Sur-Gard SG-DV4420 User manual

1

INTRODUCTION

The Sur-Gard model SG-DV4420 is a combination of

Fire control panel and SCHED-3A communicator. This

fire transmitter consists of six channels: Two class-A

alarms A1 and A2, one End of line resistor supervisory

input S1, and three closed loop supervisory S2, S3 and

S4. There is also one programmable output, an AC fail,

and a low battery detector. The SG-DV4420 can transmit

up to ten codes to the MLR2 receiver at the central

station. It includes the 12V power supply/battery charger

and the 24V power supply for the F1/F2 modem. The

standby power is obtained from a 12V battery.

The EEPROM programming is done easily and quickly

by using the SUR-GARD SG-DVT1 SCHED-3A tester. It

is only necessary to enter the account ID and options

needed. Other data such as the function bytes, delays,

etc. can be modified to meet different operating conditions.

STAND-ALONE MODE

SG-DV4420B mounted in Multi 2XF metal cabinet with

built-in 115 to 14VAC transformer, meeting ULC

requirements as a Stand-Alone fire/sprinkler transmitter.

2

SYSTEM OVERVIEW

The SG-DV4420 is intended for use as a fire transmitter

only, for connection to a sprinkler riser or to output relay

contacts of an existing fire alarm control panel. This unit

does not include U.L.C. requirements for a complete

building fire alarm system such as multi-zone with alarm

and trouble indicators.

INPUTS

• 2 Class A zones

• 1 ELR supervisory zon

• 3 Normally closed Supervisory zones

OUTPUTS

• Power supply Vaux 12V at 250mA w/15 Ah

battery 24V at 50mA output to power modem

• Operation controlled through program options

• 1 Programmable output PGM 1: Switched to

ground with current limiting resistor

ELECTRICAL SPECIFICATIONS

MAXIMUM LOOP RESISTANCE PER CONDUCTOR

Class-A loops

A1, A2 – 100 ohms

Supervisory loops

S1 – 2700 ohms ELR +/- up to250 ohms

S2,S3,S4 – 500 ohms.

Eprom part number: Type 27C256.

Nominal current draw: 260mA with fully charged

battery and F1/F2 subset

powered.

Battery Required: 6.5 Amp hr minimum to 15

Amp hr rechargeable gel-cell

or sealed lead-acid battery

mounted in panel.

TRANSFORMER

Built-in, 16,5 Vac, 37VA Class 2 Transformer.

Dimensions: 29cm(W) x 35.5cm(H) x 12.5cm(D)

Weight: 3.7Kg

FEATURES

POWER SUPPLY

The SG-DV4420 has a built-in 12VDC to 24VDC

regulated converter power supply, to operate the F1F2

subset modem, a one Amp 12VDC power supply and

battery charger. The auxiliary power supply can be used

to power smoke detectors and other devices requiring

12VDC. 800mA 12VDC is available from the AUX

(positive) and GND (negative) terminals. It also includes

AC failure and low battery detector.

EEPROM NON-VOLATILE MEMORY

The EEPROM non-volatile memory is used to store the

programmable data needed for each installation such

as the ID code, the all call response, etc...

SERIAL OUTPUT

The serial output to the F1F2 subset modem is on a 6

position modular jack. A 6 foot modular cable is supplied

with the unit.

LOW BATTERY DETECTION

When the battery voltage falls below about 11V, this

internal circuit will be activated and the programmed

low battery code will be transmitted to the central station.

WATCH DOG CIRCUIT

The Watch Dog reset circuit continously monitors the

operation of the microprocessor. If a malfunction occurs

(due to lightning or other unusual event) this circuit will

restart the microprocessor in less than 10 seconds.

LOW BATTERY DISCONNECT CIRCUIT (NOT

ON BOARD ONLY VERSION)

If the battery voltage fall below about 10.5V, the system

will electrically disconnect the battery to prevent it from

being deep discharged. The system remains disconnected

from the battery until the AC power comes back ON or

until the dead battery is replaced with a sufficiently

charged battery.

CLASS A FIRE ZONES: “A1” & “A2”

The Fire zones A1 and A2 are supervised (normally

open alarm initiating contacts) Class A circuits designed

to accept sprinkler switches, manual pull stations, building

fire alarm control panel, alarm output relay contacts or

latching four-wire smoke detectors.

Circuit A1 has an “retard” activation delay. On alarm,

(fire loop shorted) once the activation delay has expired,

the alarm is transmitted to the central station. The “retard”

activation delay is programmed at location 21. If the fire

input A1 returns to normal or swings before the activation

delay has expired, there will be no transmitted alarm.

This activation delay feature makes it possible to use

vane type waterflow switches without false alarms from

pressure surges. There is also a restore delay time

programmable at location 22, to avoid nuisance repeat

alarms.

3

SOFTWARE SPECIAL FEATURES

EASE OF PROGRAMMING

The system ID code and other programmable parameters

will be downloaded into the module EEPROM by using

the SG-DVT1 Tester (with program version 5.0 or later)

as an access terminal. The SG-DVT1 is plugged into

the SCHED-3A line modular socket.

SELECTION OF TRANSMISSION

It is possible to select, for each zone, no transmission,

alarm transmission only or alarm and restore transmissions.

ACTIVATION AND RESTORE DELAYS

The loop A1, Low Battery detect and the AC fail detect

have programmable activation and restore delays to

reduce false alarms and nuisance troubles.

BELL OUTPUT FUNCTION ON PROG. OUTPUT #1

The PGM OUT can be activated by alarm on A1 only,

A2 only or both. It has a 17 minute autoreset.

LINE TROUBLE WARNING

If the transmission line were cut; the unit would give a

2 seconds pulse to the PGM OUT output after a

programmable delay of 60 sec. or 120 sec.

The A1/A2 Class A Fire/Sprinkler circuits must have

one closed loop between its two + terminals and another

between its two - terminals. Opening one of those loops

will cause a fire trouble and shorting across the loops will

cause a fire alarm.

