机床产品/Machine Tool Products – 60CA/60CB Simple-Type Wood Cutting Machine Operation Manual

Fenu and System Introduction– 9

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

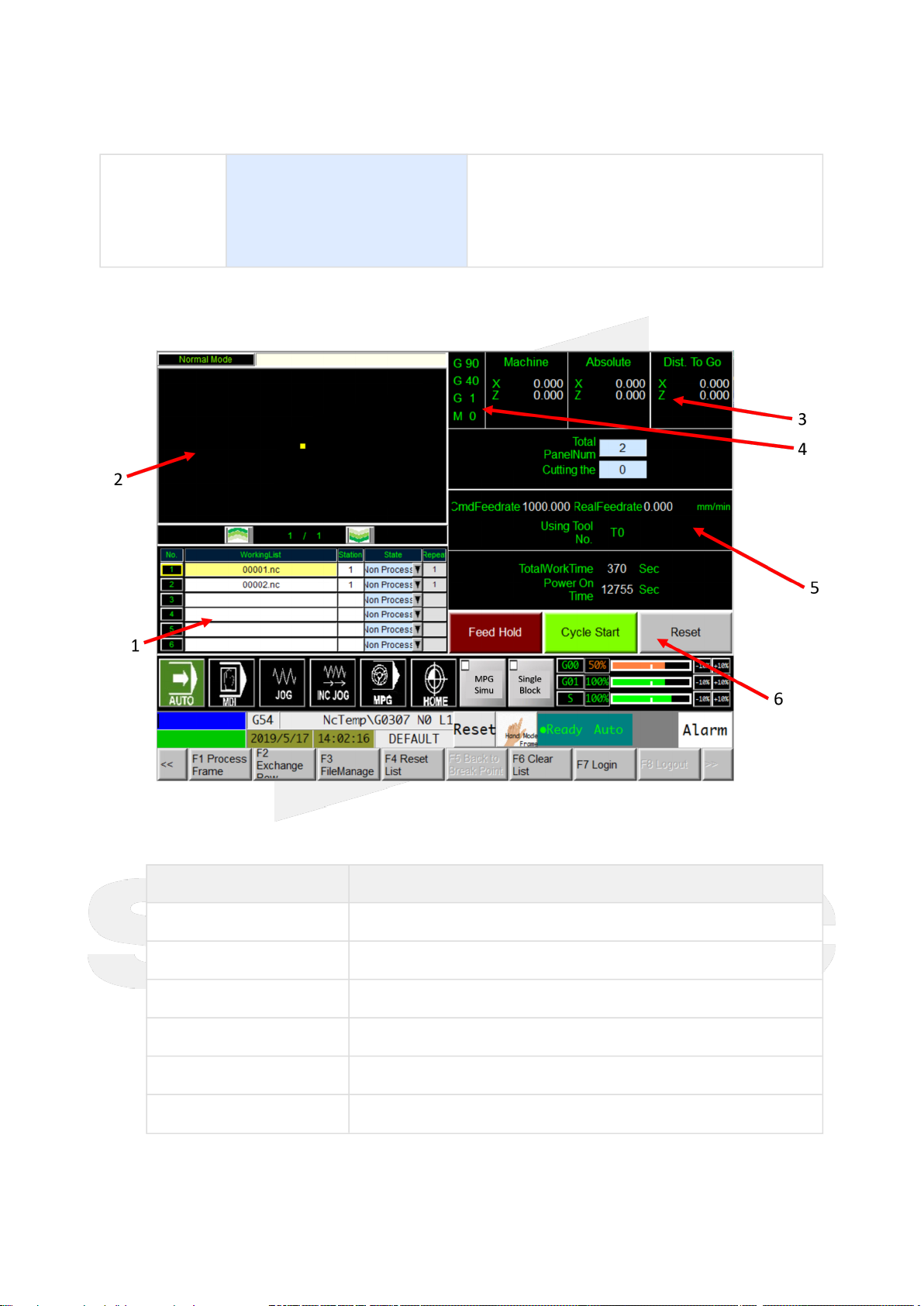

Component Those component is permently display on screen

no matter how screen change

1 Mode Selection AUTO,Change to Auto Mode

MDI,Change to MDI Mode,and screen will

change to F4 Monitor with MDI input popup

JOG,Change to JOG Mode

INJOG,Change to INJOG Mode

MPG,Change to MPG Mode

HOME,Change to HOME Mode

2 Handwheel Simulation Press the button and the box one the upper left

be green, simulation mode enable

Press again the green box disappear, simulation

mode disable.

3 Single Block Execute Press the button and the box one the upper left

be green, single block mode enable

Press again the green box disappear, single

block mode disable.

4 Reset Action trigger the software be reset, no PLC

interface will be triggered.

5 Hand Frame Panel Press the button, change screen to hand mode

frame.

This panel is provided to Syntec Technician

to customize according to customer's

demand

Axes jog,Peripheral devices, or other

additional function.

6 Feedrate Adjustment G00 rate adjust,0%,25%,50%,100%

G01 rate adjust,0%, 10%, 20%,......150%

Spindle rotation rate adjust ,0%, 10%,

20%,......120%