8

2. Therangehoodvibrateswhentheblowerison:

- Therangehoodmightnothavebeensecuredproperlytothewall.

- Checkthemotorissecuredinplace.Ifnot,thentightenthemotorinplace.

- Checkifthereisadamagedblowerwheel.Ifsochangetheblowerwheel.

3. Theblowersseemsweak:

-

Checktheductsizeusedisatleast6”.TherangehoodWILLNOTfunctionef-

cientlywithinsufcientductsize.Ensureallductjointsaresealedproperly.

- Checkifductiscloggedorifdamperunitisnotopeningproperly.Aclogged

screenonasidewallcapunitmightalsorestrictairow.

4. Thelightsworkbuttheblowerisnotspinning,isstuckorisrattling:

- Theblowermightbejammedorscrapingthebottom.

- Themotorisdefective,possiblyseized-changethemotor.

- Thethermalprotectionsystemdetectsifthemotoristoohottooperate

andshutsthemotordown.Inthiscasethemotorwillfunctionproperlyaf-

terthethermalprotectionsystemcoolsdown(approximately20minutes).

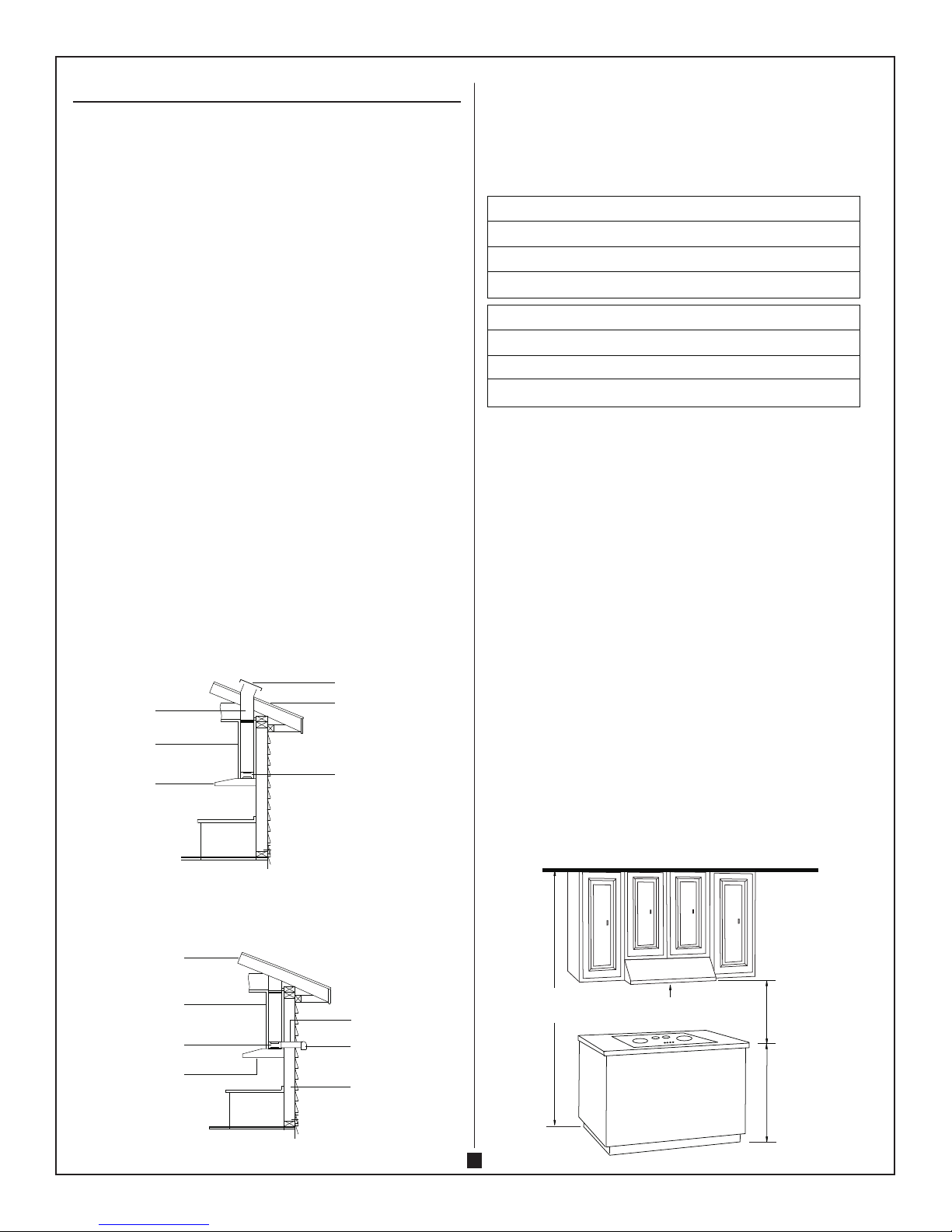

5. Thehoodisnotventingproperly:

- Makesurethedistancebetweenthecooktopandthebottomofthehood

isbetween18”to30”.