SUPERVISORY INPUTS:“S1”,“S2”,“S3”,& “S4”

There are four supervisory circuits provided, which may

be used to monitor other parameters such as main

valve and\or pressure. The first supervisory loop, S1, is

an End of Line Resistor loop. The supervisory loop S1

must have a 2.7K end of line resistor.This is not a Class

B fire circuit, since either a short or an open circuit

condition causes the same supervisory signal.The

supervisory loops S2, S3 and S4, are used for normally

closed switch contacts.

PROGRAMMABLE OUTPUT: "PGM OUT"

The SG-DV4420 has one programmable output, switching

to negative, with a 150 ohm 1W current limiting resistor.

A sensitive relay (with a coil resistance of 700 ohms or

more), a buzzer, a LED or compatible DC operated

device may be connected between the AUX (positive)

terminal and the PGM OUT (switched negative) terminal

on the main board. Typical uses are: control relay, alarm

on A1 and/or A2 indicator, line trouble warning indicator,

or “Ring Back” (call received confirmation).

The operation of the Programmable Output depends

upon which option is selected in the programming table.

See the Programming Guide for a list of programmable

operation possibilities programmed at Location 27. The

programmable output can also be controlled remotely

from the receiver.

SELECTION JUMPERS

The program selection jumper must be left open.

ON BOARD LED INDICATORS (SEE FIG. #1)

WATCH-DOG: Flashes once every 10 seconds to show

unit is functioning normally. Any other flashing period

indicates a malfunction in the unit.

TX LINE: Flashes when unit transmits data.

RX LINE: Flashes following incoming data.

A1 FIRE/TROUBLE: Light ON when zone A1 in alarm

or in trouble.

A2 FIRE/TROUBLE: Light ON when zone A2 in alarm

or in trouble.

4

INSTALLATION

running close to it, to avoid electrical noise causing

disturbance to the components.

You can use up to 5 SG-DV4420 on 1 F1/F2 subset

provided they are in the same location or 1 SG-DV4420

and 1 other subscribers control such as SG-DV1660, by

using the SUR- GARD SG-DS1 module (Y connector).

You have to connect together the 24V negative terminals

of both units, separate the ID codes and program a

different all call select for each one.

F1/F2 SUBSET

1. Remove power to the F1/F2 subset by unplugging the

A.C. adaptor from the 120 VAC outlet (if installed).

Do not remove the plug from the “Adapt" input of the

F1/F2 subset while the adaptor is powered as it may

cause an arc at the input and damage the F1/F2 subset.

2. If the telephone company installed a cable on the

"Terminal" input of the F1/F2 subset, disconnect it

and connect the 6 pin modular cable MCBL6 (6 ft.)

included with the SG-DV4420. Then connect the cable

to the SG-DV4420 Fire Transmitter. A custom length

6 pin modular cable(MCBL-C) is also available on

special order from Sur-Gard. The custom cable is

available in any length up to the maximum run length

of 50 feet. See the "F1/F2 Subset Connections" diagram

on page 10.

3. The F1/F2 subset should be installed close to the

control panel. However, if it is impossible, follow

these precautions:

• Avoid cable runs close to noise generators like

power transformer, motor, fluorescent tube, etc...

• If you can’t avoid this, or the F1/F2 subset is too

far from the control panel, it is necessary to use

low capacitance shielded cable to connect the

F1/F2 subset to the control panel.

RECOMMENDED MAXIMUM WIRE RUN

The RS-232 communication (Rx & Tx) has a

recommended maximum wire run of 50 feet, using Sur-

Gard's 6 pin modular cable.

The power supply (24Vdc) has a recommended maximum

wire run of 100 feet using:

• #18 awg unshielded 4 conductor cable

• #22 or #24 awg unshielded 4 conductor cable with

2 wires connected in parallel for each of the 24VDC

Connections.

FOR LONGER DISTANCES

For RS-232 communication distances greater than 50 feet,

shielded cable with Sur-Gard's SG-DS1 connectors at

each end must be used. One SG-DS1 has to be installed

inside the Fire Transmitter cabinet and another one inside

the F1/F2 subset box, (see Appendix B for theSG-DS1

wiring diagrams). The maximum distance maybe extended

by using a shielded cable such as those described below.

BENCH TESTING

The SG-DV4420 contains factory default programming.

Any additional programming required is done through

the SG-DVT1 tester. For many applications all that will

be required is to enter the ID number. If you need help,

talk to your Sur-Gard distributor.

Program the SG-DV4420 using the SG-DVT1 Tester

(with program version 5.0 or later) as an access terminal.

The SG-DVT1 is plugged into the SCHED-3A line modular

jack. The program select jumper J2 should be removed

from the SG-DV4420 circuit board.

Connect a 2.7K end of line resistor between the S1 input

terminal and the GND terminal. Connect a jumper on each

normaly closed supervisory zone S2, S3 and S4 input.

Connect 2 loops to the A1 and A2 Sprinkler/fire class A

input terminals - out to - in , and + out to + in. To

completely test your Fire system including the communicator

data, it is necessary to connect the unit to a test set, such

as the SG-DVT1 (see system testing procedure).

Connect a 14Vac, 20VA transformer to the AC terminals.

Before plugging in the transformer, be sure the circuit

board is not resting on anything metallic which may

cause a short.

NOTE: The SG-DV4420 will not start up if AC is OFF

and the battery is low.

MOUNTING THE PANEL

Select a dry location, close to an unswitched AC source,

close to a ground connection, and close to the F1/F2

subset (modem) location.

Remove the printed circuit board and mounting hardware

from the cardboard retainer inside the panel. Before

attaching the cabinet to the wall, press the five white

nylon printed circuit board mounting studs and the ground

connection screw into the cabinet from the back.

Pull all the cables into the cabinet and prepare them for

connection before mounting the circuit board to the

back of the cabinet. Press the circuit board down onto

the mounting studs.

With power off, wire the DV4420 as shown on fig. #1. All

normally closed (N/C) loops require a jumper if not used.

The connections to the F1/F2 subset are shown on fig.

#2. Avoid running the cable close to noise generators

like power transformer, motor, fluorescent tube, etc...

