CONTENTS

IMPORTANT WARNING ITEMS FOR SAFE OPERATION

INSTALLATION ENVIRONMENT ...................................................................................................... 1

CAUTIONS ON MACHINE OPERATION........................................................................................... 2

WARNING LABELS ........................................................................................................................... 4

IMPORTANT DIRECTIVE ITEMS............................................................................................................. 4

APPLYING POSITION OF WARNING LABELS...................................................................................... 4

CHAPTER 1 OUTLINE OF THE MACHINE

MAIN FUNCTIONS ......................................................................................................................... 1-1

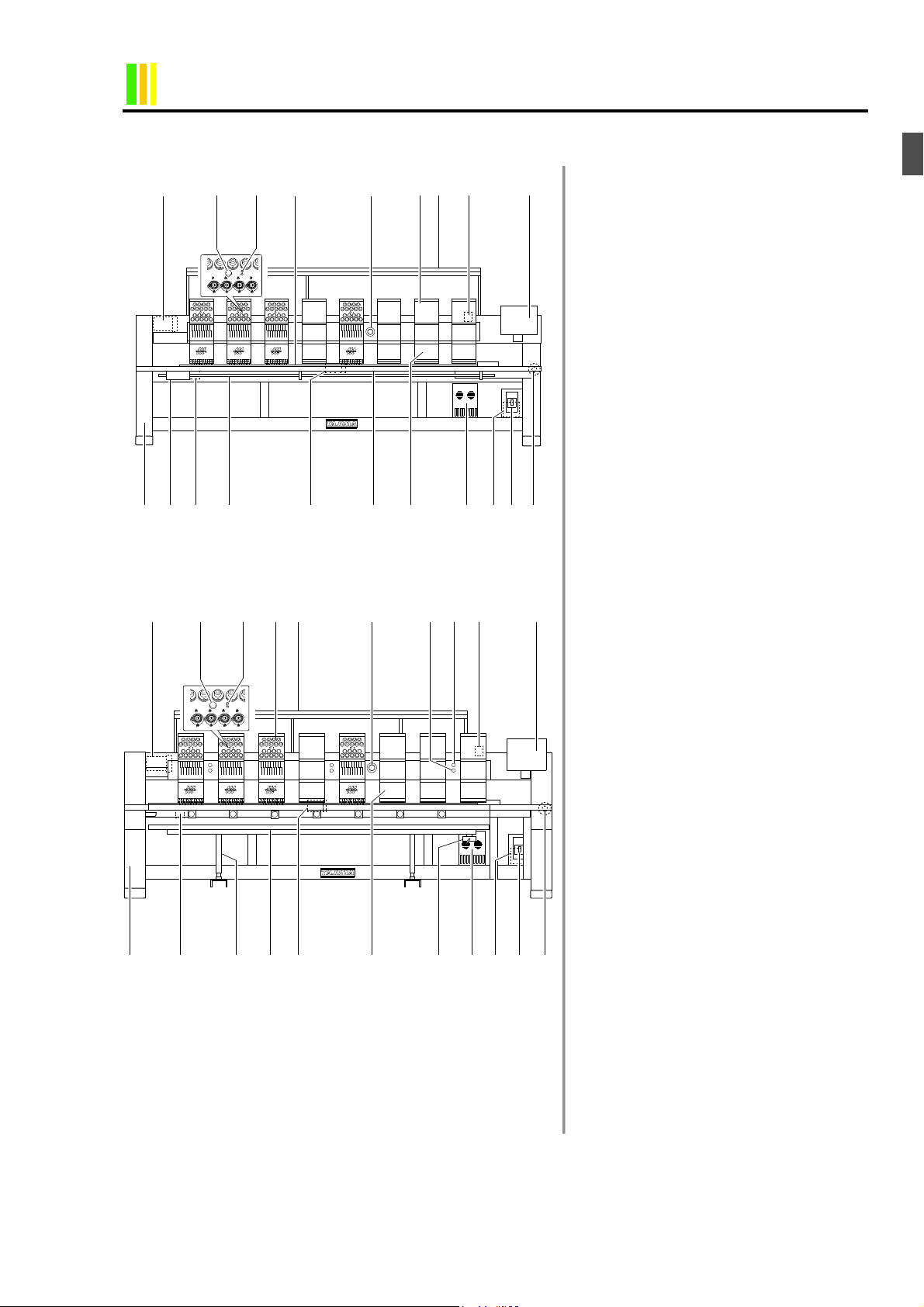

TFHX SERIES NAME OF EACH PART.......................................................................................... 1-2