- Reducethenumberofelbowsandlengthofductwork.Checkifalljoints

areproperlyconnected,sealedandtaped.

- Makesurethepowerisonhighspeedforheavycooking.

- Windfromopenedwindowsordoorsinthesurroundingareaareaffecting

theventilationofthehood.Closeallwindowsanddoorstoeliminatethe

outsideairow.

- Checkifthedirectionofductopeningisagainstthewind.Ifso,adjustthe

directionoftheductopening.

- Checkifthewrongsizeofductsarebeingused.

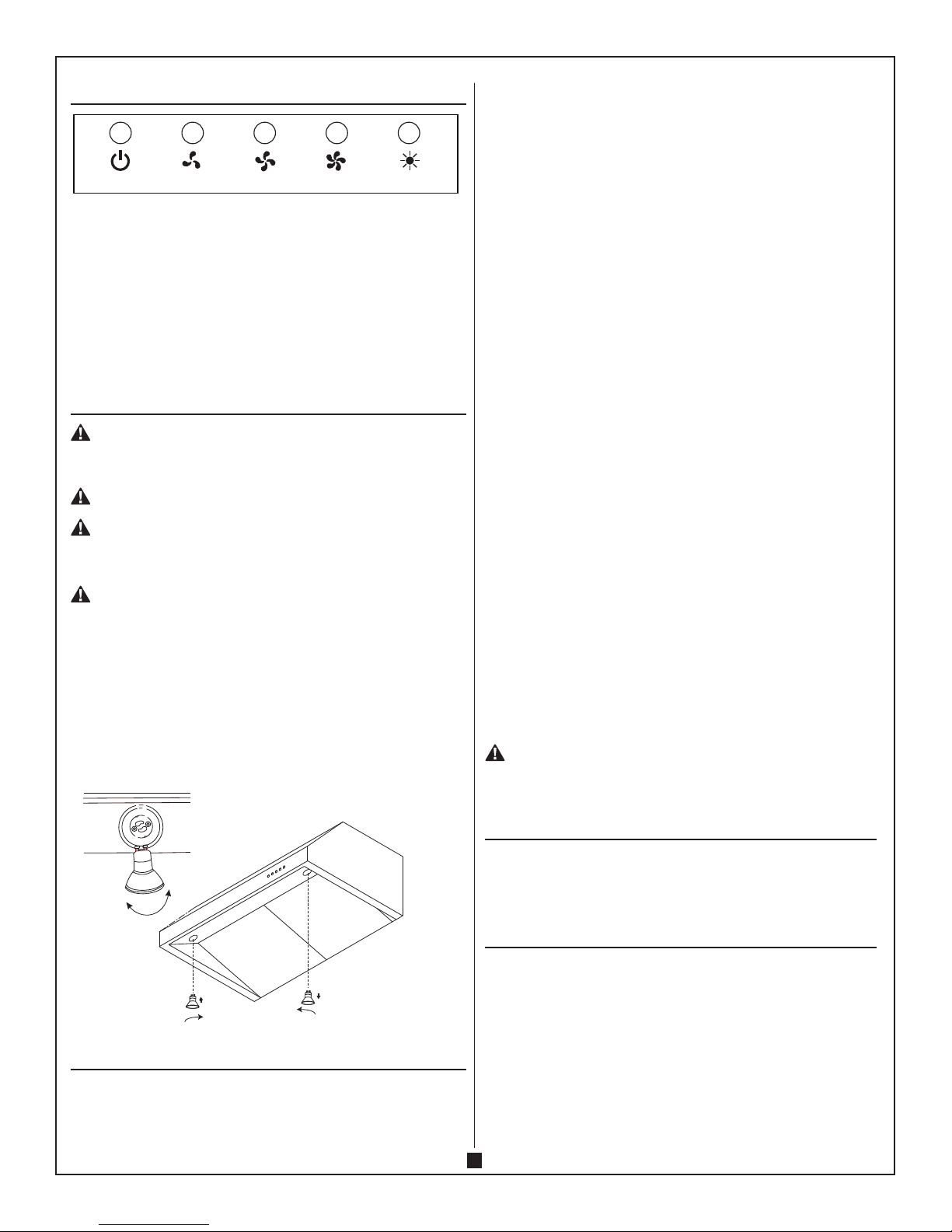

