawn from the line will be very low. There is

no switching at the switching node.

Linear dimming test:

Gradual change of current via LED(s) is possible by using

the trimming potentiometer placed on the demo board. The

HV9910 has a preset voltage reference level of 250mV when

the voltage at the LD pin of the IC is above 250mV. The

external resistor divider consisting of R2 and potentiometer

R6 can change that level by pulling down the pin LD below

250mV, reducing the LED string current in linear fashion.

The maximum output current of the HV9910DB3v.3 is about

900mA.

PWM dimming test:

During normal demo board operation, by applying a PWM

TTL level signal to pin PWMD, the output current through the

LEDs can be changed in PWM fashion in a 0 to 100% range.

In this dimming mode, the output current has normally two

levels – zero and nominal current, except at very low duty

ratios where inductor current cannot ramp up to the nominal

value within the short time.

Instructions:

VL

I

t

o

off

0=⋅

∆

0

100

200

300

400

2468

Output Voltage (V)

Current Ripple (mA)