Table of contents

7-7. To make a remaining upper thread inconspicuous (Upper thread lock timing).........106

7-8. To adjust stitching length according to a stitch length (Frame drive adjustment)......107

8. To increase embroidering efficiency...................................................................................109

8-1. To change number of lowering needle bar at slow operation

(Number of inching times at start) .............................................................................109

8-2. To collect up frame moving amount of consecutive jump stitches

in a batch to feed the frame all at once (Jump code combination)............................109

8-3. To change moving speed of needle bar case (Color change speed).......................110

8-4. To change travel speed of the frame (Frame Travel Speed) ....................................111

8-5. To set data of the design automatically after embroidery is finished

(Automatic Data Set after finishing embroidery)........................................................112

9. To edit design.....................................................................................................................114

9-1. To modify the stitch (Data Edit "Modify")...................................................................114

9-2. To modify the stitch (Data Edit "Insert") ....................................................................117

9-3. To delete the stitch (Data Edit "Delete")...................................................................121

10. Setting and resetting of password......................................................................................124

10-1. To change password (Functional limit of password) ................................................. 124

10-2. To cancel the password ............................................................................................126

11. Other functions that must be remembered.........................................................................127

11-1. To check the number of total stitches up to now (Total Stitch Counter)....................127

11-2. To color in every needle bar (Needle Bar Color).......................................................128

11-3. To display the setting color when making the design (Needle bar information)........129

11-4. To check version of current software (Software Version)..........................................130

11-5. To switch display language (Language)....................................................................130

11-6. To release fixing of main shaft motor (weak brake) ..................................................132

Chapter 6 Functions concerning frame movement

1. To return the frame (Frame Back) / to advance the frame (Frame Forward).....................136

1-1. To switch frame back / frame forward.......................................................................136

1-2. To execute by color change unit, to specify number of stitches to execute ..............137

1-3. To change a frame feed amount of frame back / frame forward ...............................139

1-4. To set All Head Sewing Start Point (Frame Back All Head Sew)..............................140

2. Necessary works after replacing the frame........................................................................141

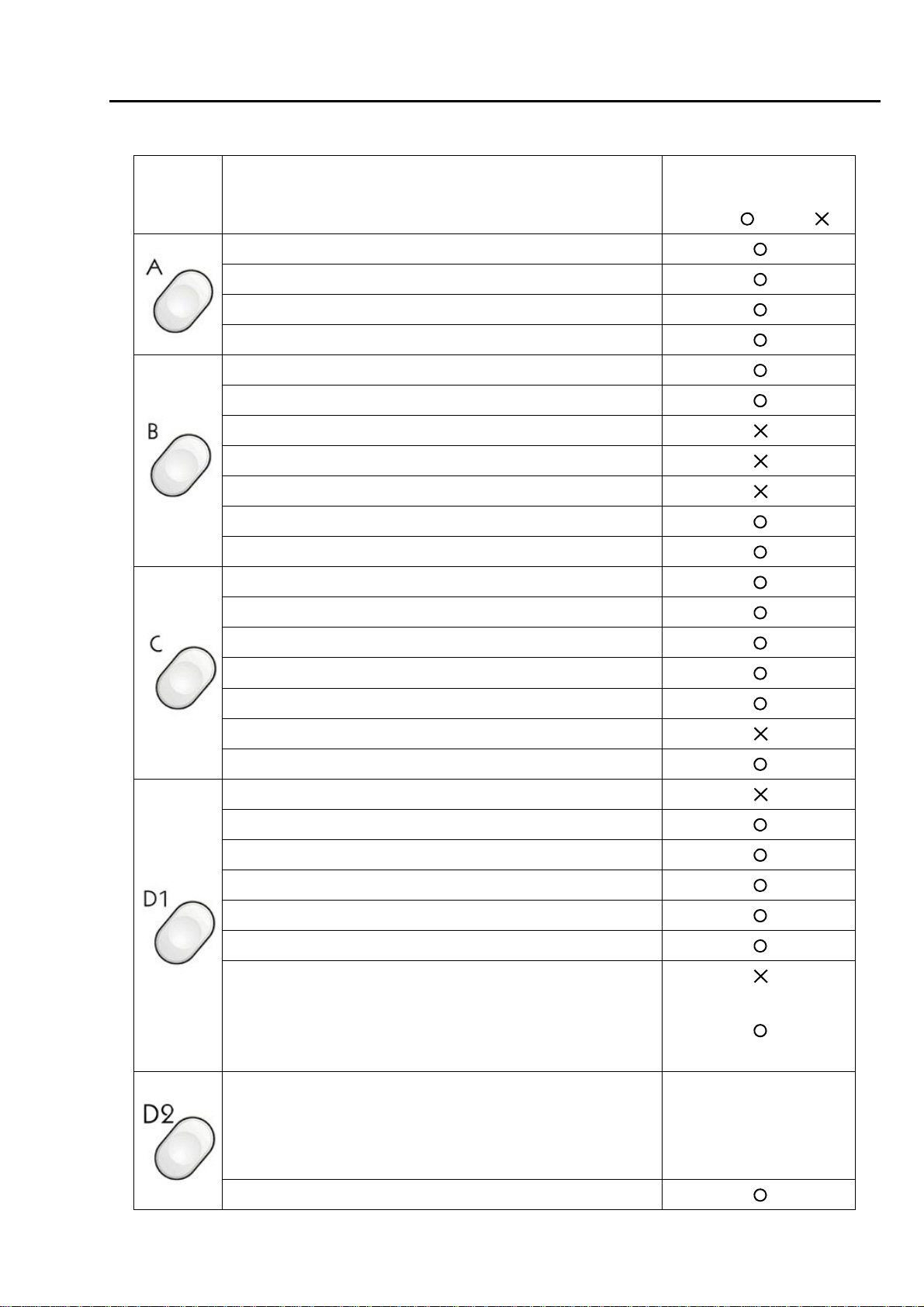

2-1. To change drive mode according to the frame that is equipped (Frame Type).........141

2-2. To rotate the design by 180° when a cap frame is equipped

(Design rotation by 180° on Cap Frame)...................................................................144