6. Thelightdoesnotwork:

- Checktoseeiflightbulbisloose.Ifso,tighten.

- Removeproblembulbandinsertoneyouknowisworking.Iftheproperly

functioninglightdoesnotcomeon,theproblemmaybethelightassem-

bly.Serviceorreplacethelightassembly.

NOTE:Forallotherinquiries,pleasecontactusat:1-800-459-4409

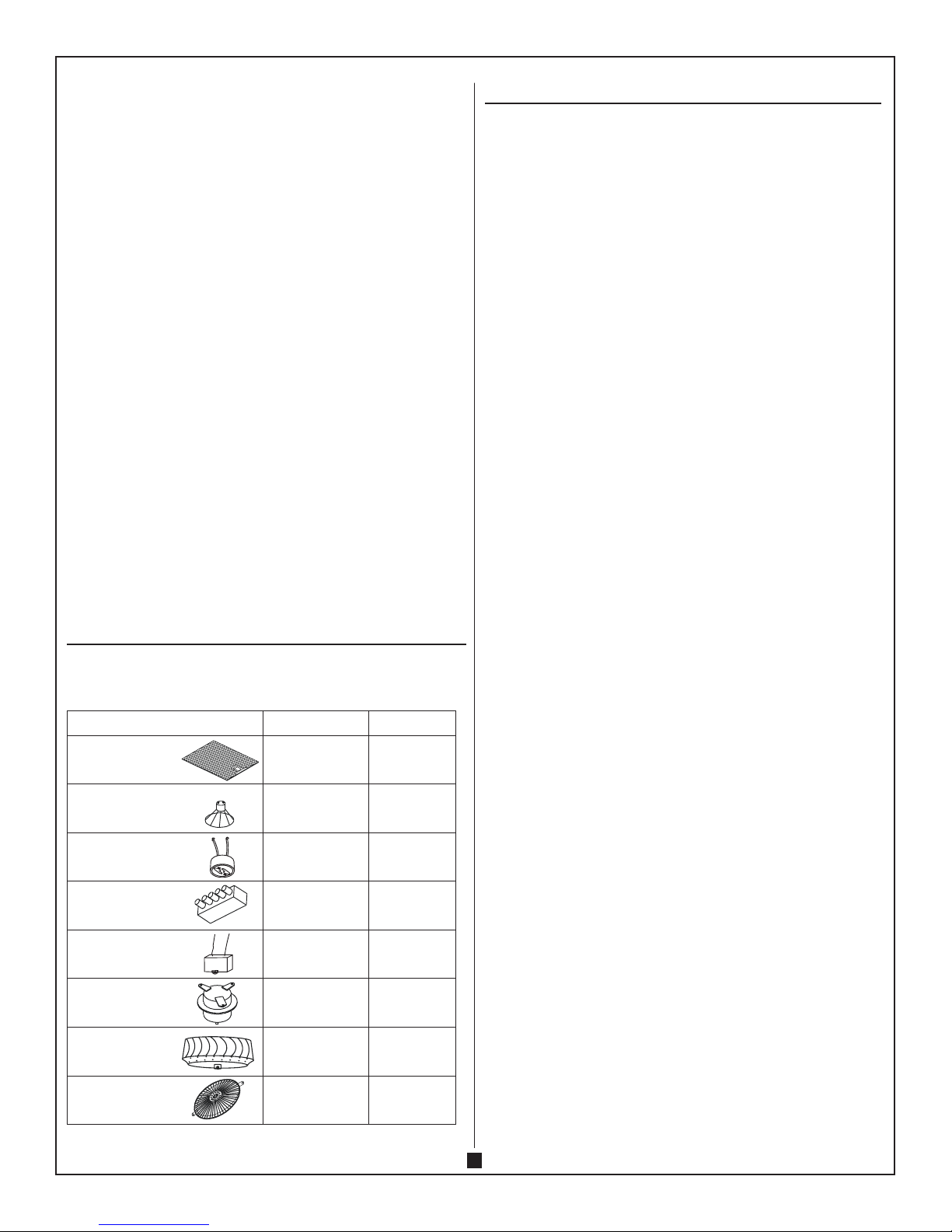

REPLACEMENT PARTS

Ifyouaremissingorrequirereplacementparts,pleasecallcustomerserviceat1-800-459-4409.

