Table of Contents

A/S timing ............................................................... 7-9

The number of inching times .............................................. 7-10

Tie stitching ............................................................ 7-11

Satin adjustment ......................................................... 7-12

Boring ................................................................... 7-13

Cording .................................................................. 7-14

Sequin ................................................................... 7-15

8. FRAME SETTING

Frame speed .............................................................. 8-2

Offset ................................................................... 8-3

Origin return ............................................................ 8-4

Frame mode ............................................................... 8-5

Initial (origin search) .................................................. 8-6

Trace .................................................................... 8-7

9. Manual operation

Manual origin return ..................................................... 9-2

Trace .................................................................... 9-3

Offset (setting for position) ............................................ 9-4

Offset (change of position) .............................................. 9-5

Offset (frame travel) .................................................... 9-6

Manual Thread Trimming ................................................... 9-7

Frame back/forward (feed unit) ........................................... 9-8

Frame back/forward (feed by n-stitches) .................................. 9-9

Frame forward ............................................................ 9-10

Frame back ............................................................... 9-11

10. Outline of functions

Rotate ................................................................... 10-2

Mirror ................................................................... 10-2

Size ..................................................................... 10-3

Repeat ................................................................... 10-3

Offset ................................................................... 10-4

Satin adjustment ......................................................... 10-6

Trace .................................................................... 10-6

11. TROUBLESHOOTING AND MAINTENANCE

When the machine is stopped during operation ............................. 11-2

When trouble occurs ...................................................... 11-4

DailyMaintenance ......................................................... 11-5

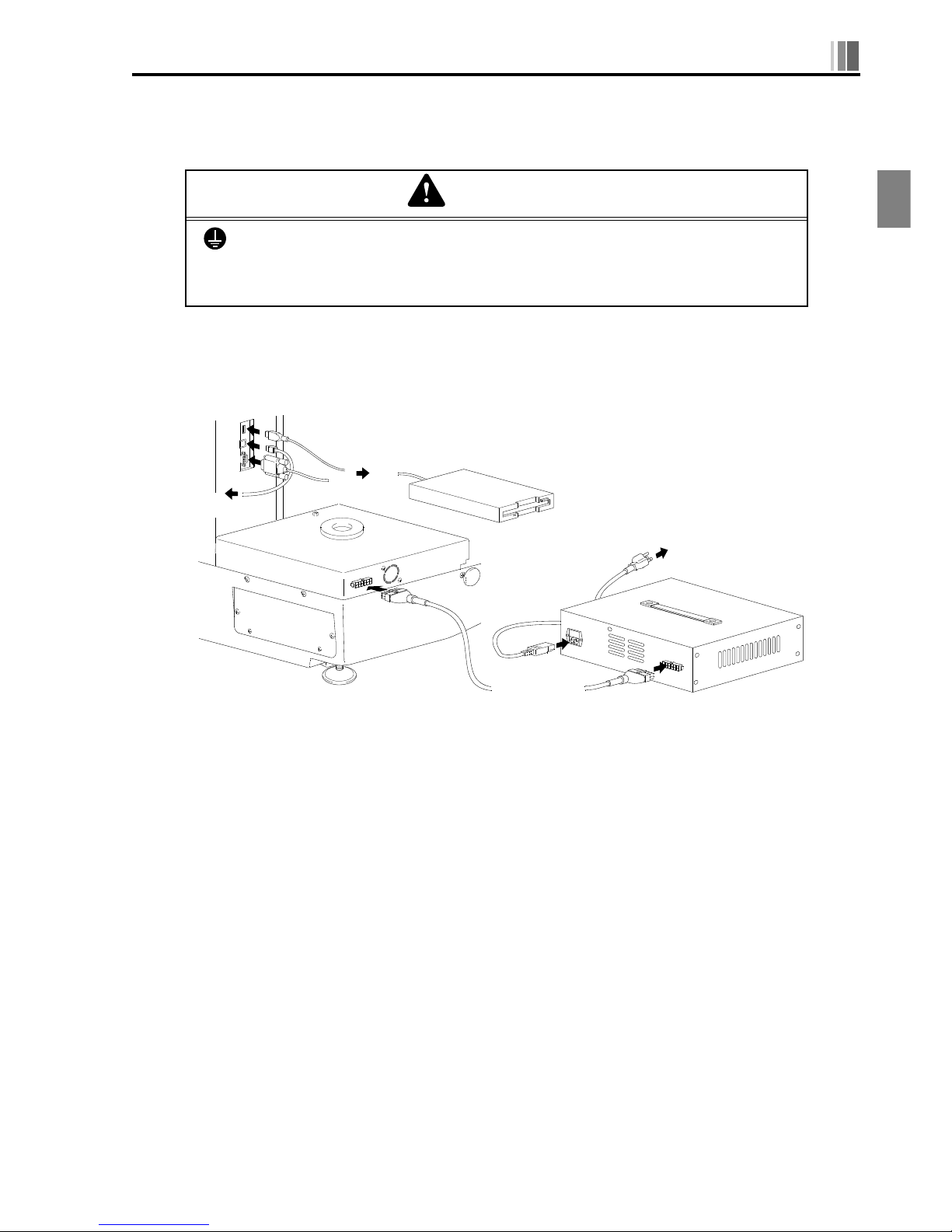

12. Electro-component parts

Power supply box ......................................................... 12-2

Panel CPU card ........................................................... 12-2

Controller card .......................................................... 12-3

Main shaft power card .................................................... 12-3

Driver card .............................................................. 12-3

Layout Drawing of Electrical Parts ....................................... 12-4

Layout Drawing of Electrical Parts (1-Needle Machine) .................... 12-5

Electrical System Diagram ................................................ 12-6

JZ05