HOOK-UP PROCEDURE

DO NOT connect the transformer or battery until all other

wiring has been connected (See power-up procedure).

Connect a ground cable from the cabinet ground connection

by the shortest and most direct route to a grounding rod

and to the Earth Ground Terminal on the panel.

Connect zone cables to zone loop inputs and put jumpers

or end of line resistors as required on any unused zones.

Connect wires supplying power to detectors to the auxiliary

supply. Make sure that the PC board is clear of wire

5

If the transmitter is not communicating (no signal on Rx

led of transmitter) to the central station at this point, call

the telephone Company and ask them to make sure

that the “Leg” is on. The telephone company will ask

you for the circuit number and the leg number which

can be found along with the service telephone number

on a card fixed on the F1/F2 subset.

REQUIREMENTS FOR ULC

INSTALLATION APPROVAL

• All components used in the system (contacts, detectors,

etc...) must be ULC listed.

• Wire the transformer to the A.C. line according to the

electrical code on a separate circuit breaker.

• The F1/F2 subset should be placed in a metal box,

(for example the SUR-GARD SG-UMBX1) close to

the control panel.

• The battery must have a minimum ampere hour

capacity of 6.5AH. In case of long time power failure,

the control panel must function normally for 24hrs.

NOTE: Refer to ULC Standard booklet “FIRE ALARM

CERTIFICATE SERVICE OF UNDEWRITER’S

LABORATORIES OF CANADA”. You can

contact ULC at Toronto for more information

or to obtain the booklet.

CONTROL POINT INFORMATION

Control point #1: programmable output PGM OUT

The control point #1 can be activated remotely from the

receiver. This is done by sending a command containing

the subscriber unit ID, which identifies to which unit the

command message is addressed and the point ID which

identifies the control point.

Point ID bytes are split into 2 digits. The first digit specifies

the type of command and the second digit indicates

which control point is to execute the command (on the

DV4420, the control point is always #1). The point ID

byte start with a letter from A to D, giving the desired

output function, as follows:

A. Turn On the specified point.

B. Turn Off the specified point (stop).

C. Turn On for 2 seconds (Pulse) the specified point.

D. Flash the specified point, 2 seconds On, 2 Seconds

Off, until a command is received to stop (B).

When a new command is received, for the programmable

output (control point #1), it replaces the command

previously in effect, if any.

Control point #1 can be activated internally (locally) by

the unit, for an “on time” of 2 seconds, when the SG-

DV4420 receives the “Kiss OFF” character from the

receiver. The “Kiss Off” character is sent by the receiver

as a confirmation signal that the last change of status

message from the SG-DV4420 was correctly received.

This output command takes priority over any command

that output point was already executing.

A. For 50 feet to 100 feet

• Use #18 awg shielded 4 conductor cable such

as Provo (Cat. Num. 1782-21) or Belden (Cat.

Num. 9814).

• #22 or #24 awg shielded 4 conductor cable.

B. For 100 feet to 500 feet

Use Low Capacitance #24 awg shielded 4 conductor

cable such as ALCATEL (Cat. Num. 371-02-24), Provo

(Cat. Num. 6652-21), or Belden (Cat. Num. 9927) for

the RS-232 communication (Rx, Tx, and SG).

You must also use a 24Vdc power supply (such as

Sur-Gard's SG-2415 24Vdc power supply) close to

the F1/F2 Subset to power it. Make sure to run a

wire (#18 or two #24 awg wires in parallel) between

the negative 24Vdc terminal of the Fire Transmitter

and the power supply, so that they are connected

together.

POWER-UP PROCEDURE

Before applying power to the SG-DV4420 or the F1/F2

subset, connect the 24V output to the “Batt” input of the

F1/F2 subset.

Connect the tansformer, wait approx. 5 seconds. Check

that A1 and A2 loop status led lights are off and the

green “A.C. POWER” led is on. If a led(s) does not turn

off, find the cause (such as loop open or shorted) and

correct it. If the “A.C. POWER LED” is off, find the cause

(such as breaker turned off) and correct it.

NOTE: To supply AC power to the SG-DV4420, the

transformer should not be connected to an

outlet that is controlled by a switch.

Check for the WATCH-DOG led pulses. This led indicator

flashes once every 10 seconds to show unit is functioning

normally. Activate a zone to be sure that the panel is

responding to signals. If the panel does not respond

and there are no indicators on, check that the wiring is

correct. If the panel is responding normally, connect the

battery. The red battery lead attaches to the positive

battery post and the black battery lead attaches to the

negative battery post.

SYSTEM TESTING

First test the system thoroughly using an SG-DVT1 tester.

Contact the monitoring station to request a transmission

test before connecting the 6 pin modular cable to the

modem. Trip an alarm on any loop. Wait for the

communication to complete and check with the monitoring

station to confirm the transmission. You can use the Rx/

Tx Led indicator to see if the transmitter receives or

transmits. Perform additional transmissions required by

the monitoring station.

The system should be tested on batteries only and AC

only, to be sure that both supplies are present and

adequate. Make sure that the AC Power to the unit is

connected to a separate, well marked, circuit breaker

which will not be turned off by accident.

6

SG-DV4420 WIRING DIAGRAM

NOT

USED

14VAC, 20VA

14V14V

14V14V

14VACAC

ACAC

AC,

7

F1/F2 SUBSET CONNECTION DIAGRAM

8

SG-DVT1 CONNECTION DIAGRAM

9

PROGRAMMING - GETTING STARTED

When the connection is established the SG-DV4420

will identify itself on the display as follows:

PROGRAMMING MODEPROGRAMMING MODE

PROGRAMMING MODEPROGRAMMING MODE

PROGRAMMING MODE

and

SG-DV4420 V1.0SG-DV4420 V1.0

SG-DV4420 V1.0SG-DV4420 V1.0

SG-DV4420 V1.0

CONNECTING...CONNECTING...

CONNECTING...CONNECTING...

