Before Installation

Please thoroughly read this guide and applicable sections of OSID Global

Application Note, document no. (25686). This manual is available online at

www.systemsensor.com.

General Description

The OSI- RE- SS is a long range projected beam smoke imaging detector

designed to provide open area protection. It is to be used with listed (UL,

EN54 , etc.), It is to be powered from a CE Certified AC/DC Power

converters to be in compliance for CE certification. The detector consists of a

transmitter/receiver unit and a reflector. Smoke entering the area between the

transmitter/receiver and reflector causes a reduction in signal. When the

obscuration reaches the alarm threshold (automatically set at the

transmitter/receiver unit), the detector generates an alarm signal. Complete

blockage of the beam causes a trouble signal. Slow changes in obscuration due

to a build-up of dirt or dust on the lens of the detector are compensated for by

a Microcontroller that continuously monitors the signal strength and

periodically updates the alarm and trouble thresholds. When the self-

compensation circuit reaches its limit, the detector generates a trouble signal,

indicating the need for service.

Three LEDs on the detector indicate the current status: a red LED for alarm,

a yellow LED for trouble, and a blinking green LED for standby operation.

The alarm signal latches and can be reset by a momentary power interruption

or by activating the remote reset input to the detector if using the remote

test/reset station model RTS151KEY.

The yellow LED will blink in specific patterns to provide a diagnostic aid

when diagnosing the cause of a trouble signal. Trouble signals automatically

reset upon removing the cause of trouble. Red and yellow LEDs can be

remotely connected to the remote Alarm and Trouble outputs. These outputs

mimic the functions of the detector’s red and yellow LEDs.

After commissioning the 4 arrows will indicate the level of automatically set

sensitivity.

Each detector contains one change over relay contact for alarm signals and

one change over relay contact for trouble signals. The trouble relay is fail

safe and will open if power is removed from the detector. Thus, an additional

EOL power supervision relay is not necessary.

The trouble contacts from all the beam detectors on one initiating circuit must

be connected after the last indicating device on the loop. This prevents a

single beam detector in trouble from disabling other initiating devices on the

same loop.

Special Applications

Due to the inherent capabilities of projected type beam detectors they are

often installed in locations where spot-type detection is impractical. Projected

type beam smoke detectors are ideally suited for environmental conditions that

might include high ceilings or areas with difficult access to the ceiling. Often

these conditions present special problems for the installation of spot- type

detectors and even greater problems for their proper maintenance. Due to the

inherent flexibility of mounting locations and large coverage area of projected

type beam detectors often the conditions above can be addressed or

minimized. Some examples of applications for beam detectors might include

aircraft hangars, cold storage warehouses, shipping warehouses, enclosed

parking facilities, sporting arenas and stadiums or concert halls. Some of these

environments might be considered not suitable for spot-type smoke detectors.

Before installing the transmitter/receiver unit or reflector in these types of

applications special consideration should be given to ensure proper operation

of the beam detector. The beam detector should not be installed in

environments where heavy condensation or icing is likely. Condensation or

icing of the reflector surface or the outer surface of the transmitter/receiver

unit will obscure the light beam resulting in a nuisance alarm. If elevated

humidity levels and rapidly changing temperatures can be expected then

condensation will likely form and the application should not be considered

acceptable for the beam detector.

In environments where a mild condensation is expected, the standard on-board

lens heaters can be initiated by activating the heating switch located in the

detector.

The beam detector should not be installed in locations where the

transmitter/receiver unit, the reflector, or the optical pathway between them

may be exposed to outdoor conditions such as rain, snow, sleet, or fog.

These conditions will impair the proper operation of the detector and must be

avoided.

Approved Accessories

The following accessories can be purchased separately for use with this beam

detector.

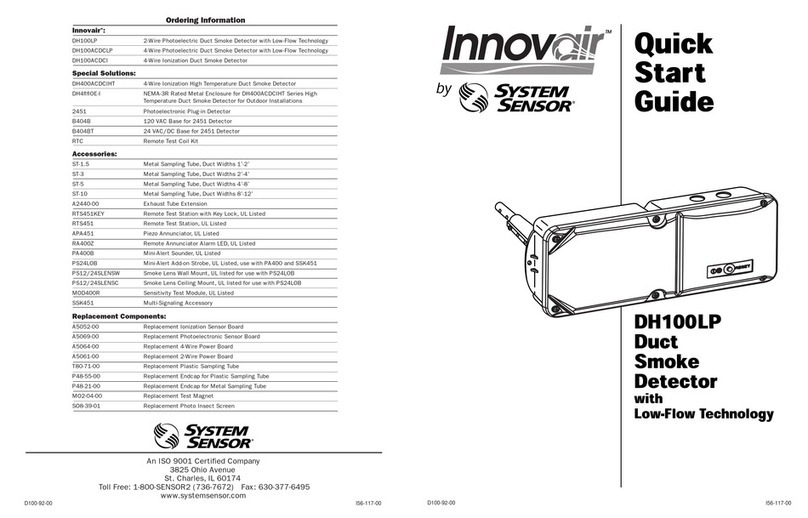

6500MMK

The 6500MMK allows reflected

beam detectors and reflectors to be

mounted to either a vertical wall or

the ceiling. The kit allows for

additional alignment range in cases

where the detector and reflector

cannot be mounted within 10° of each

other. The kit includes the hardware

necessary to mount either a single

transmitter/receiver unit or a single

reflector.

BEAMHKR

The BEAMHKR allows the reflector

to operate in environments prone to

the formation of condensation.

Condensation forming on the

reflector may result in trouble or

false alarm conditions. BEAMHKR

will lessen the likelihood of

condensation by maintaining the

reflector at a temperature that is

slightly higher than surrounding air.

The kit requires a 24V power supply.

RTS151KEY (Test Function)

The remote test accessory allows for

the beam detector to be tested and

reset remotely from ground level.

The test accessory provides test and

reset functions and green and red

LEDs that mimic the LEDs on the

detector.

Package Contents

l1 Transmitter/Receiver Unit

l1 Paintable Trim Ring

l1 Reflector

l4 Plug-in Terminal Blocks

l1 OSI-RE-SS Quick Start Guide

6 E56-6654-000