Installation Instructions

Single Lever Roman Tub Rough-In with Built-in Diverter F2003B

Tools Required for Installation

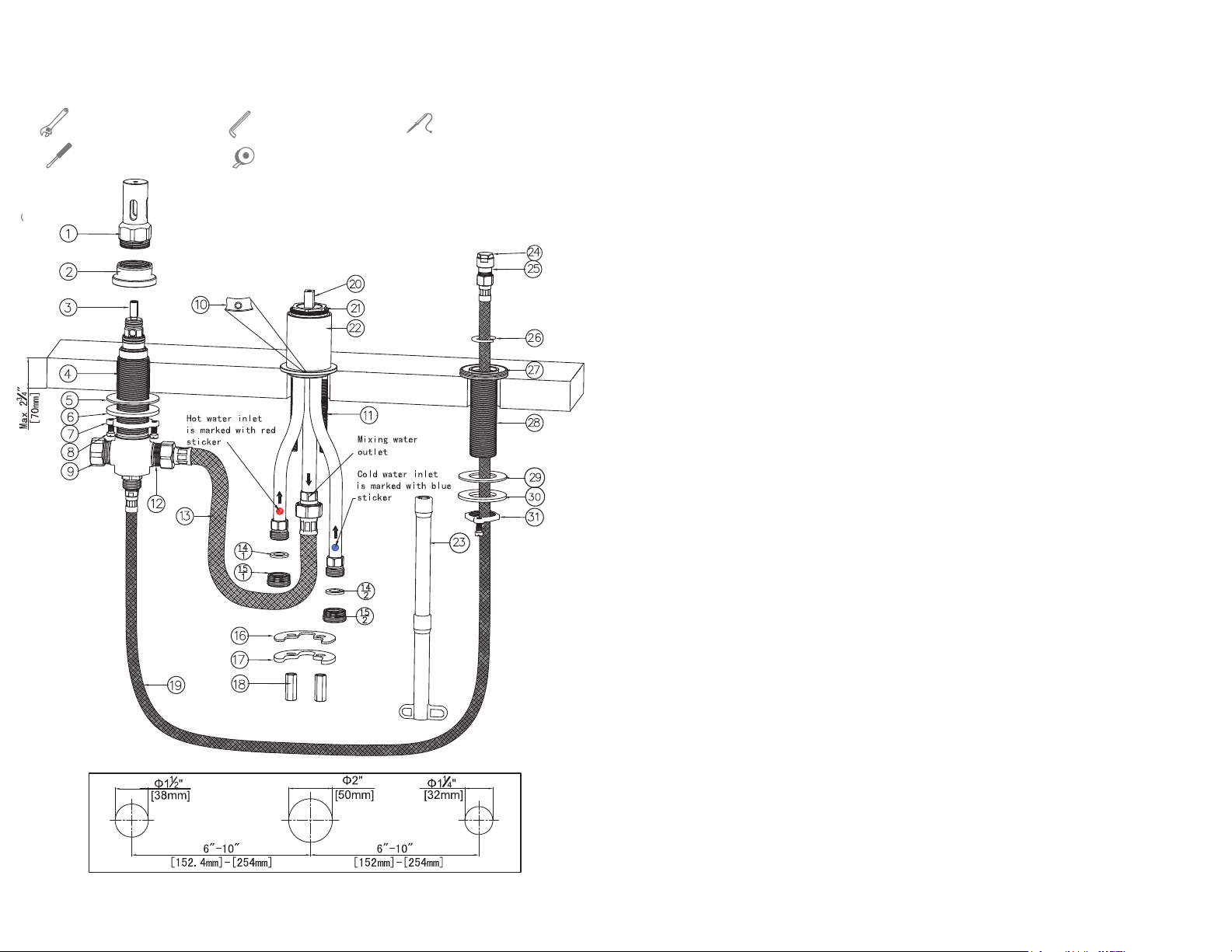

14. From underneath the deck, insert the capped

end (#24) of the braided hose (#19) through

hand shower assembly (#28).

LEAK TEST

1. Push test cap (#1) onto the top of spout

diverter assembly (#4) and thread onto top

nut (#2) until it stops.

2. Make sure braided hose (#19) is capped with

a test plug (#24).

3. Turn on cold and hot water supply lines and

inspect all connections for leaks.

4. On the finished deck, mark rough-in valve

installation location. Drill 1-1/2”(38mm) in

diameter for spout diverter assembly (#4),

drill 2” (50mm) in diameter for control unit

assembly (#22), and drill 1-1/4” (32mm) in

diameter for hand shower assembly (#28).

5. From underneath the deck, insert spout

diverter assembly (#4) through the hole with

mounting nut (#7), plate (#6) and gasket (#5)

on the spout diverter assembly (#4).

6. From above the deck, hand tighten top nut

(#2) onto diverter assembly (#4) until it stops.

8. From above the deck, insert control unit

assembly (#22) through the hole.

9. Slide mounting gasket (#16) and plate (#17)

over mounting rods (#11), and thread mount-

-ing nuts (#18) onto mounting rods (#11).

7. From underneath the deck, hand tighten

mounting nut (#7) until it stops. Then

tighten locking screws (#8) with a screw driver

to secure spout diverter assembly (#4).

10. Rotate control unit assembly (#22) until the

hole on the flange(10) points towards tub.

Then tighten mounting nuts (#18) with the

supplied socket wrench (#23).

1. Shut off cold and hot water supply.

2. Before installation, make sure the finished

deck thickness is no more than 2-3/4”(70mm).

12. From above the deck, insert hand shower

assembly (#28) through the hole.

15. Push plastic clip (#26) onto the braided hose

(#19) close to the capped end (#24). Slide down

plastic clip (#26) along the braided hose (#19)

and ensure that plastic clip (#26) sits inside the

groove of hand shower assembly’s top flange

(#27) to prevent the capped hose end (#24) from

dropping to below the finished deck.

11. Connect open port (#12) of spout diverter

assembly (#4) and outlet port (M) of control

unit assembly (#22) with the supplied 3/4”

braided hose (#13).

NOTE1: The capped port (#9) can be used.

NOTE2: Make sure braided hose (#13) is free

of kinks when it is connected.

16. Connect control unit assembly (#22) to water

supplies using proper fittings (flexible hose,

copper tubing, iron pipe or PEX -- check local

codes for proper connection). (C) is cold inlet

port marked with blue sticker and (H) is hot inlet

port marked with red sticker.

16.2. For 1/2” Copper Tube Soldering Connections,

NOTE: Prior to soldering, remove cartridge (#20)

by unscrewing retaining nut (#21). Avoid

soldering excessively at high temperature.

16.1. For 3/4” IPS Thread Connections, apply Teflon

tape onto threaded ends (#15) and connect

water supply flexible hose or tube to inlet

ports (#15).

remove 3/4” connectors (#15) and gaskets

(#14), then solder water supply tube to inlet

port (C) and (H).

3. The rough-in may be installed anywhere

on the deck. The distance between rough-

-in is recommended min 6”(152mm) and max

10”(254mm).

Adjustable Wrench Soldering Equipment

Screw Driver

Spout Diverter

Assembly

Control Unit

Assembly

Hand Shower

Assembly

Allen Wrench

Teflon Tape

(H)

(M)

(C)

13. From underneath the deck, slide mounting

gasket (#29) and plate (#30) onto hand

shower assembly (#28). Then tighten

mounting nut (#31) by hand until it stops,

and tighten locking screws with a screw

driver to secure.

3 4