Identifytherequiredpart(s)andhavethereplacementpartnumberreadywhenyoucall.

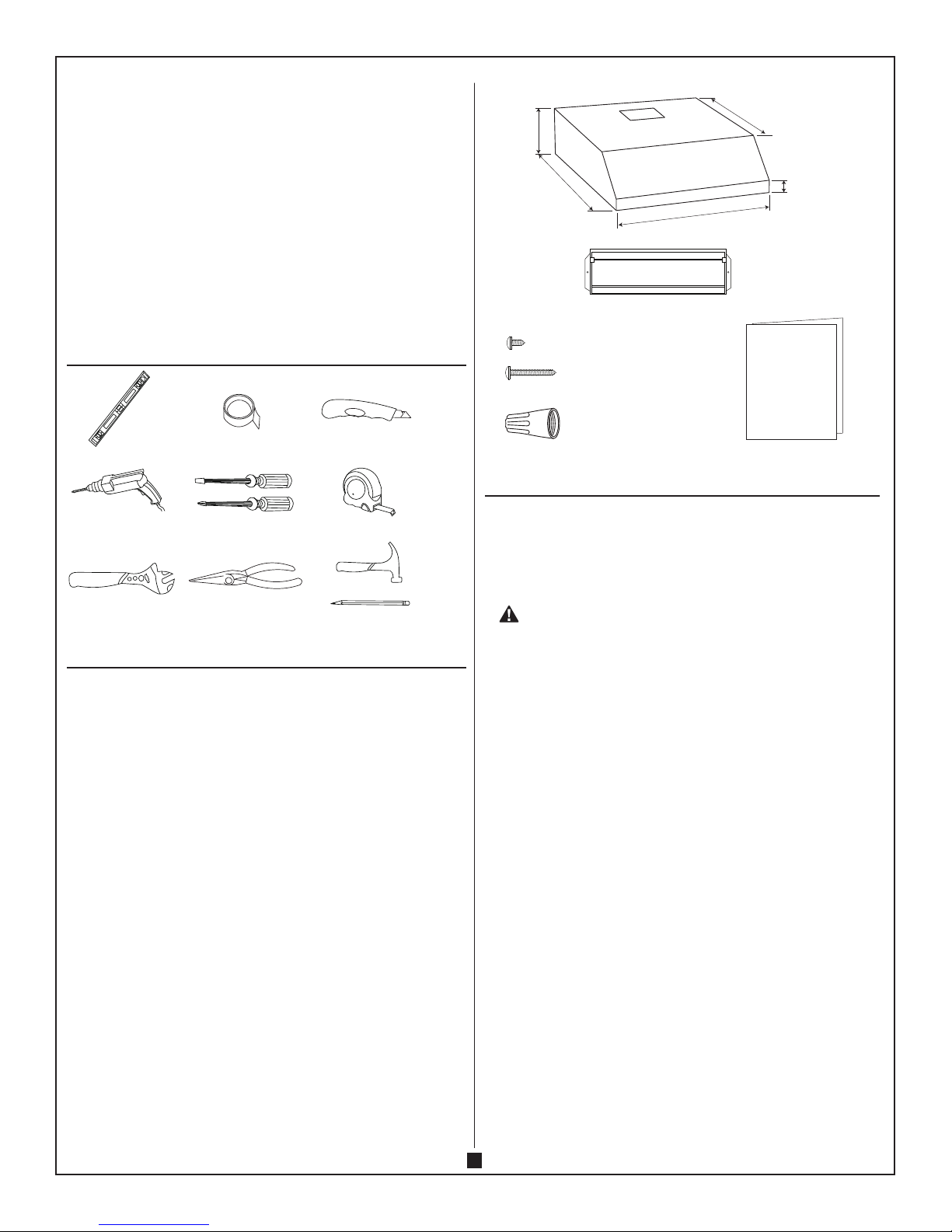

DESCRIPTION PART CODE QUANTITY

Aluminum Net YL.JS.YW.09 2

GU10Light35W YL.DQ.DL.26 2

LightHolder

(GU10Base) YL.DQ.DZ.04 2

Switch

(5pushbuttontype) YL.DQ.KG.15 1

Capacitor YL.DQ.DR.07 1

Motor YL.DQ.DJ.25 1

Fan YL.DQ.FJ.06 1

SafetyNet YL.JS.YW.20 1

1-YEAR RESIDENTIAL WARRANTY

Thisproductiswarrantedtotheoriginalpurchasertobefreeofdefectsinmaterial

andworkmanshipforone(1)yearfromthedateofpurchase.Thiswarrantydoesnot

extendtocommercialorinstitutionaluseorinstallation.Warrantyserviceshouldbe

arrangedthroughthepointofpurchase.Thepurchaserisresponsiblefortransport-

ingtheunittoandfromthepointofpurchase.Incidentalrepairsthatwouldinvolve

aminimumoftimeandeffortonbehalfofthepurchaserwillnotbeconsidered

warrantyworkandnocompensationwillbedeemedforthcoming.Anyfailureofthe

unitthatisnottraceabletoadefectinmaterialorworkmanshipisnotcoveredbythis

warranty.Thesenon-warrantableitemsinclude,butarenotlimitedto:

• Changeincolorornishduetochemicalusage

• Theuseofabrasivecleansers

• Impropermaintenanceresultingfromfailuretoreasonablyclean,careforormaintaina

productinaccordancetoQualityCraft’scleaninginstructions

• Unitnotproperlyinstalledinaccordancewithmanufacturer’sinstructions

• Damagecausedduringshipping,handlingorinstallation

• Operating,maintenance,safetyguidelinesnotbeingfollowed

• Anyalterationstotheunit

• Damagetotheunitasaresultofaccidentalimpact,re,ood,freezing,normalwear

• Lightbulbsarenotcoveredbythiswarranty

• Scratches,chips,cracksorholescausedbyshipping,storageorinstallation

Athoroughinspectionmustbemadeattimeofpickupordelivery.Iftheunitisdam-

aged,aclaimmustbemadewiththecarrier.Reportanydamagepromptlyandprior

