5

Contents

A SAFETY INFORMATION.........................................................................................................................6

A.1 General information ......................................................................................................................6

A.2 General safety .............................................................................................................................6

A.3 Personal protection equipment ........................................................................................................7

A.4 Transport, handling and storage ......................................................................................................7

A.5 Installation and assembly ............................................................................................................... 8

A.6 Water connection..........................................................................................................................8

A.7 Electrical connection .....................................................................................................................8

A.8 Use ...........................................................................................................................................9

A.9 appliance cleaning and maintenance .............................................................................................. 10

A.10 Service..................................................................................................................................... 10

A.11 Disposal of packing..................................................................................................................... 10

A.12 Machine disposal........................................................................................................................ 10

B GENERAL SAFETY RULES................................................................................................................... 11

B.1 Introduction ............................................................................................................................... 11

B.2 Mechanical safety characteristics, hazards....................................................................................... 11

B.3 Protection devices installed on the machine ..................................................................................... 11

B.4 Main switch ............................................................................................................................... 11

B.4.1 Appliance with 2 positions main switch................................................................................... 11

B.5 Safety signs to be placed on the appliance or near its area .................................................................. 11

B.6 Instructions for use and maintenance.............................................................................................. 11

B.7 Reasonably foreseeable improper use ............................................................................................ 11

B.8 End of use ................................................................................................................................ 11

B.9 Residual risks ............................................................................................................................ 11

C GENERAL INFORMATION .................................................................................................................... 12

C.1 Introduction ............................................................................................................................... 12

C.2 Definitions................................................................................................................................. 12

C.3 Machine and manufacturer's identification data ................................................................................. 12

C.4 Responsibility ............................................................................................................................ 13

C.5 Copyright.................................................................................................................................. 13

C.6 Keeping the manual .................................................................................................................... 13

C.7 Recipients of the manual .............................................................................................................. 13

D NORMAL USE .................................................................................................................................... 13

D.1 Characteristics of personnel enabled to operate on the appliance ......................................................... 13

D.2 Basic requirements for appliance use.............................................................................................. 13

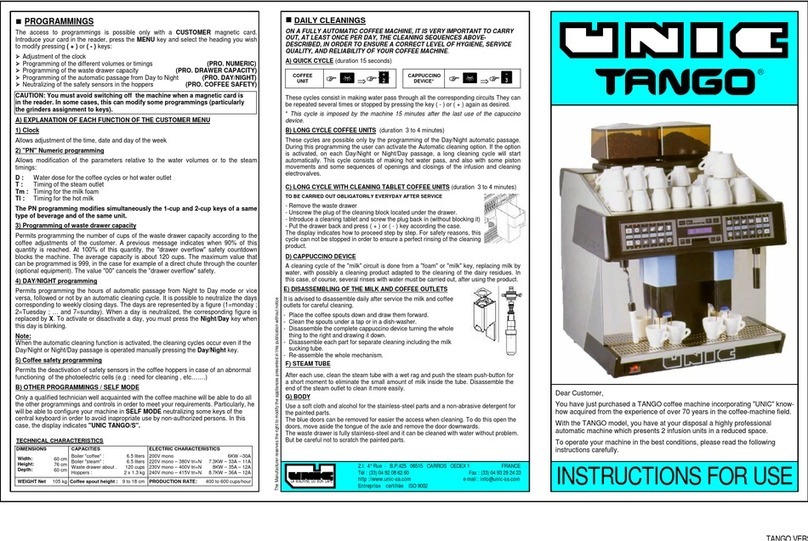

E TECHNICAL CHARACTERISTICS .......................................................................................................... 14

E.1 Data table ................................................................................................................................. 14

F DESCRIPTION PRODUCT .................................................................................................................... 14

F.1 Overview .................................................................................................................................. 14

G OPERATING....................................................................................................................................... 14

G.1 Switching on.............................................................................................................................. 14

G.2 Coffee...................................................................................................................................... 15

G.3 Screen (display) ......................................................................................................................... 15

G.4 Screen during an infusion ............................................................................................................. 15

G.4.1 Screen drink delivery ......................................................................................................... 15

G.4.2 Screen during infusion........................................................................................................ 15

H CLEANING......................................................................................................................................... 15

H.1 Intro......................................................................................................................................... 15

H.2 Daily cleaning cycles (duration ~10 minutes) .................................................................................... 16

H.3 Cleaning milk (in the case of a milk pump system) ............................................................................. 16

H.4 External cleaning........................................................................................................................ 16

I MAINTENANCE .................................................................................................................................. 16

I.1 Maintenance intervals.................................................................................................................. 16

I.1.1 Preventive Maintenance ..................................................................................................... 16

I.2 Preventive maintenance for coffee products ..................................................................................... 16

I.3 Softener ................................................................................................................................... 17

I.4 Machine disposal........................................................................................................................ 17