CONNECTING... ... CONNECTED... CONNECTED

... CONNECTED... CONNECTED

... CONNECTED

At this point the connection is complete and the SG-

DV4420 is ready to accept programming commands

from the SG-DVT1. The SG-DVT1 is in programmer mode

and will prompt you with the following message:

Prog. all data ?Prog. all data ?

Prog. all data ?Prog. all data ?

Prog. all data ?

YES NO EXITYES NO EXIT

YES NO EXITYES NO EXIT

YES NO EXIT

ENT SEL1 SEL2

At this message you can select if all data needs to be

programmed (press [ENT] to go in the programming all

data mode) or just selected few (press [SEL1] to go in

the programming selected data mode). You may also

select EXIT option to quit programmer mode by pressing

the [SEL2] button.

PROGRAMMING ALL DATA MODE

Press [ENT] to programm all data.

Prog. all data ?Prog. all data ?

Prog. all data ?Prog. all data ?

Prog. all data ?

YES NO EXITYES NO EXIT

YES NO EXITYES NO EXIT

YES NO EXIT

ENT SEL1 SEL2

When [ENT] is pressed to select YES, the SG-DV4420

will ask if you want to reset all data to defaults with the

following message:

Reset ALL Data ?Reset ALL Data ?

Reset ALL Data ?Reset ALL Data ?

Reset ALL Data ?

NO YES EXITNO YES EXIT

NO YES EXITNO YES EXIT

NO YES EXIT

ENT SEL1 SEL2

Press [ENT] if reset to defaults is not required or press

[SEL1] to reset data to defaults. You may also select

EXIT option to return to the programmer mode by

pressing the [SEL2] key.

If you press [SEL1], then the SG-DV4420 will prompt

you to go ahead with reset to factory defaults with the

following message:

ARE YOU SURE ?ARE YOU SURE ?

ARE YOU SURE ?ARE YOU SURE ?

ARE YOU SURE ?

NO YES EXITNO YES EXIT

NO YES EXITNO YES EXIT

NO YES EXIT

ENT SEL1 SEL2

Press [SEL1] to confirm or press [ENT] or [SEL2] to abort

the operation. If you press [ENT], the SG-DV4420 will go

to the Programming All Data Mode. If you press [SEL2],

the SG-DV4420 will return to the programmer mode. If

[SEL1] is pressed, the SG-DV4420 will prompt you with

the following message if the operation was aborted:

Writing FactoryWriting Factory

Writing FactoryWriting Factory

Writing Factory

and

Writing COMPLETEWriting COMPLETE

Writing COMPLETEWriting COMPLETE

Writing COMPLETE

Defaults, WaitDefaults, Wait

Defaults, WaitDefaults, Wait

Defaults, Wait

S1=DIG1 S2=DIG2S1=DIG1 S2=DIG2

S1=DIG1 S2=DIG2S1=DIG1 S2=DIG2

S1=DIG1 S2=DIG2

ADDR=00 DATA=0ADDR=00 DATA=0

ADDR=00 DATA=0ADDR=00 DATA=0

ADDR=00 DATA=011

11

1

The SG-DV4420 has it’s own EEPROM which is used

to keep in memory all the installer programming and

that won’t erase in case of power failure.

All programming must be done according to the

standards and requirements of the central station to

which this equipment is connected, and according to

the restrictions of Underwriters' Laboratories of

Canada, if applicable.

The system ID code and other programmable parameters

can be changed in the EEPROM by using the SG-DVT1

Tester (with program version 5.0 or later) as an access

terminal. The SG-DVT1 is plugged into the SCHED-3A

line modular socket. The program select jumper J2 should

be temporarily removed.

TRANSFER OF DEFAULTS TO THE EEPROM

(Hardware Reset of EEPROM to Factory Defaults). Use

the following procedure:

1. Power down the SG-DV4420 by removing both AC

and battery power.

2. Using a Plug-In jumper borrowed from J2, short pins

marked EEPROM RESET J1 together.

3. Power up the SG-DV4420 and wait approx. 5 seconds.

4. Remove the Plug-In jumper.

PROGRAMMING WITH THE SG-DVT1

Connect a SG-DVT1 (version 5.0 or more) to the SG-

DV4420 (see figure #3). Unplug the modular cable

connected to modem and connect it to SG-DVT1

transmitter jack (XTR).

Power up the SG-DVT1 Tester by connecting it to the

control panel battery using the two alligator clip (make

sure to respect the right polarities).

At the power up the SG-DVT1 display shows:

SELECT MODE V5.0SELECT MODE V5.0

SELECT MODE V5.0SELECT MODE V5.0

SELECT MODE V5.0

NOW: SCAN MODENOW: SCAN MODE

NOW: SCAN MODENOW: SCAN MODE

NOW: SCAN MODE

ENT SEL1 SEL2

Select the “PROG MODE” on the SG-DVT1 by Pressing

[SEL1] twice. The SG-DVT1 screen should be as follows:

SELECT MODE V5.0SELECT MODE V5.0

SELECT MODE V5.0SELECT MODE V5.0

SELECT MODE V5.0

NOW: PROG MODENOW: PROG MODE

NOW: PROG MODENOW: PROG MODE

NOW: PROG MODE

START PROGRAMMER MODE

Press [ENT] to start the programmer mode. The SG-

DVT1 will initiate the handshake with the SG-DV4420.

SELECT MODE V6.0SELECT MODE V6.0

SELECT MODE V6.0SELECT MODE V6.0

SELECT MODE V6.0

NOW: PROG MODENOW: PROG MODE

NOW: PROG MODENOW: PROG MODE

NOW: PROG MODE

ENT SEL1 SEL2

10

At this screen the cursor will be flashing at data digit 2.

Press [SEL1] to increment the first digit of data or press

[SEL2] to increment the second digit of data. Once the

desired data value is reached press [ENT] to accept the

change in data value. The SG-DV4420 will refresh the

display for the next address. The SG-DVT1 will display

“continue programming ?” prompt if no data is changed

for two consecutive addresses.

Continue Prog. ?Continue Prog. ?

Continue Prog. ?Continue Prog. ?