toinstallation.QualityCraftwillnotbeheldliableforanyfreightdamageordamage

causedbyleaksduetofreightdamage.Inspectionpriortoinstallationistherespon-

sibilityoftheinstaller,contractororuser.QualityCraftwillnotbeliableforfailuresor

damagethatcouldhavebeendiscoveredoravoidedbyproperinspectionandtesting.

QualityCraftwillnotbeheldliablefordamagesresultingfromtheimpropertorin-

stallationofproductsnotsuppliedbythiscompany.QualityCraftwillnotbeheldliable

forlossofuseofunit,inconvenience,costsincurredforlabour,materials,removaland

installationofreplacementunitsoranyotherincidentalorconsequentialdamages.

Costsrelatingtoobtainingaccessforrepairorreplacementaretheresponsibilityof

theuser.UndernocircumstanceshallQualityCraftoranyofitsrepresentativesbe

heldliableforinjurytoanypersonsordamagetoanyproperty.QualityCraftsobliga-

tionsshallbelimitedtotherepairorreplacementofaunit(atouroption)thatmay

prove,byoursoleexamination,tobedefectiveundernormaluseandserviceduring

thewarrantyperiod.TheCompanymayissuecreditintheamountoftheinvoicevalue

ofthedefectiveproduct(orapercentageofitaccordingtouse)inlieuofrepairor

replacement.AllreplacementsFOBQualityCraftnearestservicedepot.

QualityCraftwarrantyisnon-transferableandshallbevoidediftheunitisremoved

fromitsinitialinstallationorifitisnotinstalledfollowingthemanufacture’sspecica-

tions.Thiswarrantyshallnotapplytoanyproductthathasbeensubjecttoaccident,

alteration,misuse,abnormalchemicalconditions.Thiswarrantyismadeinlieuofall

otherwarrantiesexpressedorimplied.Nootherwarranty,expressedorimplied,is

assumedorwillbeassumed.

Importedby

QualityCraftKitchen&BathLtd.

Laval,Quebec,Canada,H7S2G7

TOLLFREETEL:1-800-459-4409

www.qualitycraft.com

MadeinChina