NAME OF EACH PART OF TEHX-C .............................................................................................. 1-4

POWER SUPPLY SPECIFICATION, POWER SUPPLY/DRIVER BOX ......................................... 1-5

SWITCHING OF POWER SUPPLY SPECIFICATION (100/200 V)................................................ 1-6

OPERATION PANEL ...................................................................................................................... 1-7

FUNCTION OF EACH PART...................................................................................................................1-7

COMMUNICATION SPEED OF SERIAL I/F CONNECTOR ................................................................1-8

EACH SETTING KEY...................................................................................................................... 1-9

FUNCTION OF EACH SETTING KEY ...................................................................................................1-9

ROTARY-TYPE TENSION BASE ................................................................................................. 1-12

FUNCTION OF TENSION BASE SWITCH ..........................................................................................1-12

FUNCTION OF THREAD BREAKAGE INDICATOR LAMP.............................................................1-12

NEEDLE BAR SUSPENSION LEVER .......................................................................................... 1-13

CHAPTER 2 OPERATION BASICS

POWER SWITCH AND EMERGENCY STOP SWITCH................................................................. 2-1

POWER SWITCH ......................................................................................................................................2-1

EMERGENCY STOP SWITCH ................................................................................................................2-1

START AND STOP ......................................................................................................................... 2-2

OPERATION BY BAR SWITCH (TFHX) ...............................................................................................2-2

OPERATION BY START/STOP SWITCH (EXCLUDING TFHX)........................................................2-3

STOP BY PRESET HALT (P.6-27)...........................................................................................................2-3

FLOPPY DISK AND FLOPPY DISK DRIVE.................................................................................... 2-4

FLOPPY DISK ...........................................................................................................................................2-4

FLOPPY DISK DRIVE (FDD) ..................................................................................................................2-4

INSTALLATION OF SOFTWARE ................................................................................................... 2-5

DISPLAY OF DISPLAY AREA ...................................................................................................... 2-10

DISPLAY AFTER TURNING ON THE POWER ..................................................................................2-10

USUAL DISPLAY ...................................................................................................................................2-10

DISPLAY DURING OPERATION .........................................................................................................2-10

INSPECTIONS BEFORE STARTING OPERATION..................................................................... 2-11

BASIC OPERATION PROCEDURE ............................................................................................. 2-12

CHAPTER 3 DESIGN DATA

DESIGN DATA INPUT (MEMORY)................................................................................................. 3-1

DESIGN DATA INPUT (FLOPPY DISK) ......................................................................................... 3-2

DESIGN DATA INPUT (EXTERNAL DEVICE)................................................................................ 3-4

STANDBY INPUT............................................................................................................................ 3-6

MEMORY DELETION ..................................................................................................................... 3-8

STITCH DATA EDIT (MODIFY) .................................................................................................... 3-10

STITCH DATA EDIT (INSERT) ..................................................................................................... 3-14

STITCH DATA EDIT (DELETE) .................................................................................................... 3-18

STITCH DATA EDIT (CLEANUP) ................................................................................................. 3-21

FLOPPY DISK (DESIGN DATA WRITING)................................................................................... 3-23

FLOPPY DISK (DESIGN DATA DELETING) ................................................................................ 3-27

FLOPPY DISK (FORMATTING).................................................................................................... 3-29

CHAPTER 4 OPERATION OF THE MACHINE

MANUAL COLOR CHANGE ........................................................................................................... 4-1

MANUAL THREAD TRIMMING....................................................................................................... 4-2

MANUAL ORIGIN RETURN............................................................................................................4-3

MANUAL OFFSET .......................................................................................................................... 4-4

TRACE ............................................................................................................................................ 4-5

MANUAL FRAME TRAVEL.............................................................................................................4-6

FRAME BACK/FORWARD ............................................................................................................. 4-8

FRAME ORIGIN MEMORY (TFHXII, TFHX-IIC).......................................................................... 4-10

FRAME ORIGIN MEMORY (TFHX, TFHX-C, TEHX-C)................................................................ 4-12

POWER RESUME (TFHXII, TFHX-IIC)......................................................................................... 4-13

POWER RESUME (TFHX, TFHX-C, TEHX-C) ............................................................................. 4-15

STITCH COUNTER/DESIGN TIME .............................................................................................. 4-16

CONFIRMATION MODE...............................................................................................................4-17

GC06