Continue Prog. ?

YES REDO EXITYES REDO EXIT

YES REDO EXITYES REDO EXIT

YES REDO EXIT

ENT SEL1 SEL2

Press [SEL1] to redo the last address or press [ENT] to

continue with the next address. You may also select

EXIT option to return to the tester mode by pressing the

[SEL2] key.

PROGRAMMING SELECTED DATA MODE

Prog. all data ?Prog. all data ?

Prog. all data ?Prog. all data ?

Prog. all data ?

YES NO EXITYES NO EXIT

YES NO EXITYES NO EXIT

YES NO EXIT

ENT SEL1 SEL2

If you select “NO” by pressing [SEL1] at this prompt, the

SG-DV4420 will allow you to select an address:

SELECT ADDRESS:SELECT ADDRESS:

SELECT ADDRESS:SELECT ADDRESS:

SELECT ADDRESS:

ADDR=0ADDR=0

ADDR=0ADDR=0

ADDR=000

00

0

At this screen the cursor will be flashing at address

digit 2. Change the address to the desired address by

pressing [SEL1] to increment the first digit of address

or [SEL2] to increment the second digit of address.

Once the address is selected, press [ENT] and the

current data at that address will show:

SELECT ADDRESS:SELECT ADDRESS:

SELECT ADDRESS:SELECT ADDRESS:

SELECT ADDRESS:

ADDR=00 DATA=0ADDR=00 DATA=0

ADDR=00 DATA=0ADDR=00 DATA=0

ADDR=00 DATA=011

11

1

The flashing cursor will indicate that you can change

the data now. Change the data to the desired data by

pressing [SEL1] to increment the first digit of data or

[SEL2] to increment the second digit of data. Once the

desired address value is reached, press [ENT] for the

SG-DV4420 to accept the change in address value. The

SG-DV4420 will refresh the display for the next address.

If no address or data is changed for two consecutive

addresses then the SG-DVT1 will prompt you if to

continue programming as follows:

Continue Prog. ?Continue Prog. ?

Continue Prog. ?Continue Prog. ?

Continue Prog. ?

YES REDO EXITYES REDO EXIT

YES REDO EXITYES REDO EXIT

YES REDO EXIT

ENT SEL1 SEL2

Press [SEL1] to redo the last address or press [ENT] to

continue with the next address. You may also select

EXIT option to return to the programmer mode by

pressing the [SEL2] key.

EXIT PROGRAMMER MODE

To exit programmer mode, select EXIT from continue

message from PROGRAMMING ALL DATA mode or

PROGRAMMING SELECTED DATA mode and then select

EXIT from programming all data prompt by pressing the

[SEL2] key.

Prog. all data ?Prog. all data ?

Prog. all data ?Prog. all data ?

Prog. all data ?

YES NO EXITYES NO EXIT

YES NO EXITYES NO EXIT

YES NO EXIT

ENT SEL1 SEL2

The SG-DV4420 will prompt as follows:

PROGRAMMING MODEPROGRAMMING MODE

PROGRAMMING MODEPROGRAMMING MODE

PROGRAMMING MODE

ENDED! BYE...ENDED! BYE...

ENDED! BYE...ENDED! BYE...

ENDED! BYE...

This concludes the SG-DV4420 programming.

11

[03] TO [0C] TRANSMISSION SELECT

It is possible to select, for each zone, no transmission,

alarm transmission only or alarm and restore transmission.

This feature provides for by-passing zones you don’t

want transmitted to the receiver.

00 = NO TRANSMISSION.

01 = TRANSMISSION OF ALARM ONLY.

02 = TRANSMISSION OF ALARM AND RESTORE

DEFAULT

[03] Transmission Select for FIRE INPUT A1 02

[04] Transmission Select for FIRE TROUBLE A1 02

[05] Transmission Select for FIRE INPUT A2 02

[06] Transmission Select for FIRE TROUBLE A2 02

[07] Transmission Select for SUPERVISORY S1 02

[08] Transmission Select for SUPERVISORY S2 02

[09] Transmission Select for SUPERVISORY S3 02

[0A] Transmission Select for SUPERVISORY S4 02

[0B] Transmission Select for LOW BATT. DETECT 02

[0C] Transmission Select for AC FAIL DETECT 02

[0D] TO [16] ZONE ASSIGNMENT

This feature permits each zone to be assigned to the

zone number desired, taking full advantage of the receiver

line card decoding. DEFAULT

[0D] Zone Assignment for FIRE INPUT A1 01

[0E] Zone Assignment for FIRE TROUBLE A1 02

[0F] Zone Assignment for FIRE INPUT A2 03

[10] Zone Assignment for FIRE TROUBLE A2 04

[11] Zone Assignment for SUPERVISORY S1 05

[12] Zone Assignment for SUPERVISORY S2 06

[13] Zone Assignment for SUPERVISORY S3 07

[14] Zone Assignment for SUPERVISORY S4 08

[15] Zone Assignment for LOW BATT. DETECT 01

[16] Zone Assignment for AC FAIL DETECT 02

[17] TO [20] FUNCTION BYTE

This feature permits each zone to be assigned to the

zone description desired, taking full advantage of the

receiver line card decoding for central station without

automation. DEFAULT

[17] Function Byte for FIRE INPUT A1 50

[18] Function Byte for FIRE TROUBLE A1 50

[19] Function Byte for FIRE INPUT A2 50

[1A] Function Byte for FIRE TROUBLE A2 50

[1B] Function Byte for SUPERVISORY S1 50

[1C] Function Byte for SUPERVISORY S2 50

[1D] Function Byte for SUPERVISORY S3 50

[1E] Function Byte for SUPERVISORY S4 50

[1F] Function Byte for LOW BATT. DETECT 51

[20] Function Byte for AC FAIL DETECT 51

PROGRAMMING GUIDE

NOTE: All data shown are generally in Decimal

Values (Except for alarm/restore codes which

may be in Hex value). The locations are in

Hex value.

LOCATION

[00] IDENTIFICATION CODE

You may change the account identification code by

entering a two digit number in hex. (DEFAULT 01).

