4| Application status

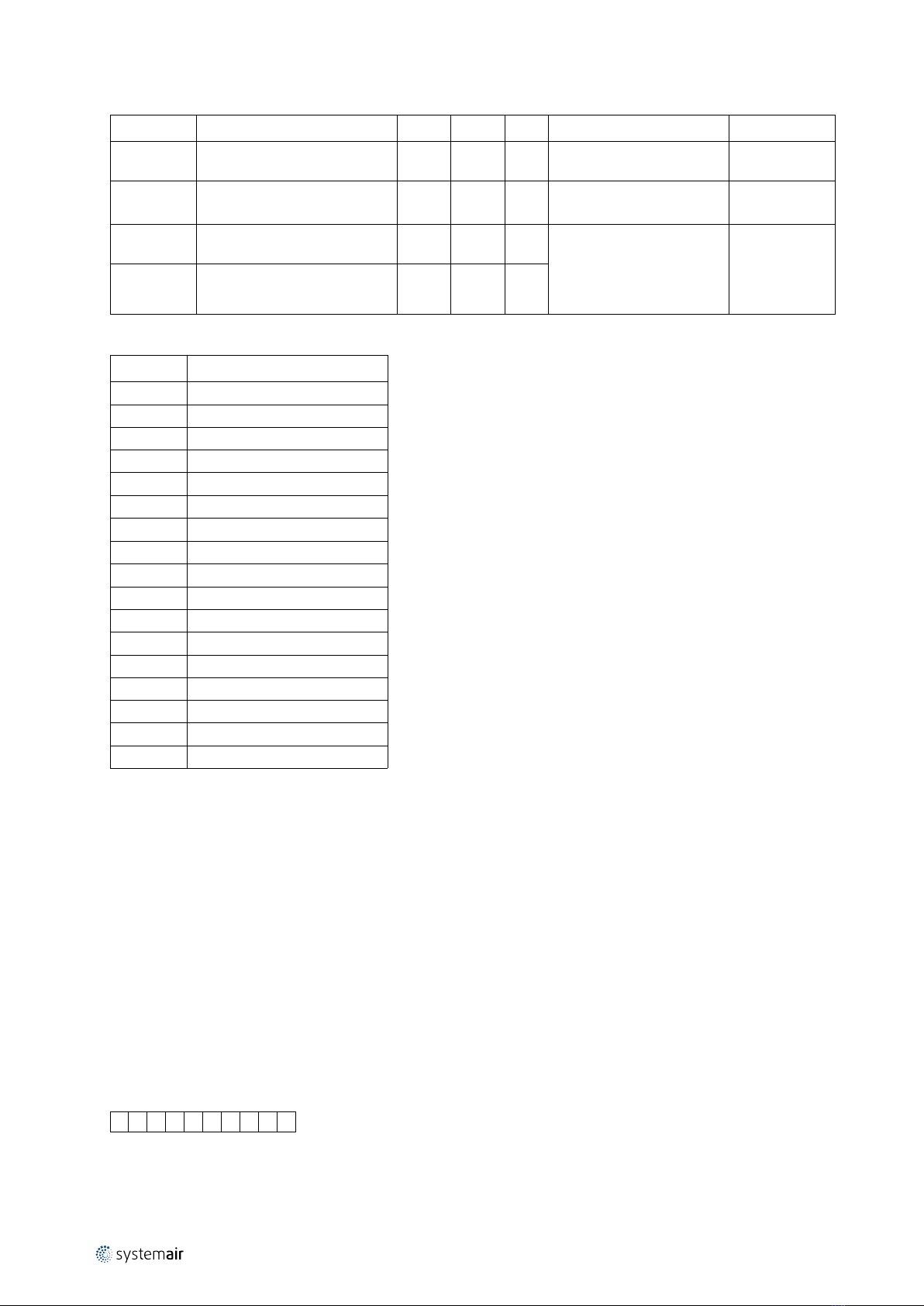

Table 1 Thermostat HVAC Modes mapping

Thermostat Mode Command Class Basic CC Set/Report Value Mapped as

Number Mode

0x0A Auto changeover 0xFF Comfort Mode

0x0D Away 0x00 Energy Saving Mode

10 Application status

Some of the implemented CCs need to be translated to the Ventilation Unit via the Modbus interface. Due to some rea-

sons that communication couldn’t be available, for example – disconnected/damaged communication cable. In order to

cover such situations, the Application Status Command Class has been implemented.

So, In case of no communication between Z-Wave Adapter and the Ventilation Unit Module, the Device will send “Appli-

cation Reject Request” for all Z-Wave commands required communication with the Ventilation Unit.

If the Modbus communication is up and running, the device is always available to respond in the specified time, i.e. the

device will never report “Application Busy” command.

11 Temperature setpoint

The device supports “Thermostat Auto changeover” setpoint type only. The setpoint range varies in depend of the ven-

tilation system type (Table 3) and some other ventilation unit configurations. All of these dependencies must be fixed

at inclusion time, so the system will be fully defined. The Host shall retrieve the setpoint range using the Thermostat

Setpoint Capabilities Get V3 command. In additional to the reported Min and Max Values, 0°C is supported as well.

The device accepts the setpoints in a predefined step in the reported range. It is available via the Configuration CC, pa-

rameter 5 (see Table 2: Configuration Parameters).

12 Fan mode

The device will support Fan Auto Mode, if both RH and CO2senors are present. This must be done at inclusion time.

The Z-Wave Systemair Ventilation supports following Thermostat Fan Modes:

Thermostat Fan Mode Ventilation Unit Fan

Bit Off Value Mode Mode Level

0 0 Auto/Auto Low Demand/Automatic Auto

1- -

Manual

Off

0 1 Low Low

0 3 High High

0 5 Medium Normal

13 Boost Mode

The Systemair Z-Wave Ventilation has implemented a Boost Mode. That mode overrides the selected fan speed, setting

it to a predefined level (usually high) for a predefined time period.

To set the Boost Mode remotely via Z-Wave, the Binary Switch CC is used. But that binary switch is a bit special – Once

it is turned ON, it locks itself in ON position for the predefined time period, and it can’t be turned off until that time peri-

od expires.

The Host can use the Ventilation System Boost mode in case of smoke or fire alarm for example.

14 Alarms

The implemented Notification CC V3 is used to report the device malfunctions:

• Notification Type 0x09 – “System”

• Event Type 0x03 – “System Hardware Failure with manufacture proprietary code”

The failures are reported in a two bytes value, where each bit represents a certain alarm. If the bit is set (1) the alarm is

active, and if the bit is cleared (0) the alarm is not active.

| A002