[01] OPTION 1 - ALL CALL SELECT

An “All Call” is a command sent by the central station’s

receiver after each scanning of 8 identification codes.

If a transmitter has an alarm at this moment, it can be

sent immediately to the central station, if the unit is

programmed to respond to that “All Call”. With this feature,

it is usually not necessery for that transmitter to wait for

its turn to be polled, before it is able to send an alarm

to the central station.

00 = NO RESPONSE ON ALL CALL,

01 = RESPONSE ON ALL CALL #1 ONLY,

02 = RESPONSE ON ALL CALL #2 ONLY,

03 = RESPONSE ON BOTH ALL CALLS ( #1 AND #2 ).

04 = RESPONSE ON ALL CALL #1 IF ID CODE IS

ODD AND ON ALL CALL #2 IF ID CODE IS EVEN.

NOTE: A number programmed higher than 04 gives

the same selection as 04. When 2 transmitters

are used on the same F1F2 subset, each

must have a different All Call. (DEFAULT 04).

Example of receiver scanning

01-02-03..08-ALL CALL #1-09-0A-0B..10-ALL CALL #2-

..

It is recommended that just 1 All Call be selected, and

the choice of All Call be divided evenly over the installations.

In this way, approximately an equal number of subscribers

will be programmed for All Calls #1 and #2.

If two units are connected on the same modem (F1F2

subset): Skip at least 2 codes between your 2 identification

codes. (ex: #01,#04 so that 02 and 03 are used at other

locations.) Each unit should have a different All Call

selected. So with automatic all call selection, you should

have an odd and an even identification code. No response

on All Call should be used for lower security installations,

and when more than two units are connected to one

modem - for the 3rd and additional units.

[02] OPTION 2 - ALL CALL ANSWER SELECT

00 = ALL CALL ANSWER ON ALARM AND RESTORE.

01 = ALL CALL ANSWER ON ALARM ONLY.

The unit can send an alarm and a restore on All Call,

but it is possible and preferable to limit it to sending

only the alarms and wait for the polling of its account

code before sending the restores. (DEFAULT 01).

12

NOTE: For a listing of all function byte possibilities,

refer to “Line Card DVACS* Alarm Decoder

Version 4” sheet.

[21] TO [26] ACTIVATION AND RESTORE DELAYS

The loop A1, Low Battery detect and the AC fail detect

have programmable activation and restore delays to

reduce false alarms and nuisance troubles. Program

the duration of activation and restore delays in seconds

(in decimal).

DEFAULT

[21] Activation Delay for FIRE A1 20

[22] Restore Delay for FIRE A1 40

[23] Activation Delay for AC FAIL 20

[24] Restore Delay for AC FAIL 40

[25] Activation Delay for LOW BATT. 20

[26] Restore Delay for LOW BATT. 40

[27] PROGRAMMABLE OUTPUT MODE

The programmable output can be activated as indicated

below. (DEFAULT = 04).

LEFT DIGIT:

0X = NO INDICATION.

1X = ALARM ON A1 INDICATION.

2X = ALARM ON A2 INDICATION.

3X = ALARM ON A1 OR A2 INDICATION.

4X = LINE FAULT INDICATION.

8X = RING BACK (CONFIRMATION) SIGNAL AFTER

KISS OFF (2 SECONDS PULSE). RIGHT DIGIT IS

IGNORED

RIGHT DIGIT:

The programmable output activation time, after an event

selected with left digit, can be selected as indicated below.

X0 = Steady ON.

X1 = Indication (2 sec. pulse) after 30 sec.

X2 = Indication (2 sec. pulse) after 60 sec.

*DVACS is a registered trade mark of Electro Arts Limited and covers

a wide variety of products.

Full DVACS compatability applies only when the Sur-Gard equipment is

connected to the RS-232 port of a DVACS F1F2-List 3 (or a DVACS

F1F2-List 1) subset which is connected to a DVACS HUB-324 (or DVACS

HUB-308) card.

13

PROGRAMMING WORK SHEET

CUSTOMER ______________________________________ CONTACT ________________________________________

ADDRESS ___________________________________________________________________________________________

____________________________________________________________________________________________________

TEL. # ___________________________________________ FAX # ____________________________________________

ID CODE _________________________________________ LINE # ___________________________________________

CHECKSUM ______________________________________ DATE ____________________________________________

Automation

Location Default USER

[00] Identification Code 00 I____|____|

[01] All Call 04 I____|____|

[02] All Call Answer on alarm only\alarm restore 01 I____|____|

[03] Transmission Select for FIRE INPUT A1 02 I____|____|

[04] Transmission Select for FIRE TROUBLE A1 02 I____|____|

[05] Transmission Select for FIRE INPUT A2 02 I____|____|

[06] Transmission Select for FIRE TROUBLE A2 02 I____|____|

[07] Transmission Select for SUPERVISORY S1 02 I____|____|

[08] Transmission Select for SUPERVISORY S2 02 I____|____|

[09] Transmission Select for SUPERVISORY S3 02 I____|____|

[0A] Transmission Select for SUPERVISORY S4 02 I____|____|

[0B] Transmission Select for LOW BATT. DETECT 02 I____|____|

[0C] Transmission Select for AC FAIL DETECT 02 I____|____|

[0D] Zone Assignment for FIRE INPUT A1 01 I____|____|

[0E] Zone Assignment for FIRE TROUBLE A1 02 I____|____|

[0F] Zone Assignment for FIRE INPUT A2 03 I____|____|

[10] Zone Assignment for FIRE TROUBLE A2 04 I____|____|

[11] Zone Assignment for SUPERVISORY S1 05 I____|____|

[12] Zone Assignment for SUPERVISORY S2 06 I____|____|

[13] Zone Assignment for SUPERVISORY S3 07 I____|____|

[14] Zone Assignment for SUPERVISORY S4 08 I____|____|

[15] Zone Assignment for LOW BATT. DETECT 01 I____|____|

[16] Zone Assignment for AC FAIL DETECT 02 I____|____|

[17] Function Byte for FIRE INPUT A1 50 I____|____|

[18] Function Byte for FIRE TROUBLE A1 50 I____|____|

[19] Function Byte for FIRE INPUT A2 50 I____|____|

[1A] Function Byte for FIRE TROUBLE A2 50 I____|____|

[1B] Function Byte for SUPERVISORY S1 50 I____|____|

14

Automation

Location Default USER

[1C] Function Byte for SUPERVISORY S2 50 I____|____|

[1D] Function Byte for SUPERVISORY S3 50 I____|____|

[1E] Function Byte for SUPERVISORY S4 50 I____|____|

[1F] Function Byte for LOW BATT. DETECT 51 I____|____|

[20] Function Byte for AC FAIL DETECT 51 I____|____|

[21] Activation Delay for FIRE A1 20 I____|____|

[22] Restore Delay for FIRE A1 40 I____|____|

[23] Activation Delay for AC FAIL 20 I____|____|

[24] Restore Delay for AC FAIL 40 I____|____|

[25] Activation Delay for LOW BATT. 20 I____|____|

[26] Restore Delay for LOW BATT. 40 I____|____|

[27] Programmable Output Mode 04 I____|____|

CHART OF PROGRAMMABLE ZONE BITS AND FUNCTION BYTES

PROGRAM VERSION DV-4420-A (AUTOMATION) AND DV-4420-L (LIBRARY 4/2 STYLE)

DV-4420-A (Automation) DV-4420-L (Library 4/2 style)

Input Zone Std. F. byte Funct. Zone Zone Std. F. byte Funct. Zone

Name bit Addr Zn bit Addr byte Description bit Addr Zn bit Addr byte Description

Fire A1 0D 01 17 50 ----- Alm Zn#01 0D 01 17 30 Water Alm Zn# 01

Trouble A1 0E 02 18 50 ----- Alm Zn# 02 0E 01 18 37 Other Trb Zn# D8

Fire A2 0F 03 19 50 ----- Alm Zn# 03 0F 01 19 0C Fire Alm Zn# 10

Trouble A2 10 04 1A 50 ----- Alm Zn# 04 10 02 1A 37 Other Trb Zn# D9

Sup. 1 11 05 1B 50 ----- Alm Zn# 05 11 01 1B 35 Lpres Trb Zn# C8

Sup. 2 12 06 1C 50 ----- Alm Zn# 06 12 01 1C 34 Hpres Trb Zn# C0

Sup. 3 13 07 1D 50 ----- Alm Zn# 07 13 01 1D 36 Valve Trb Zn# D0

Sup. 4 14 08 1E 50 ----- Alm Zn# 08 14 01 1E 40 Tempr Alm Zn# 01

Low Batt. 15 01 1F 51 ----- Alm Zn# 09 15 08 1F 6D LowBt Alm Zn# 08

AC Fail 16 02 20 51 ----- Alm Zn# 10 16 03 20 37 Other Trb Zn# DA

“AUTOMATION” means suggested function bytes to program if the receiver is used with a central station computer

software such as SIMS or TAMCO and/or to have the alarms received as zones 1-10 without descriptive words such

as “Fire” or “Valve”.

“LIBRARY 4/2 STYLE” means suggested function bytes to program to display a “4/2 style” zone description. When

output to the printer or RS-232 computer port, the first digit of the zone tells you what type of zone it is, and the second

digit tells you what zone number it is, (just like the 2 digit alarm code in 4/2 digital dialer format). In the example, the

zone will be received as “Water alarm zone #01” for the Fire zone A1, “Fire alarm zone #10” for the Fire zone A2, etc...

15

PROBLEM, SYMPTOMS

Questions to ask yourself when doing

troubleshooting:

nNew installation?

nExisting installation that was working?

nCommunication failed under what

circumstances? (during power failure,

after work done on building or system)

nIntermittent problem?

SOLUTION, ACTION

1. Verify the Tx and Rx led indicators on the panel:

RX: Should flash with polling at fairly steady rate.

If inactive, check that the panel is otherwise

functioning, check the watch dog led, and items

2 through 4 below, then contact the telephone

company to be sure that leg is “ON”.

TX: Flashes each time panel answers polling, longer

burst for alarms, restores, openings, closings,

etc... The Interval between flashes depends on

the number of subscribers polled. When an alarm

triggered, check if there is only one transmission

(burst). Often needing two or more attempts to

communicate is a sign of network problems.

2. Verify 24VDC supply to the F1/F2 modem subset. It should

be between 24 and 26VDC. If more than one panel is

connected to the same modem, negatives of the panel 24

volts modem power supplies must be connected together.

3. Verify the connections between the panel and the F1/F2

subset. Check the cable, the jacks, 24VDC power and

serial connections if more than 1 control is connected to

the same F1/F2 subset. Try your spare modular cable.

NOTE: If the cable length to the subset is longer

than 50 feet, you must use low capacitance shielded

cable for the serial connections and extra, heavy

gauge wires for the 24V

DC

.

4. Verify the options settings on the F1/F2 subset. (don’t

change them - just look and advise the telephone

company of any discrepancies!) There are 3 dip switch

units of 6 switches each inside, behind the magnetically

attached faceplate. #1 is adjusted by the telephone

company for levels. On #2, switches 2, 3, 5, 7, and 8

must be in the “ON” position. FOR #3, all switches must

be “OFF”.

5. Test the operation of the panel with a SG-DVT1 tester. If

working correctly, switch modes on the SG-DVT1 and test

communication through the F1/F2 subset and panel’s

modular cable.

TROUBLE SHOOTING

16

PROBLEM, SYMPTOMS SOLUTION, ACTION

6. If all the above checks indicate that the panel and wiring

are correct, and the SG-DVT1 cannot communicate with

the central station, contact your telephone company.

Advise the company technician of any action taken so

far. Request that the telephone company verify the

following:

nThe leg on status

nHub options

nLoop back test

nReceiver polling seen on leg

nControl panel answering polling

Your tests above will give you an indication of what

to expect. For example, If the panel Tx led shows no

activity, you won’t expect the telephone company to

see the panel answering the polling!

7. If there is some, but unsatisfactory communication, have

the telephone company measure the distortion on the

leg. Each bit transmitted should be near 6.6mS long.

Distortion can cause bits, eg: spaces or zeros, to be

shorter and be incorrectly sampled, causing rejection of

the data. If you have the equipment and know-how,

check this yourself before calling the telephone company.

8. Check the software version of the panel,newer

programs may have some improvements to work on

higher distortion lines.

Panel sends ID ok, does not always respond to

status report requests, or does not send alarms

or other longer transmissions, or, receiver has

periods of incorrect response for this subscriber.

A1 or A2 Fire/Trouble LED on. Verify the class a loops A1 and A2 wiring: + to + , - to

- (see connection diagram page 6).

TROUBLE SHOOTING

17

APPENDIX A -

SG-DS1 WIRING DIAGRAMS

18

APPENDIX B -

SG-DV4420 PROGRAMMING FLOW CHART

V6.0V6.0 V6.0

Limited Warranty

Sur-Gard Security Systems Ltd. warrants that for a period of twelve months from the date of purchase, the product shall be free

of defect in materials and workmanship under normal use and that in fulfilment of any breach of such warranty,

Sur-Gard Security Systems Ltd. shall, at its option, repair or replace the defective equipment upon return of the equipment to

its repair depot. This warranty applies only to defects in parts and workmanship and not to damage incurred in shipping or

handling, or damage due to causes beyond the control of Sur-Gard Security Systems Ltd. such as lightning, excessive

voltage, mechanical shock, water damage, or damage arising out of abuse, alteration or improper application of the

equipment.

The foregoing warranty shall apply only to the original buyer, and is and shall be in lieu of any and all other warranties, whether

expressed or implied and of all other obligations or liabilities on the part of Sur-Gard Security Systems Ltd. This warranty

contains the entire warranty. Sur-Gard Security Systems Ltd. neither assumes, nor authorizes any other person purporting to

act on its behalf to modify or to change this warranty, nor to assume for it any other warranty or liability concerning this

product.

In no event shall Sur-Gard Security Systems Ltd. be liable for any direct, indirect or consequential damages, loss of

anticipated profits, loss of time or any other losses incurred by the buyer in connection with the purchase, installation or

operation or failure of this product.

WARNING: Sur-Gard Security Systems Ltd. recommends that the entire system be completely tested on a regular basis.

However, despite frequent testing, and due to, but not limited to, criminal tampering or electrical disruption, it is possible for

this product to fail to perform as expected.

© 1999SGSecurityCommunications

401MagneticDrive,Units24-28

Downsview,OntarioCanadaM3J3H9

Tel (416)665-4494

Fax(416)665-4222

TollFree1-800-418-7618

www.sur-gard.com 29000633R001

PrintedinCanada

This manual suits for next models

1

Table of contents

Popular Control Panel manuals by other brands

Ness

Ness D8X Installation & programming manual

Honeywell

Honeywell Silent Knight SKE Series Installation and operation manual

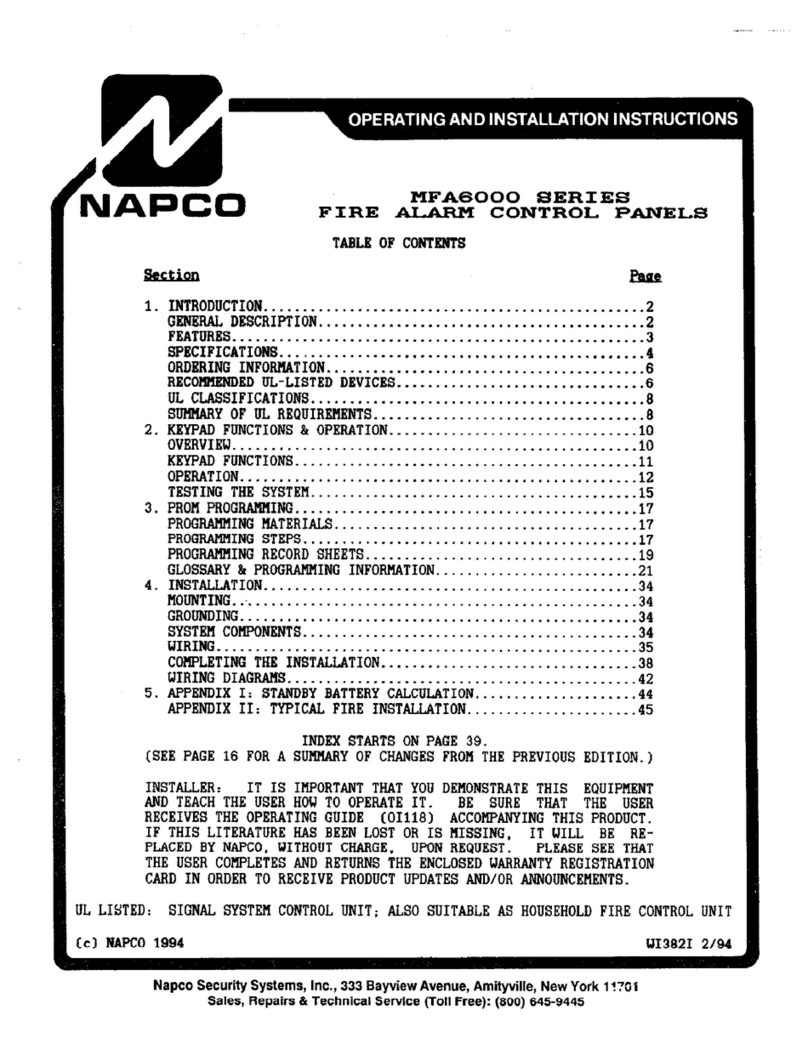

NAPCO

NAPCO MFA6000 Operating and installation instructions

EAD

EAD LP-LPD quick start guide

Biamp

Biamp TEC-X 1000 Installation & operation guide

Avanza

Avanza aSL.1503 aSmart Lite user manual